Liquid crystal display device and manufacturing method thereof

A liquid crystal display device and liquid crystal layer technology, applied in nonlinear optics, instruments, optics, etc., can solve problems such as lengthening process time, poor friction process, and reducing dark state brightness, so as to reduce production costs and prevent static moiré (Mura, the effect of enhancing the center contrast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0033] It should be noted that, for the sake of clarity of illustration, the drawings of the present invention only show structural features related to the inventive point of the present invention, while other structural features are omitted.

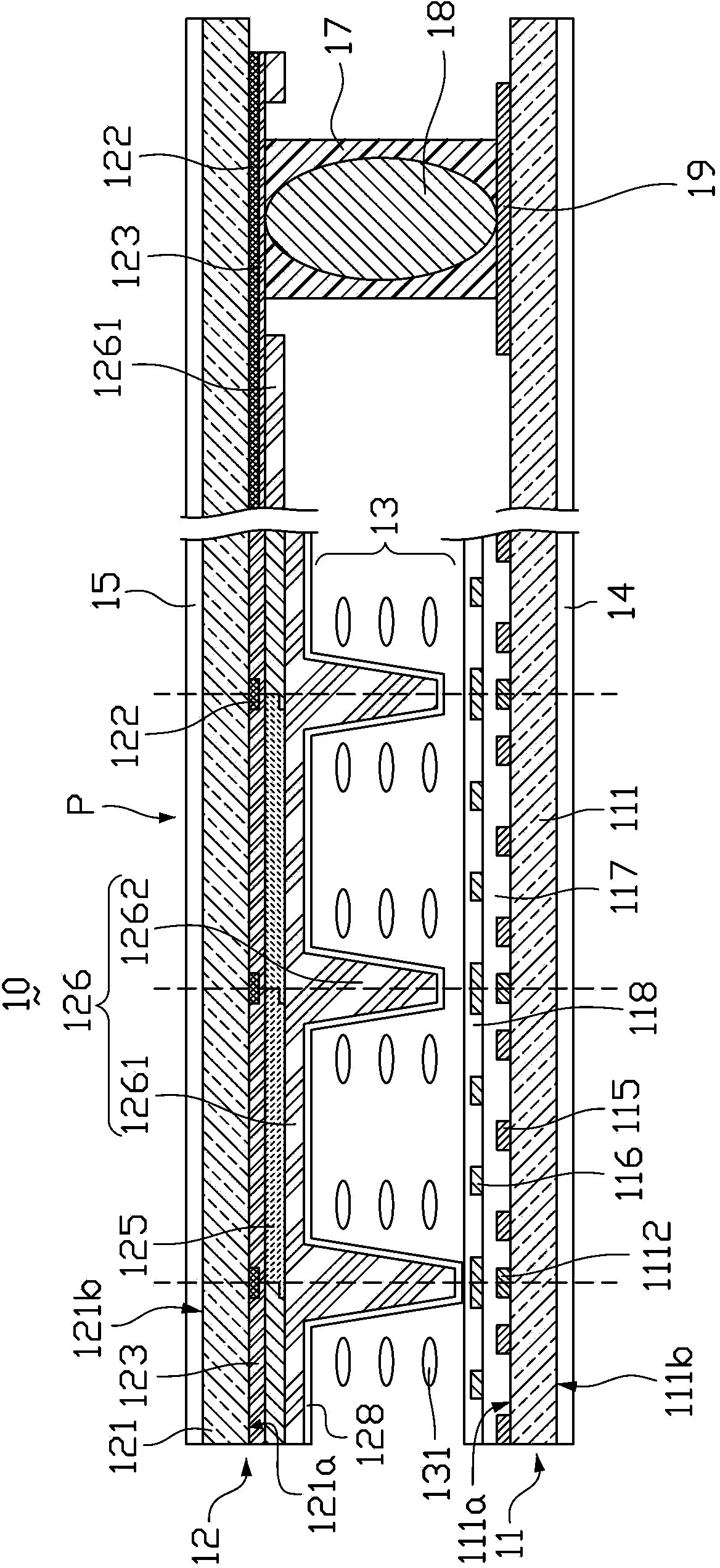

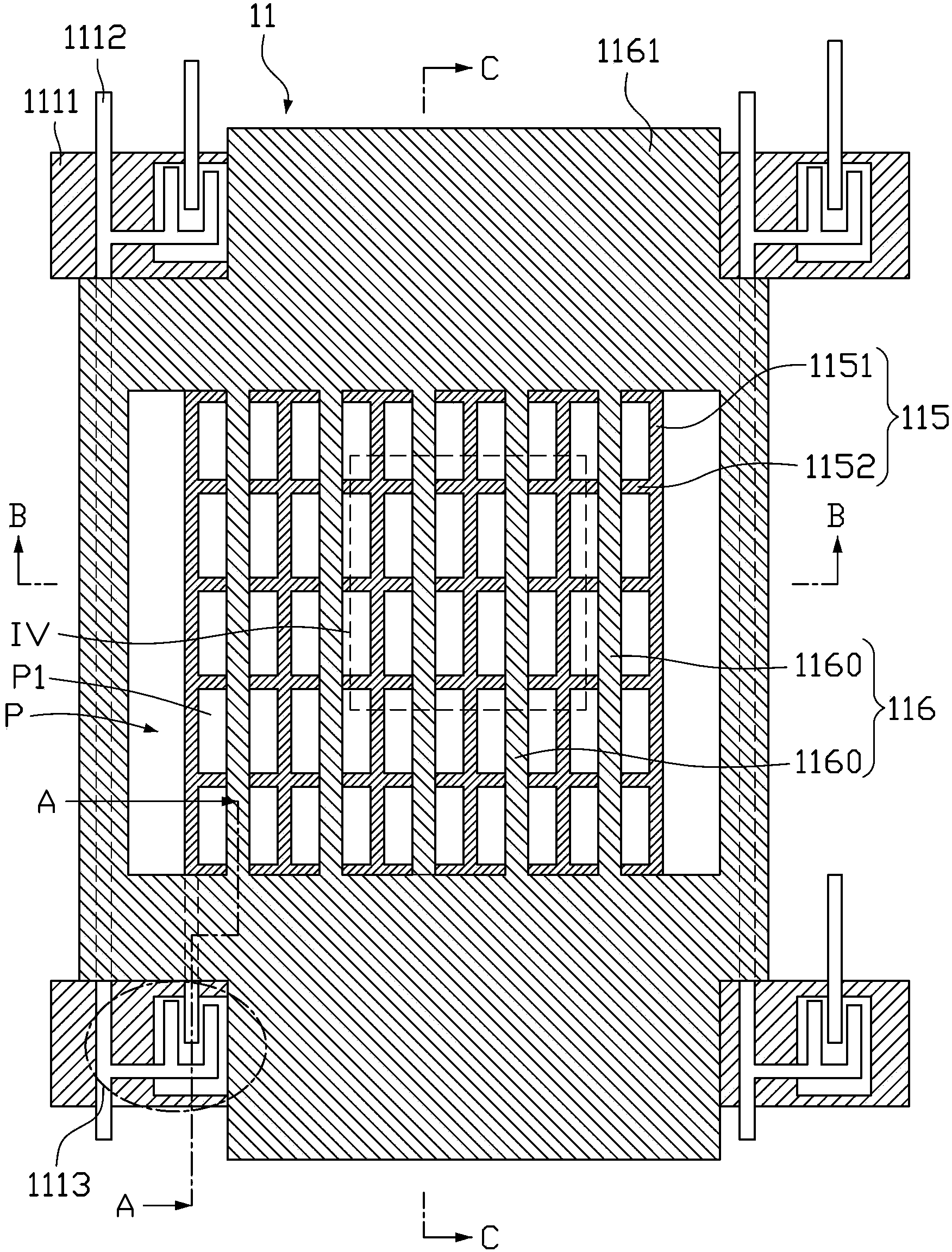

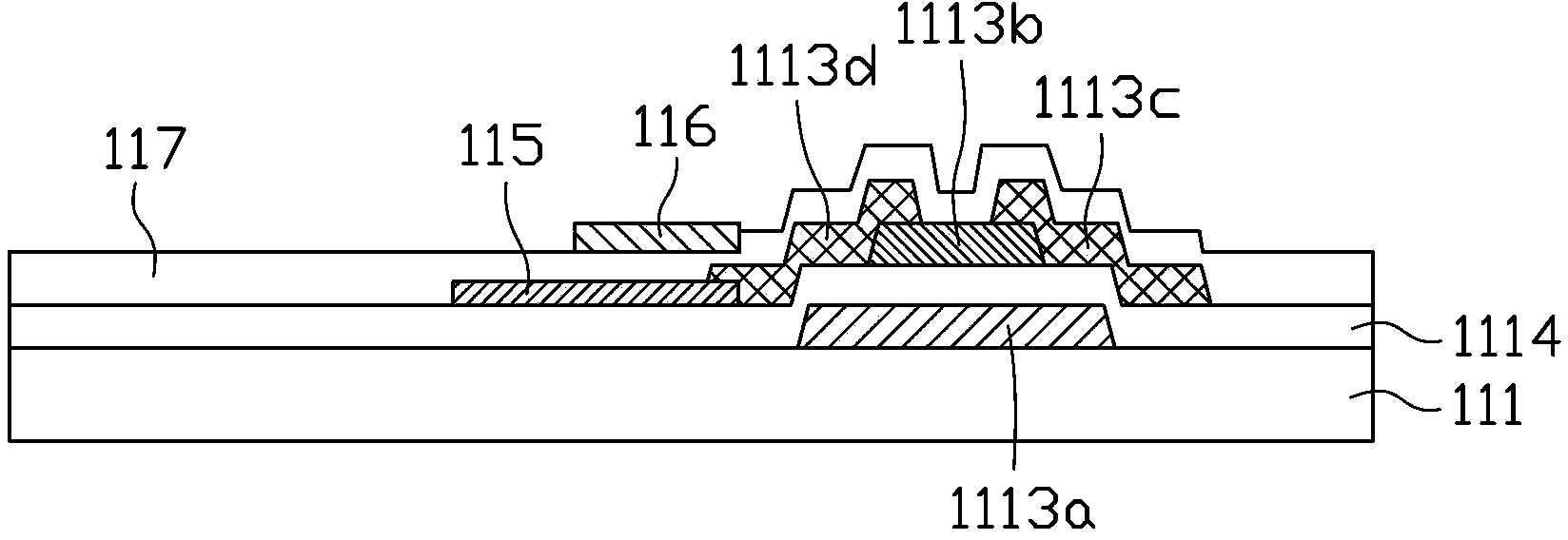

[0034] figure 1 It is a schematic structural diagram of a liquid crystal display device according to an embodiment of the present invention. The liquid crystal display device 10 of the embodiment of the present invention includes an array substrate 11 and a color filter substrate 12 disposed opposite to each other, and a liquid crystal layer 13 sandwiched between the array substrate 11 and the color filter substrate 12 . A plurality of pixel regions P ( figure 1 The area between every two adja...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com