Ultra-thin expansion steel structure fire-proof paint capable of resisting hydrocarbons fire and preparation method thereof

A kind of fireproof coating, ultra-thin technology, applied in the direction of fireproof coating, coating, etc., can solve the problem of not being able to use fireproof coating for steel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

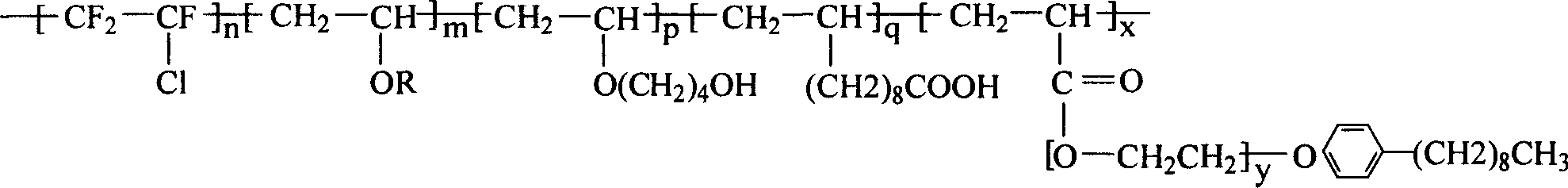

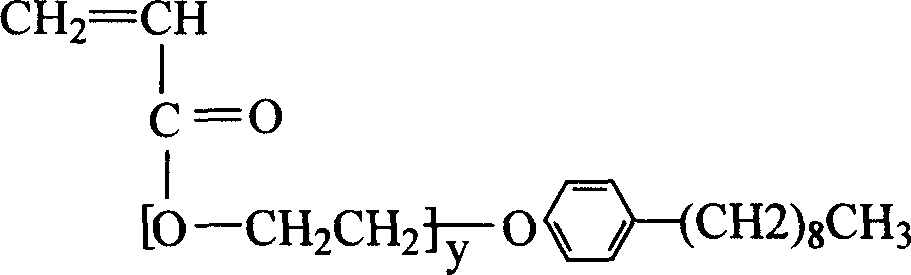

Method used

Image

Examples

Embodiment 1

[0072] Please refer to the 4 fire retardant coating formulations of the present invention listed in Table 1. First, add the fluorine-containing polymer emulsion and the silicone-modified polyacrylate emulsion into the mixing tank according to the formula 1 in Table 1, and after stirring evenly, add the fire prevention additive (ammonium polyphosphate, melamine phosphate, melamine, pentaerythritol) , filler (titanium dioxide, zinc oxide, kaolin and aluminum silicate fiber) and propylene glycol, after stirring for 20 minutes, put it into a sand mill and grind it once, then add expanded graphite, mix evenly, and discharge into barrels. The performance of the fire retardant coating of the present invention obtained is shown in formula 1 of table 2.

Embodiment 2

[0074] According to formula 2 in Table 1, first add fluorine-containing polymer emulsion and silicone modified polyacrylate emulsion into the mixing tank, after stirring evenly, add fire prevention additives (ammonium polyphosphate, melamine phosphate, melamine, pentaerythritol), filler (titanium dioxide, zinc oxide, kaolin and aluminum silicate fiber) and propylene glycol, after stirring for 10 minutes, put it into a sand mill and grind it once, then send it into a ball mill and grind it for 15 minutes, then add expanded graphite, mix evenly, and discharge into barrels. The performance of the fire retardant coating of the present invention obtained is shown in formula 2 of table 2.

Embodiment 3

[0076] According to formula 3 in Table 1, first add fluorine-containing polymer emulsion and silicone modified polyacrylate emulsion into the mixing tank, stir evenly, add fire prevention additives (ammonium polyphosphate, melamine phosphate, melamine, pentaerythritol), filler ( Titanium dioxide, zinc oxide, kaolin and aluminum silicate fibers) and propylene glycol, after stirring for 30 minutes, put into a ball mill to grind one pass, then add expanded graphite, mix evenly, discharge and load into barrels. The properties of the fire retardant coating of the present invention are shown in formula 3 of table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com