Construction process for plugging and consolidating concrete crack through chemical grouting

A construction technology, concrete technology, applied in bridge reinforcement, foundation structure engineering, foundation structure repair, etc., can solve concrete cracks, reduce concrete strength and function, and be prone to danger, etc., to achieve tight crack sealing without gaps, Not easy to crack again, the effect of no pollution to the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

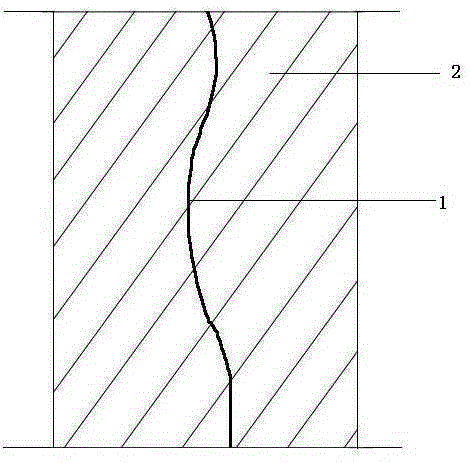

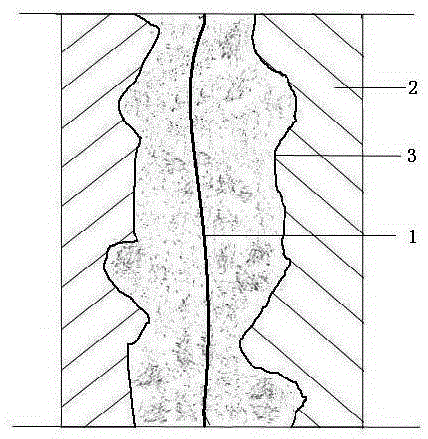

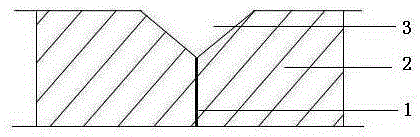

[0021] According to attached Figure 1-6 , the present invention will be further described in detail in combination with specific embodiments.

[0022] The chemical grouting construction technology for sealing and strengthening concrete cracks includes the following steps.

[0023] In the first step, open a V-shaped groove (3) with a width of 20 mm on the upper part and a depth of at least 20 mm along the crack (1) on the concrete (2).

[0024] The second step is to flush the V-groove (3). Use an 80KG high-pressure water gun to wash away sand, floating dust and other sundries in the V-shaped groove (3).

[0025] The third step is to block the V-groove (3). as attached Figure 4 , first use German KOSTERKD2 (4) to evenly coat the V-shaped groove 3, apply German KOSTERNBI (5) evenly between 10 minutes and 20 minutes after applying German KOSTERKD2 (4), and then use German KOSTERKB-Pur (6) to cover the V-shaped groove (3) Carry out plugging and filling. When using German KO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com