Cotton elastic tubular shirt fabric and textile process thereof

A tubular and fabric technology, applied in the field of textile fabrics, to achieve the effect of comfortable and natural wearing, improved hand feeling and smooth surface

Inactive Publication Date: 2010-08-11

JIANGYIN LONGMA TEXTILE

View PDF1 Cites 24 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

And in existing fabrics, the fabrics that can meet the above requirements simultaneously are less

Method used

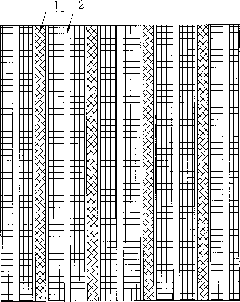

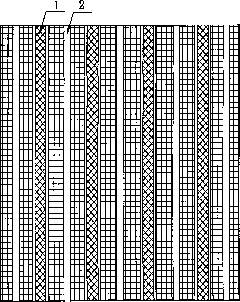

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a cotton elastic tubular shirt fabric which is woven from warp and weft, wherein tubular convex layers are arranged on the fabric along the warp direction at intervals; each tubular convex layer is woven by a passive type twin-shaft weaving method; the warp comprises cotton yarns and polyester yarns; and the weft comprises cotton yarns and Lycra core-spun yarns, wherein the Lycra core-spun yarns are formed by wrapping the cotton yarns and / or the polyester yarns outside Lycra yarns. The textile process comprises: a processing technique comprising the steps of yarn cutting, warping and drafting; a simultaneously-performed dampening process which comprises the steps of weft straightening and weft winding; a weaving process; a grey fabric inspecting process; an after finishing process; a finished fabric inspecting process and the like, wherein in the weaving process, the tubular convex layers are arranged in the warp at intervals; the Lycra yarns are woven in the weft at intervals; a plane layer part of the fabric is woven by a plain weaving method; and the tubular convex layer part of the fabric is woven by a twill weaving method. The fabric can enable a textile to have better elasticity in the transverse direction and be comfortable, fit, natural and dynamic in wear, and wrinkles can easily and automatically recover.

Description

A kind of cotton elastic tubular shirt fabric and its textile process technical field The invention relates to a textile fabric, in particular to a cotton-elastic tubular shirt fabric with lateral elasticity and a weaving process thereof. Background technique In the prior art, there are many kinds of textile fabrics, including natural pure cotton fabrics, silk fabrics, woolen fabrics and other plant fiber fabrics. Chemical fiber fabrics include fabrics containing polyester yarns, fabrics containing nylon yarns, fabrics containing polypropylene yarns, fabrics containing spandex yarns, etc., as well as fabrics blended with natural yarns and chemical fiber yarns. Among them, fabrics woven with natural yarns, such as pure cotton fabrics, have the advantages of good air permeability, good hygroscopicity, natural environmental protection, comfortable wearing, no side effects on the human body, and no static electricity. However, because pure cotton fabrics are easy to wrinkle, ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): D03D13/00D03D15/00D03D15/217D03D15/283D03D15/40D03D15/47D03D15/50D03D15/56

Inventor 顾平娟

Owner JIANGYIN LONGMA TEXTILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com