Bending tester

A bending test and tester technology, applied in the field of bending tester, can solve the problems of material incorrosion resistance, inaccurate test results, inability to distinguish whether it meets the requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

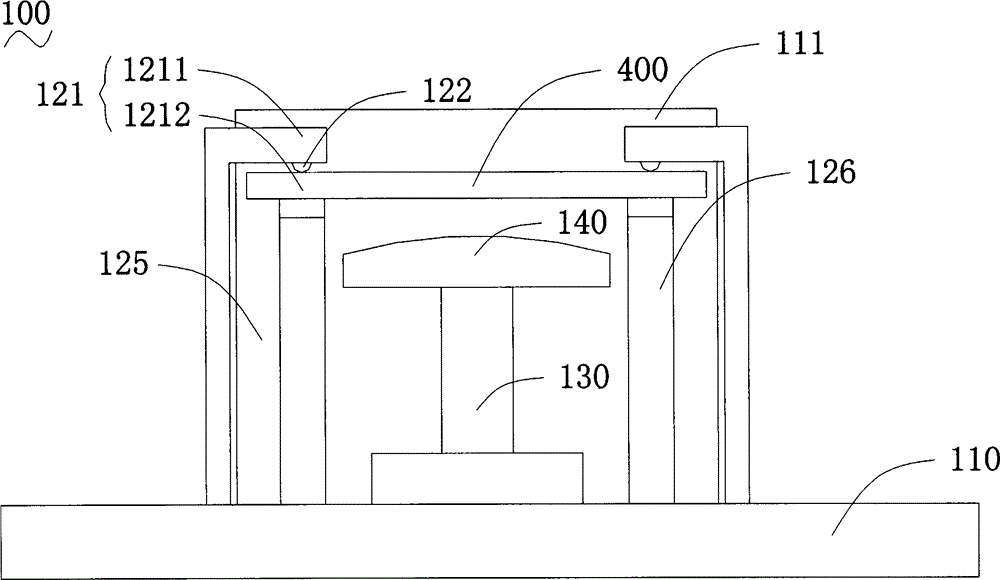

[0034] Please refer to figure 1 , Embodiment 1 discloses a bending tester 100, including: a test platform 110 for performing a bending test on a test sample 400, and two bars on the test platform 110 are used to press against the test sample 400 during the test. The load supporting mechanism at both ends extends out of the operating shaft 130 on the test platform, the bending test mold 140 above the operating shaft 130 and the driving mechanism (not shown) for driving the operating shaft 130 .

[0035] Among them, the test sample 400 is mainly strip-shaped parts such as steel plates, rubber plastic plates, and epoxy new material coatings in the oil and gas pipeline industry. Both load supporting mechanisms are equipped with clamps for clamping one end of the test sample 400. The holding structure 121, in this embodiment, the holding structure 121 is a pair of oppositely arranged movable pads, including a first pad 1211 at the top and a second pad 1212 at the bottom, the first ...

Embodiment approach 2

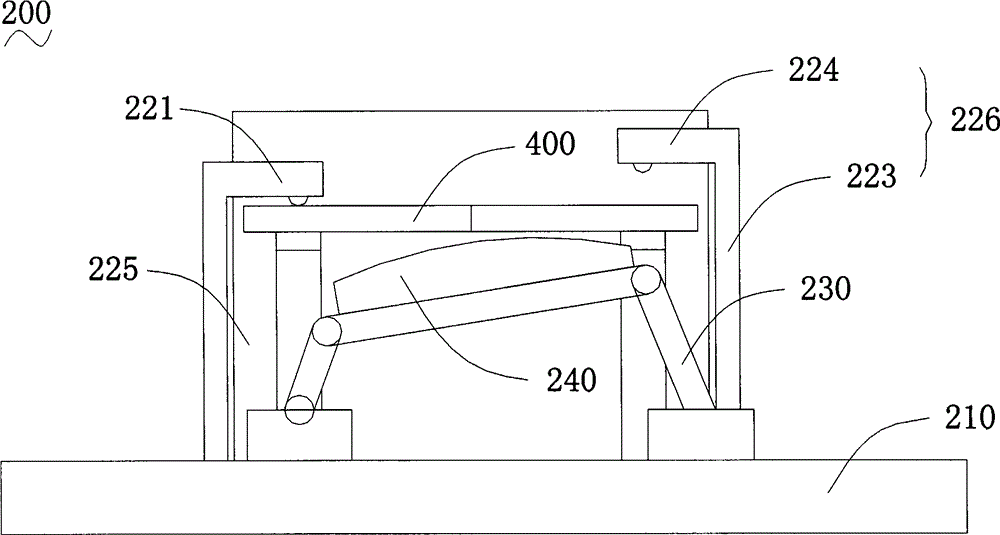

[0043] Please refer to figure 2 , Embodiment 2 discloses a bending tester 200, including: a test platform 210 for performing a bending test on a test sample 400, and two bars on the test platform 210 are used to press against the test sample 400 during the test. The load support mechanism at both ends extends out of the operating shaft 230 on the test platform, the bending test mold 240 above the operating shaft 230 and the driving mechanism (not shown) for driving the operating shaft 230 .

[0044] The difference from Embodiment 1 is that the above two load supporting mechanisms include a first load supporting mechanism 225 and a second load supporting mechanism 226 , and the second load supporting mechanism 226 is higher than the first load supporting mechanism 225 .

[0045] The first load supporting mechanism 225 is provided with a clamping structure 221 for clamping one end of the test sample 400. In this embodiment, the clamping structure 221 can be similar to the clamp...

Embodiment approach 3

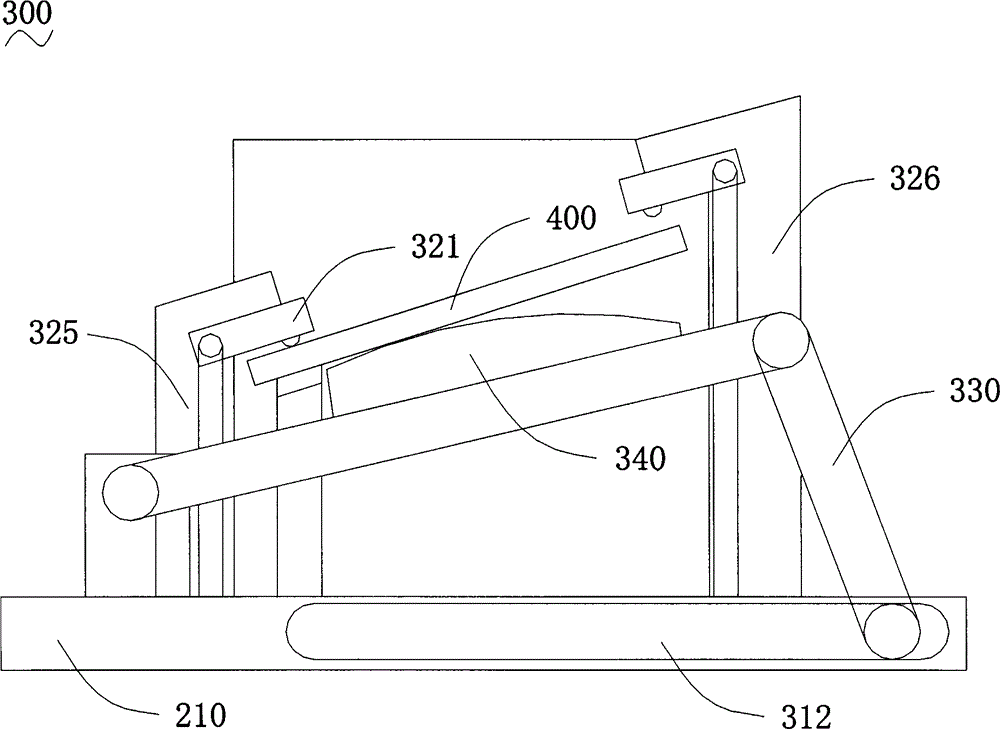

[0049] Please refer to image 3 , Embodiment 3 discloses a bending tester 300, including: a test platform 310 for performing a bending test on a test sample 400, and two bars on the test platform 310 are used to press against the test sample 400 during the test. The load support mechanism at both ends extends out of the operating shaft 330 on the test platform, the bending test mold 340 above the operating shaft 330 and the driving mechanism (not shown) for driving the operating shaft 330 . Wherein, the second load supporting mechanism 326 is higher than the first load supporting mechanism 325 , and the first load supporting mechanism 325 is provided with a clamping structure 321 for clamping one end of the test sample 400 .

[0050] The difference from Embodiment 2 is that the operating shaft 330 is a two-bar linkage mechanism, wherein a guide groove 312 is provided on the test platform 310, and one end of one linkage mechanism is arranged in the guide groove, and can be Und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com