Al2O3 nano-particle enhanced chromium-free Dacromet anti-corrosion paint, coating, and reparation method of paint and coating

A nanoparticle, anti-corrosion coating technology, applied in anti-corrosion coatings, coatings and other directions, can solve the problems of high consumption, danger, easy to cause cancer, etc., to improve compactness, ensure anti-corrosion performance and strength, improve mechanical properties and anti-corrosion. Effects of Corrosive Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

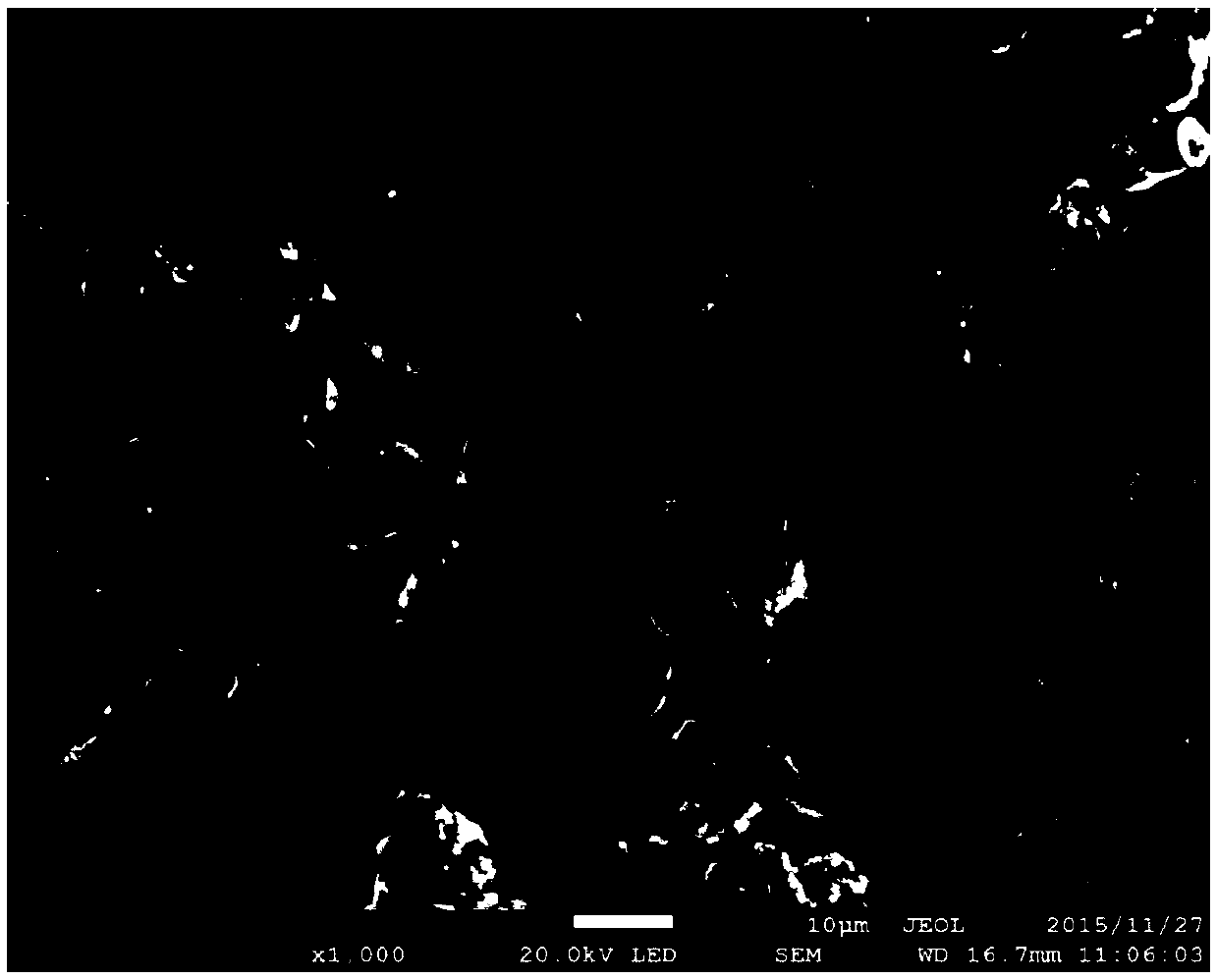

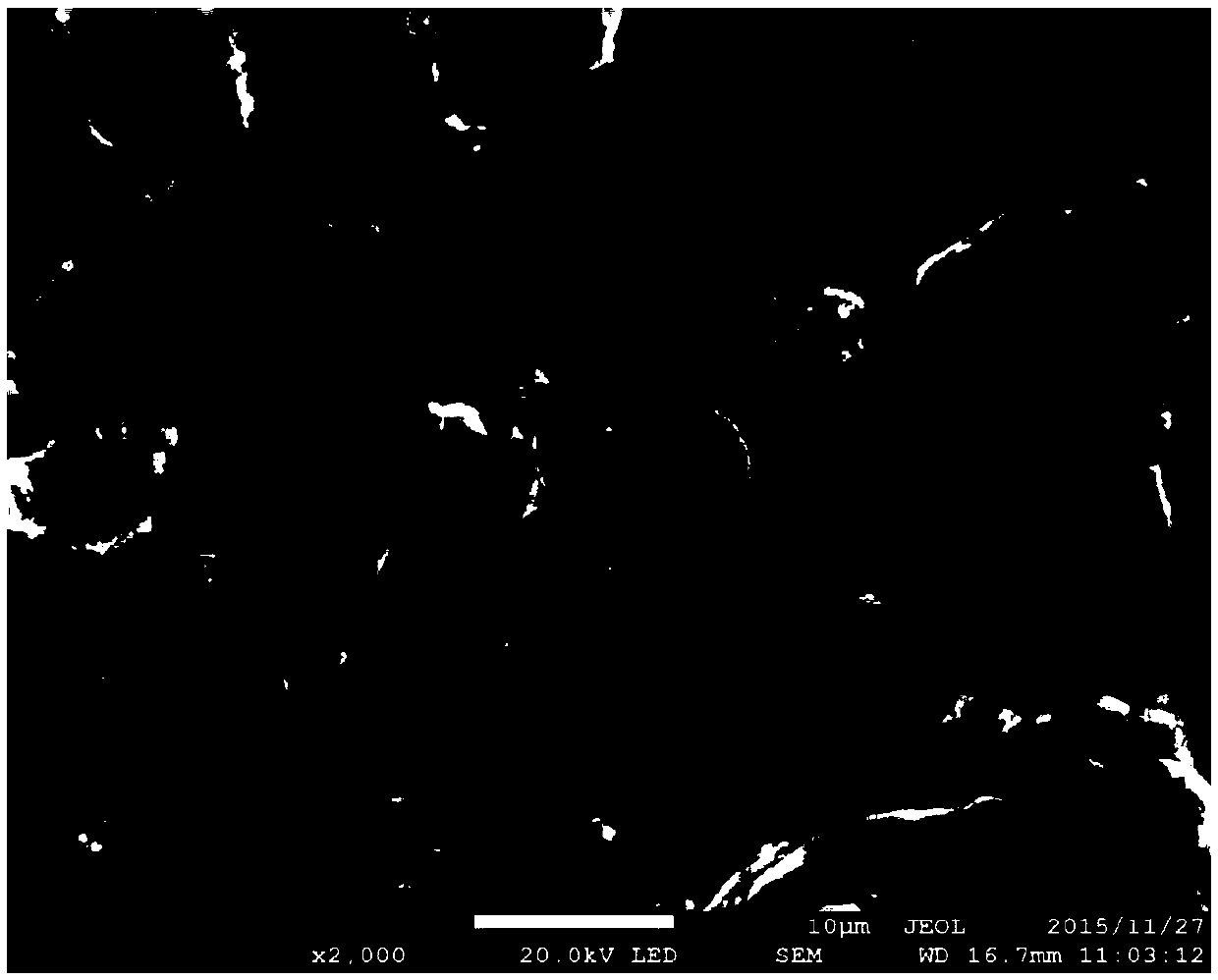

Image

Examples

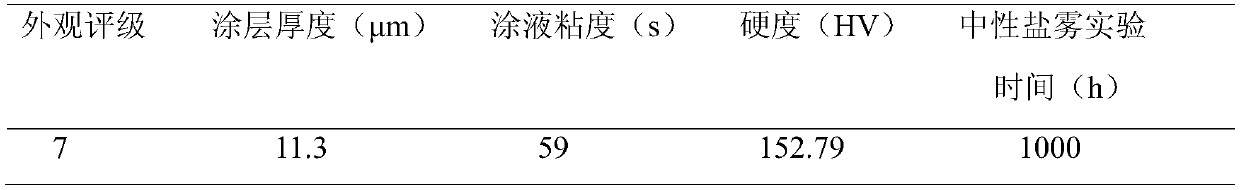

Embodiment 1

[0039] coating

[0040] a kind of Al 2 o 3 Nano particle reinforced chrome-free dacromet anticorrosion paint, its preparation method comprises the following steps:

[0041] 1) Preparation of metal slurry: Weigh 3.84kg flake zinc powder, 0.76kg flake aluminum powder, 4kg wetting agent (polyethylene glycol 400) and 100g dispersant (OP-10) according to the ratio, and weigh Wetting agent to fully wet the flaky zinc powder and flaky aluminum powder and stir evenly to obtain the mixed solution I, dissolve the dispersant with an appropriate amount of water, then add the obtained dispersant aqueous solution to the mixed solution I, and stir evenly at room temperature for 6~ 10h, get the metal paste;

[0042] 2) Modified Al 2 o 3 Preparation of nanoparticles: hydrolyze 100g of silane coupling agent AC-66 in water, then add 200g of Al 2 o 3 Nanoparticles, then add 90g of emulsifying dispersant OP-10, after the nanoparticles are fully dispersed, sonicate for 15-20min, and finally ...

Embodiment 2

[0052] coating

[0053] a kind of Al 2 o 3 Nano particle reinforced chrome-free dacromet anticorrosion paint, its preparation method comprises the following steps:

[0054] 1) Preparation of metal slurry: Weigh 3.3kg flake zinc powder, 0.7kg flake aluminum powder, 3.6kg wetting agent (polyethylene glycol 400) and 80g dispersant (OP-10) according to the ratio, and weigh Take the wetting agent to fully wet the flaky zinc powder and flaky aluminum powder and stir evenly to obtain the mixed solution I, dissolve the dispersant with an appropriate amount of water, then add the obtained dispersant aqueous solution to the mixed solution I, and stir evenly at room temperature for 6 ~10h, get the metal paste;

[0055] 2) Modified Al 2 o 3 Preparation of nanoparticles: 80g of silane coupling agent AC-66 was hydrolyzed in water, and then 180g of Al was added 2 o 3 Nanoparticles, then add 80g of emulsifying dispersant OP-10, after the nanoparticles are fully dispersed, then ultrason...

Embodiment 3

[0064] coating

[0065] a kind of Al 2 o 3 Nano particle reinforced chrome-free dacromet anticorrosion paint, its preparation method comprises the following steps:

[0066]1) Preparation of metal slurry: Weigh 3.612kg flake zinc powder, 0.688kg flake aluminum powder, 4.3kg wetting agent (polyethylene glycol 400) and 100g dispersant (OP-10) according to the ratio, and weigh Take the wetting agent to fully wet the flaky zinc powder and flaky aluminum powder and stir evenly to obtain the mixed solution I, dissolve the dispersant with an appropriate amount of water, then add the obtained dispersant aqueous solution to the mixed solution I, and stir evenly at room temperature for 6 ~10h, get the metal paste;

[0067] 2) Modified Al 2 o 3 Preparation of nanoparticles: 125g of silane coupling agent AC-66 was hydrolyzed in water, and then 250g of Al was added 2 o 3 Nanoparticles, then add 125g of emulsifying dispersant OP-10, after the nanoparticles are fully dispersed, then ul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com