Composite coating low-temperature temperature measurement optical fiber and preparation method thereof

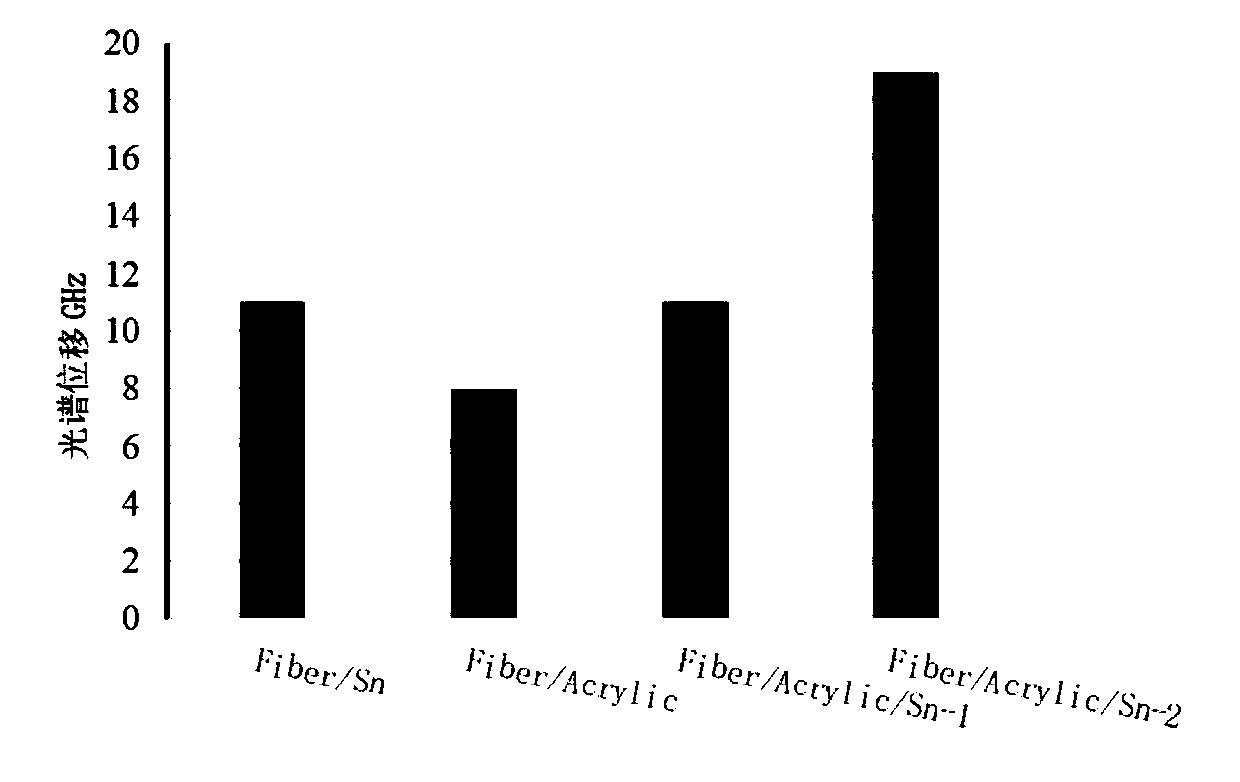

A technology of temperature measuring fiber and composite coating, applied in cladding fiber, coating, metal material coating process, etc., can solve the problems of low sensitivity of temperature measuring fiber, decrease of interlayer interface bonding force, etc., and achieve spectral shift Significant, improved temperature sensitivity, excellent interlayer bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

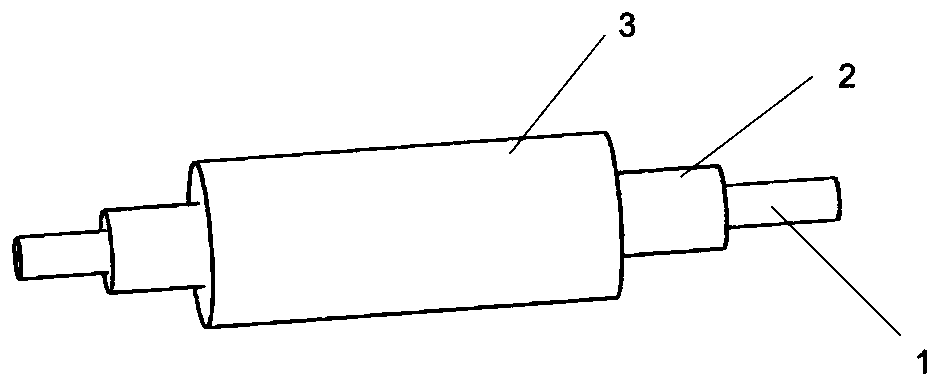

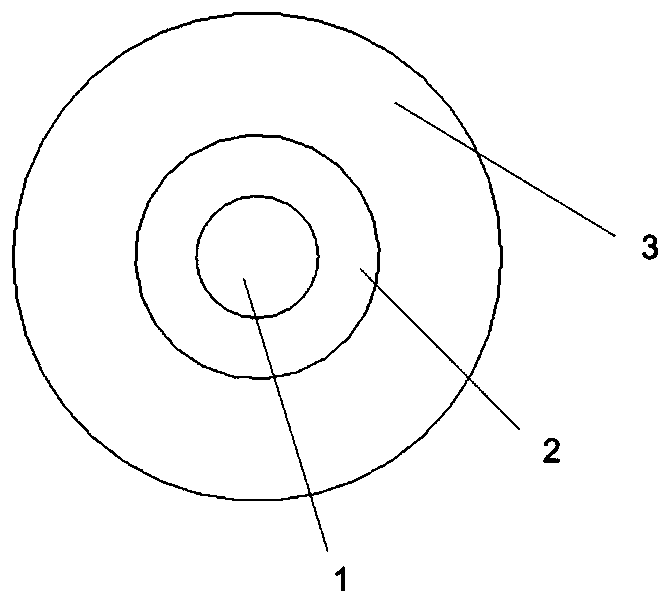

[0039] The preparation method of the above-mentioned composite coating temperature measuring optical fiber comprises the following steps:

[0040] 1. The acrylic resin is coated on the surface of the bare optical fiber by dip coating-ultraviolet curing process, and after multiple coatings, a polymer coating with a layer thickness of 10 μm to 200 μm is formed on the surface of the bare optical fiber;

[0041]2. Using a cold spraying machine, metal powder (Sn (99.9% weight purity), PbSnAg (62% Sn, 36% Pb and 2% Ag), InBi (66.3% In and 33.7% Ag) with an average particle size of 100nm to 50μm %Bi), SnAg (98.5% Sn and 1.5% Ag) or InSn (69.5% In and 30.5% Sn)), the specific ratio of each metal fluctuates within 2%; after preheating at 60-200 ° C, spray on the polymerization coating surface, spraying gas and powder feeding gas are N 2 , the gas pressure is 0.5~3MPa, and the spraying distance is 10~30cm;

[0042] 3. The optical fiber sprayed with the metal coating is quickly heat-tr...

Embodiment 1

[0045] (1) The acrylic resin is subjected to a dip coating-ultraviolet curing process, and after multiple coatings, a polymer coating with a thickness of about 60 μm is formed on the surface of the bare optical fiber.

[0046] (2) Using a low-pressure cold spraying machine, spray metal tin (Sn) powder with an average particle size of 5 μm on the surface of the polymer coating at 200 ° C, and the spraying gas and powder feeding gas are both N 2 , the gas pressure is 1MPa, the spraying distance is 20cm, and finally a 60μm metal tin coating is formed on the surface of the polymer.

[0047] (3) The optical fiber sprayed with the metal coating is quickly heat-treated in a high-temperature furnace at 235° C. for 50 seconds to form a dense metal coating.

[0048] (4) Place the prepared composite coated temperature-measuring optical fiber at 50° C. for 24 hours before use.

Embodiment 2

[0050] (1) The acrylic resin is dipped and coated-ultraviolet curing process, and after multiple coatings, a polymer coating with a thickness of about 200 μm is formed on the surface of the bare optical fiber.

[0051] (2) Using a low-pressure cold spraying machine, spray metal indium bismuth (InBi) alloy powder with an average particle size of 50 μm on the surface of the polymer coating (2) at 60 ° C, and the spraying gas and powder feeding gas are both N 2 , a gas pressure of 3 MPa, a spraying distance of 30 cm, and finally a 120 μm metal indium bismuth coating is formed on the surface of the polymer.

[0052] (3) The optical fiber sprayed with the metal coating is rapidly heat-treated in a high-temperature furnace at 80° C. for 50 seconds to form a dense metal coating.

[0053] (4) Place the prepared composite coated optical fiber at 50° C. for 24 hours for use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com