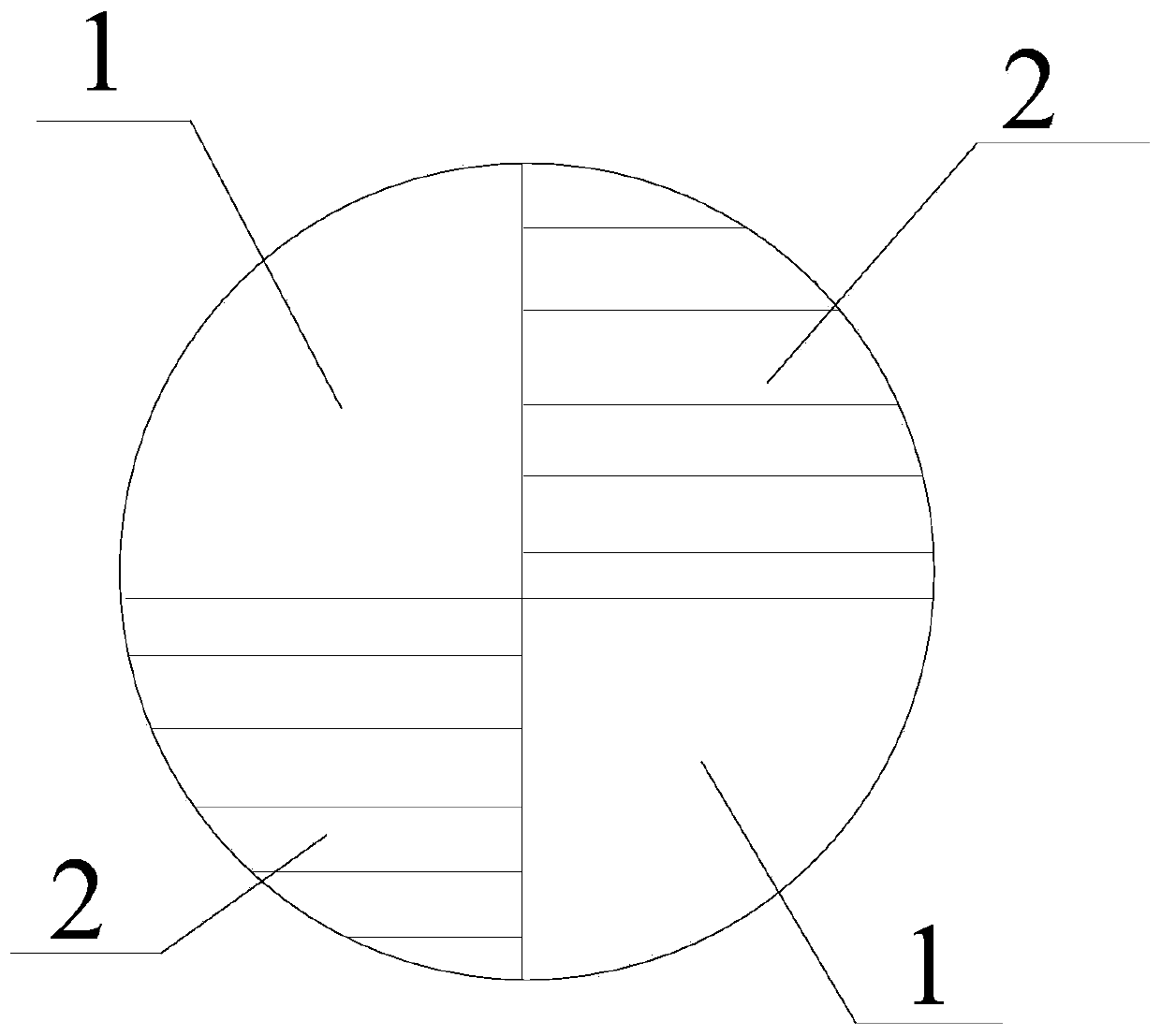

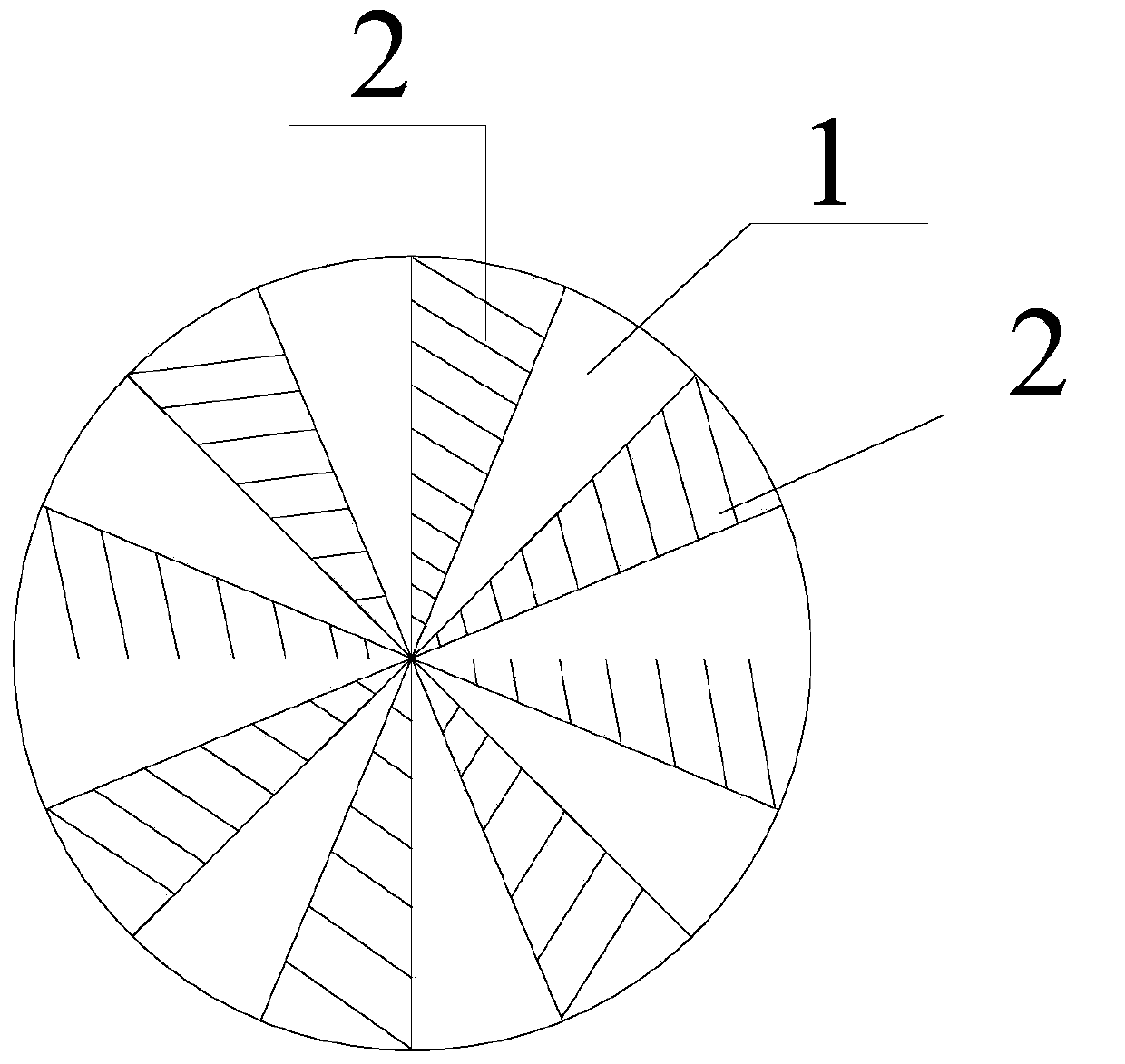

Piece-shaped temperature-regulating energy-storage phase-change fiber and preparation method thereof

An energy storage phase change, orange-lobed technology, applied in fiber processing, fiber chemical characteristics, rayon manufacturing, etc., can solve the problems of slow heat transfer, slow temperature regulation, and sensitivity needs to be further improved. Low, increase the speed, improve the effect of temperature regulation and insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] 1) Preparation of thermally conductive masterbatch: use a large twin-screw extruder to mix thermally conductive powder alumina and polyester-polyethylene terephthalate (PET) at a mass ratio of 10:90 to prepare thermally conductive Masterbatch; the temperature values of the large twin-screw extruder from left to right are 200°C, 220°C, 230°C, 240°C, 260°C, 270°C, 280°C, the speed of the main engine is 150r / min, and the feeding The speed is 28g / min;

[0044]2) Preparation of phase change masterbatch: use a beaker to hold 50g of attapulgite, place it in an ultrasonic instrument at 70°C for ultrasonic oscillation, then add 35g of octadecane solution dropwise, stir with a medicine spoon to make it evenly adsorbed, and continue to oscillate 30min, and then place it in a vacuum oven at 70°C for more than 12h to make it fully adsorbed to prepare a composite phase change material, and then combine the composite phase change material with polyester-polyethylene terephthalate (P...

Embodiment 2

[0054] 1) Preparation of thermally conductive masterbatch: use a large twin-screw extruder to prepare thermally conductive powder boron nitride and polyester-polyethylene terephthalate (PET) at a mass ratio of 10:90. Thermally conductive masterbatch; the temperature values of the large twin-screw extruder from left to right are 200°C, 220°C, 230°C, 240°C, 260°C, 270°C, 280°C, and the speed of the main engine is 150r / min. The material speed is 28g / min;

[0055] 2) Preparation of phase change masterbatch: use a beaker to hold 50g of attapulgite, place it in an ultrasonic instrument at 70°C for ultrasonic oscillation, then add 35g of octadecane solution dropwise, stir with a medicine spoon to make it evenly adsorbed, and continue to oscillate 30min, and then place it in a vacuum oven at 70°C for more than 12h to make it fully adsorbed to prepare a composite phase change material, and then combine the composite phase change material with polyester-polyethylene terephthalate (PET...

Embodiment 3

[0062] 1) Preparation of thermally conductive masterbatch: use a large twin-screw extruder to prepare thermally conductive powder silicon carbide and polyester-polyethylene terephthalate (PET) at a mass ratio of 10:90 to obtain thermally conductive Masterbatch; the temperature values of the large twin-screw extruder from left to right are 200°C, 220°C, 230°C, 240°C, 260°C, 270°C, 280°C, the speed of the main engine is 150r / min, and the feeding The speed is 28g / min;

[0063] 2) Preparation of phase change masterbatch: use a beaker to hold 50g of attapulgite, place it in an ultrasonic instrument at 70°C for ultrasonic oscillation, then add 35g of octadecane solution dropwise, stir with a medicine spoon to make it evenly adsorbed, and continue to oscillate 30min, and then place it in a vacuum oven at 70°C for more than 12h to make it fully adsorbed to prepare a composite phase change material, and then combine the composite phase change material with polyester-polyethylene tere...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com