Patents

Literature

75results about How to "Strong bonding between layers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

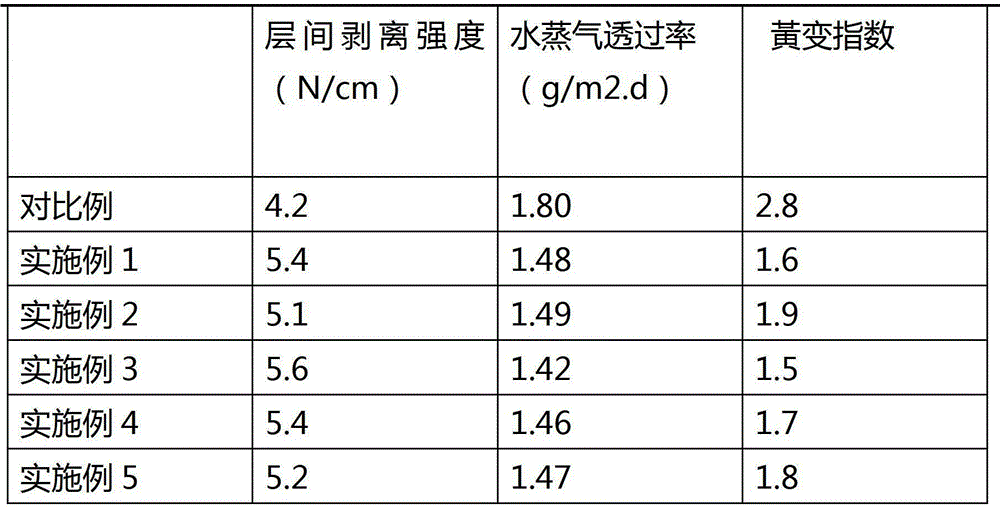

Solar panel back film and manufacturing technology thereof

ActiveCN103346182AImprove bindingStrong bonding between layersFinal product manufactureSynthetic resin layered productsPolyesterManufacturing technology

A solar panel back film comprises a PET film matrix with the thickness of 100-350 micrometers. Fluorine-containing polymer coatings of 15-30micrometers cover the two faces of the matrix, and the fluorine-containing polymer coatings are formed by mixing raw material components according to a proportion to obtain mixed emulsion and coating the PET film matrix by the mixed emulsion which is swollen under the temperature between 80 DEG C and 200 DEG C, wherein raw materials of the fluorine-containing polymer coatings comprise, by mass, polyester PET powder, fluorine-containing resin, solvent, a cross-linking agent, padding and ethylene glycol. The polyester PET powder is polyester PET powder with grain size smaller than 25 micrometers, wherein the polyester PET powder is formed by smashing precipitate obtained by dissolving in phenol-carbon tetrachloride mixed solvent. The fluorine-containing resin is fluorine-containing macromolecule resin. The solar panel back film is easy to process, tearing resistant and superior in electrical insulation performance and weather fastness.

Owner:ZHEJIANG VENTURA PHOTOVOLTAIC MATERIALS

Optical conversion luminous film and preparation method thereof

ActiveCN101571235AGood luminous consistencyPrevent glareLuminescent paintsSynthetic resin layered productsChemistryColor rendering index

The invention relates to an optical conversion luminous film and a preparation method thereof. The optical conversion luminous film is formed by a diffusion film and a mixed paint layer on the diffusion film; the optical conversion luminous film has the thickness of 30-200mum, wherein, the thickness of the diffusion film is 20-70mum; the mixed paint layer is made of 10.000-30.000% of yellow luminous fluorescent material, 0.001-2.000% of red luminous fluorescent material, 60.000-89.000% of polymer resin, 1.000-5.000% of bi-amino silane, 0.000-20.000% of diluting agent and 0.000-5.000% of accessory ingredient. By combining the yellow luminous fluorescent material and the red luminous fluorescent material, the invention can realize the aim of regulating chromaticity coordinate, color temperature and color rendering index, thus preparing the optical conversion luminous film which is made of the fluorescent materials and has the advantages of high color rendering index of the photodiffusion effect, good property of uniform light, anti-dazzle, high light conversion efficiency, low cost, excellent aging characteristic and simple production technique.

Owner:DALIAN LUMINGLIGHT SCIENCE & TECHNOLOGY CO LTD

Environmentally-friendly automotive trim composite material and preparation method thereof

ActiveCN106827751AImprove wear resistanceExcellent formabilityPolyureas/polyurethane adhesivesSynthetic resin layered productsFiberThermoplastic

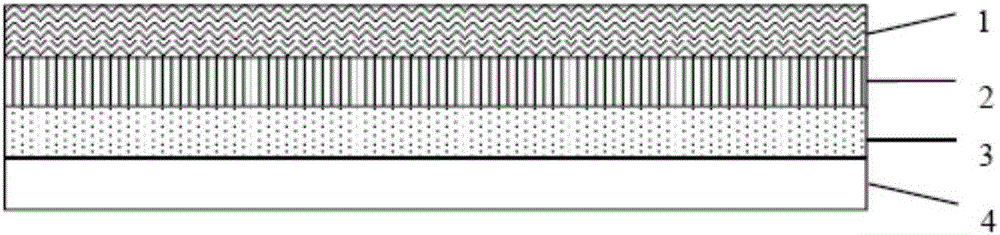

The invention provides an environmentally-friendly automotive trim composite material and a preparation method thereof. The automotive trim composite material comprises a surface layer, a foaming layer, a hot melt glue layer and a skeleton structure layer, wherein the surface layer is a TPU (Thermoplastic Polyurethanes) film layer, a TPO (Thermoplastic Polyolefin) film layer, a PU (Poly Urethane) film layer, a PP (Propene Polymer) film layer or a genuine leather layer; the foaming layer is a PP foaming layer, a PPF foaming layer, a PU foaming layer or a PE (Poly Ethylene) foaming layer; the hot melt glue layer is a TPU hot melt glue layer, an EVA (Ethylene-vinyl Acetate Copolymer) hot melt glue layer, a PE hot melt glue layer, a PA (Poly A) hot melt glue layer or other hot melt glue layers; the skeleton structure layer is made of a glass fiber modified PP composite material, a carbon fiber modified PP composite material, or an ABS (Acrylonitrile Butadiene Styrene) modified PP composite material. According to the environmentally-friendly automotive trim composite material and the preparation method thereof provided by the invention, the surface layer with the foaming layer is glued with a skeleton structure through an environmentally-friendly hot melt glue, so that the gluing degree is good, the rejection rate is low, the product forming quality is effectively ensured, and the manpower is saved; the product is wear-resisting, high in tearing strength and dimensional stability, not easy to strip, attractive in appearance, and environmentally-friendly in production process without pollution; the product can be recycled.

Owner:DONGGUAN XIONGLIN NEW MATERIAL TECH

Superhard composite coated cutting tool and preparation method thereof

ActiveCN106119763AAlleviate the problem of weak bindingHighlight substantive featuresMolten spray coatingBoron nitrideCemented carbide

The invention provides a superhard composite coated cutting tool. The structure of the superhard composite coated cutting tool comprises a cemented carbide substrate, a metal transition layer and a cubic boron nitride coating doped with metallic nickel, wherein the metal transition layer and the cubic boron nitride coating are sequentially sprayed to the surface of the cemented carbide substrate. The superhard composite coated cutting tool is reasonable in structural design, excellent in wear resistance, high in interlayer bonding force and long in service life. The invention further provides a preparation method of the superhard composite coated cutting tool. The preparation method comprises steps as follows: metal micro-powder and cubic boron nitride composite micro-powder coated with the metallic nickel on the surface are taken as raw materials, and the metal transition layer and the cubic boron nitride coating doped with the metallic nickel are sequentially sprayed to the surface of the cemented carbide substrate with a supersonic flame spraying method. The preparation method adopts a simple process, equipment can operate automatically, and industrialization is facilitated.

Owner:FUNIK ULTRAHARD MATERIAL

Middle coating for vehicle furnace drying

InactiveCN101270257AMeet the paintingMeet needsLiquid surface applicatorsEpoxy resin coatingsEpoxyAcrylic resin

The invention relates to an automobile drying primer surfacer. Amino resin is taken as a crosslinking agent to have crosslinking reaction with resin with hydroxyl, such as alkyd resin, polyester resin, epoxy resin, acrylic resin, etc., and the primer surfacer which has the advantages of high hardness, good adhesion, firm interlayer bonding, good excessive roasting, good decorativeness, wear resistance, gloss retention, good color retention and low cost is processed and produced through re-mixing the alkyd resin, the epoxy resin and the amino resin according to the mechanisms of condensation, polymerization, curing and film formation; the automobile drying primer surfacer is characterized in that 15 portions to 25 portions of amino resin, 19 portions to 21 portions of polyester resin, 2.7 portions to 2.9 portions of epoxy resin, 25 portions to 35 portions of alkyd resin, 16 portions of 26 portions of pigment and filler and 2 potions to 7 portions of diluent are re-mixed; and then a promoter in a certain proportion is added in; finally the automobile drying primer surfacer is obtained.

Owner:SHIYUAN JINFENG CHEM INDAL

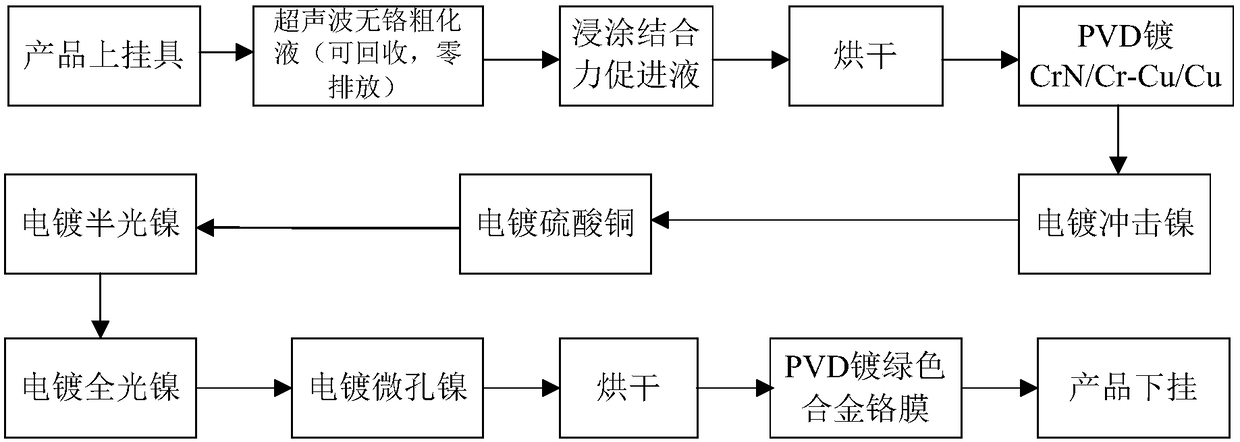

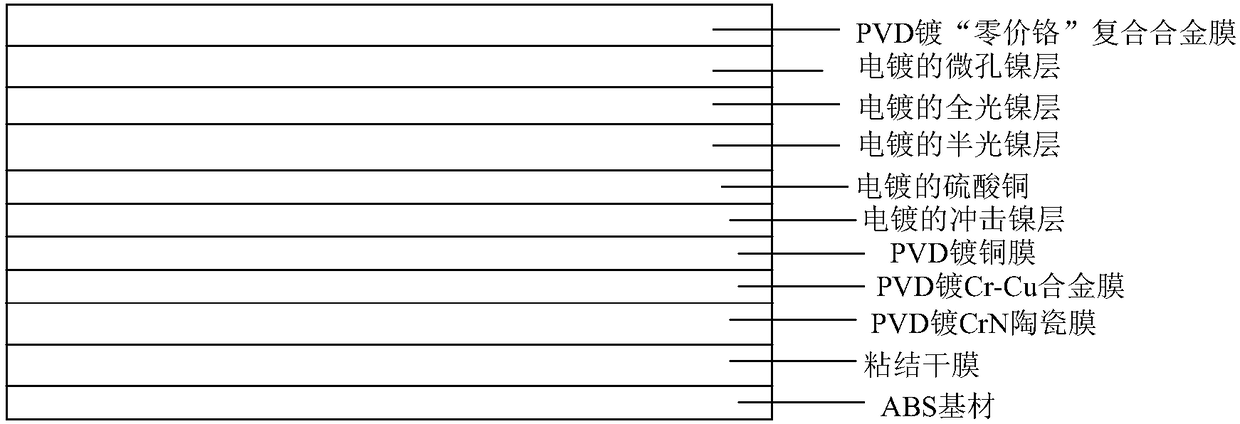

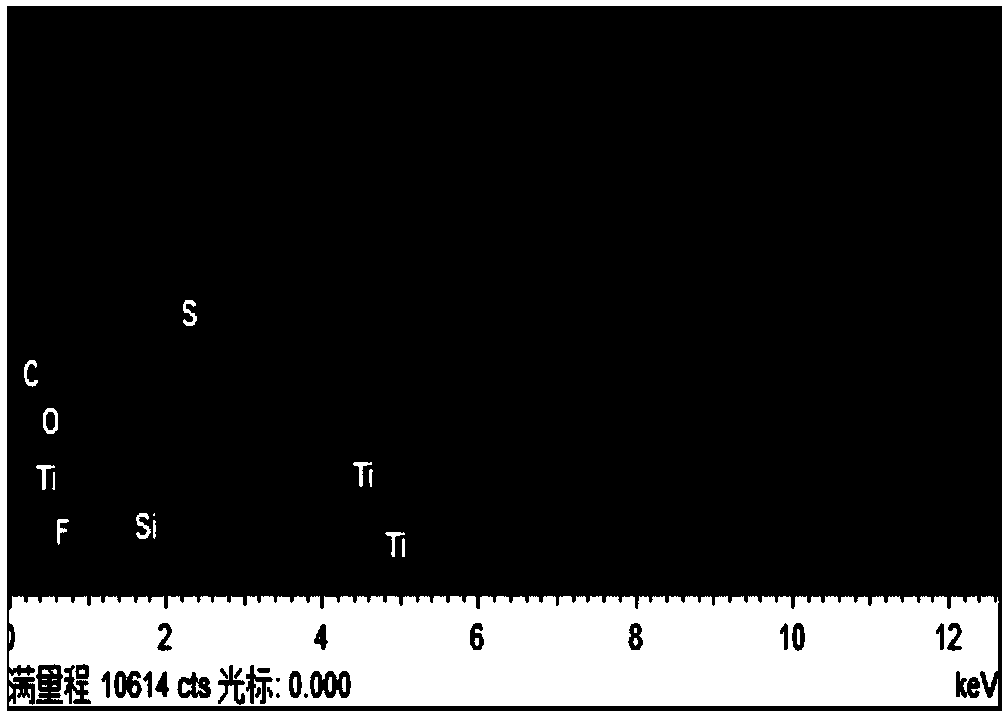

Plastic non-chrome roughening treatment method and water-saving electroplating method thereof

ActiveCN108220959AStrong bonding between layersEmission reductionVacuum evaporation coatingSputtering coatingWater savingWastewater

The invention provides a plastic non-chrome roughening treatment method and a water-saving electroplating method thereof. A plastic workpiece is put into a non-chrome roughening solution to be treated; the surface of the treated plastic workpiece is coated with a binding force accelerant in a dipping manner; finally, the plastic workpiece is subject to plasma activation treatment. According to thetechnical scheme, the better interlayer binding force can be achieved between obtained plastic and a coating, the traditional electroplating process can be completely replaced, in the whole process that the surface of the plastic workpiece is electroplated with a chromium film, toxic chemicals of hexavalent chromium or trivalent chromium and the like are not used, the discharge amount of waste water can be 50% of or lower than the discharge amount of traditional electroplated water, the process is stable, commercial mass production is achieved, and the green surface treatment process with thewide prospect is provided.

Owner:蒙城繁枫真空科技有限公司

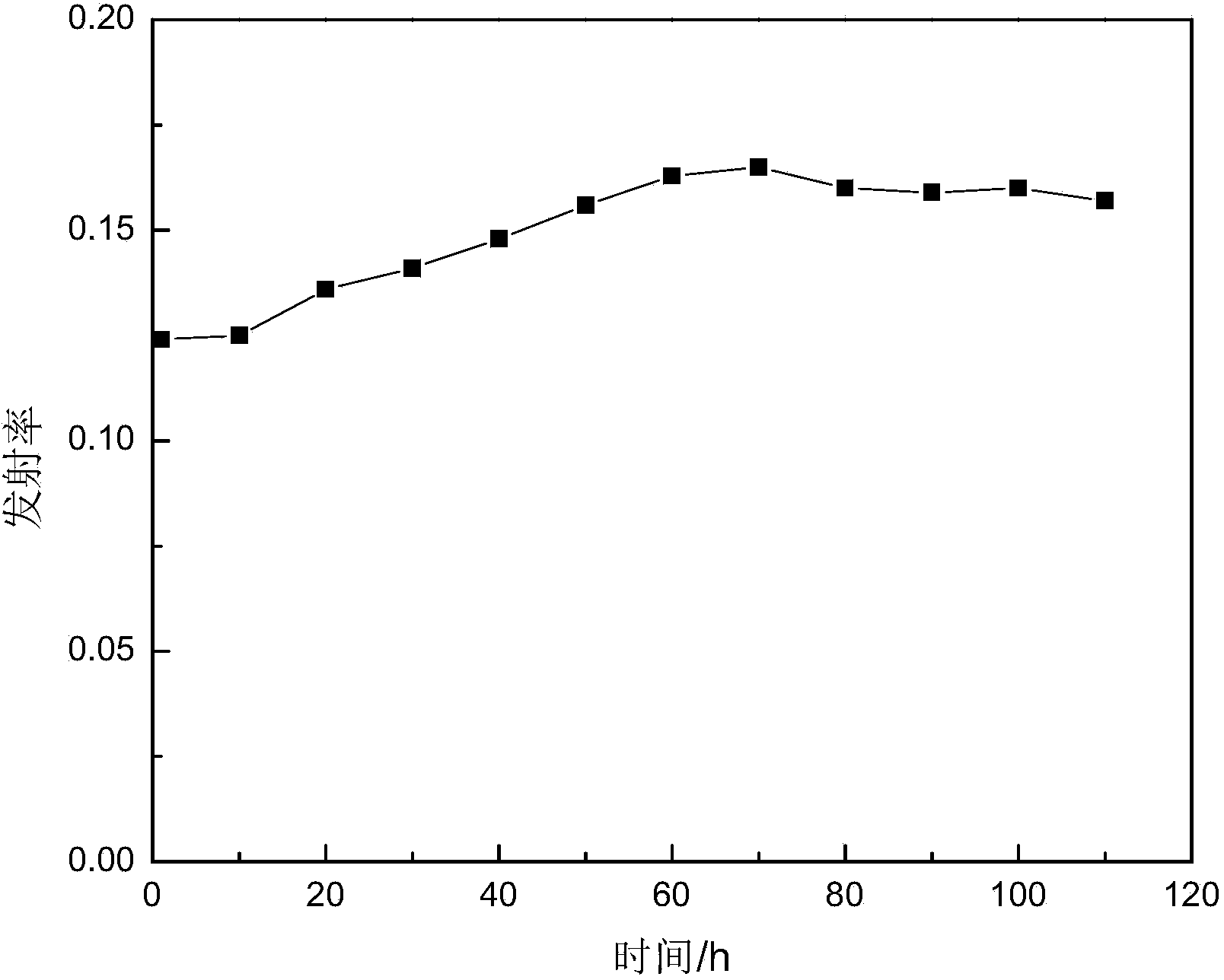

High-temperature-resisting, high-bonding-strength and low-infrared-emissivity composite coating and preparation method thereof

ActiveCN103963380AImprove high temperature stabilityChange the coefficient of thermal expansionVacuum evaporation coatingSputtering coatingSputteringLow emissivity

The invention discloses a high-temperature-resisting, high-bonding-strength and low-infrared-emissivity composite coating and a preparation method thereof. The composite coating comprises a diffusion obstruction layer composed of a devitrified glass coating, a low-emissivity functional layer composed of a devitrified glass containing Au powder, and a MgO protecting film in sequence from the inner layer to the outer layer; during preparation, the raw material powder is uniformly mixed, is smelted at high temperature, is quenched, is subjected to ball milling, and is baked to obtain glass dust; organic carrier and the glass dust are mixed to obtain the diffusion obstruction layer coating; the organic carrier, the Au powder and the glass dust, and conducting ball milling are mixed to obtain low-emissivity functional layer coating after ball billing is carried out; the diffusion obstruction layer coating is brushed on a substrate, and then baking and sintering are carried out to obtain the diffusion obstruction layer; the low-emissivity functional layer coating is brushed onto the diffusion obstruction layer, and baking and sintering are carried out to obtain the low-emissivity functional layer; the magnetic control sputtering method is adopted to prepare the MgO film on the low-emissivity functional layer to complete the preparation of the compound coating. The technical process of the composite coating is simple, the technology efficiency is high, and the product performance is good.

Owner:NAT UNIV OF DEFENSE TECH

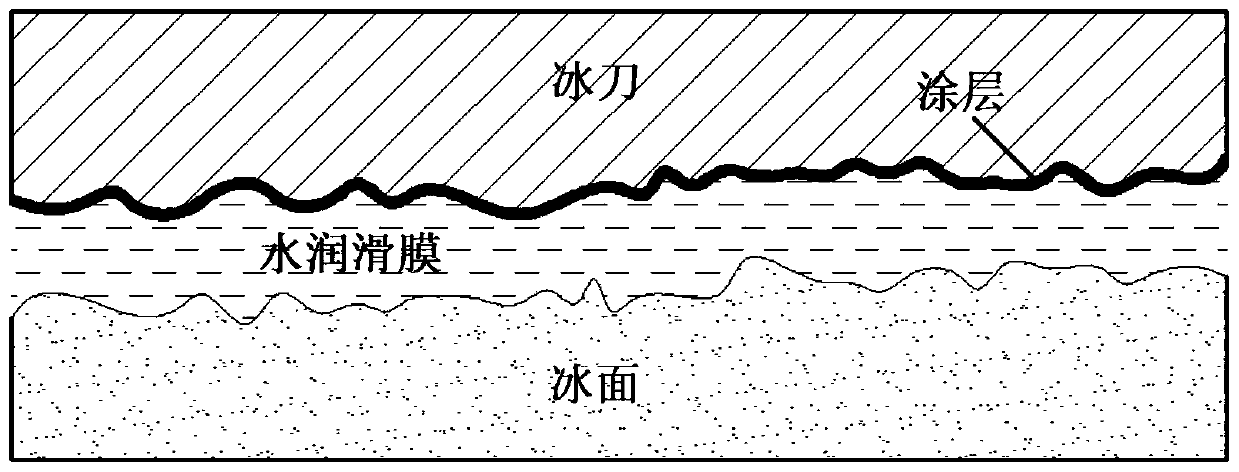

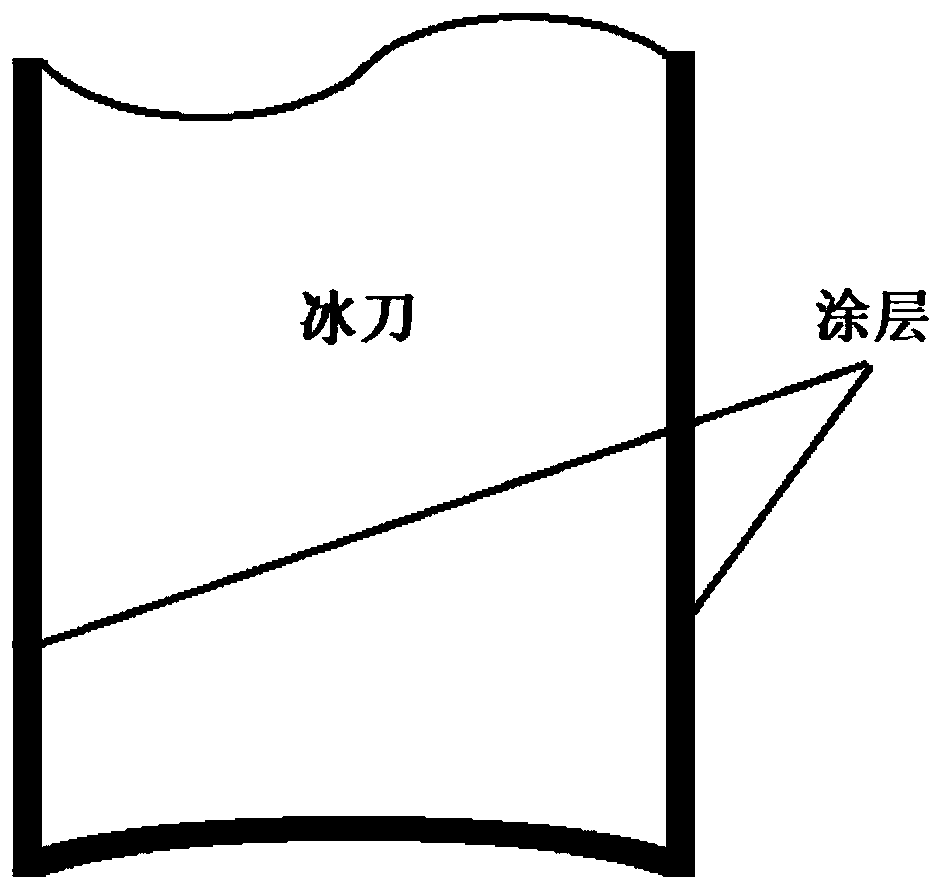

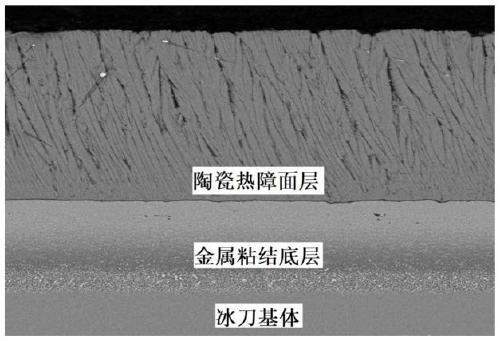

Novel ice skate blade drag reduction technology and implementation method thereof

InactiveCN109972097AAchieve drag reductionNovel technical principleVacuum evaporation coatingSputtering coatingWater basedHeat flow

The invention provides a novel ice skate blade drag reduction technology and an implementation method thereof, aiming at the dynamic characteristics and technical status of skating sports equipment. According to the novel ice skate blade drag reduction technology and the implementation method, through surface modification treatment on an ice skate blade substrate, the heat conductivity coefficientof an ice skate blade and heat loss caused by friction heat conduction to the ice skate blade substrate are obviously reduced, the heat flow distribution coefficient of the friction heat conduction to the ice surface is increased, and more friction heat is used for melting the ice surface to increase the thickness of a water lubricating film, so that water-based lubrication drag reduction is realized, the friction coefficient of the ice surface is greatly reduced, and the tribological performance of the ice skate blade is improved. The novel ice skate blade drag reduction technology and the implementation method have the outstanding characteristics of novel technical principle, remarkable drag reduction effect, easiness in engineering realization and the like.

Owner:NORTH CHINA UNIVERSITY OF TECHNOLOGY

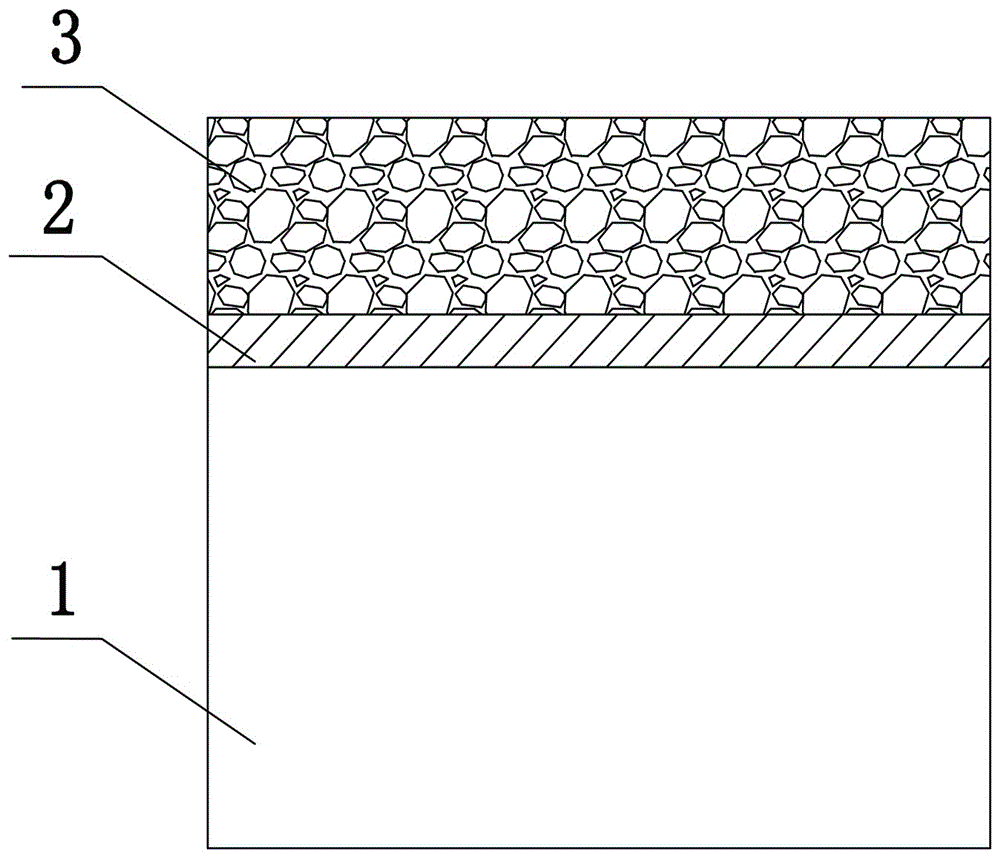

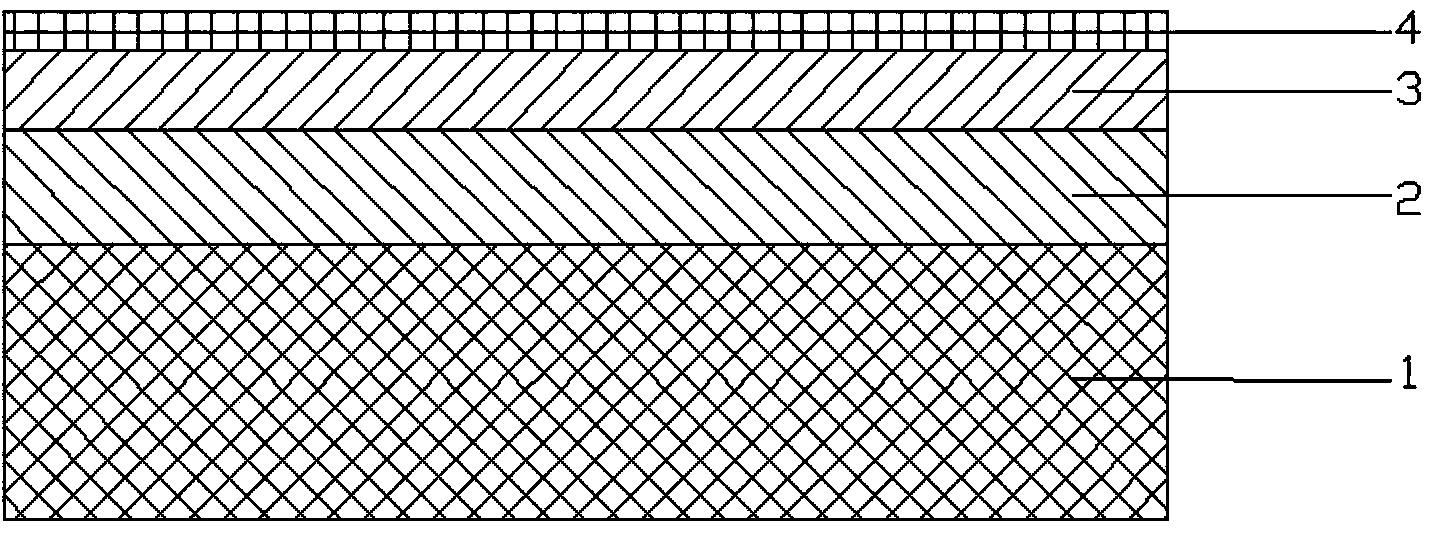

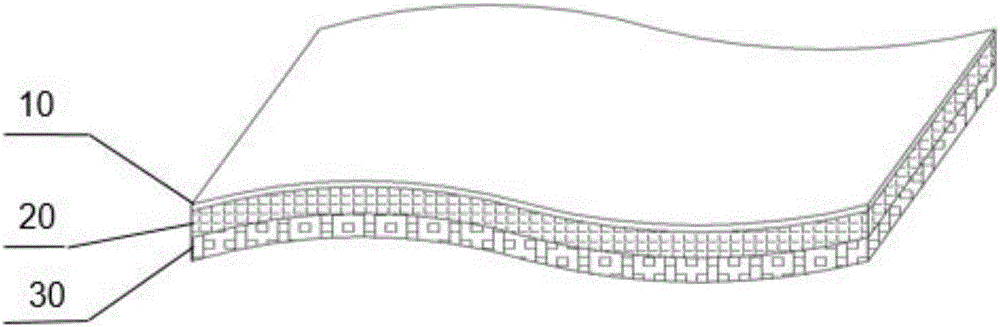

Flexible heat preservation and heat insulation film and preparation method thereof

InactiveCN106042550ARealize thermal insulationAvoid heat conductionSynthetic resin layered productsCoatingsThermal insulationReflective layer

The invention discloses a flexible heat preservation and heat insulation film. The flexible heat preservation and heat insulation film is characterized in that a PE protective film, a PET plastic thin film and an aerogel coating are included; the outer surface of the PE protective film is provided with an aluminum film reflecting layer; the PET plastic thin film is arranged between the PE protective film and the aerogel coating. According to the flexible heat preservation and heat insulation film, the aerogel coating serves as a main function achieving layer for heat preservation and heat insulation, a nano porous structure can effectively inhibit gas heat conduction and solid heat conduction, and therefore the heat insulation performance is efficient; the aluminum reflecting layer can overcome the defect that aerogel cannot inhibit radiation heat conduction, so that the material achieves heat preservation and heat insulation comprehensively; the thickness of the flexible heat preservation and heat insulation film is only a few millimeters, and therefore the flexible heat preservation and heat insulation film can adapt to multiple complex geometrical shapes and mechanical and thermal property requirements; interlayer bonding is firm, and the service life is long.

Owner:SUZHOU JUNYUE NEW MATERIAL TECH

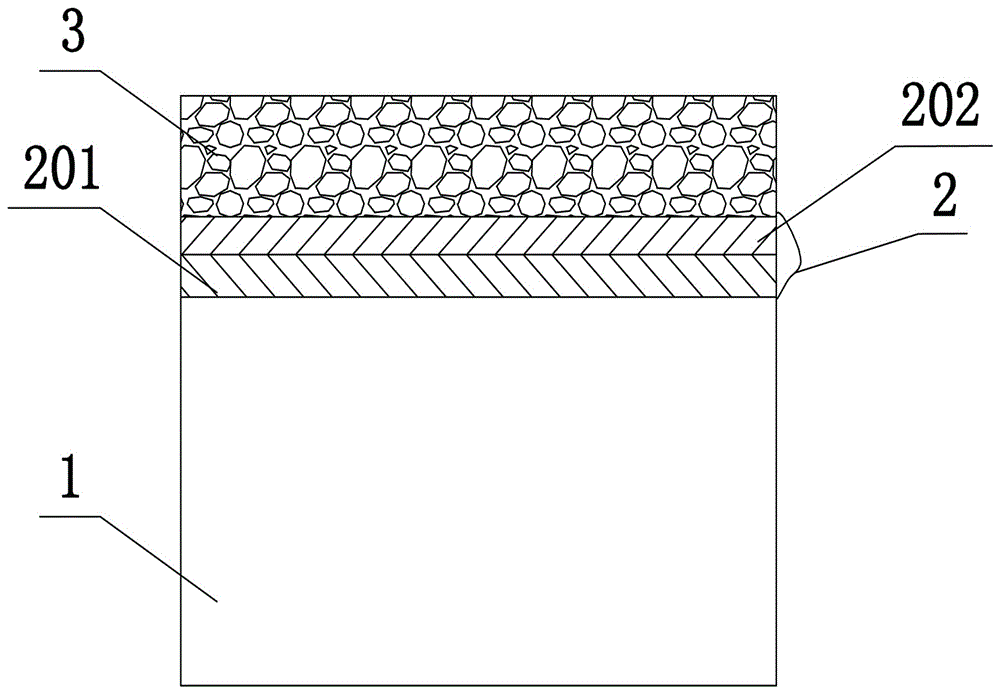

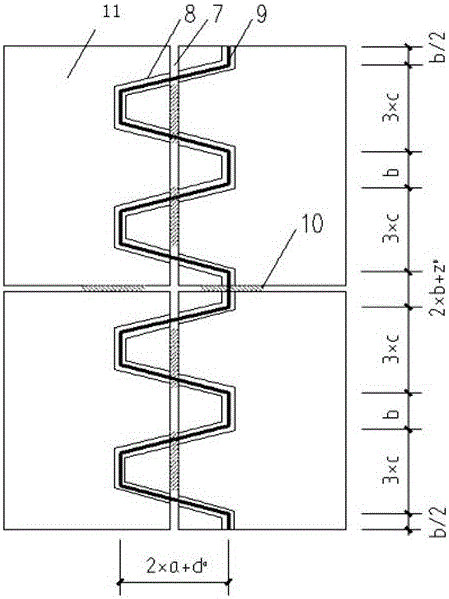

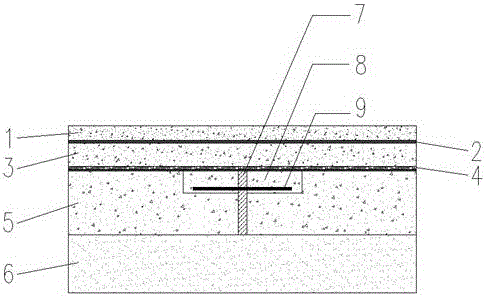

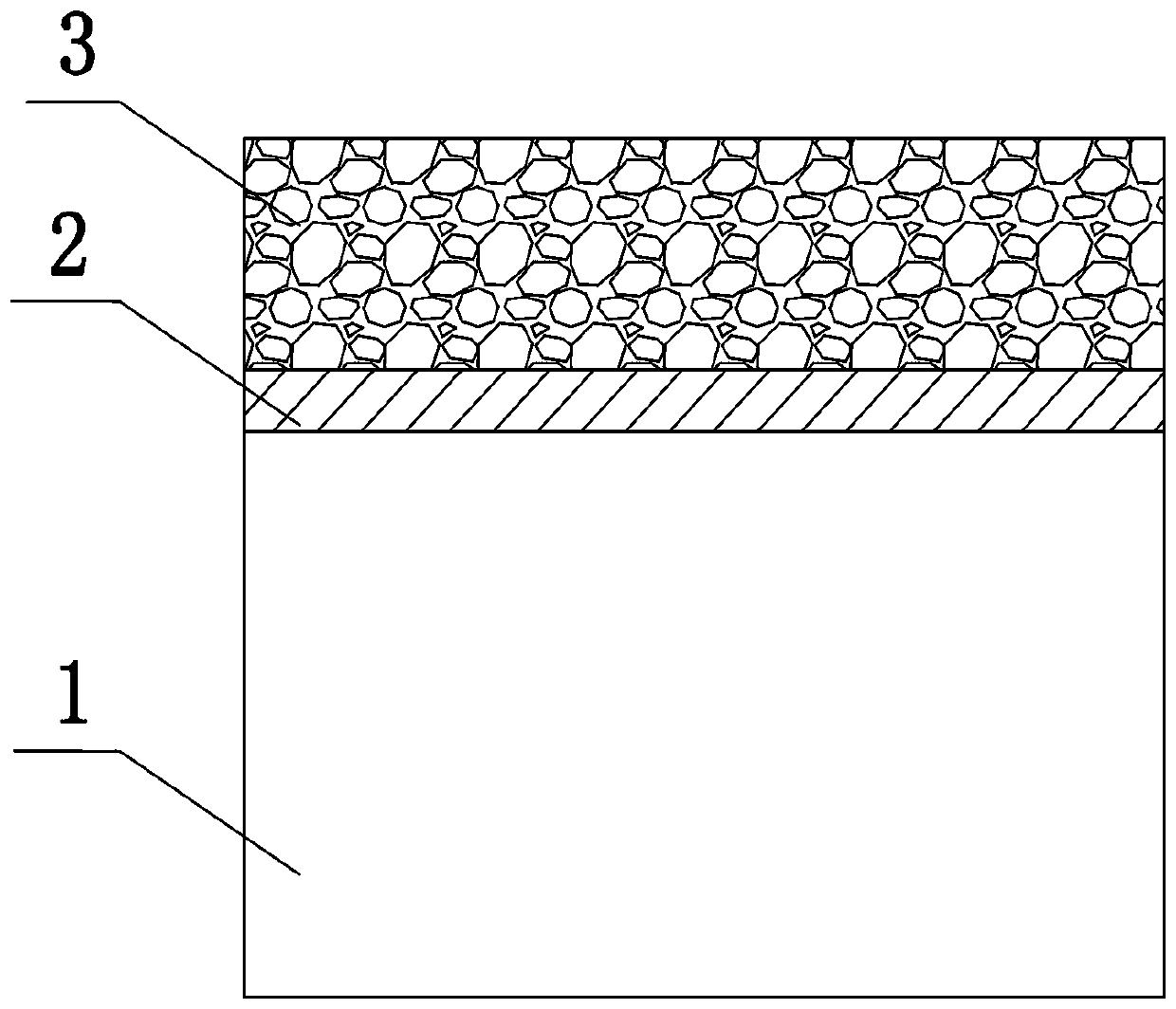

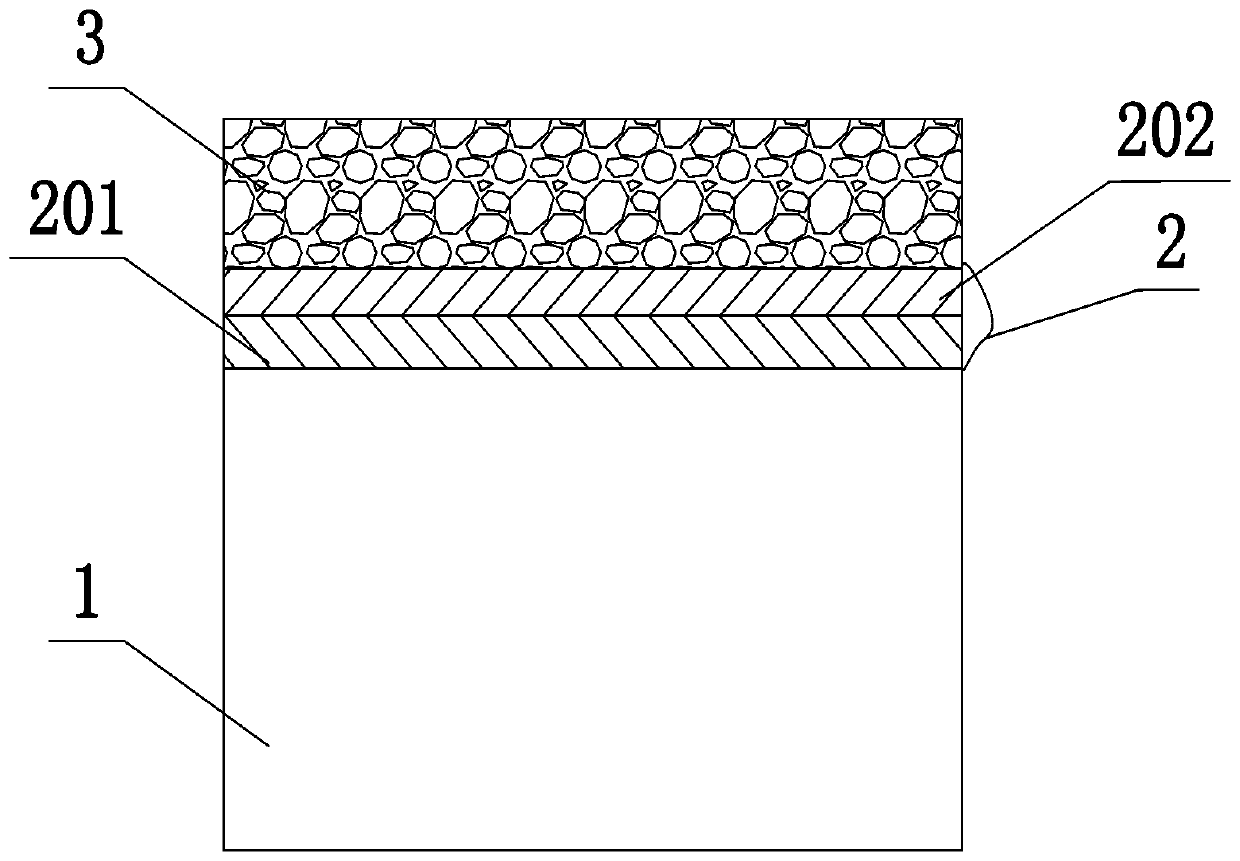

Composite structure for suppressing reflection cracks of old cement concrete pavement and reconstruction method

ActiveCN106436525AExtension reduction or blockingInhibit expansionPaving detailsEpoxyReconstruction method

The invention discloses a composite structure for suppressing reflection cracks of an old cement concrete pavement. The composite structure comprises a base layer, an old cement slab laid on the base layer and an asphalt concrete overlay laid on the old cement slab, and also comprises a multi-scale hybrid-fiber reinforced epoxy asphalt chip seal laid between the old cement slab and the asphalt concrete overlay; the asphalt concrete overlay comprises a lower layer of medium-grained asphalt concrete, a modified emulsified asphalt binder layer and an upper layer of stone mastic asphalt, which are sequentially laid from the bottom to the top. The invention further discloses a reconstruction method of the composite structure for suppressing reflection cracks of an old cement concrete pavement, and the reconstruction method comprises local constraints of steel bar forming, planting of steel bars and completion of the multi-scale hybrid-fiber reinforced epoxy asphalt chip seal. According to the composite structure and the reconstruction method disclosed by the invention, the overall bearing capacity of the pavement which is reconstructed by the old cement slab can be improved, the interlayer bonding force between the old cement slab and the asphalt concrete overlay is effectively increased, the generation of the reflection cracks is suppressed and the condition that the reflection cracks are prevented from extending to the asphalt concrete overlay is avoided.

Owner:NANTONG ROAD & BRIDGE ENG CO LTD

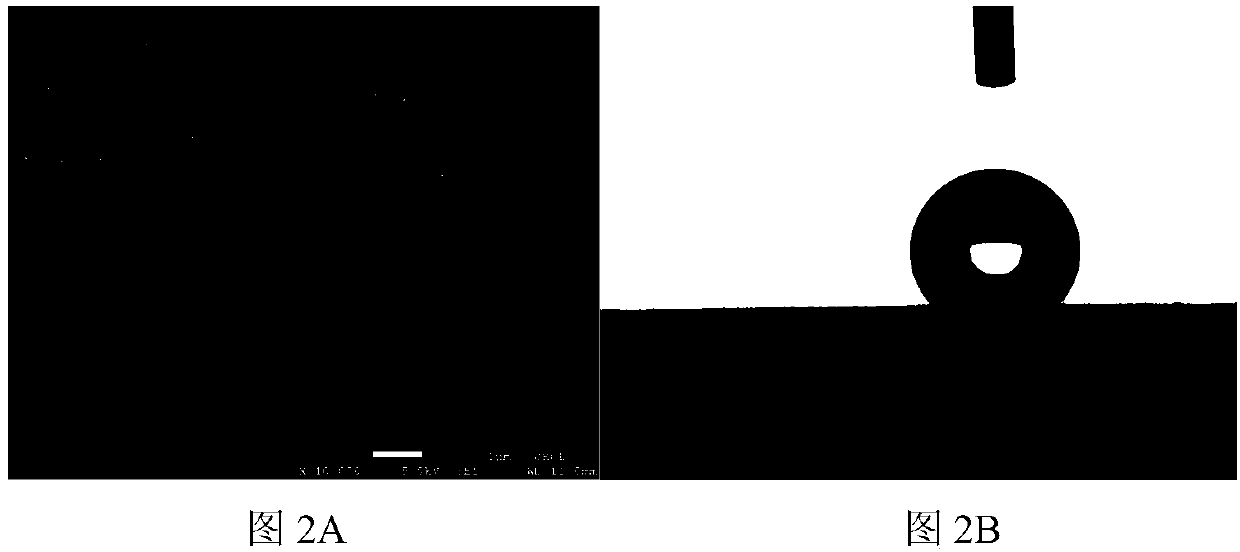

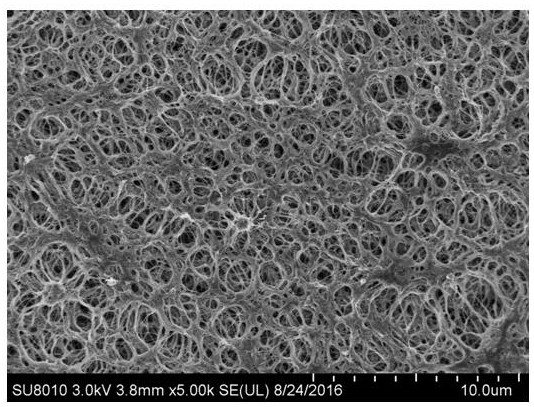

Microporous PTFE composite carbon nanotube paper and preparation method thereof

ActiveCN108677597AImprove conductivityStrong self-cleaningPaper/cardboardFlat articlesPapermakingCarbon nanotube

The invention discloses microporous PTFE composite carbon nanotube paper and a preparation method of the microporous PTFE composite carbon nanotube paper, and belongs to the technical field of papermaking. The microporous PTFE composite carbon nanotube paper is formed by uniformly compounding PTFE and carbon nanotubes, is of a network cross-overlapping structure and has uniform micropores, PTFE isuniformly distributed on pore walls, the micropores are superhydrophobic pores, the maximum air permeability is close to 90 microns / (Pa.S), the maximum elongation at break is up to 400%, the resistivity is not greater than 470 momega.cm, the thickness is not smaller than 32 microns, and the contact angle is greater than 120 degrees. The microporous PTFE composite carbon nanotube paper is preparedby the steps of preparing a base material and a wetting lubricant and performing orientation pretreatment, stretching pore forming and heat treatment. The preparation method disclosed by the invention is simple and easy to realize, and the microporous PTFE composite carbon nanotube paper prepared by the invention well inherits properties of excellent conductivity, self-cleaning ability, interlayer bonding force and the like in the PTFE composite carbon nanotube paper. Furthermore, the microporous PTFE composite carbon nanotube paper is further greatly improved in air permeability and softer.

Owner:KUNMING NATAI TECH CO LTD

Prepreg fiber cloth and preparation method thereof

The present invention relates to the field of prepreg fiber cloths, and discloses a prepreg fiber cloth and a preparation method thereof. According to the present invention, at least partial surface of the prepreg fiber cloth is wrapped with a resin adhesion layer, and the prepreg fiber cloth is characterized in that magnetic chopped fibers are arranged between the resin adhesion layer and the fiber cloth and the included angle between the magnetic chopped fibers and the fiber cloth is more than 0 DEG; and the prepreg fiber cloth has excellent interlayer bonding force when the prepreg fiber cloth is subjected to hot pressing into the composite plate.

Owner:BYD CO LTD

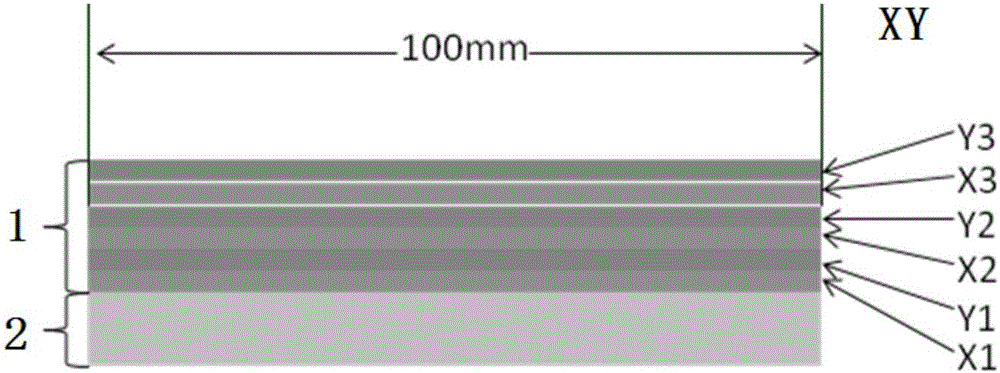

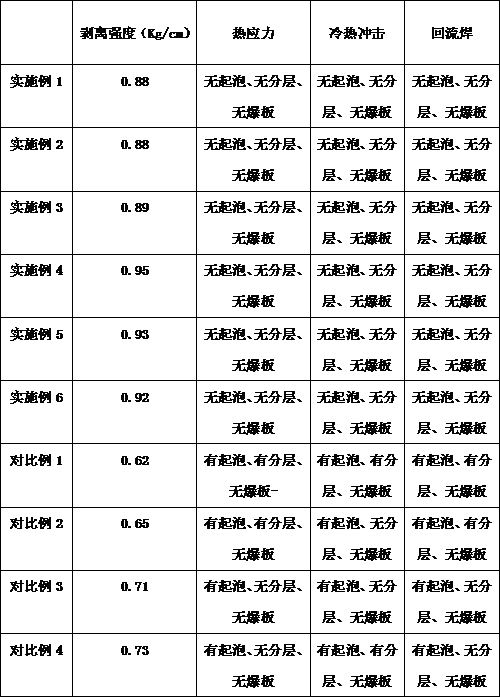

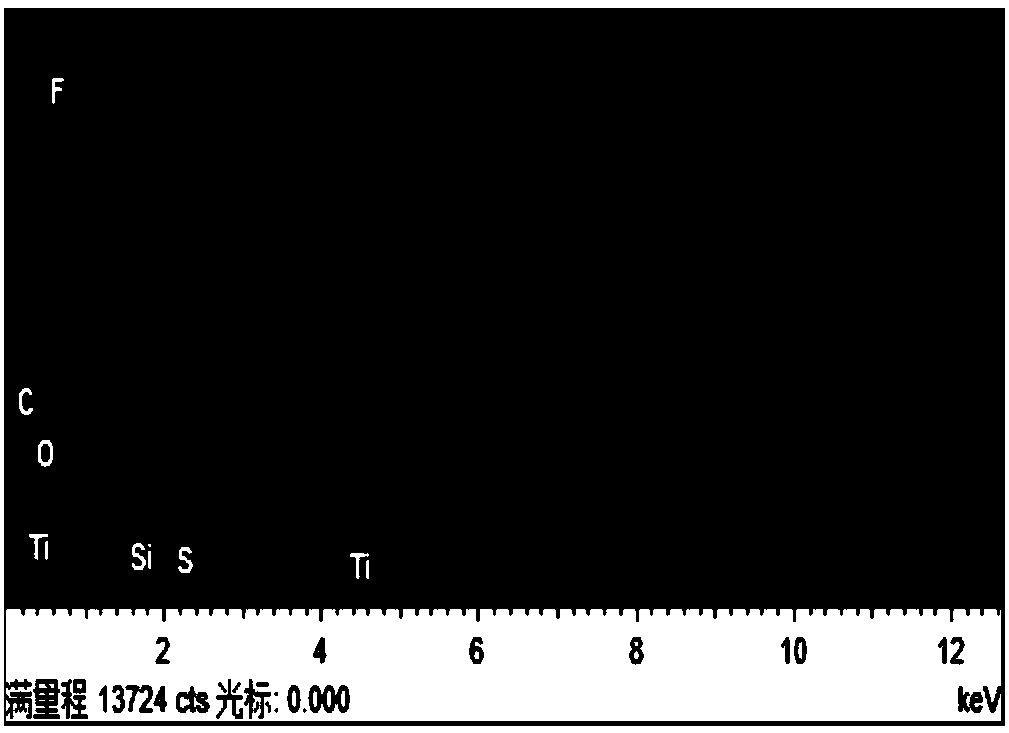

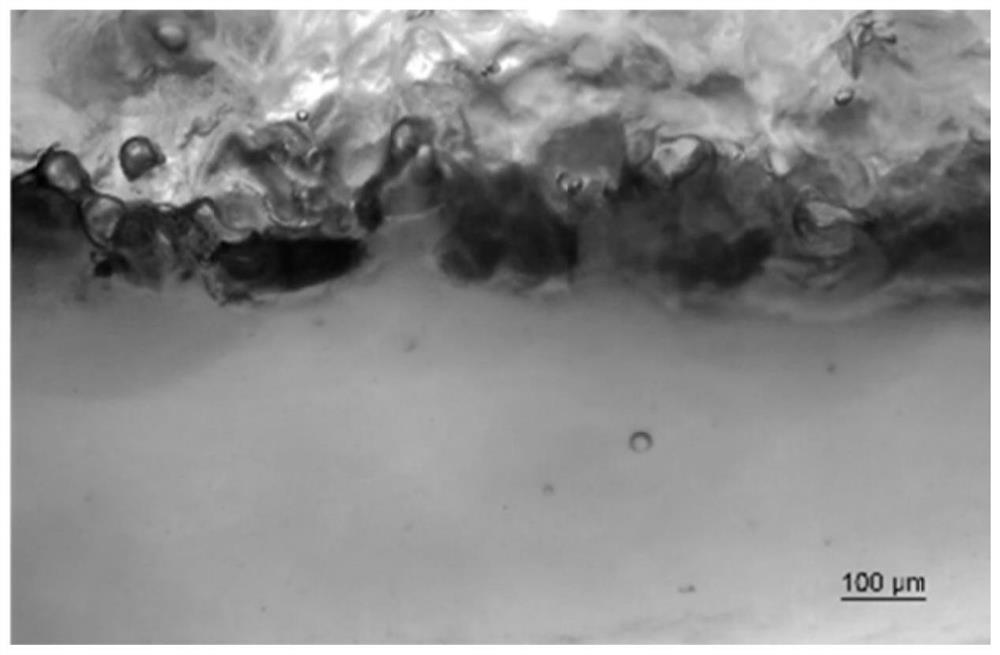

Browning method for improving interlayer bonding force of printed circuit board

ActiveCN111867275AImprove wettabilityGood dispersionInsulating substrate metal adhesion improvementPrinted circuit secondary treatmentTest sampleEngineering

The invention discloses a browning method for improving the interlayer bonding force of a printed circuit board and belongs to the technical field of circuit boards. The browning method comprises thefollowing steps S1, of cleaning, putting a copper foil in a cleaning solution I for soaking for 3-5 min, adding a cleaning solution II, continuing soaking for 3-5 min, then sequentially putting the copper foil in hydrogen peroxide and ethanol for soaking for 2-3 min, and then drying the copper foil with nitrogen; S2, presoaking, putting the cleaned copper foil into a presoaking solution, and carrying out ultrasonic oscillation for 3-5 minutes; S3, browning, namely browning the presoaked copper foil in a browning tank in which browning liquid is stored; and S4, washing, putting the browned copper foil into deionized water, washing with the water, and drying with nitrogen. The method is advantaged in that after browning, a sample plate shows good anti-stripping performance, and the strippingstrength is as high as 0.95 Kg / cm; thermal performance test is carried out, respectively six times of tin immersion are carried out, 100 times of cold and hot impact circulation and six times of reflow soldering test on the laminated sample are carried out, that the test sample has no bubbling, layering or plate explosion phenomenon is observed, and the interlayer bonding force is strong.

Owner:国网河南省电力公司西峡县供电公司

Surface enhanced treatment process for metal bearing of numerically-controlled machine tool

InactiveCN108251786AImprove bindingLow wear and tear rateMolten spray coatingSolid state diffusion coatingPlasma beamMachine tool

The invention relates to a surface enhanced treatment process for a metal bearing of a numerically-controlled machine tool. The process comprises the following steps: surface cleaning and activating:putting the metal bearing in a phosphoric acid buffer solution to be soaked for 20-30 min, then adding a cleaning activator thereinto, and carrying out ultrasonic treatment for 5-10 min; nitrocarburizing: putting the metal bearing in a nitrifying furnace, introducing nitrogen, and treating the metal bearing for 2.2-2.4 h at 565+ / -2 DEG C; and compound metal paint spraying: coating compound metal powder to the outer layer of the metal bearing by means of plasma beam fusion covering. By means of multi-time enhanced treatment on the surface layer of the metal bearing, the process has an excellentmechanical property, and the toughness and the wear resistance are enhanced remarkably. By selecting a proper raw material proportion, the bonding forces between the coatings and a matrix and betweenthe coatings are great, the wear delamination rate is low, and the service life is prolonged by more than two folds.

Owner:MAANSHAN XINQIAO IND DESIGN CO LTD

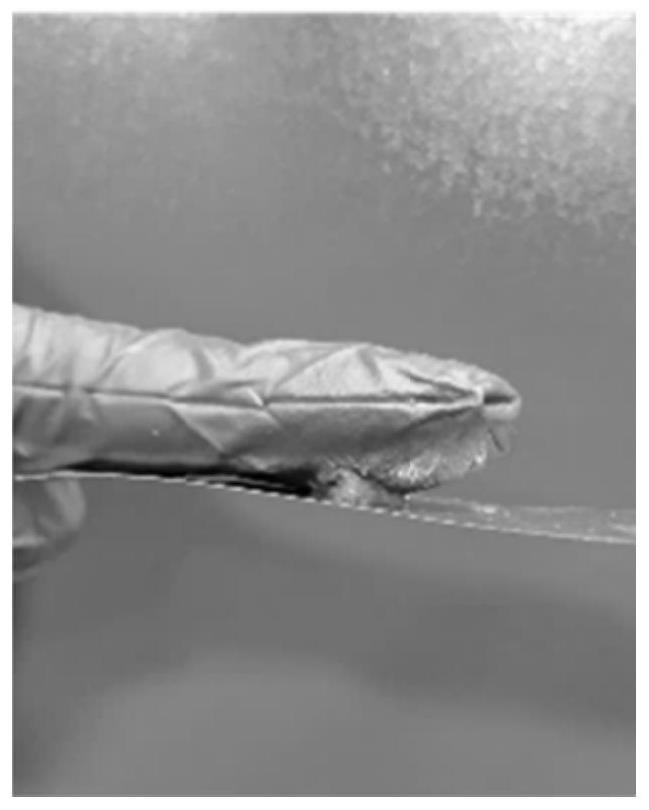

Steel-titanium composite plate and preparation method thereof

ActiveCN109226262AReduce manufacturing costImprove surface qualityTemperature control deviceMetal rolling arrangementsTitaniumComposite plate

The invention relates to the technical field of steel-titanium composite plate preparation, in particular to a steel-titanium composite plate, wherein at least one of the upper surface and lower surface of a steel plate base layer is compounded with a titanium plate layer. The invention also provides a preparation method of the steel-titanium composite plate, which comprises the following steps: acarbon steel coil strip and a titanium plate are respectively placed at a temperature of 200-200 DEG C for heating and are respectively placed at a temperature of 500-650 DEG C for heating again; theheated carbon steel coil and titanium plate are placed on a cold rolling differential composite rolling mill for rolling and composite forming, a steel-titanium composite plate blank is placed in a bell furnace again, and a diffusion heat treatment sintering process is used, the sintering temperature is controlled at 700-700 DEG C and the sintering temperature is controlled at 20-48 hours. The method has the advantages of low manufacturing cost, good product surface quality, strong interlayer binding force, high thickness control precision and no environmental pollution.

Owner:OKUMTEC TECH WENZHOU CO LTD

Anti-corrosion process for prefabricated cabin body

InactiveCN111804546AImprove mechanical propertiesStrong adhesionCoatingsSpecial surfacesMechanical engineeringAerospace engineering

The invention discloses an anti-corrosion process for a prefabricated cabin body, and relates to the field of anti-corrosion materials. The anti-corrosion process for the prefabricated cabin body comprises the following steps of cabin body surface treatment, primer preparation, primer coating, intermediate paint coating, finish paint coating, coating quality inspection and acceptance inspection and the like. The defects in the prior art are overcome, through a series of coating construction of the priming paint, the intermediate paint and the finishing paint, each coating gives play to the protective characteristic, the operation steps of the anti-corrosion process are rigorous, the surface of the cabin body is not prone to corrosion, and the service life of the cabin body is longer.

Owner:吉林德蕴电气集团股份有限公司

Stain-resistant high-temperature liquid asphalt coating and preparation method thereof

ActiveCN107739572AImprove antioxidant capacityMeet the use requirementsAntifouling/underwater paintsPaints with biocidesCoated surfaceRoom temperature

The invention discloses a stain-resistant high-temperature liquid asphalt coating and a preparation method thereof, belonging to the technical field of stain-resistant coatings. The preparation methodcomprises the following steps: firstly, mixing a solvent, polyphenylene sulfide, a structural blending agent and an additive in proportion to prepare slurry; mixing the slurry with a hydrophobic modifier to prepare a coating; and coating the surface of a pre-treated substrate with the coating, and heating and preserving the temperature for a period of time and cooling to room temperature to obtain the stain-resistant high-temperature liquid asphalt coating. The stain-resistant high-temperature liquid asphalt coating provided by the invention meets the using demand in a high-temperature liquidasphalt environment; the coating and the substrate material form a good interlaminar bonding force, a hydrophobic surface is formed on the surface of the coating, the stain-resistant performance of the compound coating is improved, and the stain area of the high-temperature liquid asphalt is smaller than 10%.

Owner:BEIHANG UNIV

Aluminum silicon carbide heat-sink base plate and manufacturing method thereof

ActiveCN106987836ASmall coefficient of thermal expansionImprove heat resistanceHeat inorganic powder coatingHeat resistanceThermal expansion

The invention discloses an aluminum silicon carbide heat-sink base plate and a manufacturing method thereof. The manufacturing method comprises the following steps of: preparing slurry by low-temperature glass powder and mixed printing ink; sintering the slurry on an aluminum silicon carbide substrate; and greatly reducing a sintering temperature of an insulating layer to 450-550 DEG C. The manufactured aluminum silicon carbide heat-sink base plate has good interlayer binding force and insulating performance and is low in thermal expansion coefficient; and a thick film insulating layer is good in heat resistance.

Owner:深圳市如器科技有限公司

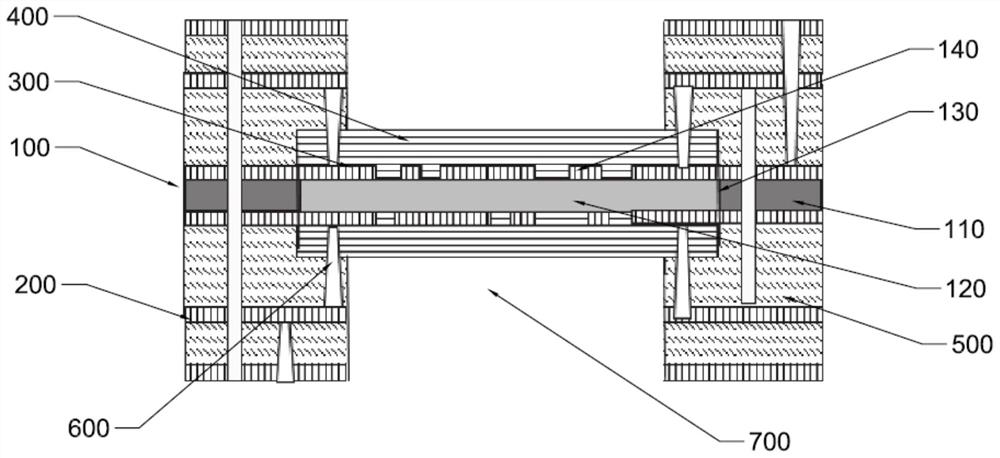

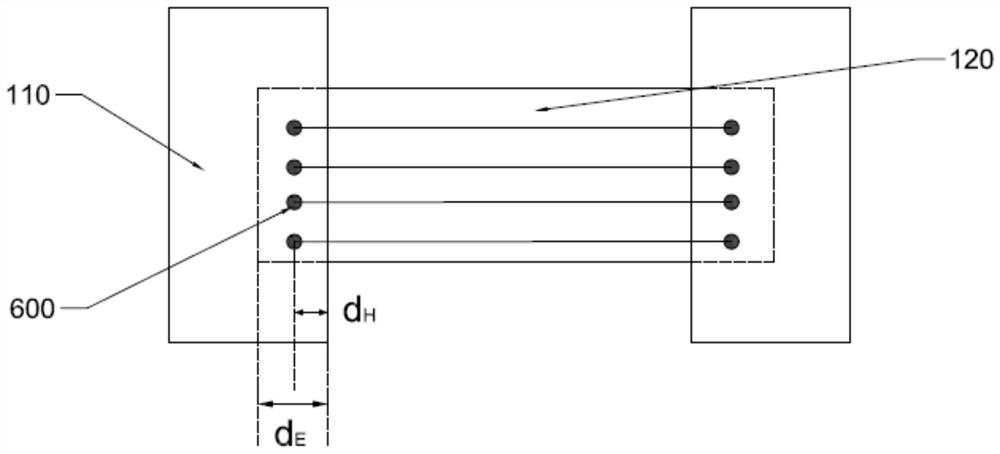

Rigid-flex printed circuit board and manufacturing method thereof

InactiveCN112020217ALow costSmall ups and downsPrinted circuits structural associationsMultilayer circuit manufactureHemt circuitsStructural engineering

The invention discloses a rigid-flex printed circuit board. The flexible printed circuit board comprises a rigid-flexible combined substrate located in the middle and a plurality of metal layers on the upper side and the lower side. The rigid-flexible combined substrate comprises a rigid substrate and a flexible substrate. The flexible substrate is embedded in a small unit window formed in the rigid substrate; a circuit pattern is formed on the surface of the rigid-flexible combined substrate; cover films are adhered to the upper and lower sides of the flexible substrate; a protective film isattached to the outer side of the covering film; wherein the metal layers are pressed on the outer side of the rigid-flexible combined substrate, the metal layers are combined through prepregs, the metal layers and the rigid-flexible combined substrate are combined through prepregs, electrical connection holes are formed between the metal layers, between the metal layers and the rigid substrate and between the metal layers and the flexible substrate, and windows are formed in the upper side and the lower side of the flexible substrate and enable a covering film of the flexible substrate to beexposed. The invention further provides a manufacturing method of the rigid-flex printed circuit board. According to the invention, the processing difficulty is low, the interlayer bonding force is strong, the flexible substrate is embedded into the rigid substrate, the connectivity is good, and the cost of the flexible substrate is saved.

Owner:SHENZHEN HUALIN CIRCUIT TECH

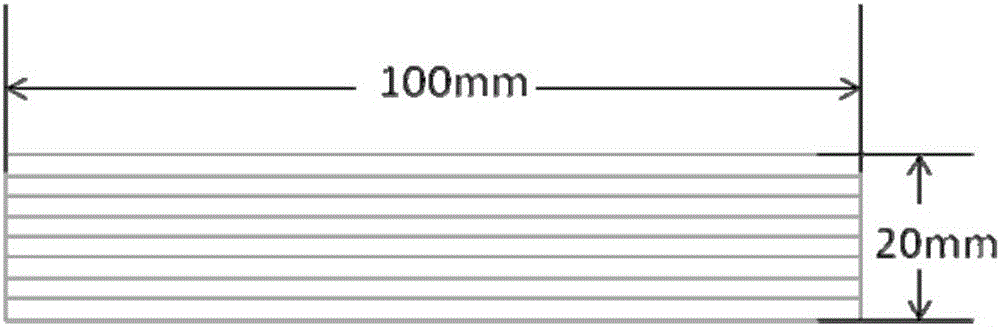

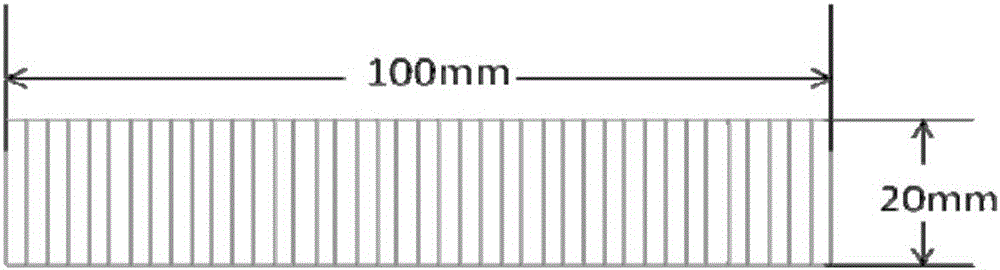

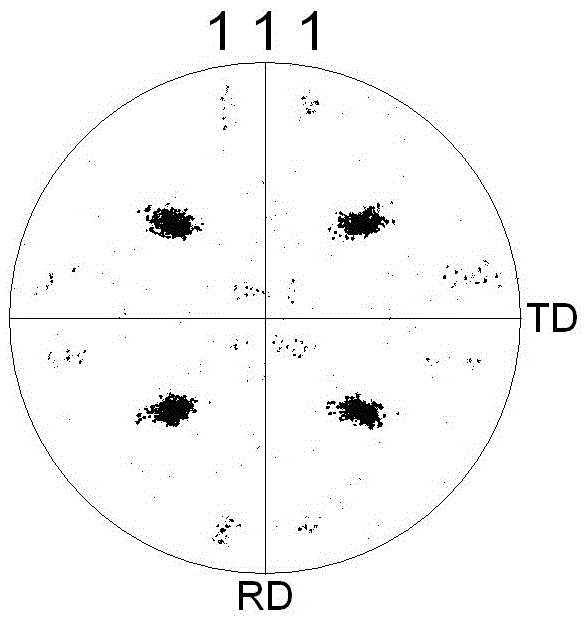

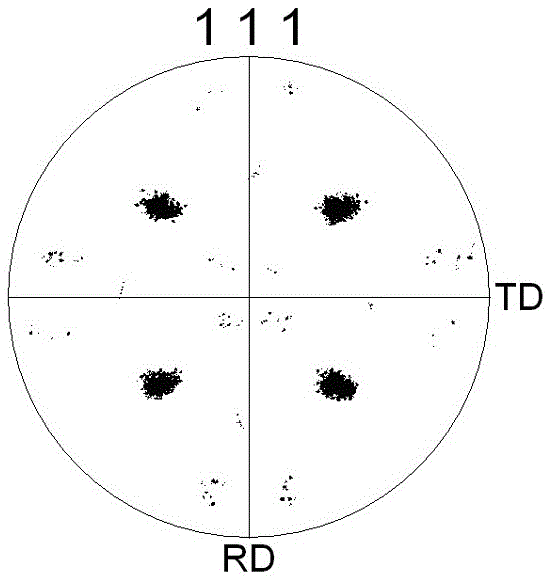

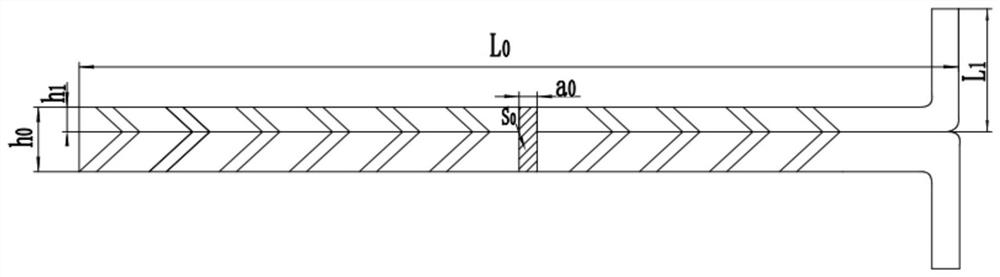

Preparation method of high-performance textured copper-nickel alloy composite base band for coated conductor

The invention discloses a preparation method of a high-performance textured copper-nickel alloy composite base band for a coated conductor. The initial material of a surface layer is copper-nickel mixed powder (with code name of A) with the weight percentage content of nickel of 60%, and the initial material of a core layer is nickel-tungsten mixed powder (with code number of B) with the weight percentage content of tungsten of 9-10%. A preparation process comprises the following steps: filling the mixed powder A and B to a die layer by layer according to a sequence of A-B-A, carrying out cold isostatic pressing to prepare a three-layer initial composite blank with an outer layer being A and a core layer being B, firstly carrying out cold isostatic pressing on the initial composite blank, then carrying out compacting sintering by adopting cold isostatic pressing to obtain a layered copper-nickel alloy composite billet, and then carrying out large-deformation cold rolling on the layered copper-nickel alloy composite billet, wherein the pass deformation of the first five passes is 20-25%, the deformation of each subsequence pass is 3-10%, and the total deformation is 90%, and finally carrying out recrystallizing heat treatment with heat preservation of 50-90min at 900 DEG C, so as to obtain the non-magnetic copper-nickel alloy composite base band with high strength and strong cubic structure.

Owner:HENAN NORMAL UNIV

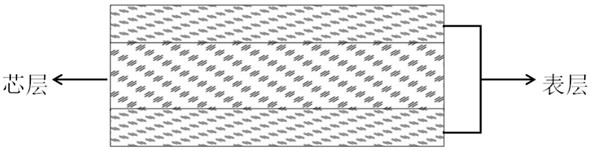

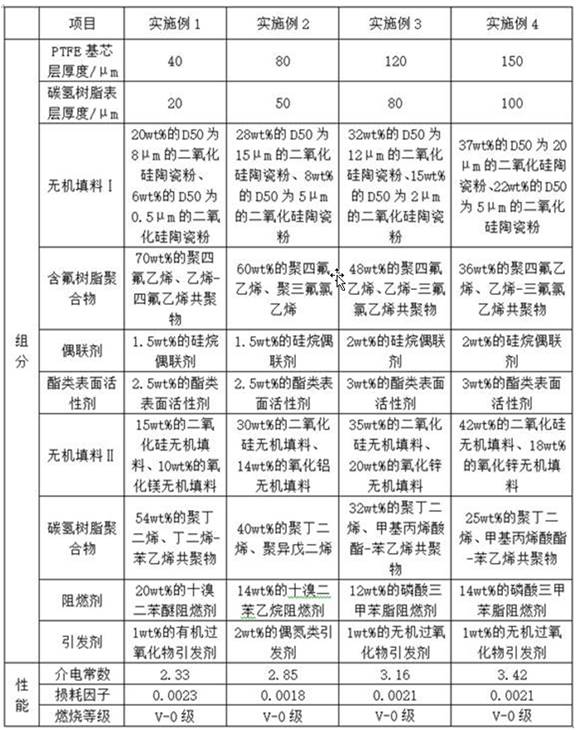

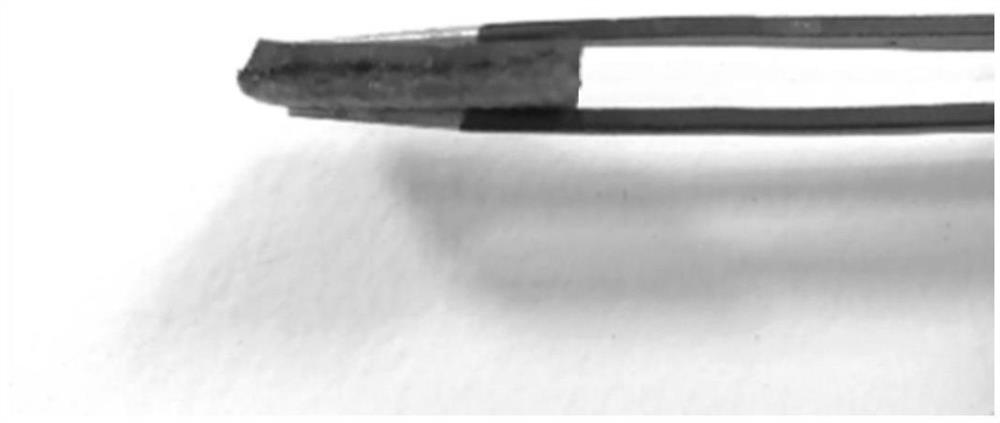

Flame-retardant low-dielectric-constant bonding sheet and preparation method thereof

ActiveCN113861863AConvenient sourceSimple preparation processNon-macromolecular adhesive additivesFilm/foil adhesivesRaw materialLow-k dielectric

The invention discloses a flame-retardant low-dielectric-constant bonding sheet and a preparation method thereof. The bonding sheet comprises a PTFE-based core layer in the middle and hydrocarbon resin surface layers on the upper surface and the lower surface; the PTFE-based core layer is reinforced by adopting two kinds of ceramic powder with different particle sizes, and the core layer film is obtained through an extrusion stretching forming process, so that the density and the elongation at break of the core layer can be obviously improved, and support is provided for the upper surface layer and the lower surface layer; the film is formed on the surface layer by adopting a multi-time blade coating process, so that defects are reduced, density is improved, and flame retardance is improved. The bonding sheet abandons the traditional glass fiber cloth reinforcing material, has the advantages of isotropy, high density, flame retardance, adjustable dielectric constant, lower loss, good bonding strength and mechanical property, can meet the interlayer bonding of a multi-layer circuit board, and is stable and reliable in signal transmission. The bonding sheet is wide in raw material source, simple in operation process, environment-friendly, easy for large-scale batch production, wide in application field and good in market prospect.

Owner:CHINA ELECTRONICS TECH GRP NO 46 RES INST

Superhard composite coated cutting tool and its preparation method

ActiveCN106119763BAlleviate the problem of weak bindingHighlight substantive featuresMolten spray coatingBoron nitrideCemented carbide

The invention provides a superhard composite coated cutting tool. The structure of the superhard composite coated cutting tool comprises a cemented carbide substrate, a metal transition layer and a cubic boron nitride coating doped with metallic nickel, wherein the metal transition layer and the cubic boron nitride coating are sequentially sprayed to the surface of the cemented carbide substrate. The superhard composite coated cutting tool is reasonable in structural design, excellent in wear resistance, high in interlayer bonding force and long in service life. The invention further provides a preparation method of the superhard composite coated cutting tool. The preparation method comprises steps as follows: metal micro-powder and cubic boron nitride composite micro-powder coated with the metallic nickel on the surface are taken as raw materials, and the metal transition layer and the cubic boron nitride coating doped with the metallic nickel are sequentially sprayed to the surface of the cemented carbide substrate with a supersonic flame spraying method. The preparation method adopts a simple process, equipment can operate automatically, and industrialization is facilitated.

Owner:FUNIK ULTRAHARD MATERIAL

A kind of back film of solar battery panel and production process thereof

ActiveCN103346182BImprove bindingStrong bonding between layersFinal product manufactureSynthetic resin layered productsPolyesterCross-link

A solar panel back film comprises a PET film matrix with the thickness of 100-350 micrometers. Fluorine-containing polymer coatings of 15-30micrometers cover the two faces of the matrix, and the fluorine-containing polymer coatings are formed by mixing raw material components according to a proportion to obtain mixed emulsion and coating the PET film matrix by the mixed emulsion which is swollen under the temperature between 80 DEG C and 200 DEG C, wherein raw materials of the fluorine-containing polymer coatings comprise, by mass, polyester PET powder, fluorine-containing resin, solvent, a cross-linking agent, padding and ethylene glycol. The polyester PET powder is polyester PET powder with grain size smaller than 25 micrometers, wherein the polyester PET powder is formed by smashing precipitate obtained by dissolving in phenol-carbon tetrachloride mixed solvent. The fluorine-containing resin is fluorine-containing macromolecule resin. The solar panel back film is easy to process, tearing resistant and superior in electrical insulation performance and weather fastness.

Owner:ZHEJIANG VENTURA PHOTOVOLTAIC MATERIALS

TEMPO oxidized nanocellulose-based composite hydrogel and preparation method thereof

The invention provides TEMPO oxidized nano-cellulose-based composite hydrogel and a preparation method thereof. The method comprises the following steps: 1, dissolving chitosan, polyvinyl alcohol and TEMPO oxidized nano-cellulose in an acetic acid solution, wherein the mass ratio of chitosan to polyvinyl alcohol to TEMPO oxidized nano-cellulose is (0.03-0.35): (0.14-0.8): (0.01-0.405); performing stirring to obtain a mixed system, freezing the mixed system, and obtaining a gel-like mixture; 2, pouring a polyvinyl alcohol solution on the surface of the gelatinous mixture, freezing the obtained mixture at the temperature of 30 DEG C below zero to 10 DEG C below zero, and then performing unfreezing to obtain the TEMPO oxidized nanocellulose-based composite hydrogel, so that the mechanical property and functionality of the hydrogel are improved by utilizing a double-crosslinking network and a double-layer asymmetric structure.

Owner:SHAANXI UNIV OF SCI & TECH

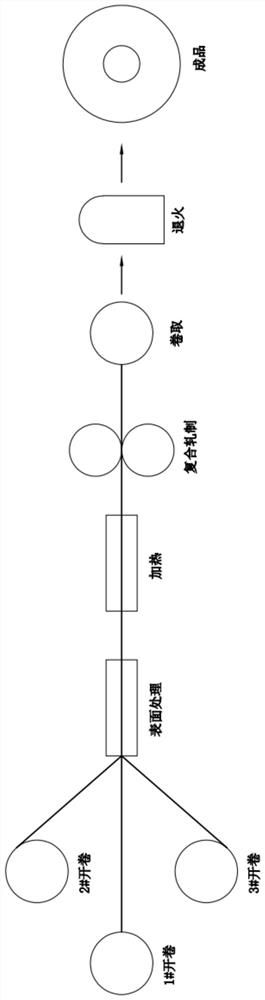

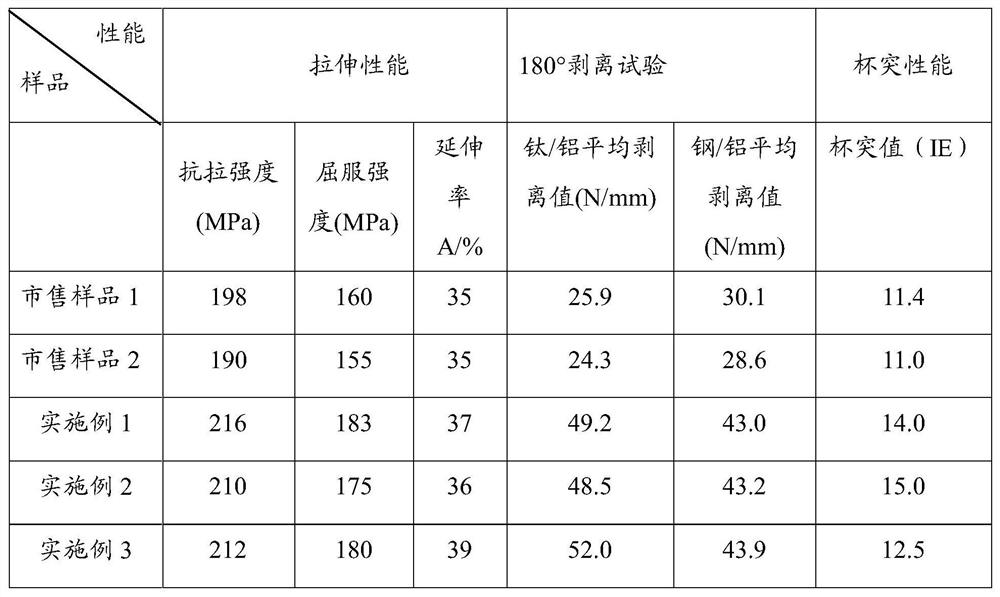

Layered titanium-aluminum steel composite strip coil material and preparation method thereof

ActiveCN112090961ACorrosion resistanceTitanium Corrosion ResistanceFurnace typesAuxillary arrangementsSS - Stainless steelTitanium

The invention discloses a layered titanium-aluminum-steel composite strip coil material and a preparation method thereof. According to the layered titanium-aluminum-steel composite strip coil material, an aluminum strip coil serves as a base material, a pure titanium strip coil is compounded on the upper surface of the aluminum strip coil, and a stainless steel strip coil is compounded on the lower surface of the aluminum strip coil; and the thickness ratio of the aluminum strip coil to the pure titanium strip coil to the stainless steel strip coil is 8: (1.5-3): (2-3). The production processflow comprises the steps of uncoiling, carrying out surface treatment, heating, rolling, coiling, annealing and obtaining a finished product coiled material, and the production processes in the process flow are continuous production line type production except annealing. The composite coiled material prepared by the method has the characteristics of being corrosion-resistant, wear-resistant, freeof toxicity, bacteria-resistant, and good in magnetic conductivity and thermal conductivity; and the interlayer binding force of the composite strip coil material is greatly improved.

Owner:新疆湘润新材料科技有限公司

Modified epoxy coating and preparation method and application thereof

PendingCN111704844ALong application periodImprove compactnessAnti-corrosive paintsEpoxy resin coatingsZinc phosphatePolymer science

The invention discloses a modified epoxy coating as well as a preparation method and application thereof, wherein the modified epoxy coating is prepared from a modified base material, an antirust pigment, a diluent and an auxiliary agent, wherein the modified base material is prepared from 15-35 parts of modified epoxy resin and 5-20 parts of a modified amine curing agent; the antirust pigment isone or more of micaceous iron ash, zinc phosphate, aluminum triphosphate and ferrophosphorus powder, and the quantity of the antirust pigment is 15-40 parts; the use amount of the diluent is 3-10 parts; the auxiliary agent is one or more of a dispersing agent, an anti-settling agent and a defoaming agent, and the use amount of the auxiliary agent is 3-15 parts. The modified epoxy paint is single-component intermediate paint, is convenient to use, can be used for carrying out anticorrosive treatment on special-shaped workpieces in a dip-coating mode, can also be used in a spraying mode, can coexist all the components at the same time at the normal temperature, and is long in quality guarantee period, and the corrosion resistance of a steel structure is improved through matched use of the intermediate paint and priming paint.

Owner:河北省同创交通工程配套产品产业技术研究院 +1

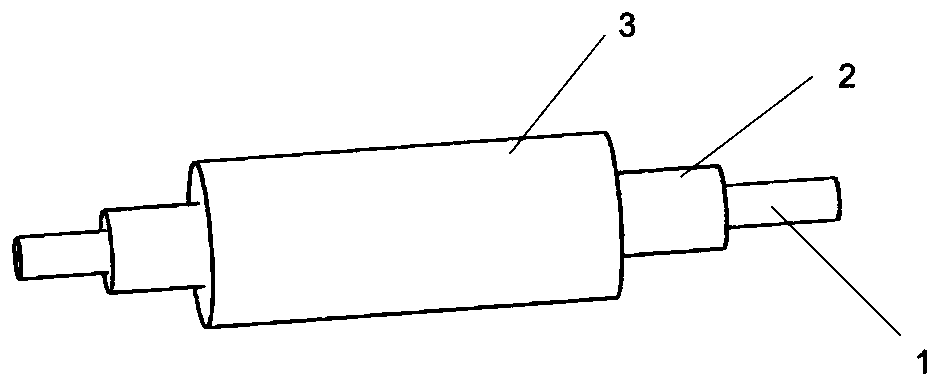

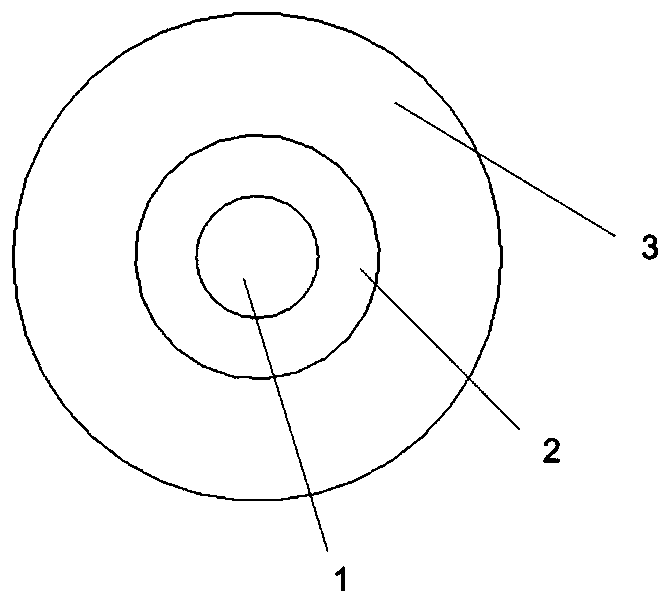

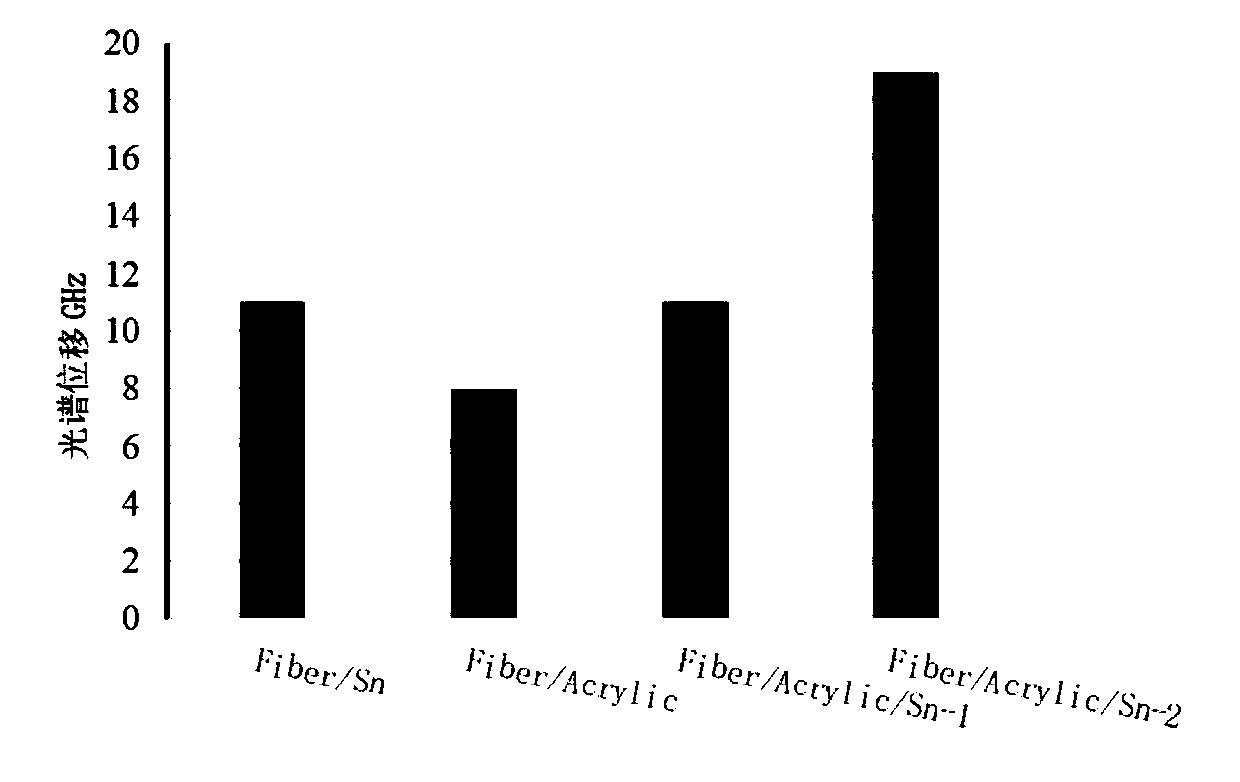

Composite coating low-temperature temperature measurement optical fiber and preparation method thereof

InactiveCN111413762AIncreased temperature sensitivityAvoid pyrolysisCladded optical fibreThermometers using physical/chemical changesAcrylic resinBare fiber

The invention relates to a composite coating low-temperature temperature measurement optical fiber and a preparation method thereof. The optical fiber comprises a bare optical fiber, a polymer coatingand a metal coating. The preparation method of the composite coating temperature measurement optical fiber comprises the following steps: 1, coating acrylic resin on the surface of a bare optical fiber by adopting a dip-coating-ultraviolet curing process, and forming a polymer coating on the surface of the bare optical fiber through multiple times of coating; 2, adopting a cold spraying machine,and spraying metal powder to the surface of the polymer coating after being preheated, wherein the spraying gas and the powder feeding gas are both N2; 3, performing rapid heat treatment on the optical fiber sprayed with the metal coating through a high-temperature furnace, and forming a compact metal coating on the surface of the polymer coating; 4, standing the composite coating temperature measurement optical fiber obtained in the step 3 for 24 hours to obtain a finished product. According to the invention, the temperature sensitivity of the temperature measurement optical fiber at low temperature is improved, and the problem that the polymer is easily decomposed at high temperature due to direct contact between molten metal and the polymer in the traditional melt coating process is effectively avoided.

Owner:BEIJING JIAOTONG UNIV +1

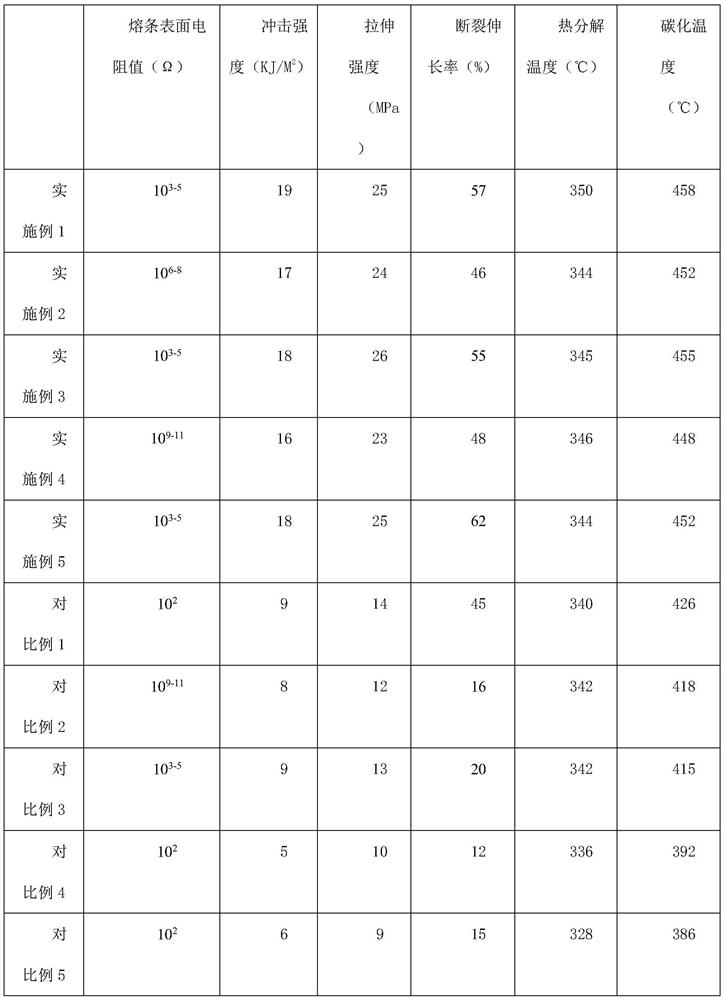

Decomposition resistant ps conductive masterbatch

ActiveCN112111122BExcellent high temperature resistance and physical and mechanical propertiesBroaden the field of applicationAntistatic MaterialsPolycarbonate

The invention discloses a decomposition-resistant PS conductive masterbatch. The decomposition-resistant PS conductive masterbatch includes the following raw materials by weight percentage: 5-10% of superconducting carbon black, 30-60% of high-impact polystyrene, toughened 18 to 30% of antioxidants, 3 to 9% of reinforcing agents, 0.2 to 0.8% of coupling agents, 0.2 to 1.2% of antioxidants, 0.2 to 1.2% of EBS, and 3 to 8% of EMA. In the present invention, superconducting carbon black is used as the conductive carrier, high impact polystyrene PS is used as the base material, and compound toughening agent, reinforcing agent, coupling agent, antioxidant, EBS and EMA are respectively used as lubricants. , dispersant and compatibilizer are compounded according to the appropriate ratio, and the obtained decomposition-resistant PS conductive masterbatch has excellent high temperature resistance and physical and mechanical properties; the decomposition-resistant PS conductive masterbatch can not only be used in polycarbonate and other needs The antistatic materials produced by high temperature co-extrusion can also be used in corresponding conductive and antistatic packaging materials such as electronics, electrical appliances, communications, aerospace, etc., to achieve safe and effective ESD protection for packaged electronic products.

Owner:浙江三和塑料有限公司

A kind of microporous PTFE composite carbon nanotube paper and preparation method thereof

ActiveCN108677597BImprove conductivityStrong self-cleaningPaper/cardboardFlat articlesPolymer scienceCarbon nanotube

The invention discloses microporous PTFE composite carbon nanotube paper and a preparation method of the microporous PTFE composite carbon nanotube paper, and belongs to the technical field of papermaking. The microporous PTFE composite carbon nanotube paper is formed by uniformly compounding PTFE and carbon nanotubes, is of a network cross-overlapping structure and has uniform micropores, PTFE isuniformly distributed on pore walls, the micropores are superhydrophobic pores, the maximum air permeability is close to 90 microns / (Pa.S), the maximum elongation at break is up to 400%, the resistivity is not greater than 470 momega.cm, the thickness is not smaller than 32 microns, and the contact angle is greater than 120 degrees. The microporous PTFE composite carbon nanotube paper is preparedby the steps of preparing a base material and a wetting lubricant and performing orientation pretreatment, stretching pore forming and heat treatment. The preparation method disclosed by the invention is simple and easy to realize, and the microporous PTFE composite carbon nanotube paper prepared by the invention well inherits properties of excellent conductivity, self-cleaning ability, interlayer bonding force and the like in the PTFE composite carbon nanotube paper. Furthermore, the microporous PTFE composite carbon nanotube paper is further greatly improved in air permeability and softer.

Owner:KUNMING NATAI TECH CO LTD

Gradient compound material and preparation method

InactiveCN101077644BReduce manufacturing costLarge compositional variabilityCeramic layered productsMetal layered productsAlloyTransition layer

The gradient composite material consists of a base, transition layers and a working layer combined through metallurgical combination, and has composition and performance in controlled gradient changefrom the base to the working layer. The transition layers include several layers, and the working layer may be one or several layers. Each of the transition layers has thickness of 0.1-50 mm, preferably 0.5-5 mm, and the working layer has thickness of 0.1-1000 mm, preferably 2-30 mm. When the working layer is of ceramic or high alloy, the transition layer adjacent to the working layer has high content of ceramic or alloy. The composite material has reasonable comprehensive performance and the working layer has excellent performance.

Owner:NANJING SHENGRUN TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com