Processing technology and material of rotary asymmetrical self-retractable spring belt buckle

An asymmetric and processing technology, applied in metal processing equipment, fasteners, manufacturing tools, etc., can solve the problems of easy scratches on the surface of products, restrictions on the materials used in products, and the structure of castings is not dense enough to achieve beautiful molding, Low production cost and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

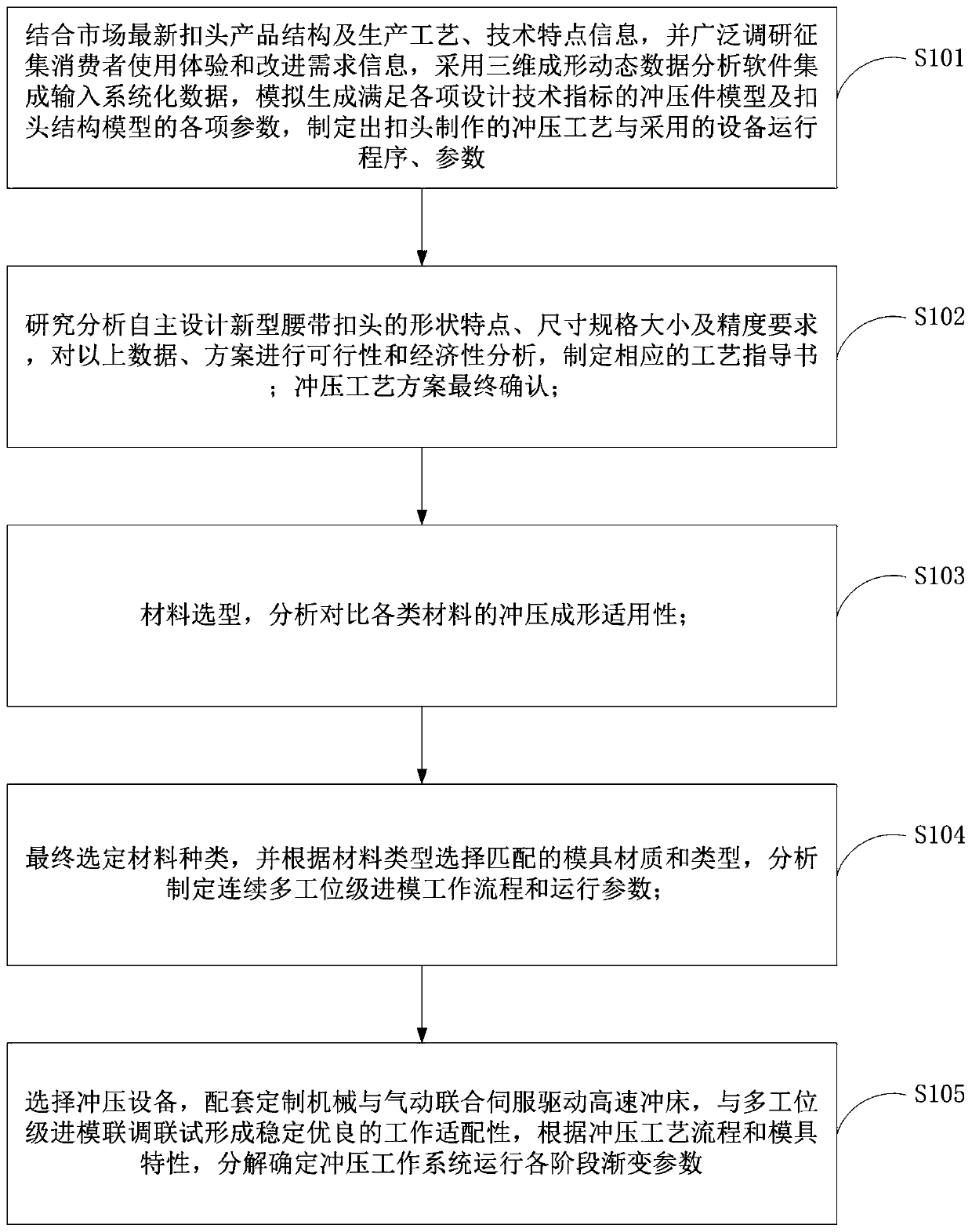

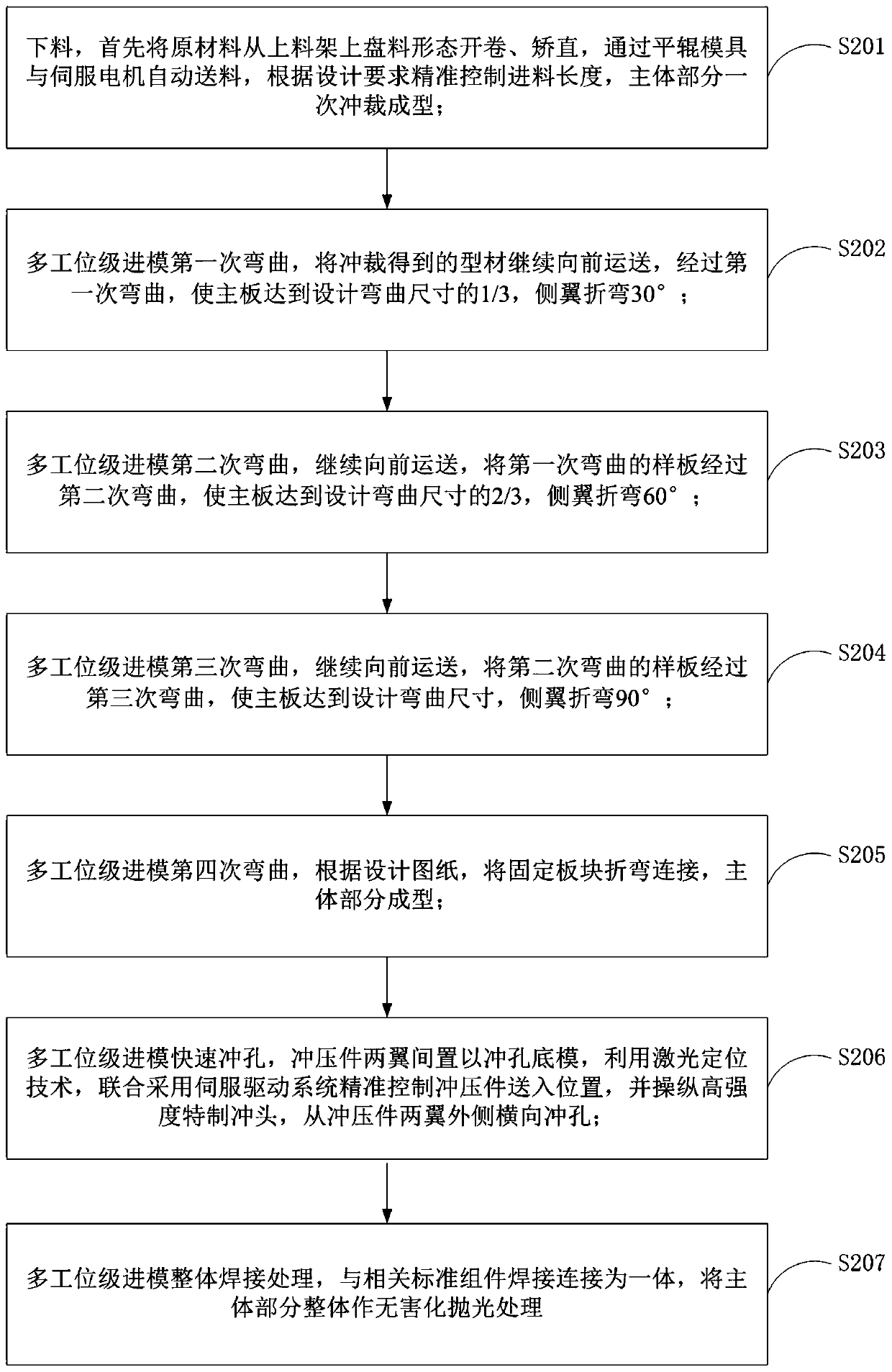

Method used

Image

Examples

Embodiment Construction

[0054] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

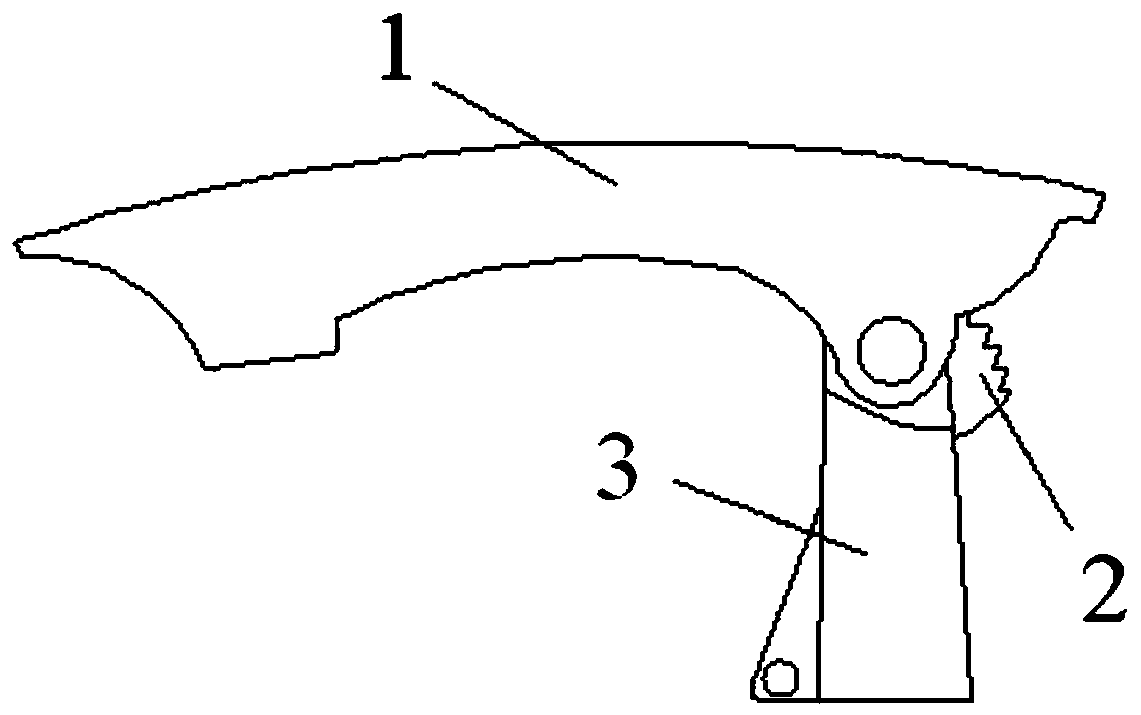

[0055] A rotary asymmetrical self-expanding spring belt buckle, provided with a buckle head 1, the front end of the buckle head 1 is integrally provided with a connecting part 1-2, and the rear end of the buckle head 1 is symmetrically provided with unequal installation holes 1-1; the installation shaft 2-1 on the buckle 2 is inserted into the installation hole 1-1, the installation shaft 2-1 is covered with a collar 2-2, and the outer wall of the collar 2-2 There are locking teeth 2-3 on the top;

[0056] The mounting shaft 2-1 is hoisted with a fixed frame 3, and the rear end of the fixed frame 3 is integrally provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com