Patents

Literature

30results about How to "Realize secondary atomization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

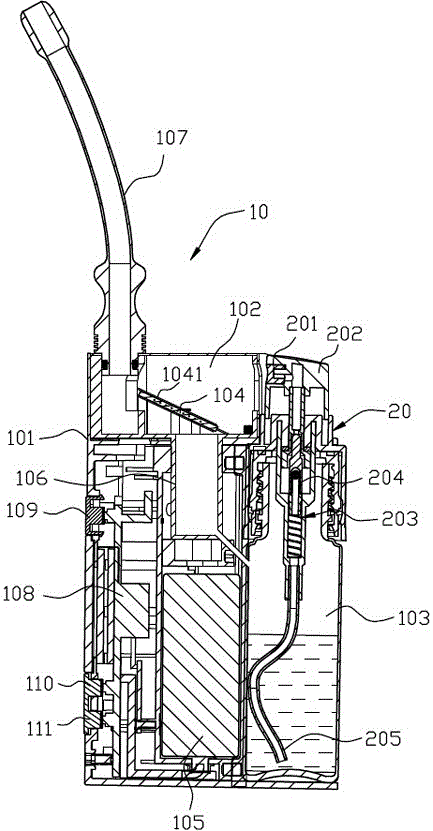

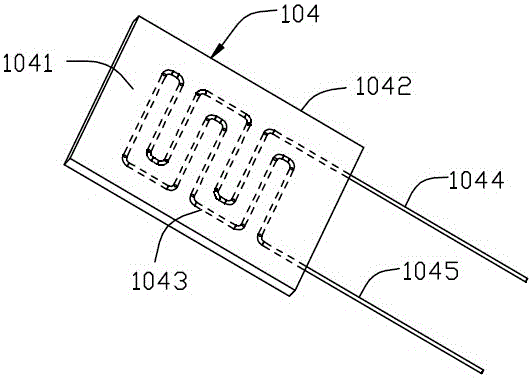

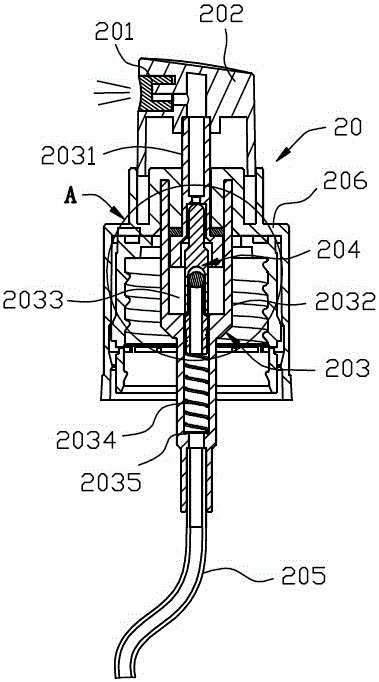

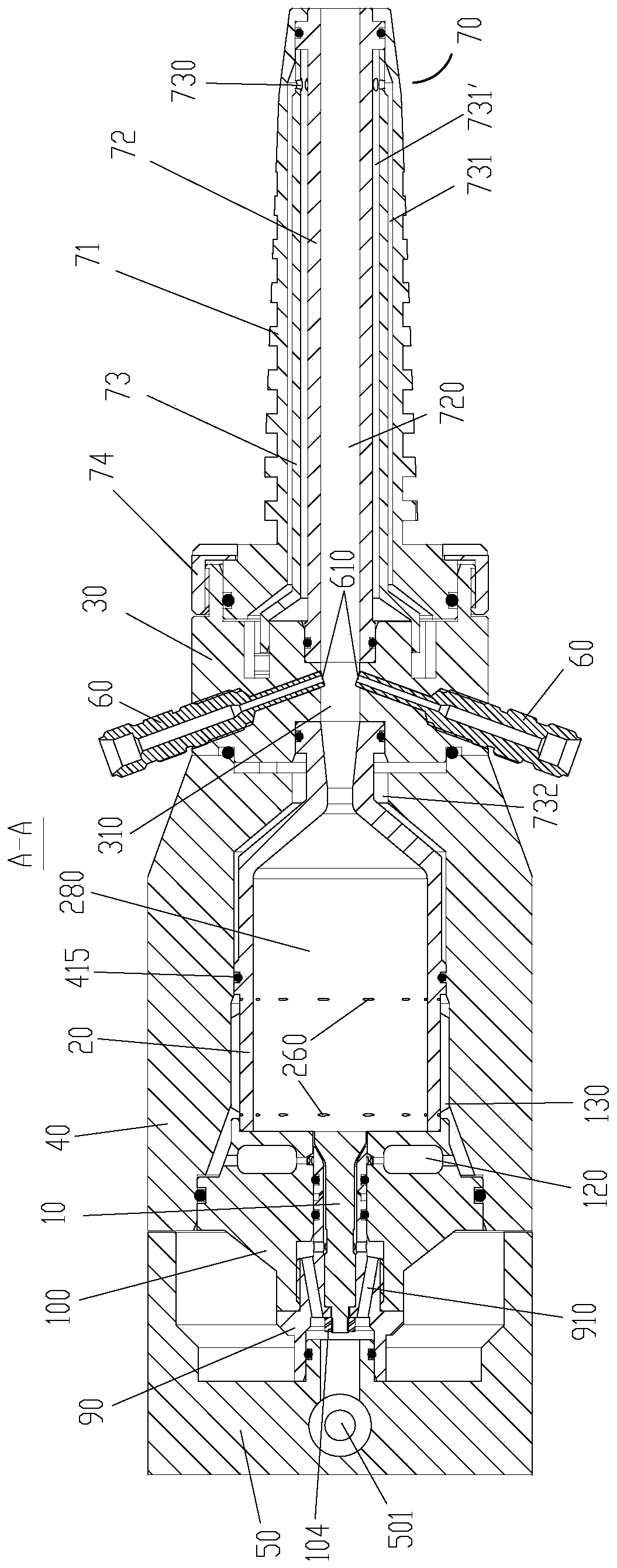

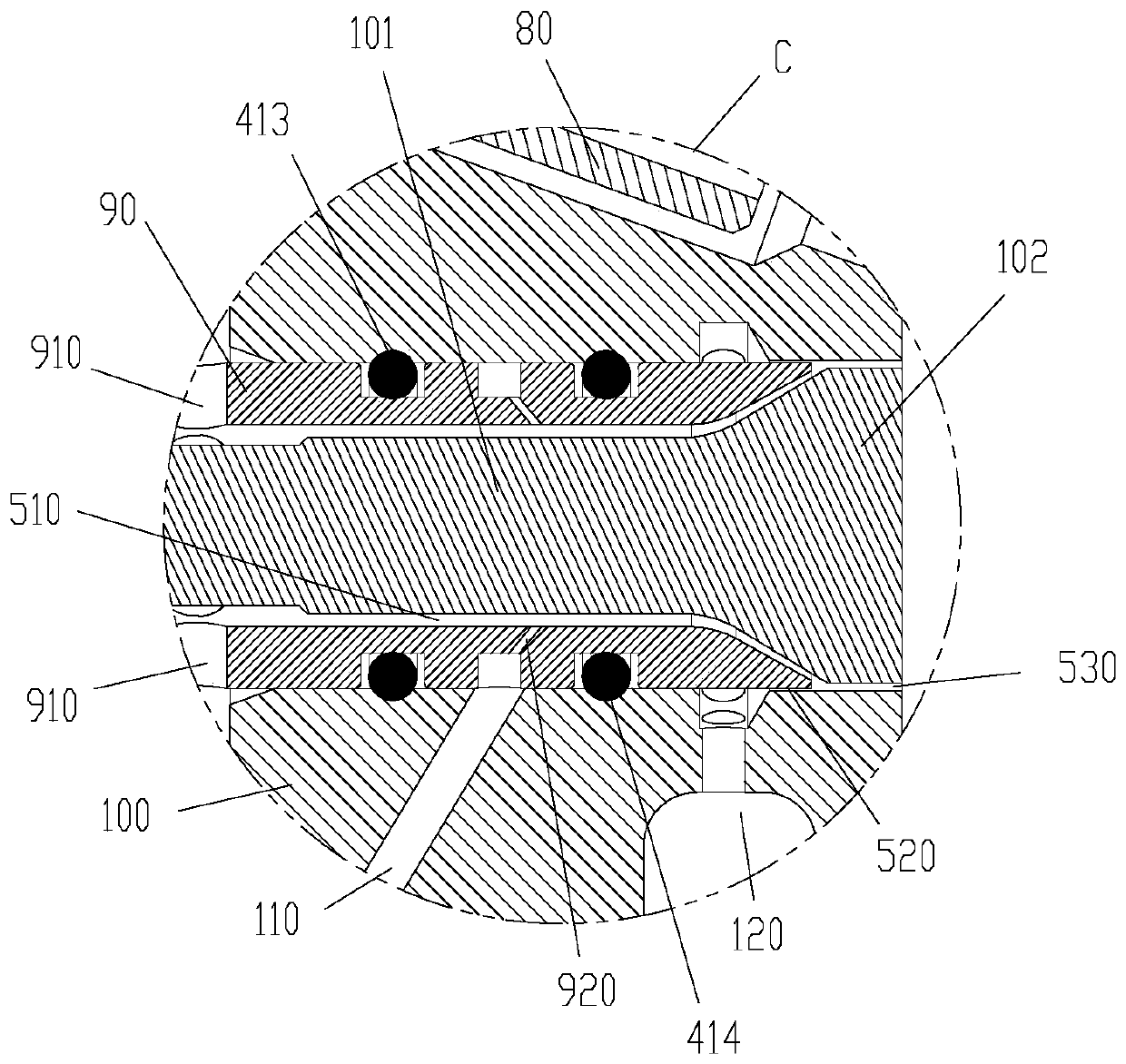

Jet-type atomization device

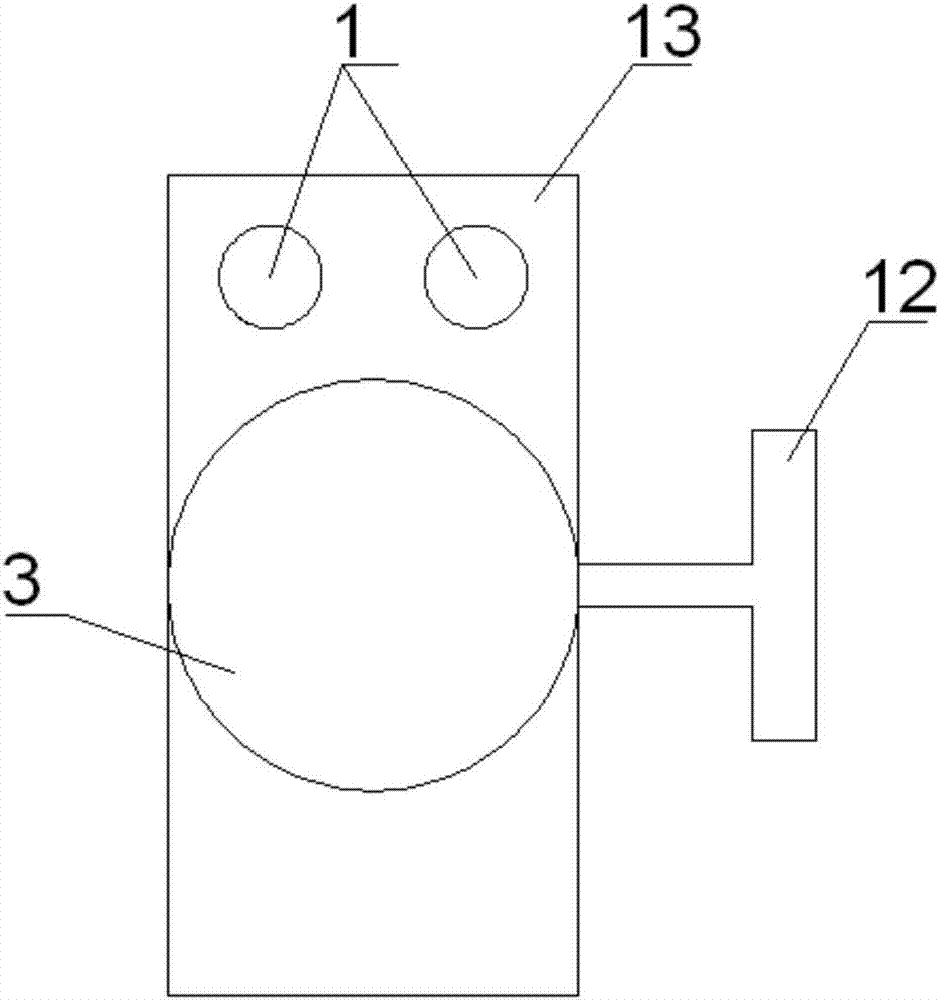

PendingCN105901775AImprove atomization efficiencyRealize secondary atomizationMedical devicesTobacco devicesLiquid storage tankEngineering

The invention discloses a jet-type atomization device. The jet-type atomization device comprises a shell, a liquid storage tank, a jet device, a heating element and a power supply. An atomization chamber is arranged in the shell; the liquid storage tank is used for storing cigarette liquid to be atomized; the jet device is used for jetting the cigarette liquid into the atomization chamber to form cigarette liquid particles of a certain particle size; the heating element is located in the atomization chamber and provided with a heating surface, the heating surface is used for bearing the cigarette liquid particles and heating and evaporating the cigarette liquid particles to form smoke; the power supply is arranged in the shell and used for supplying power to the heating element. Compared with the prior art, the jet-type atomization device improves the atomization efficiency, improves the smoking taste for users and improves the use experience as a jetting mode and a heating mode are adopted for dual atomization.

Owner:SHENZHEN FIRST UNION TECH CO LTD

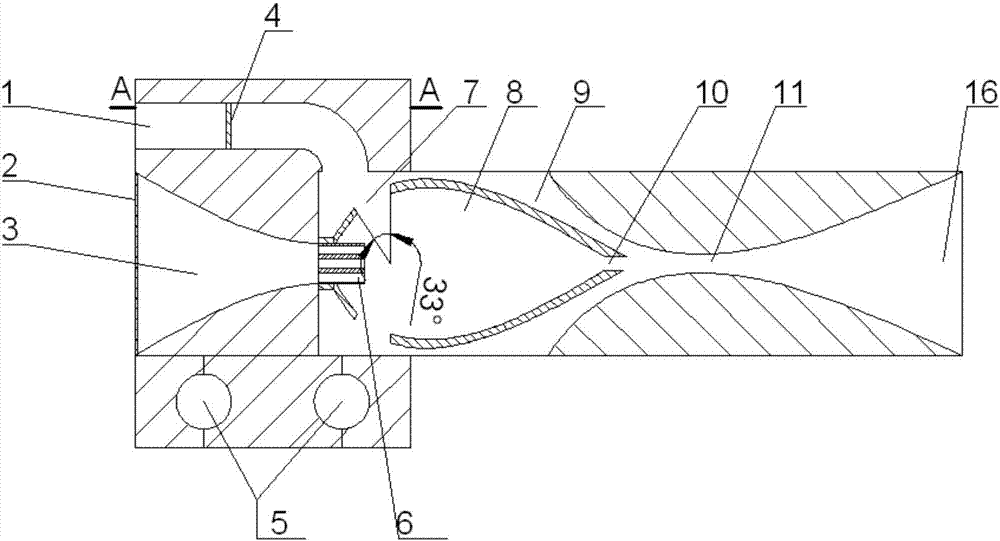

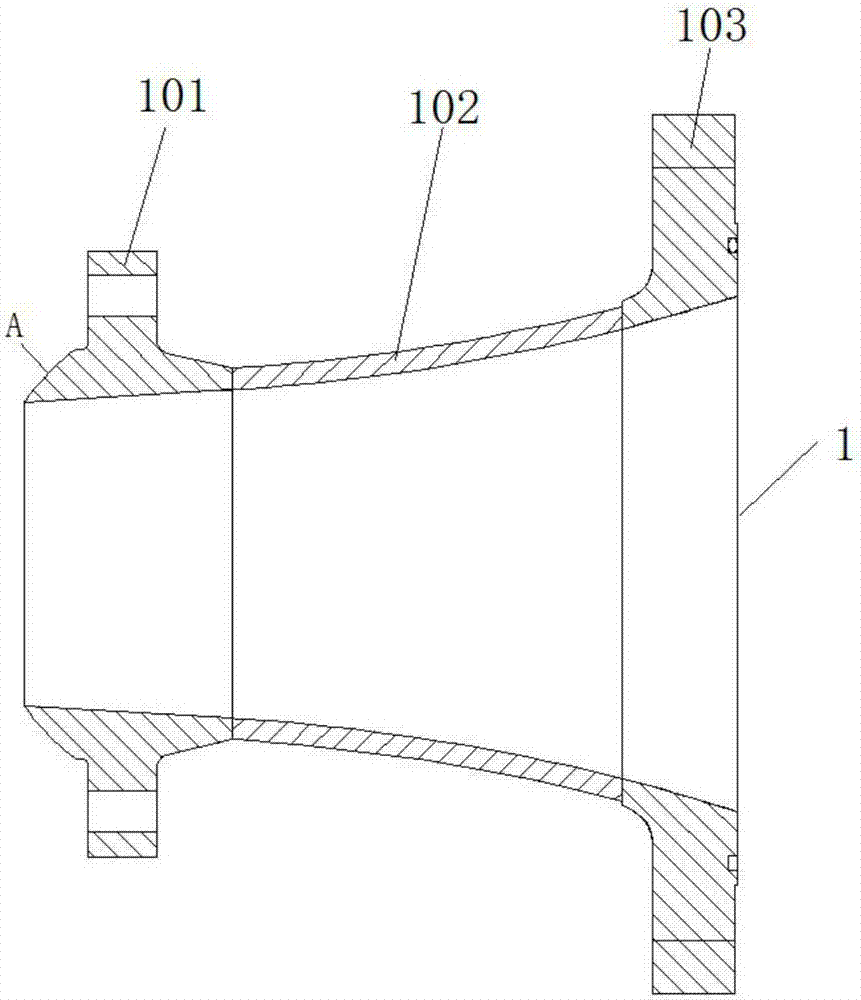

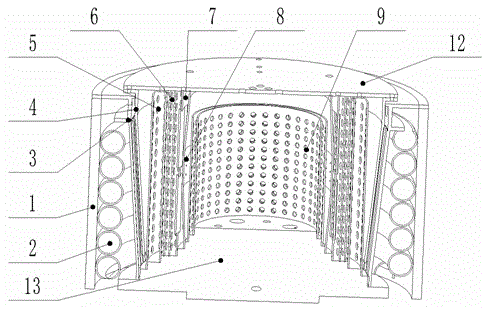

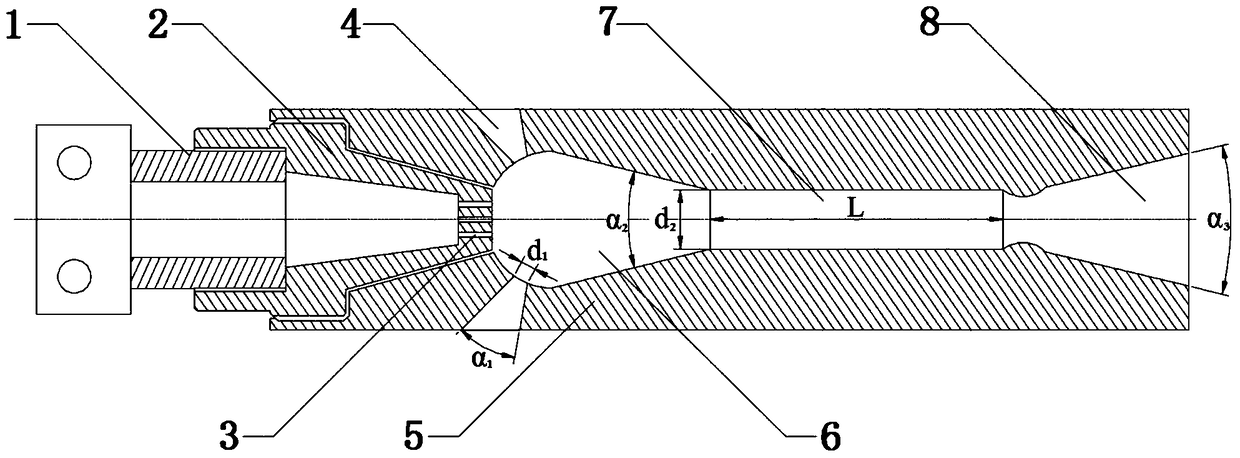

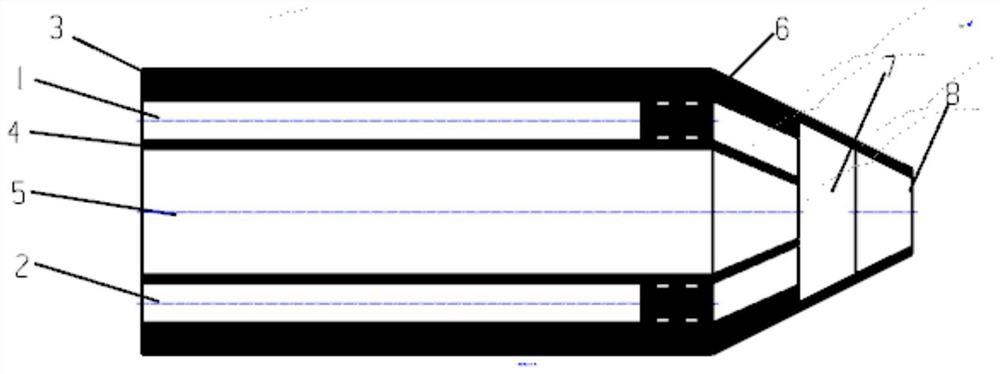

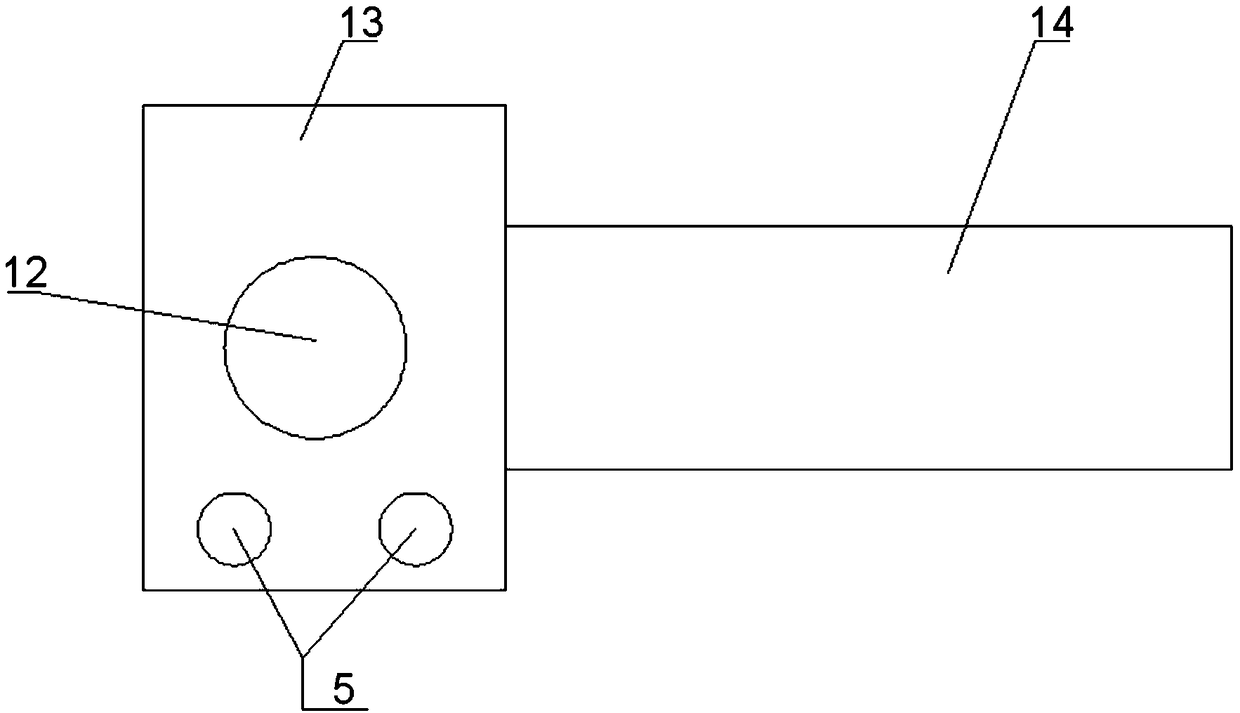

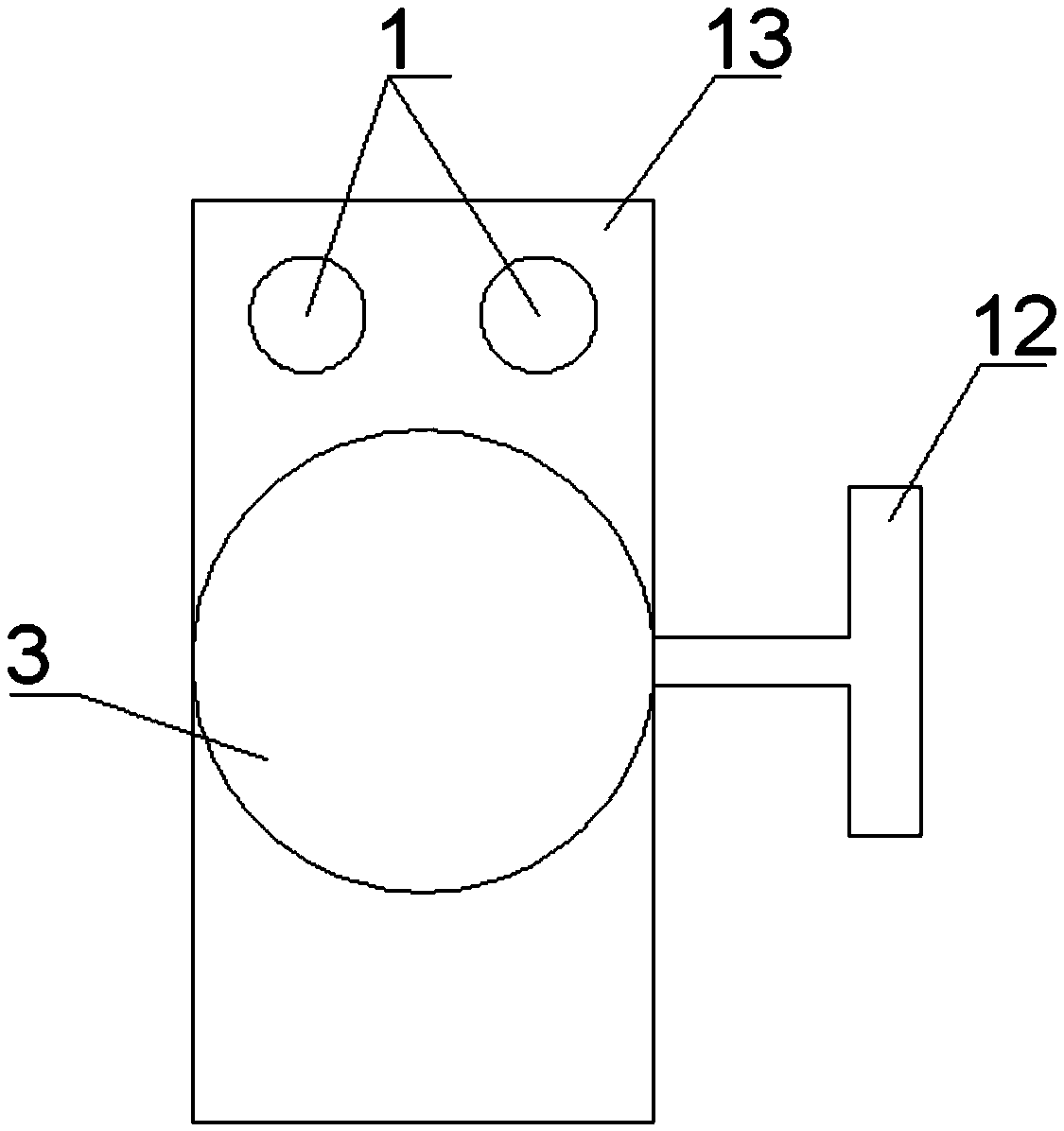

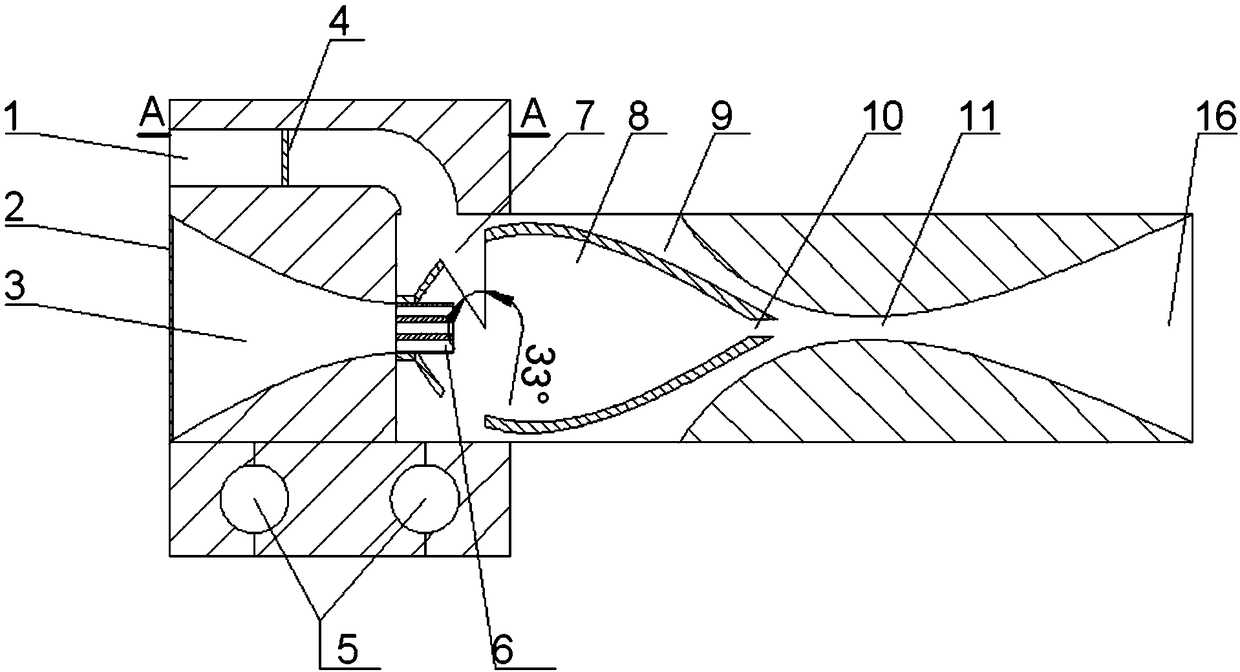

Multi-level atomization bi-phasic flow water mist atomization generating device for mine

Provided is a multi-level atomization bi-phasic flow water mist atomization generating device for a mine. The device comprises a rectification canister and a multi-level atomization canister, the rectification canister is internally provided with two gas guiding channels and one liquid guiding channel, the rear end of the liquid guiding channel is provided with a porous nozzle, the porous nozzle enters an impact atomizing chamber, the rear end of the impact atomizing chamber is provided with a Venturi mixing channel, liquid enters the porous nozzle through the liquid guiding channel, primary atomized jet is generated, negative pressure is formed in the impact atomizing chamber, partial gas of the gas guiding channels is sucked into the atomizing chamber, the gas is collided with the primary atomized jet, secondary atomization is achieved, water mist of the secondary atomization is mixed with gases in a gas side channel at a jet opening portion, and is atomized again in the Venturi mixing channel, during extinguishment, fast extinguishment and cooling are achieved through the multi-level atomization of nitrogen and water. Through the multi-level atomization bi-phasic flow water mist atomization generating device for the mine, after the extinguishment and before a pit is opened, air is automatically switched in the gas guiding channels, heat exchange and cooling are achieved through the multi-level atomization of the air and water, unnecessary waste of the nitrogen can be avoided, and the device is high in atomization degree and economical and practical.

Owner:LIAONING TECHNICAL UNIVERSITY

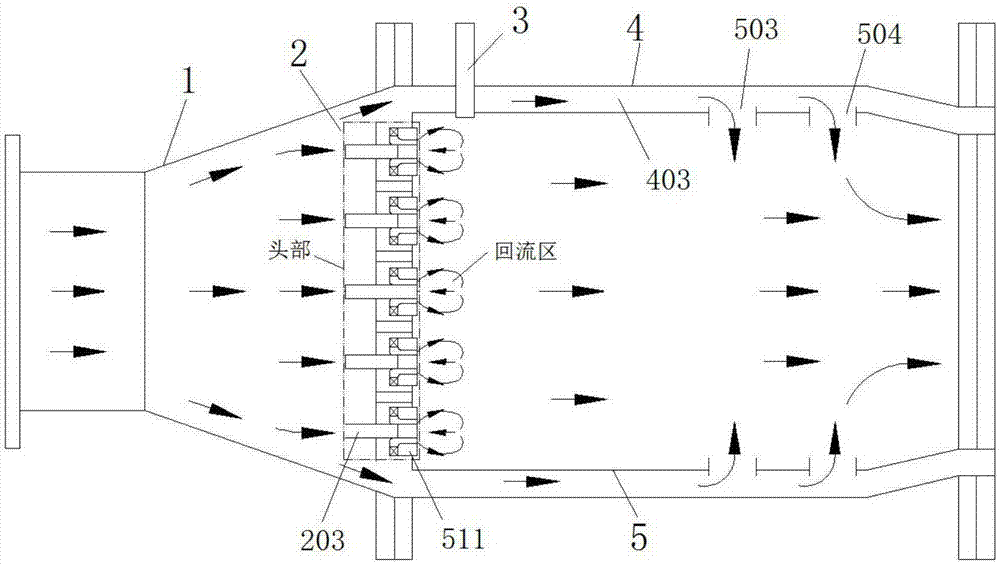

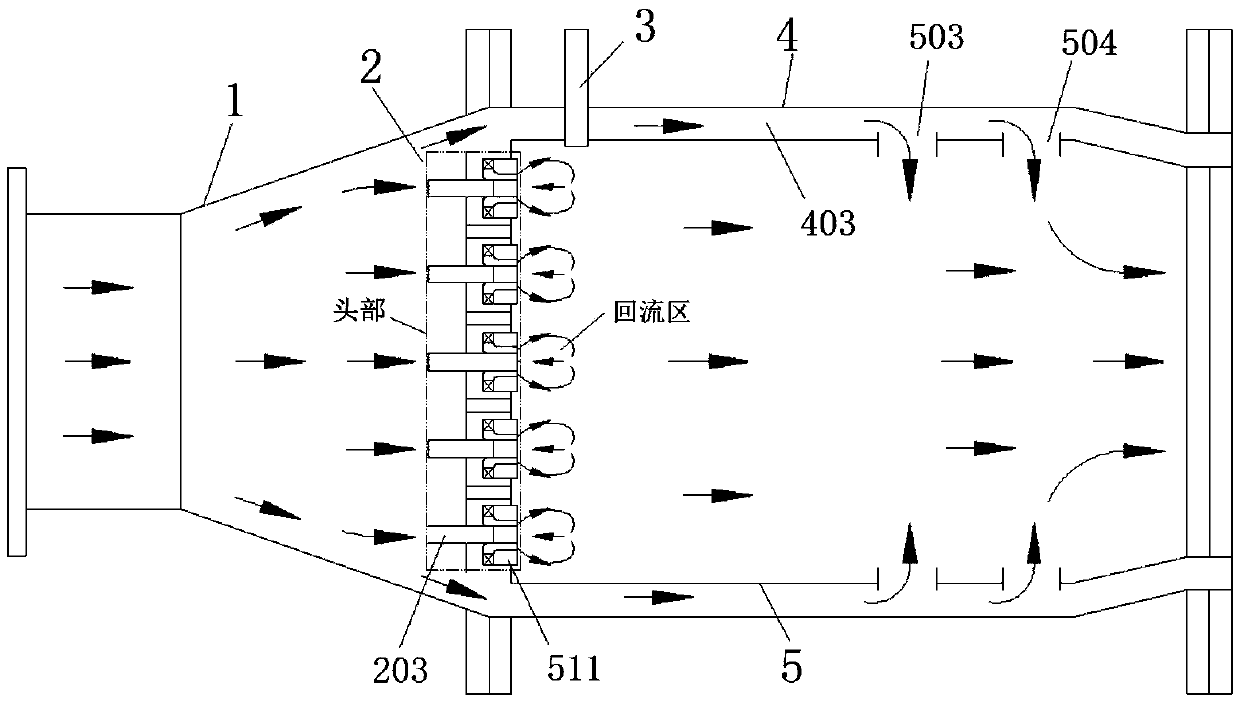

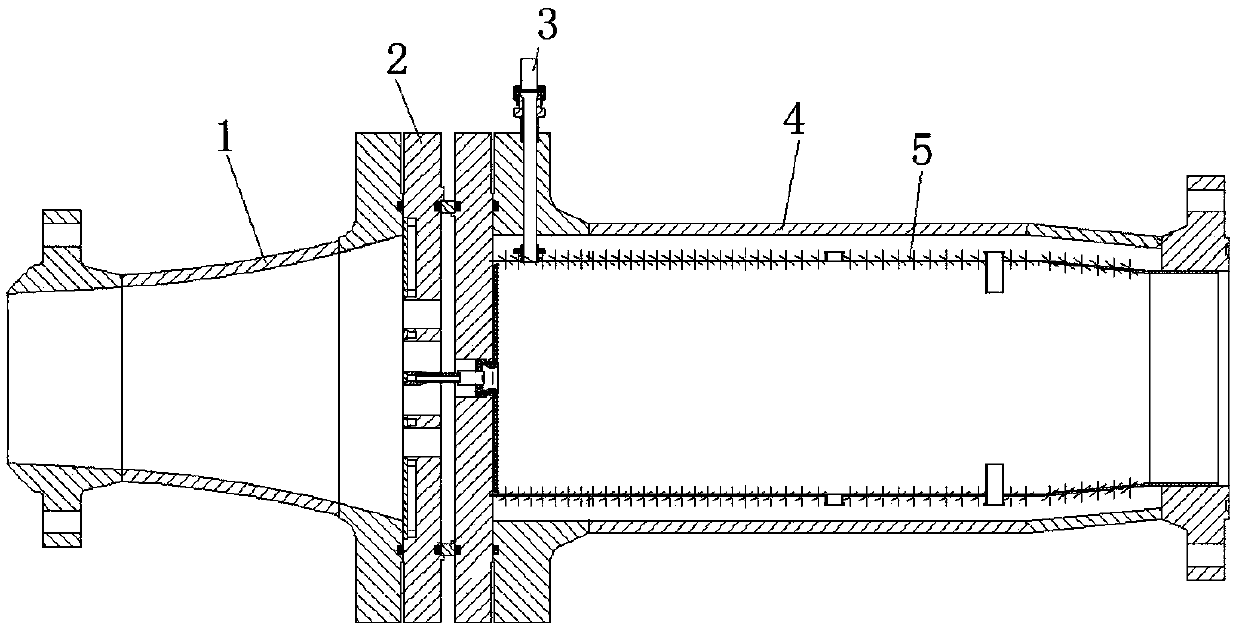

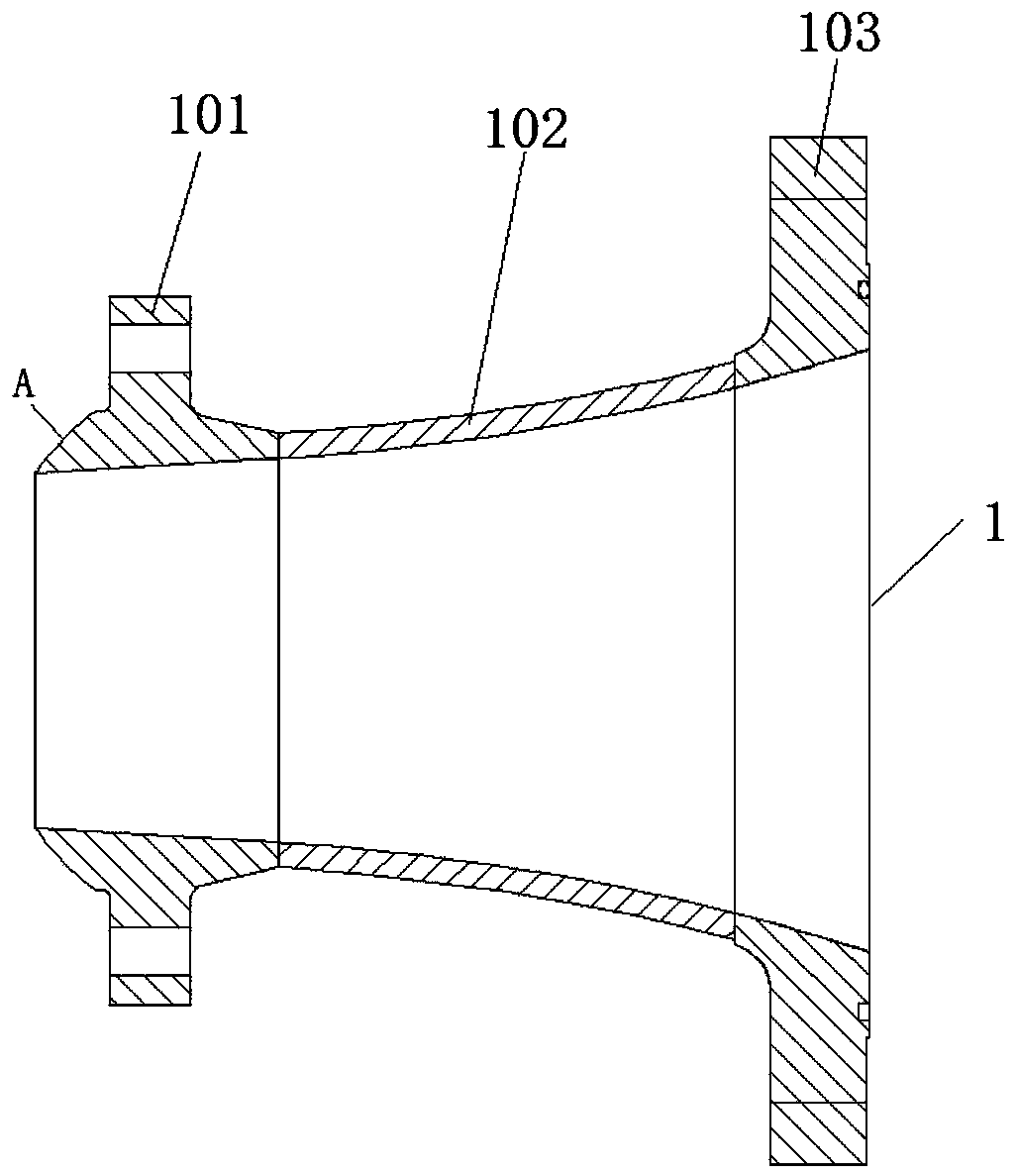

Multi-point injection fuel gas generator using ethanol as fuel

The invention provides a multi-point injection fuel gas generator using ethanol as a fuel. The generator comprises a diffuser, a fuel split atomizing device, a high-energy plasma ignition electric nozzle, a shell and a flame tube, the fuel split atomizing device and a head adapter section are fixed between a rear flange and a shell front flange, the high-energy plasma ignition electric nozzle 3 is fixed on the shell and a barrel body, an annular channel is arranged between the shell and the barrel body, a floating ring installation seat is arranged at the position, 20 mm -50 mm away from the head transferring section, of the barrel body, a clamping ring is arranged on the floating ring installation seat, a floating ring is fixed on the clamping ring, the end part of the high-energy plasma ignition power nozzle is fixed on the floating ring, and fuel supplementing holes and mixing holes are sequentially formed in an axial direction of the barrel body. The generator solves many problems existing in the existing fuel gas generator with the ethanol as the fuel, and has the advantages that the gas enthalpy value is high, the reliability of an ignition system is improved, the geometrical size under the large-volume flow is relatively small, weight is light, a cooling water system does not need to be arranged, running cost is low, combustion efficiency is high, and the service life is long.

Owner:四川艾蒙特航空器材有限公司

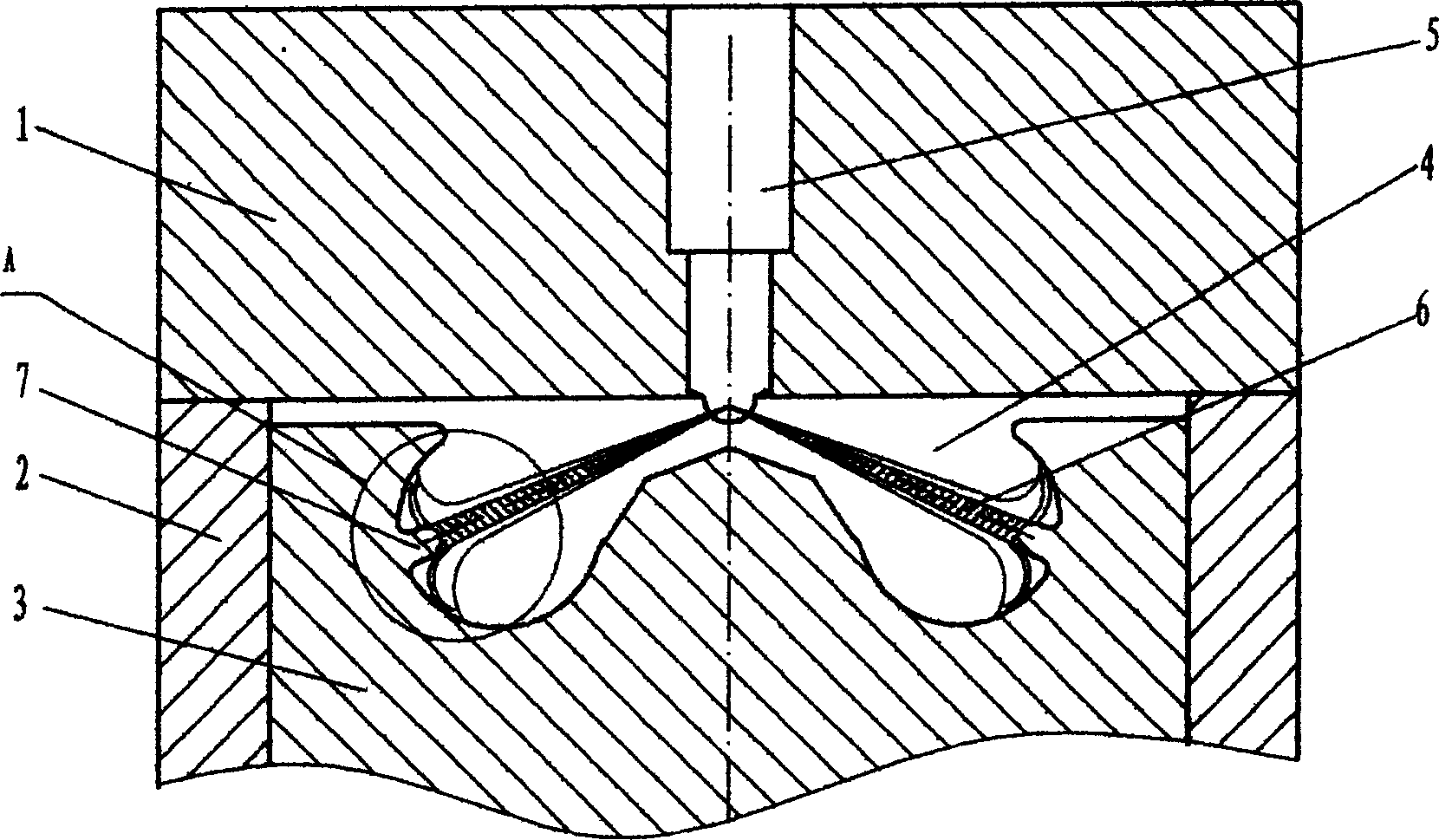

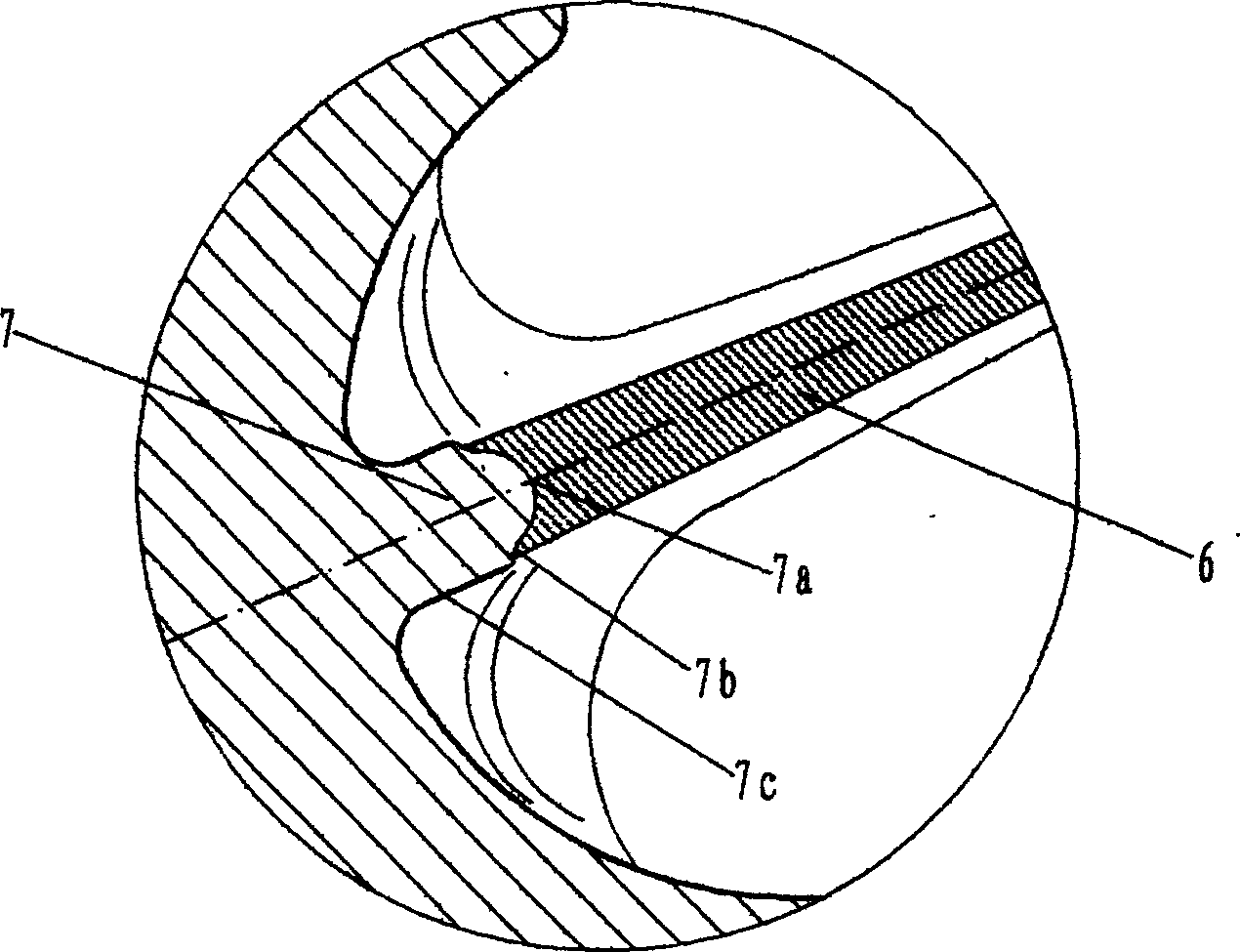

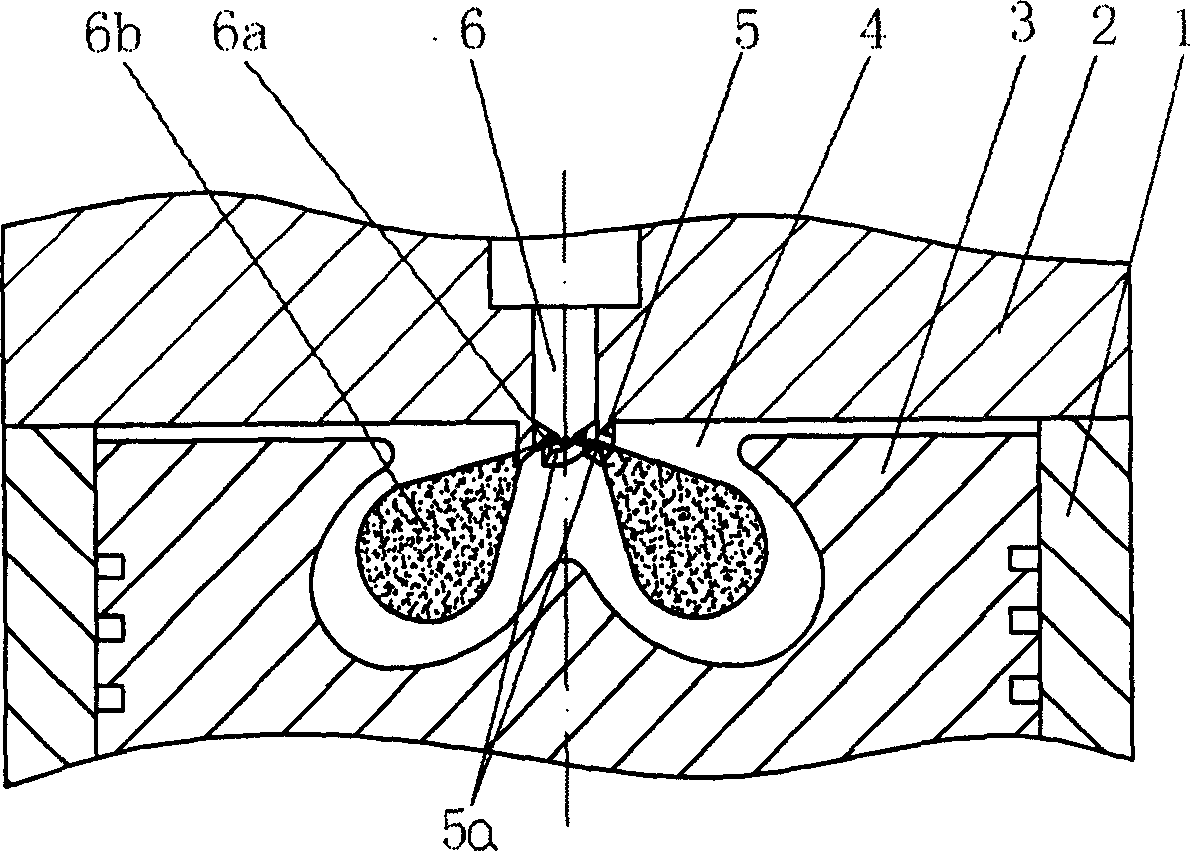

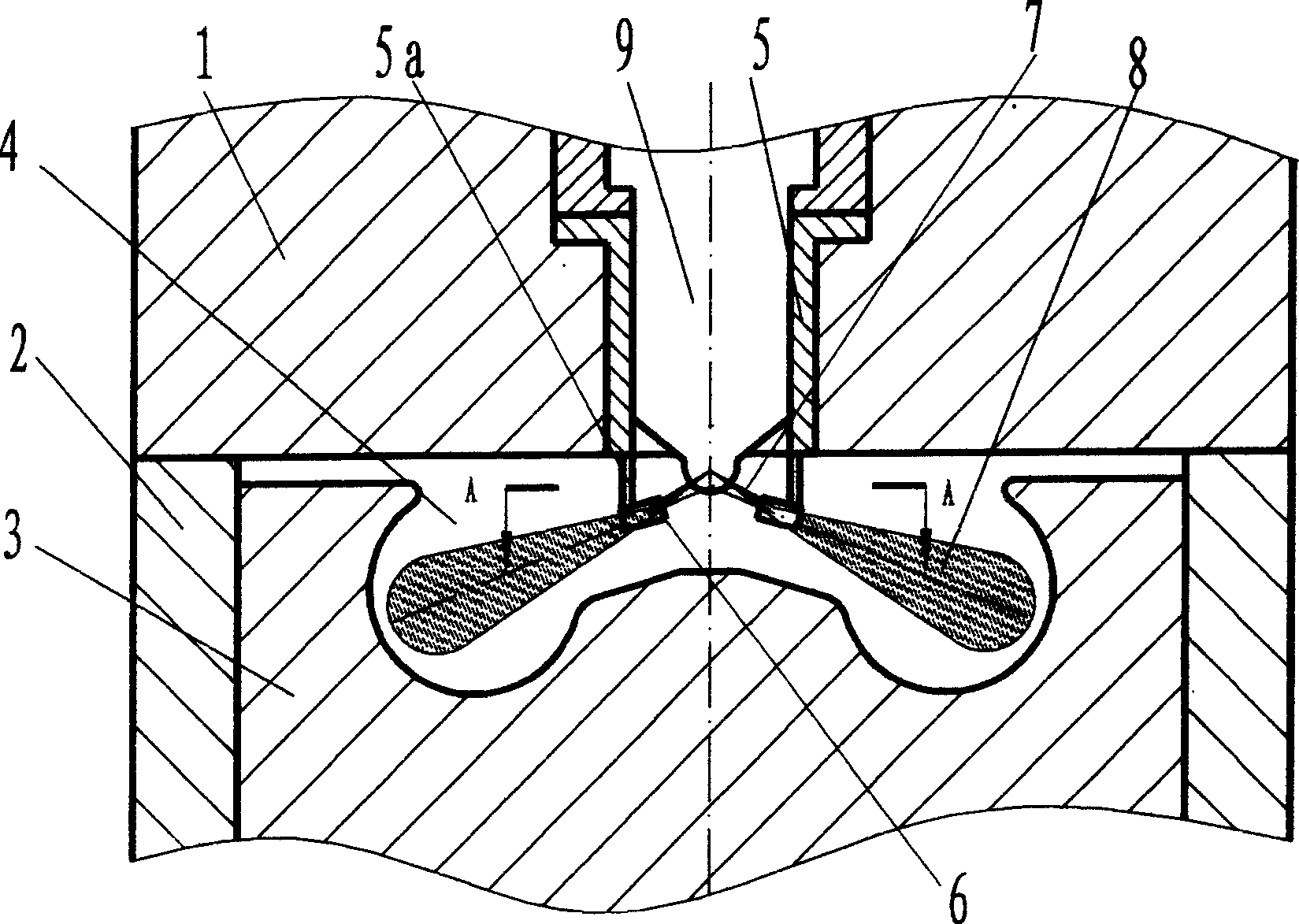

Spraying guidance system of internal combustion engine

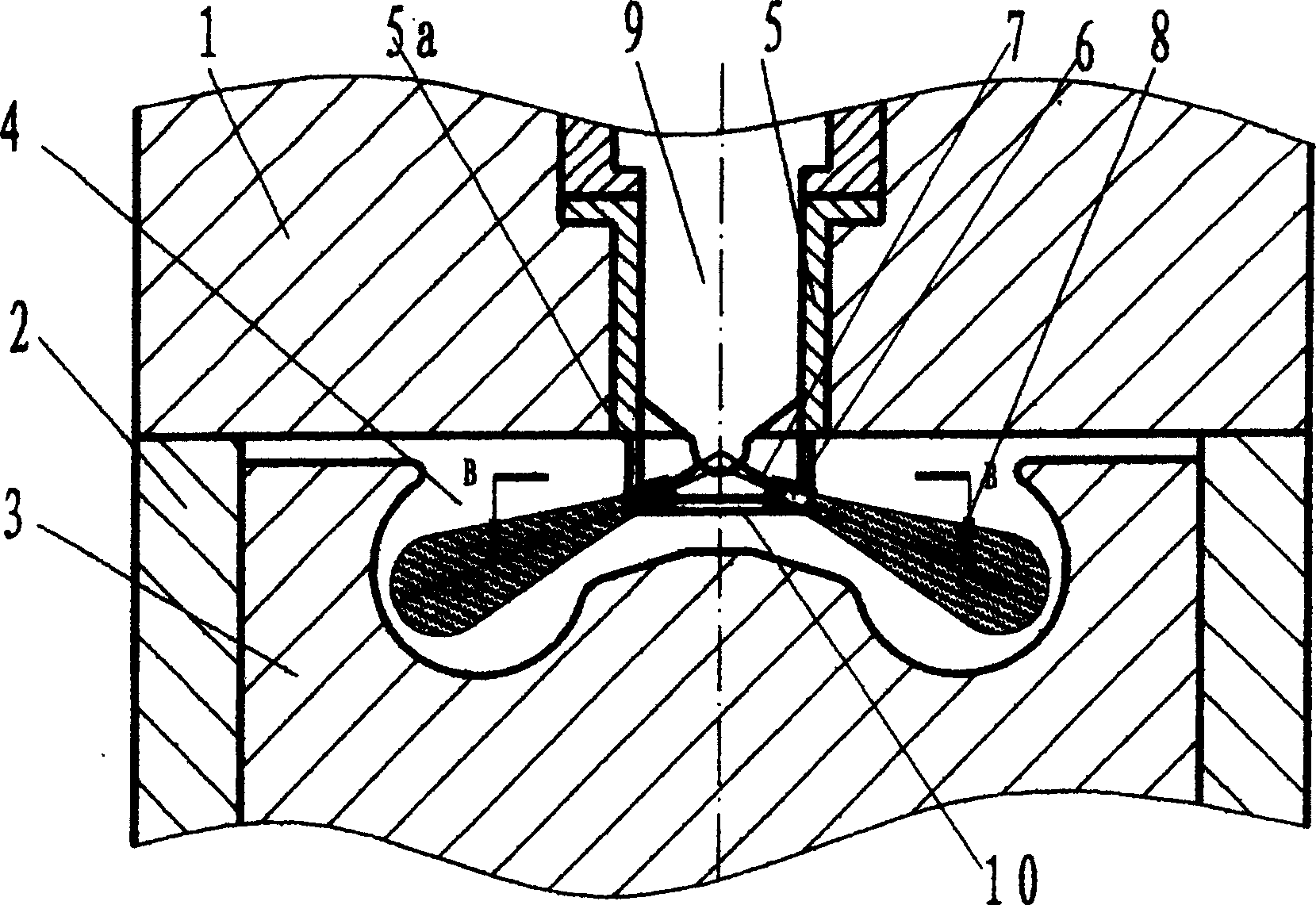

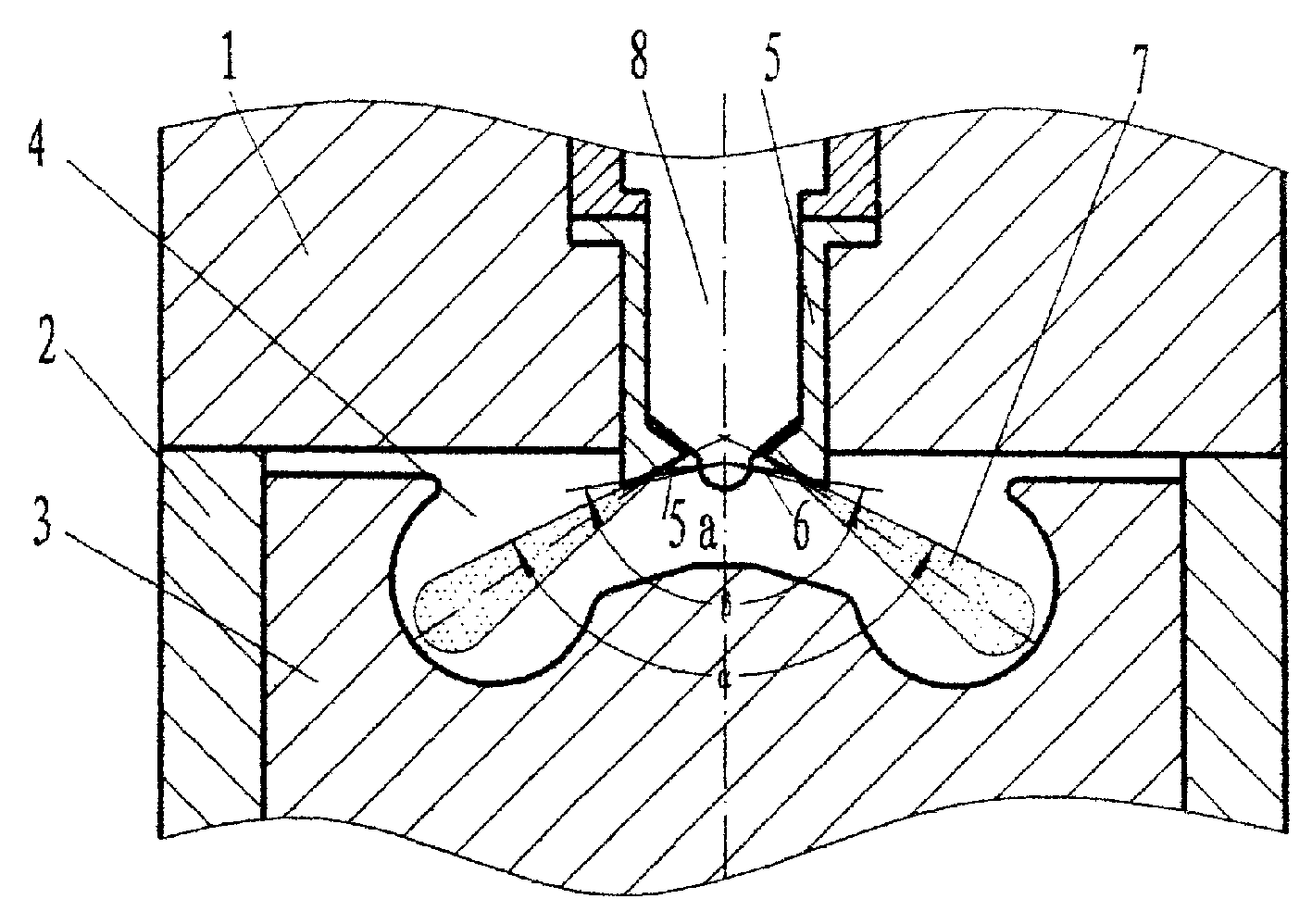

InactiveCN1480642AIncrease involvementQuality improvementInternal combustion piston enginesFuel injection apparatusGuidance systemCombustion chamber

A spray guide system of IC engine features that a spray guide step is made on the inner surface of omega-type combustion chamber. When the pistor is raising up in the primary spray phase, the oil beam is sprayed onto said guide step, which can reflect part of the oil beam and quickly disperse the rest along its guide arc, so realizing secondary atomizing.

Owner:DALIAN UNIV OF TECH

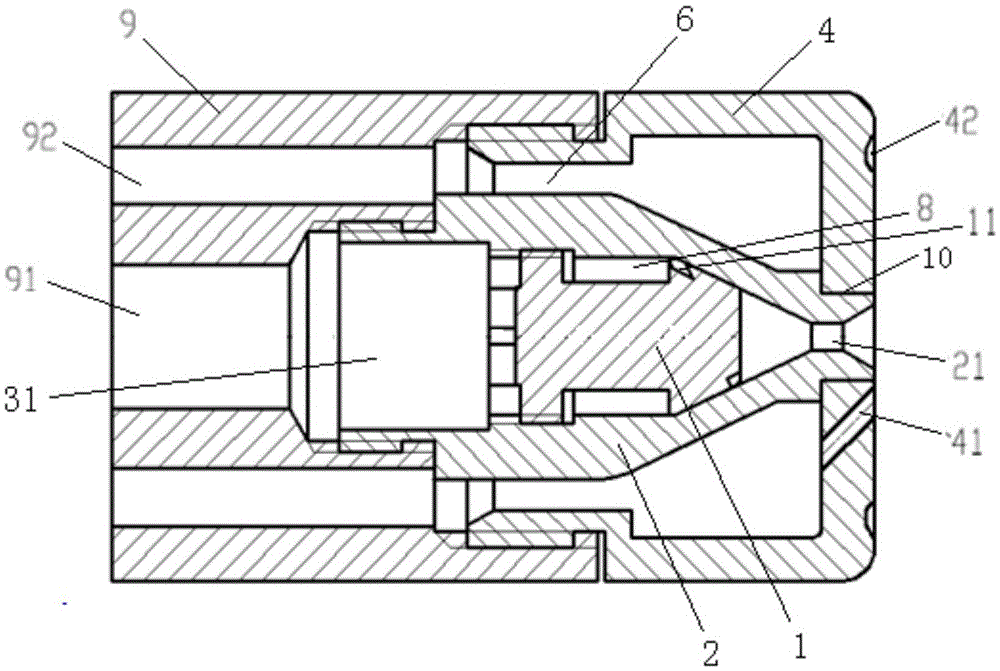

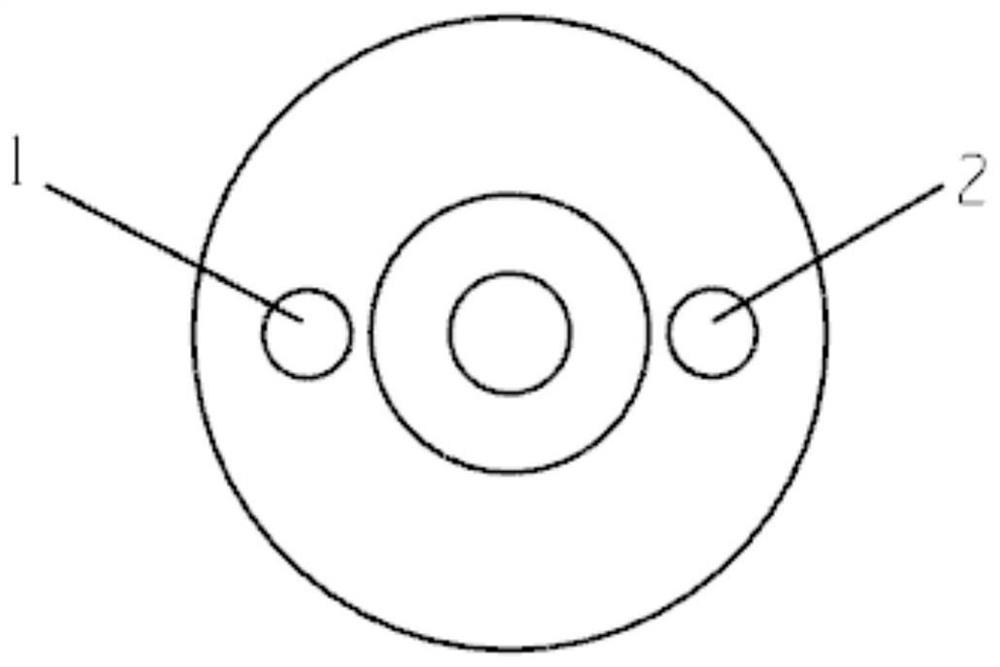

Fixed bed multiphase atomizing nozzle

The invention provides a fixed bed multiphase atomizing nozzle, comprising a whirlcone, an inner nozzle and an outer nozzle which are coaxially arranged in sequence; the head of the whirlcone is provided with multiple first whirling grooves; the outer wall of the whirlcone and the inner wall of the inner nozzle define a liquid phase channel; the head of the inner nozzle is provided with a liquid phase spray orifice; the liquid phase channel is communicated with the liquid phase spray orifice by the first whirling grooves; the area of the end face of the head of the outer nozzle is 1.5-5 times the cross sectional area of the greatest cross section of the inner nozzle; the middle of the end face of the head of the outer nozzle is provided with a fixing hole; the outer wall of the inner nozzle and the inner wall of the outer nozzle define a gas phase channel; the end face of the head of the outer nozzle is provided with multiple whirling holes around the fixing hole, and the gas phase channel is communicated with the whirling holes; on the end face of the head of the outer nozzle, the outer sides of the whirling holes are further provided with multiple gas phase spray holes around the fixing hole, and the multiple gas phase spray holes are communicated with the gas phase channel. According to the atomizing nozzle, the atomizing angle and the atomizing diameter are both increased greatly, the atomizing effect is better, and the atomizing range is larger.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

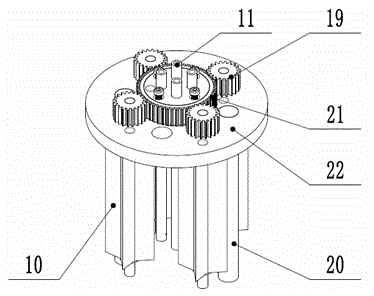

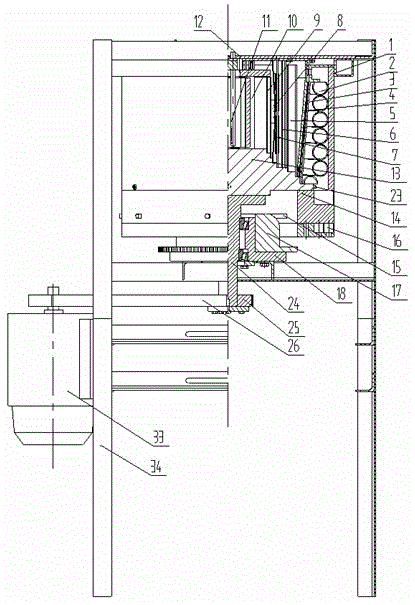

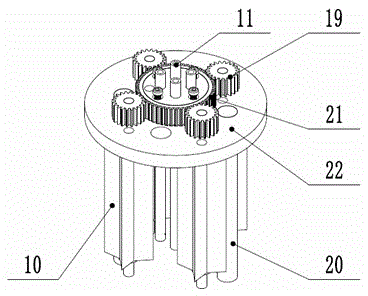

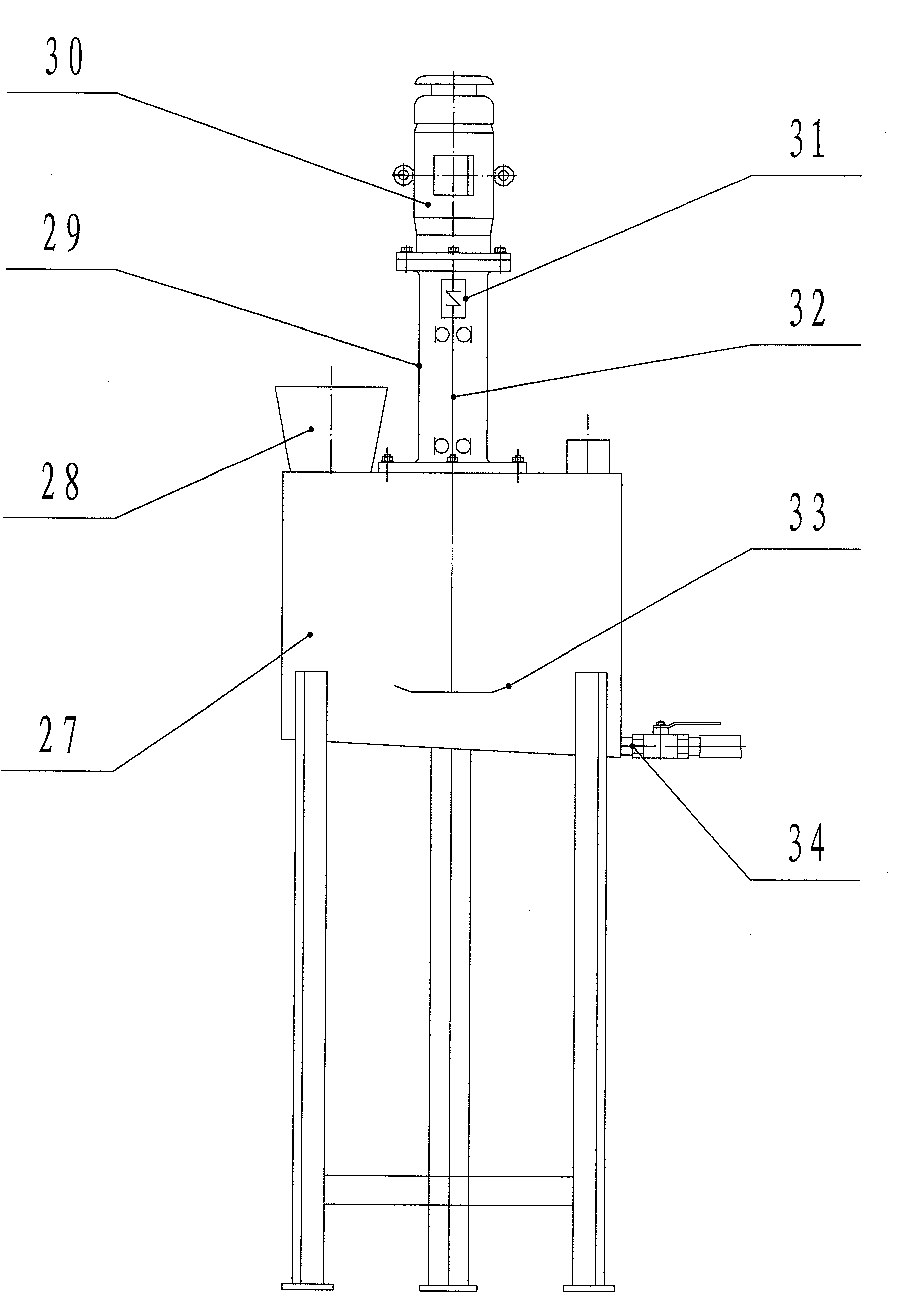

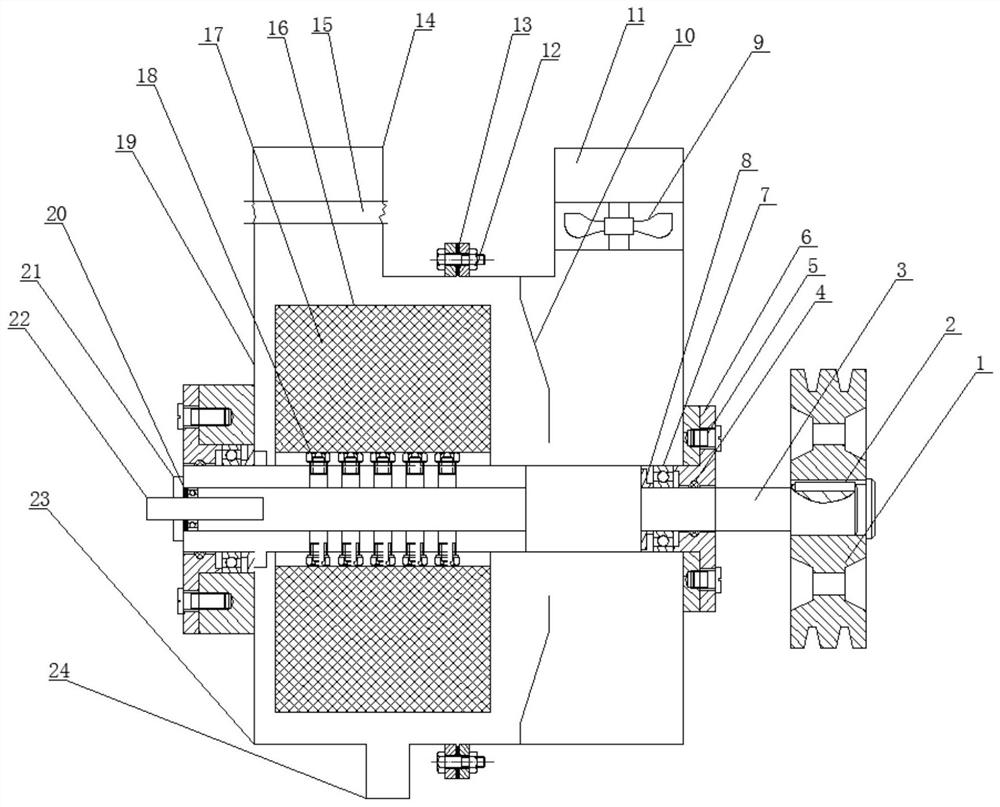

Labyrinth type hypergravity liquid-liquid extraction separator

InactiveCN104815459ALarge mass transfer areaWell mixedLiquid solutions solvent extractionImpellerElectric machinery

The invention discloses a labyrinth type hypergravity liquid-liquid extraction separator which comprises a housing, a filler helix tube, a mixed mass transfer mechanism, a separation collection mechanism, a top cover plate, a pedestal, a bearing sleeve, a shaft and a motor. The mixed mass transfer mechanism comprises a feed planet impeller mixing device, a mass transfer device and conical milling fluid wheels. The mass transfer device is arranged between the feed planet impeller mixing device and the conical milling fluid wheels. The separation and collection mechanism comprises a phase-splitting trough, a spring switch and a collecting tank. By the extraction separator provided by the invention, high-efficiency extraction is realized, and two-phase separation is also considered. A multi-layer packing structure increases mass transfer area of a two-phase fluid. Due to the complex packing layer structure, mixing is more uniform. Reaction time is prolonged, and extraction rate is enhanced. The separation and collection mechanism, used as an important part of the extraction process, realizes integration of extraction and separation.

Owner:KUNMING UNIV OF SCI & TECH

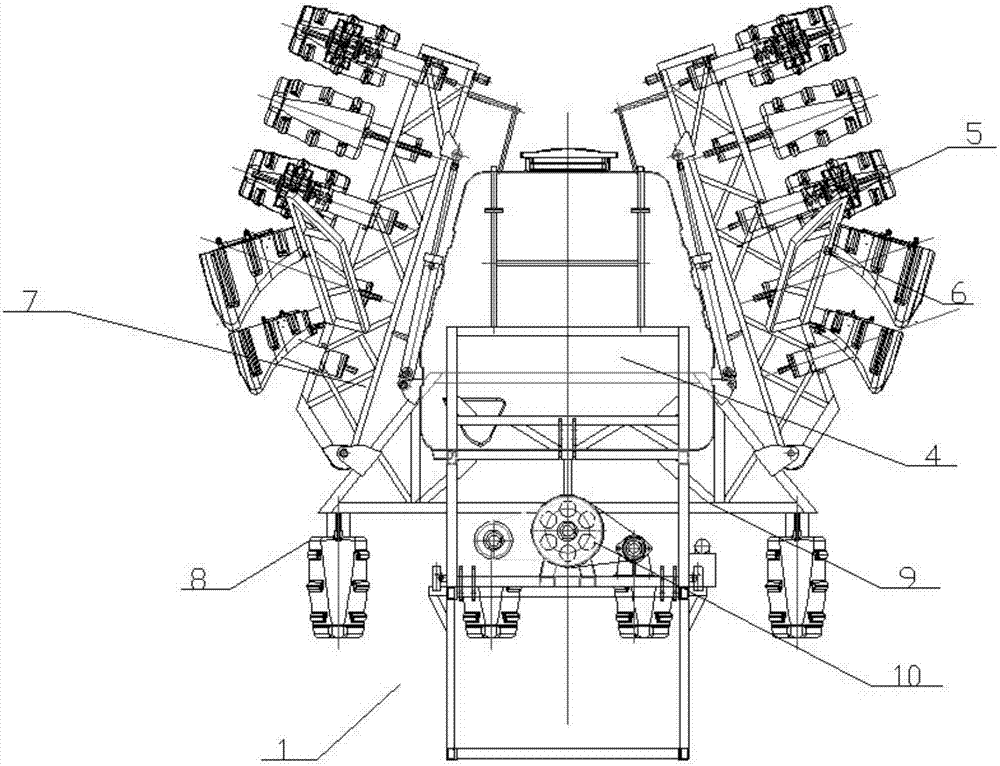

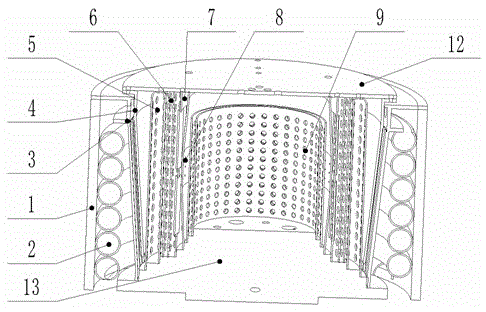

Air supply device and special cotton pesticide applicator applying same

ActiveCN107306929AStrong penetrating powerRealize secondary atomizationInsect catchers and killersPesticide applicationAirflow

The invention provides an air supply device and a special cotton pesticide applicator applying the same. The air supply device comprises an air duct, an air distribution cylinder and a flow guide plate. The air duct conveys high-pressure airflow into the flow guide plate through the air distribution cylinder, and the flow guide plate is connected with the air distribution cylinder through a supporting plate. A spraying device comprises the air supply device and a sprinkler, wherein the sprinkler is fixedly connected with the air supply device through an upper supporting plate and a lower supporting plate and fixedly arranged at an air outlet of the flow guide plate to form secondary atomization. The special cotton pesticide applicator is easy to mount, convenient to use and capable of simultaneously applying pesticides to cotton seedlings in different periods, sensitively changing the length and the height of a spraying cantilever and rapidly adapting to different pesticide application area, and has the advantages of high pesticide application efficiency, wide pesticide application area, simplicity and rapidness in commissioning operation, low cost and the like.

Owner:NANTONG HUANGHAI CHEM MACHINERY

Diesel oil engine secondary atomization combustion system

InactiveCN1479008AQuality improvementImprovements in emission indicatorsFuel re-atomisation/homogenisationMachines/enginesCombustion systemCombustion

A secondary-atomizing conbustino system for diesel engine features that a guiding conic body is arranged under the oil nozzle, and when the oil sprayed by multi-hole nozzle is in touch with said conic body, it is further atomized and uniformly distributed to form a combustible mixed gas. Its advantage is high combustion speed.

Owner:DALIAN UNIV OF TECH

A multi-point injection gas generator using ethanol as fuel

The invention provides a multi-point injection fuel gas generator using ethanol as a fuel. The generator comprises a diffuser, a fuel split atomizing device, a high-energy plasma ignition electric nozzle, a shell and a flame tube, the fuel split atomizing device and a head adapter section are fixed between a rear flange and a shell front flange, the high-energy plasma ignition electric nozzle 3 is fixed on the shell and a barrel body, an annular channel is arranged between the shell and the barrel body, a floating ring installation seat is arranged at the position, 20 mm -50 mm away from the head transferring section, of the barrel body, a clamping ring is arranged on the floating ring installation seat, a floating ring is fixed on the clamping ring, the end part of the high-energy plasma ignition power nozzle is fixed on the floating ring, and fuel supplementing holes and mixing holes are sequentially formed in an axial direction of the barrel body. The generator solves many problems existing in the existing fuel gas generator with the ethanol as the fuel, and has the advantages that the gas enthalpy value is high, the reliability of an ignition system is improved, the geometrical size under the large-volume flow is relatively small, weight is light, a cooling water system does not need to be arranged, running cost is low, combustion efficiency is high, and the service life is long.

Owner:四川艾蒙特航空器材有限公司

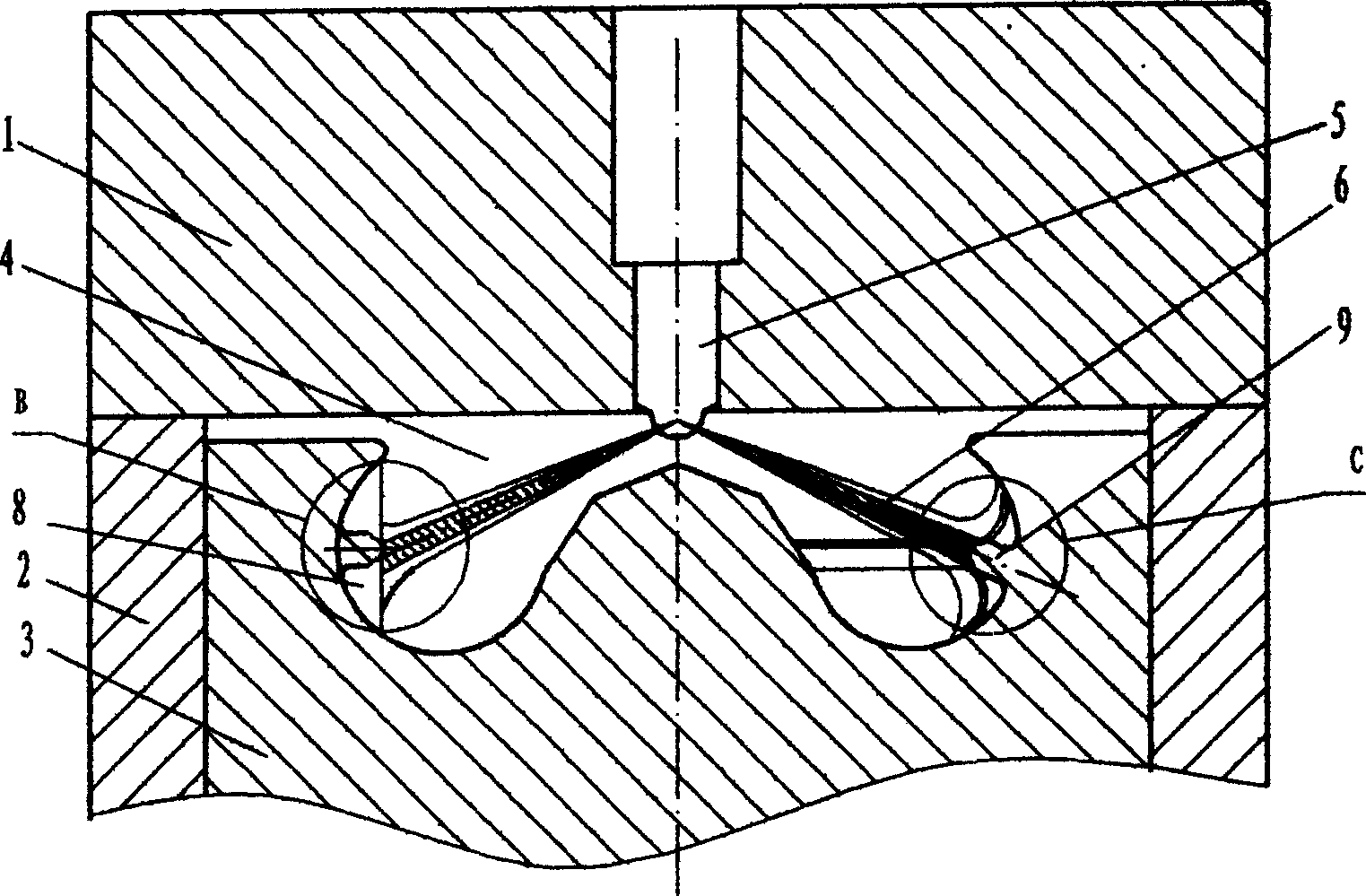

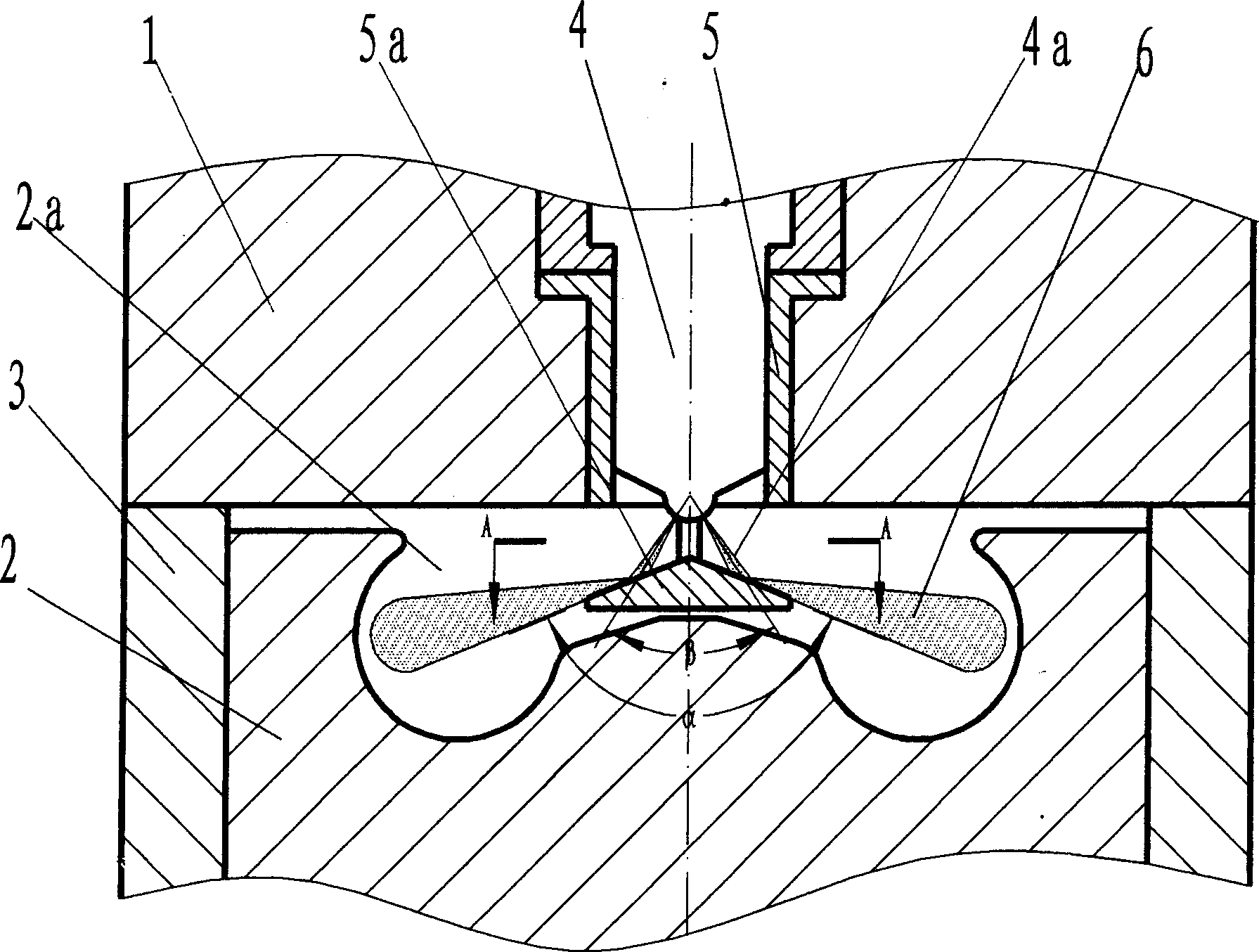

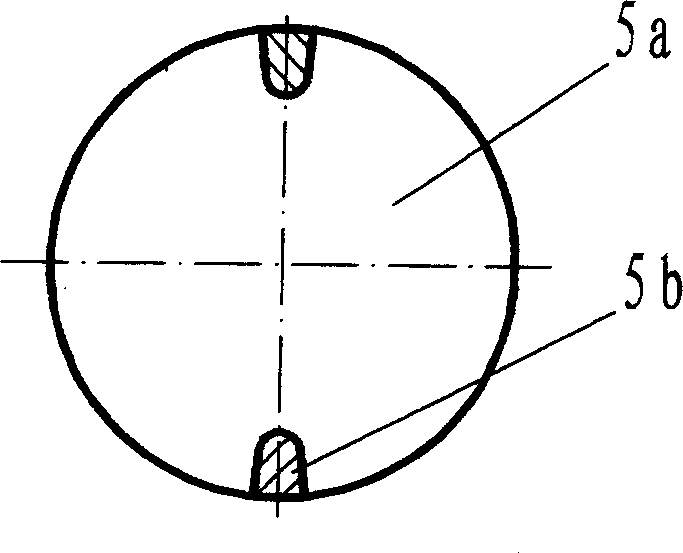

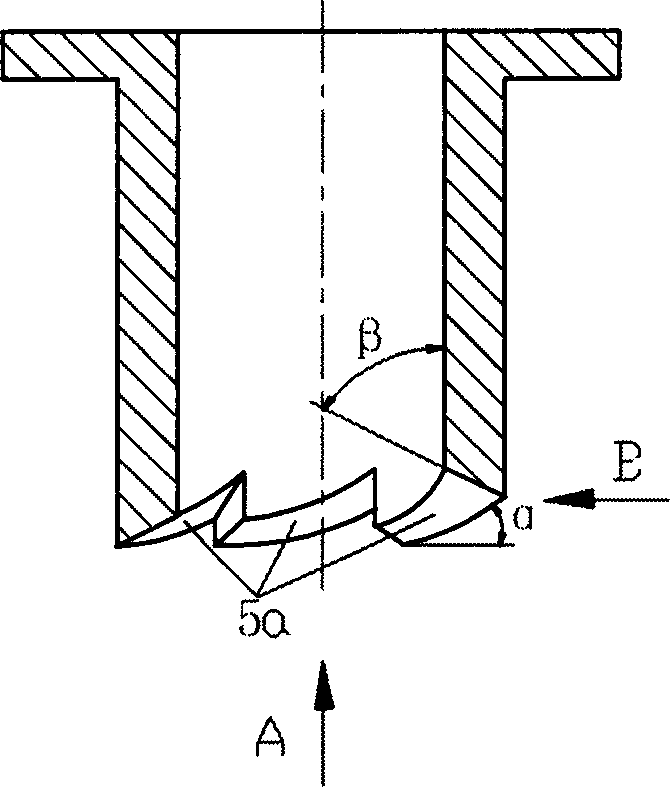

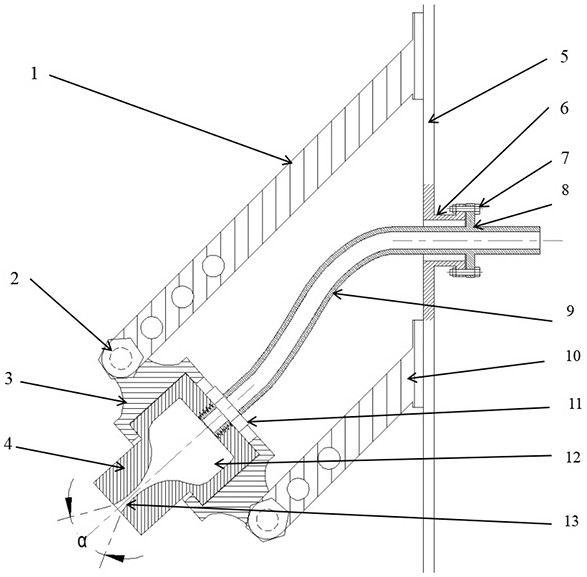

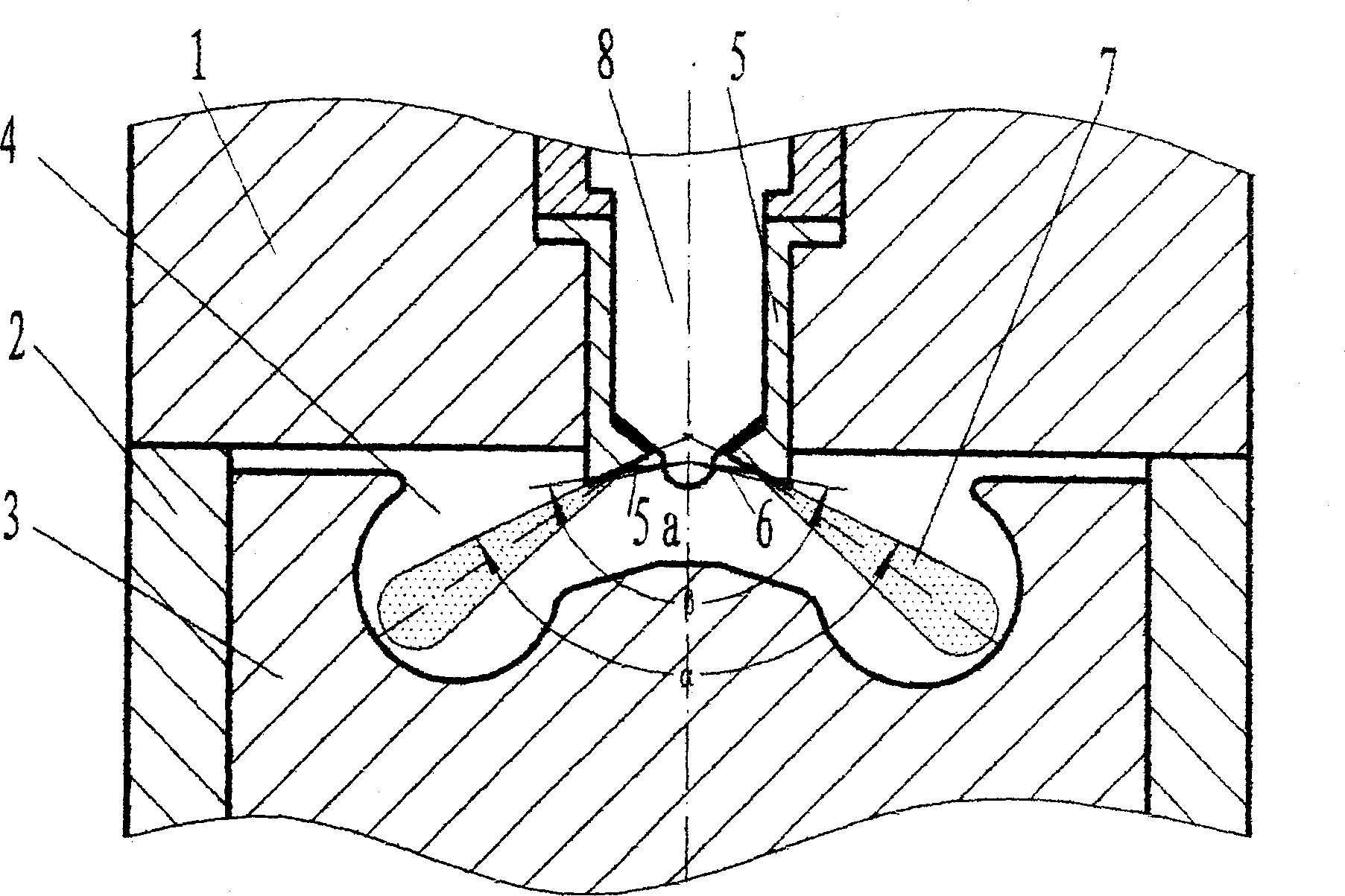

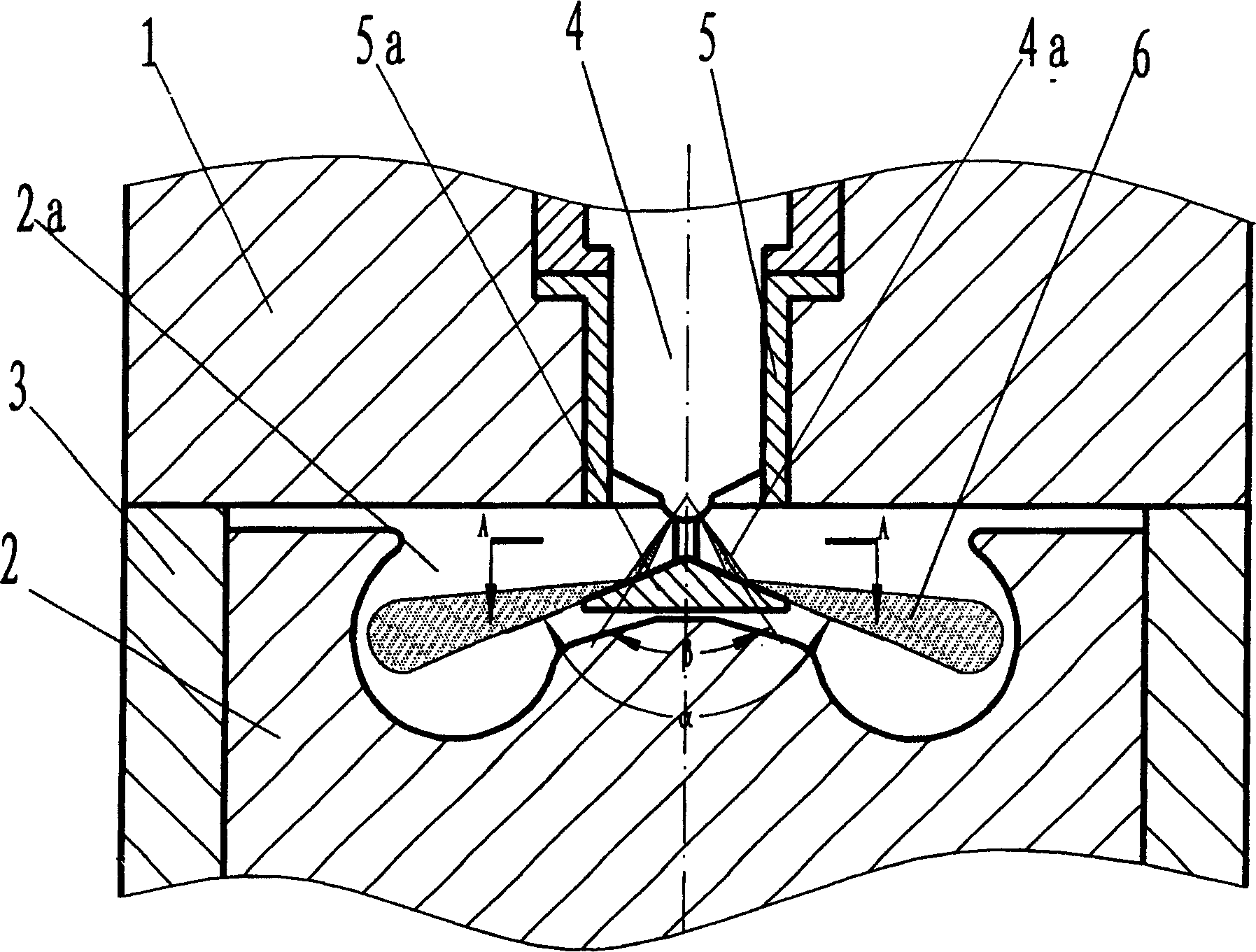

Internal combustion engine guide collision burning system

InactiveCN1651747AQuality improvementImprove other emission indicatorsInternal combustion piston enginesPistonsCombustion systemCombustion

The present invention relates to a guide collision combustion system of internal combustion engine, belonging to the field of engine mixed gas formation and combustion technology. It is characterized by that the lower end of guide ring placed on the periphery of fuel nozzle is equipped with a guide surface of primary fuel beam, and the moulding surface of the guide surface, circumferential included angle alpha and longitudinal included angle beta can be defined after copulation experiment. The primary fuel beam injected from fuel nozzle can be spread along the guide surface, and can be injected in the sector form so as to implement secondary atomization, so that it can greatly improve quality of engine combustible mixed gas and can make the combustion quick and complete.

Owner:DALIAN UNIV OF TECH

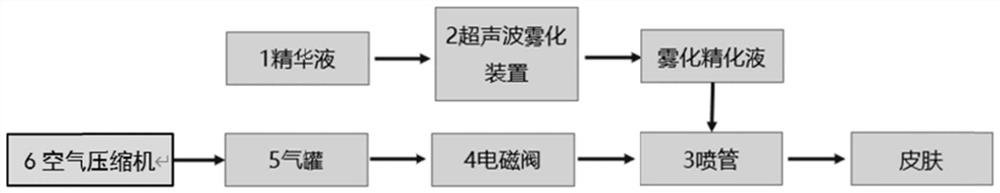

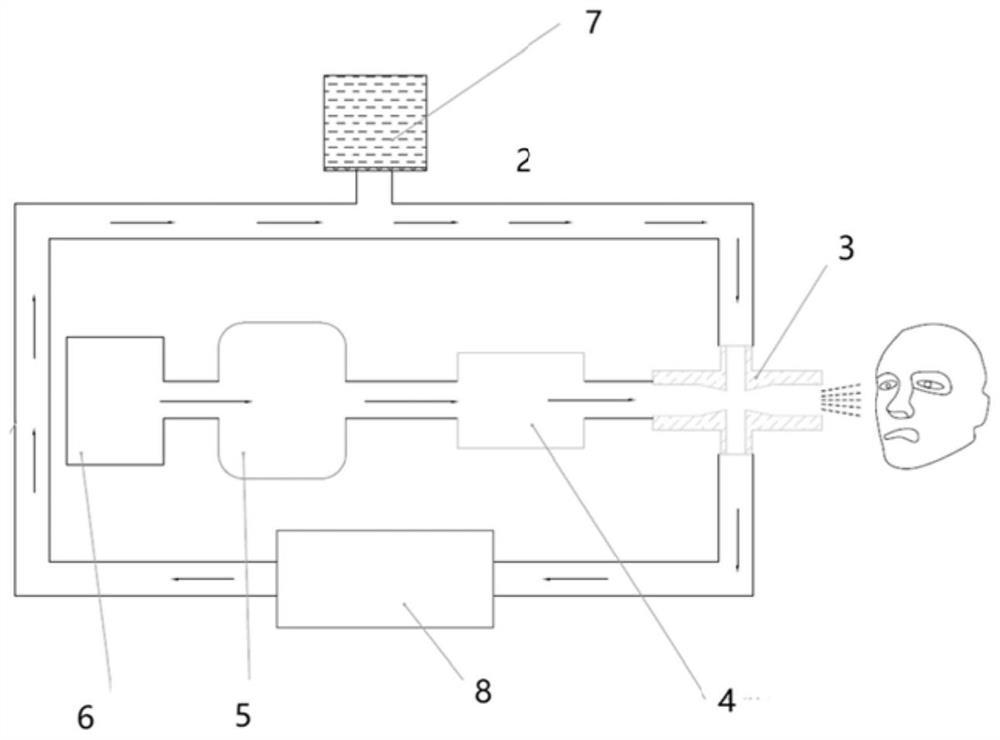

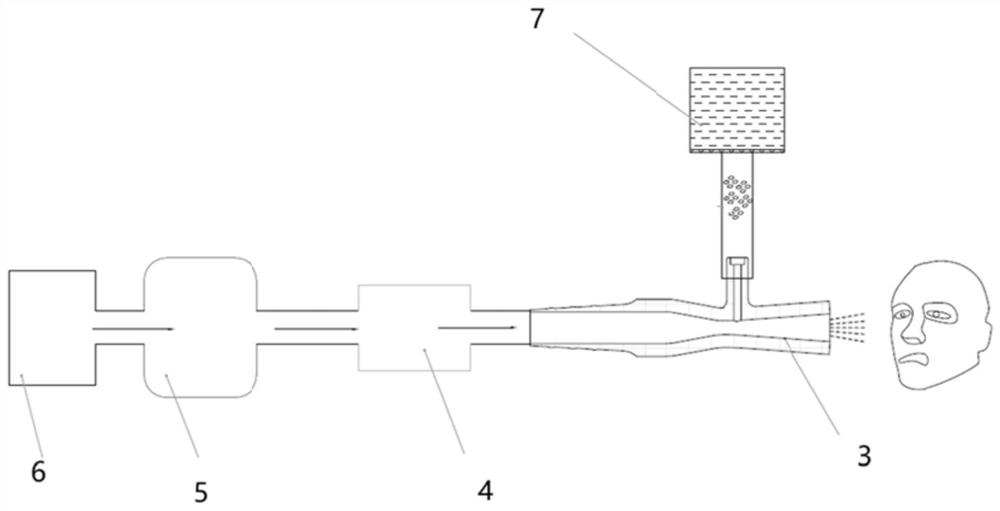

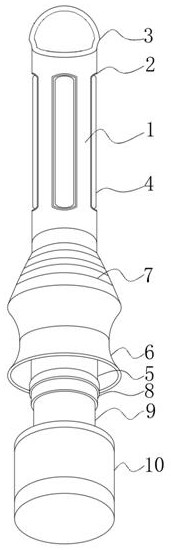

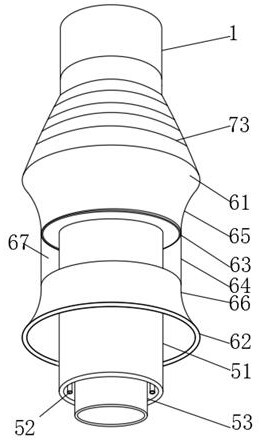

Nanometer atomization introduction beauty instrument and control method thereof

PendingCN114569882ASmall particle sizeImprove absorption and utilizationMedical devicesMedical atomisersPhysicsUltrasonic atomization

The invention relates to a nanometer atomization leading-in beauty instrument and a control method thereof. The nanometer atomization leading-in beauty instrument comprises a spray pipe, a high-pressure gas source, an essence supply device and a pipeline, one end of the spray pipe is an outlet facing a receptor to be guided in, the other end of the spray pipe is connected with a high-pressure gas source, an essence inlet is formed in the spray pipe, and a pipeline is arranged on the essence inlet and connected with an essence supply device; the essence supply device comprises a cosmetic liquid container and an ultrasonic atomization sheet, an outlet of the cosmetic liquid container is connected with the pipeline, and the ultrasonic atomization sheet is arranged at the outlet of the cosmetic liquid container. According to the scheme, the characteristics that ultrasonic atomization is uniform, the atomization particle size is small, and waste is little are adopted, atomized essence is adsorbed into the nozzle through high-pressure and high-speed airflow, atomization mixing is conducted again, and the essence is guided into the skin and reaches the basal layer of the skin in a finer and more efficient mode. By means of the efficient introduction mode, the absorption and utilization rate of the beauty liquid can be increased, and a beautifier can experience the amazing beauty effect brought by an instrument in a shorter time.

Owner:ZHEJIANG YIGE ENTERPRISE MANAGEMENT GRP CO LTD

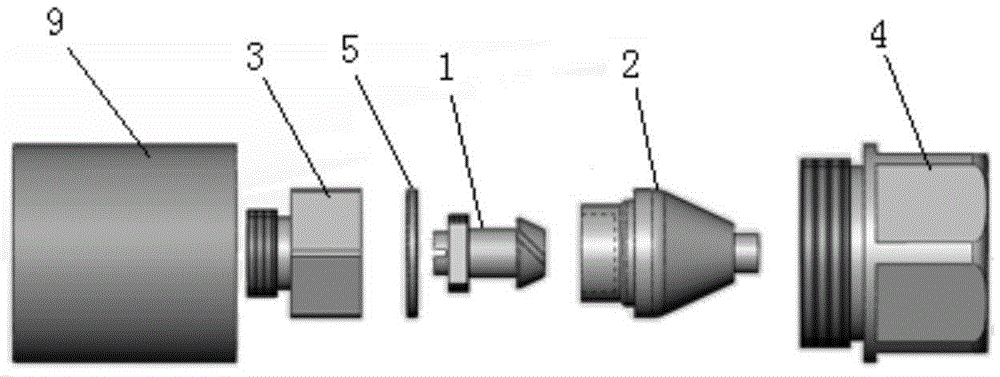

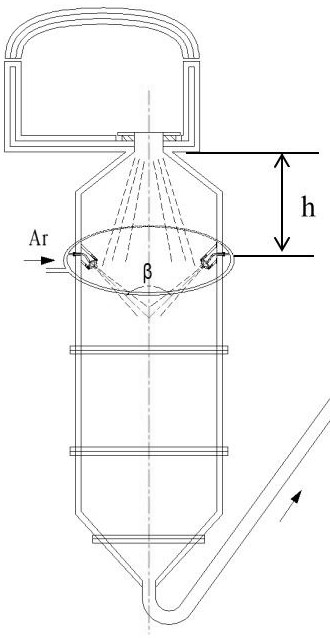

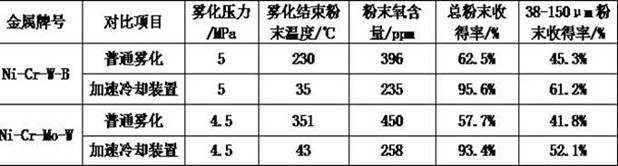

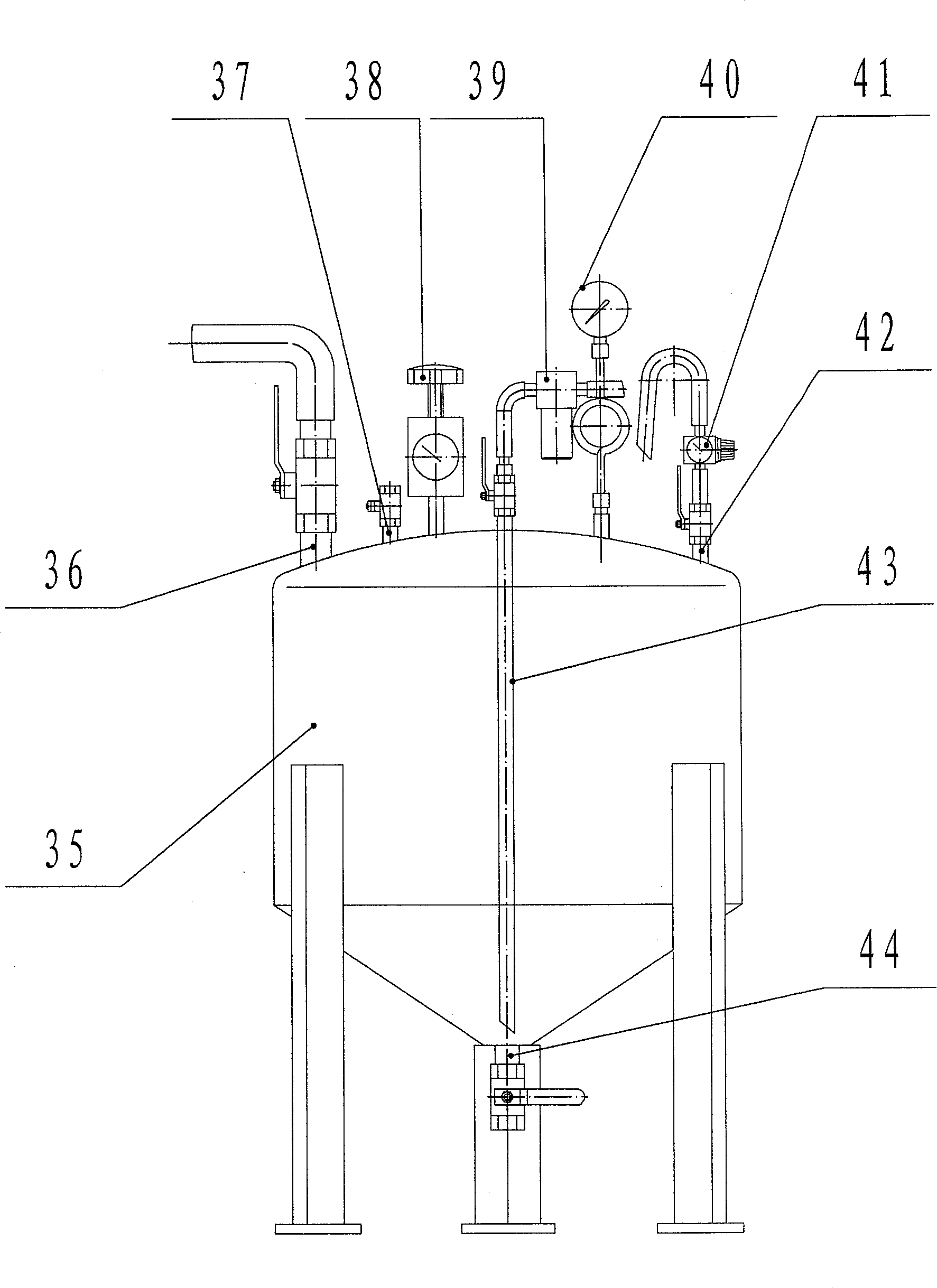

Gas atomization device and method for secondary atomization and accelerated cooling

ActiveCN111715886ARealize secondary atomizationHigh yieldIncreasing energy efficiencyStructural engineeringOxygen content

The invention discloses a gas atomization device and method for secondary atomization and accelerated cooling. The device is fixedly arranged on the furnace wall of an atomization chamber and comprises an upper support, a lower support, a nozzle, a high-pressure hose and a pipeline flange; the upper support and the lower support are fixed to the inner side of the furnace wall up and down respectively, and a plurality of screw holes are distributed on each of the upper support and the lower support; a nozzle outer sleeve is fixedly arranged between the upper support and the lower support, the nozzle outer sleeve is connected with the upper support and the lower support through adjusting bolts, the bottom of the nozzle is fixedly arranged in the nozzle outer sleeve, a hollow cavity is formedin the nozzle, the high-pressure hose penetrates through the nozzle outer sleeve to be in communication with the bottom of the nozzle, and the other end of the high-pressure hose penetrates through the furnace wall to be in communication with the pipeline flange; and the pipeline flange is fastened and sealed with a furnace wall flange on the outer side of the furnace wall through fixing bolts. The gas atomization device has the advantages that secondary atomization is carried out on liquid drops which are not sufficiently atomized for the first time, so that the yield of fine powder is increased, and the oxygen content of the powder is reduced.

Owner:ZHONGTIAN SHANGCAI ADDITIVE MFG CO LTD

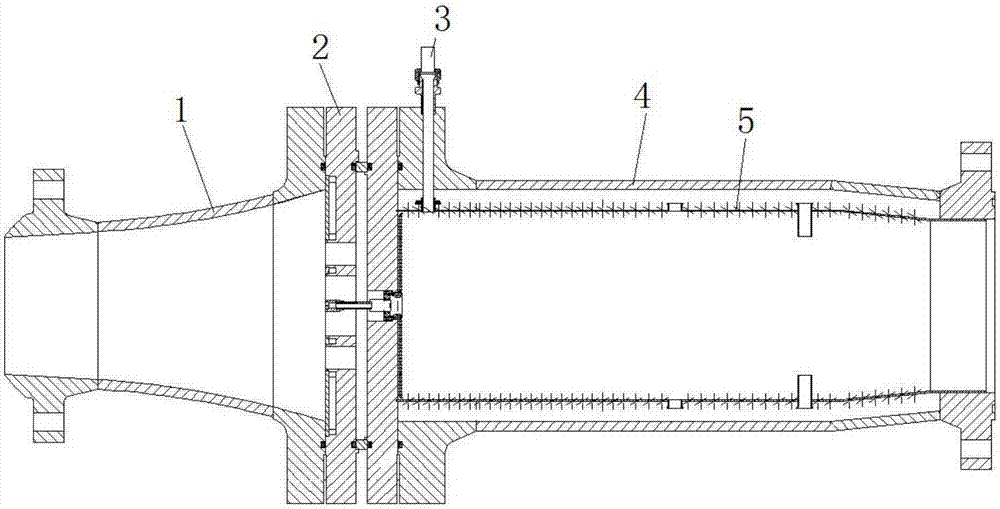

A multi-stage atomization type two-phase flow fine water mist generating device for preventing and controlling coalfield fires

ActiveCN105715292BAchieve atomizationEasy to operateDust removalFire preventionFire controlDouble phase

A multi-stage atomization type two-phase flow water mist generation device for controlling a coal field fire is suitable for managing a coal-rock cavity high-temperature zone in a large-area coal field fire zone.The device comprises a pressure water supply pipe, a multi-hole nozzle and a jet flow atomization barrel.An impact atomization chamber, a mixing acceleration chamber and a diffusion jet chamber are arranged in the jet flow atomization barrel in sequence.The end, close to the multi-hole nozzle, of the impact atomization chamber is provided with a hemispheric inner wall, and the inner wall is provided with a slant conical air suction hole so that the impact atomization chamber can be communicated with the external environment.Pressure water supplied by the pressure water supply pipe is preliminarily atomized through the multi-hole nozzle; external air is automatically sucked into the impact atomization chamber under negative pressure generated by jet flow of the nozzle to collide with mist flow formed in preliminary atomization, and secondary atomization is achieved; then, the mist flow and the air are further mixed and rubbed in the mixing acceleration chamber, and atomization is performed again; then, the atomized water is jetted to a coal field fire control zone through the diffusion jet chamber.The device does not need an additional compressed air system and is compact and simple in structure, safe, reliable, easy to operate, high in portability and high in atomization degree.

Owner:CHINA UNIV OF MINING & TECH

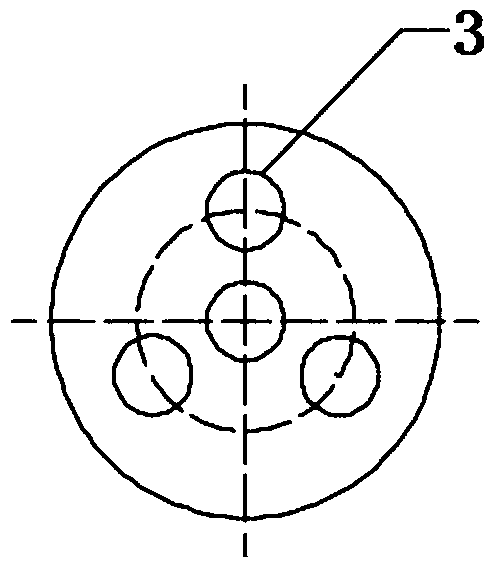

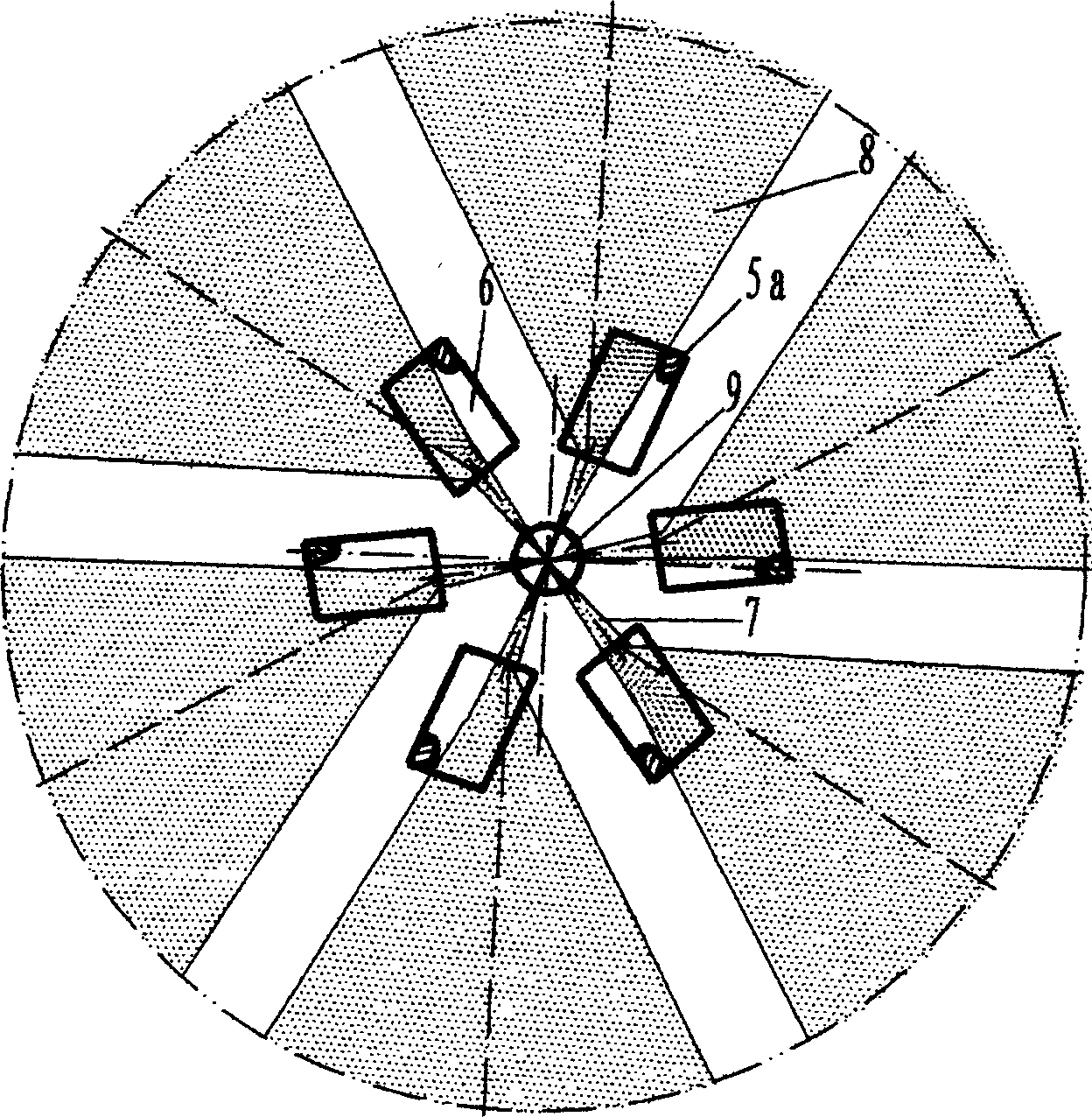

Guide blade combustion system of internal combustion engine

InactiveCN1271328CImprovements in emission indicatorsEmission reductionFuel injection apparatusMachines/enginesCombustion systemCombustion

A combustion system with guide blade for IC engine features that the guide blades are arranged under the oil nozzle. When the oil beam is sprayed onto the guide blades, its surface can quickly spread it for realizing secondary atomizing. Its advantages are uniform high-quality atomizing, and high combustion speed.

Owner:DALIAN UNIV OF TECH

A labyrinth type supergravity liquid-liquid extraction separator

InactiveCN104815459BLarge mass transfer areaWell mixedLiquid solutions solvent extractionImpellerElectric machinery

The invention discloses a labyrinth type supergravity liquid-liquid extraction separator, which comprises a shell, a packing spiral tube, a mixing mass transfer mechanism, a separation and collection mechanism, a top cover plate, a base, a bearing seat sleeve, a shaft, and a motor; The mass mechanism includes a feeding planetary impeller mixing device, a mass transfer device, and a conical grinding wheel, and the mass transfer device is set between the feeding planetary impeller mixing device and the conical grinding wheel; the separation and collection mechanism includes a phase separation tank, an elastic switch , collection tank; the device of the present invention takes into account the two-phase separation while realizing high-efficiency extraction, the multi-layer packing structure increases the mass transfer area of the two-phase liquid, the complex packing layer structure makes the mixing more uniform, prolongs the reaction time, and improves the Extraction rate; The separation and collection mechanism, as an important component of the extraction process, realizes the integration of extraction and separation.

Owner:KUNMING UNIV OF SCI & TECH

A mine-used Fengshui matching scattering type dust removal device

ActiveCN107654253BAchieve securitySmall particle sizeDust removalFire preventionEngineeringHigh pressure water

Disclosed is a mining geomancy-matched scattering-type dust removing device. The mining geomancy-matched scattering-type dust removing device consists of a spraying annular cylinder, an atomizing nozzle, an air sending cylinder body, a rotating bracket and a telescopic bracket. The air inlet end of the air sending cylinder body is connected with an air sending hose. The air outlet end of the air sending cylinder body is provided with a metal head plug. Two rings of annular air seams of different directions are formed in the periphery of the metal head plug. The air sending cylinder body is externally provided with the spraying annular cylinder body in a sleeved mode. The water outlet end of the spraying annular cylinder body is provided with the atomizing nozzle. The water inlet end of therear part of the spraying cylinder body is connected with a high-pressure water inlet pipe. The air inlet hose and the high-pressure water inlet pipe are each provided with an air pressure gauge, a water pressure gauge and an adjusting valve. A filter net is arranged at the front end of the high-pressure water inlet pipe. Fast joints are arranged at an air inlet of the air inlet hose and a waterinlet of a high-pressure hose. The height of a bracket can be vertically adjusted, and adjusting is convenient according to the scene situation. The mining geomancy-matched scattering-type dust removing device is small in size, good in atomizing effect, simple in operation and convenient to use, can be flexibly installed in every dust outburst position in a mine, and is suitable for underground coal mine dust removing work.

Owner:TAIYUAN UNIV OF TECH

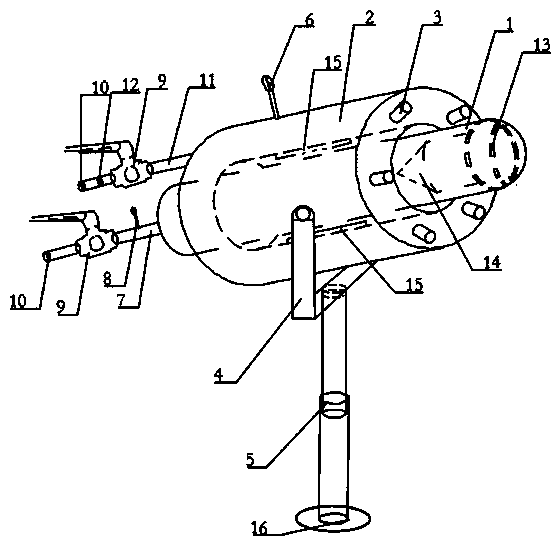

Vertical rotary spraying type seed dressing machine

InactiveCN100553426CExtension of timeFull spray coatingSeed coating/dressingSurface spreadingAgricultural engineering

Owner:江苏优科植物保护有限公司

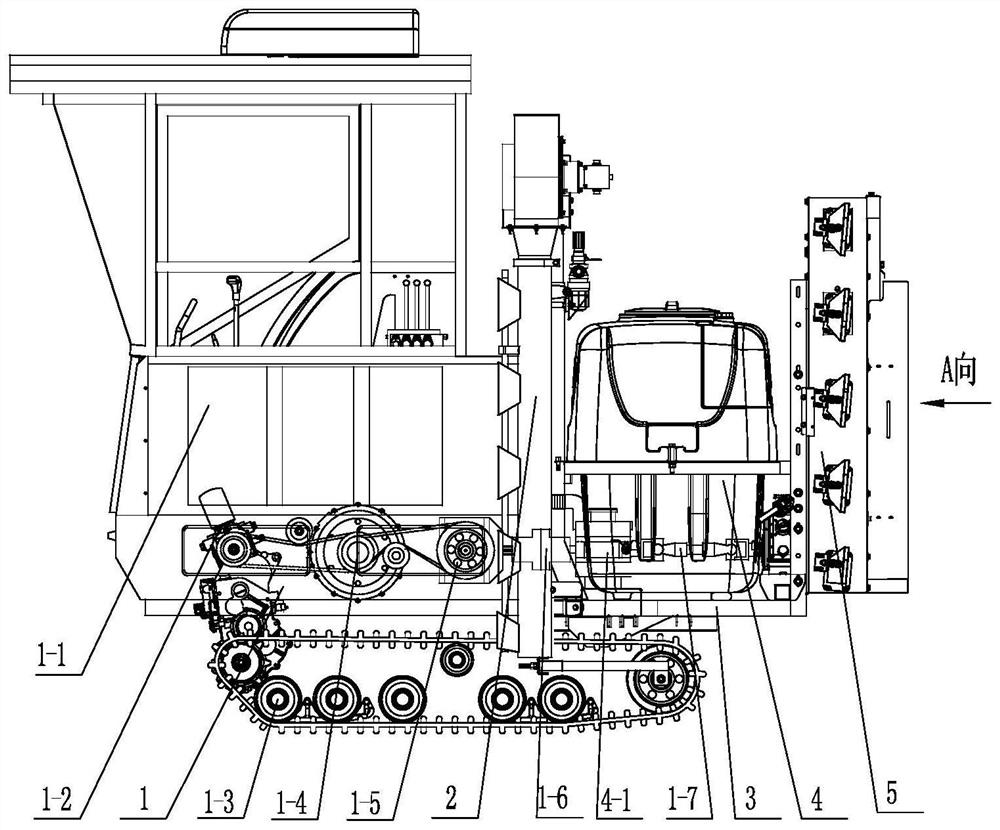

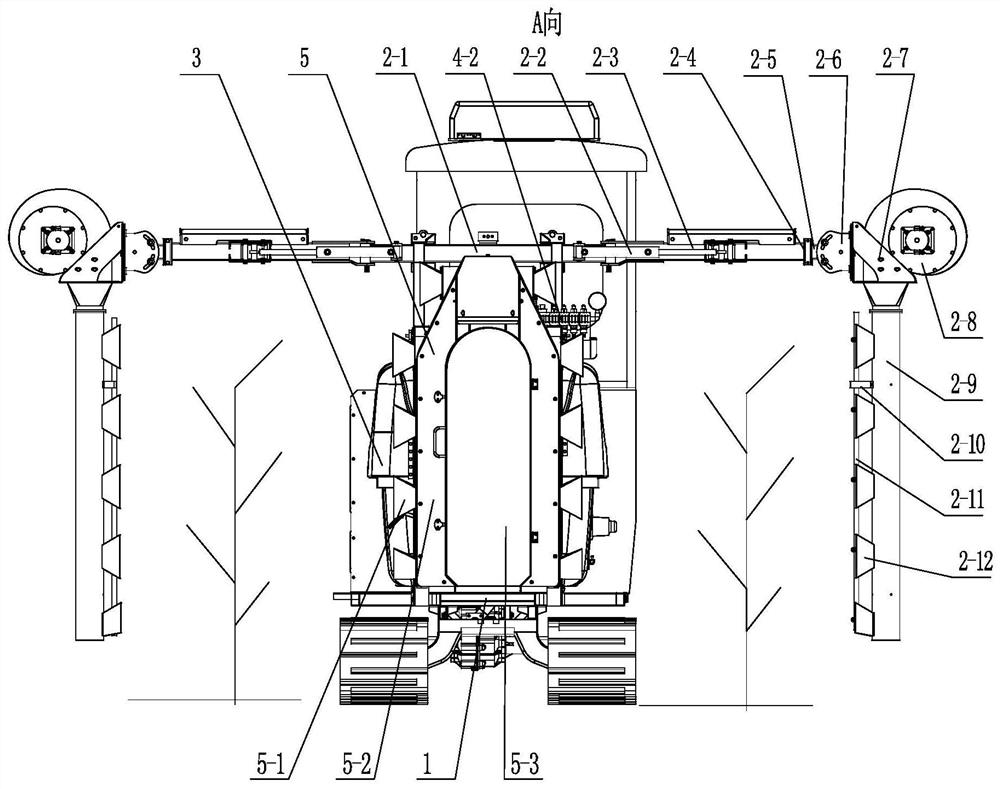

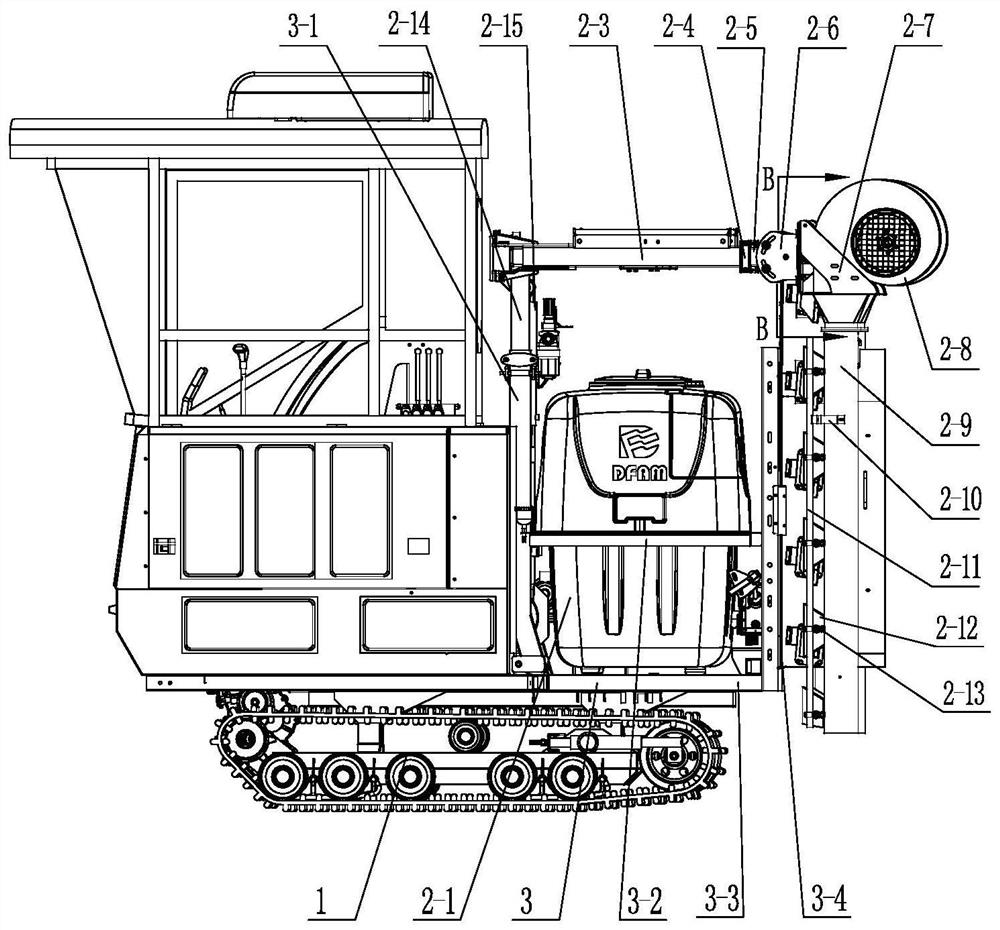

Track mounted grape sprayer

ActiveCN106508864BAdjustable angleImprove adhesionInsect catchers and killersSprayerAgricultural engineering

The invention relates to a crawler-suspended grape sprayer, which comprises a crawler-type chassis and a frame installed on the crawler-type chassis. A liquid delivery mechanism is installed on the frame; the liquid delivery mechanism includes a medicine box and a control pump connected to the frame, and the fixed air supply spray mechanism includes an air chamber, a fan blade assembly arranged in the air chamber, and a plurality of movable air outlet hoods and drives. Mechanism, the suspension air spraying mechanism includes a cantilever assembly and two groups of air supply assemblies that can be adjusted along the cantilever assembly. The invention has a reasonable and compact structure, the spraying area is on the inner, upper and outer sides of the two rows of grapes, and the air is supplied in the vertical direction on both sides of the inner and outer sides at the same time, and the angle of the air supply can be adjusted conveniently, which can meet the needs of grape crops in each growth cycle. Apply pesticides evenly on the upper, middle and lower layers.

Owner:CHANGZHOU DONGFENG AGRI MACHINERY GROUP

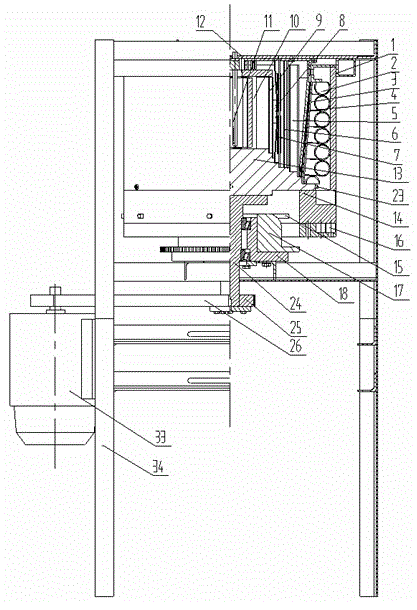

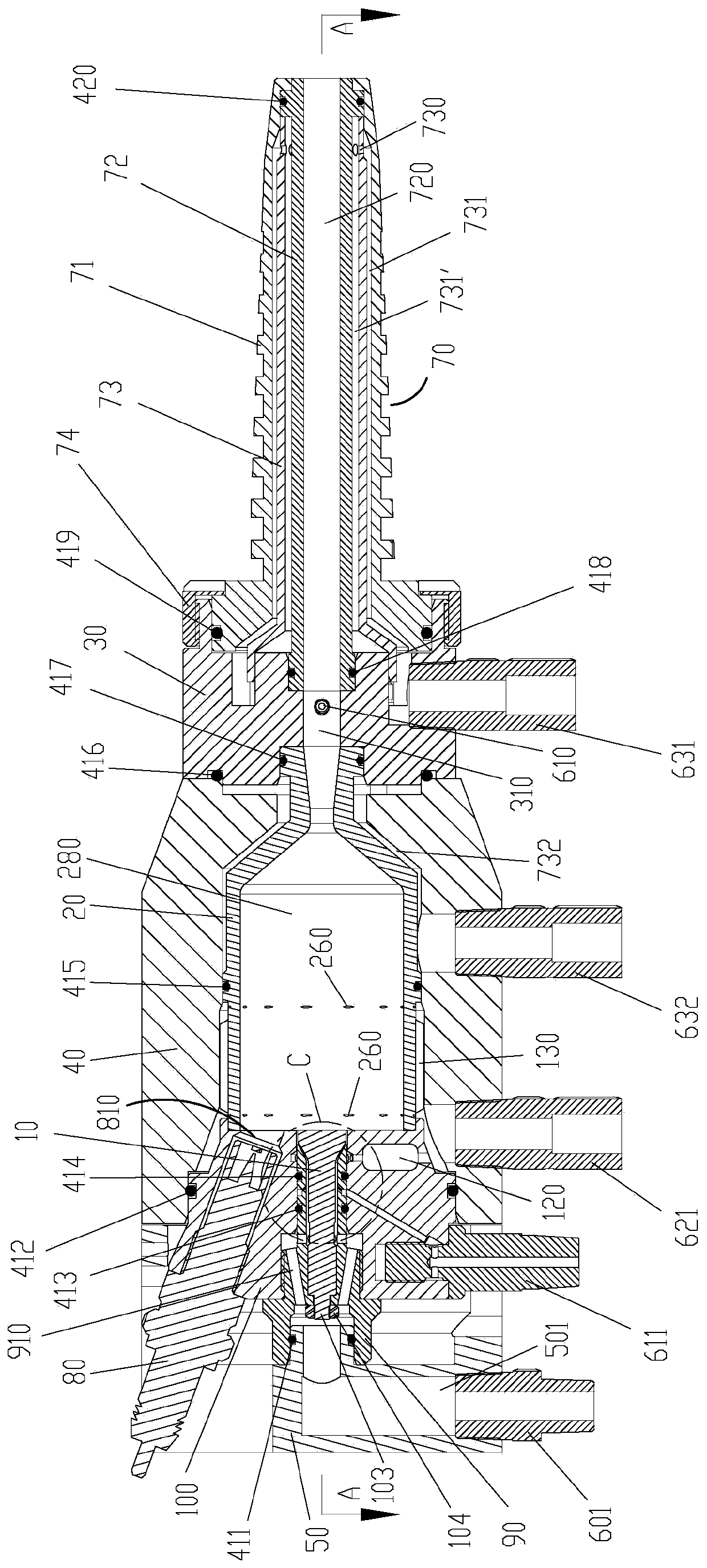

A low-temperature high-speed flame spray gun

ActiveCN111549309BRealize secondary atomizationAvoid burnsMolten spray coatingCombustion chamberEngineering

The invention discloses a low-temperature high-speed flame spraying gun. A combustion chamber is installed in the outer gun body. The outer gun body head installs the gun barrel body through the intermediate connecting body. The powder feeding nozzle is installed on the intermediate connecting body. The entrance of the combustion chamber is sealed by a head cover of the combustion chamber, a central cone is arranged through the head cover of the combustion chamber, and a fuel nozzle is sheathed outside the central cone. A trumpet-shaped annular oxygen / fuel channel is formed between the fuel nozzle and the center cone body, and an annular primary nitrogen mixing straight channel is formed between the center cone head and the head cover of the combustion chamber. There is a spark plug on the combustion chamber head cover. The outer gun body tail cover is installed at the outer gun body tail. An oxygen inlet joint communicated with the oxygen / fuel passage is installed on the tail cover of the outer gun body. A fuel injection joint communicating with the oxygen / fuel passage is installed on the combustion chamber head cover. A nitrogen inlet joint communicated with the primary nitrogen mixing straight passage and the secondary nitrogen injection eccentric hole is installed on the outer gun body. The invention can obtain a high flame flow velocity, and can make the flame flow temperature within a reasonable low temperature range and be greatly adjustable.

Owner:NAT INNOVATION INST OF DEFENSE TECH PLA ACAD OF MILITARY SCI

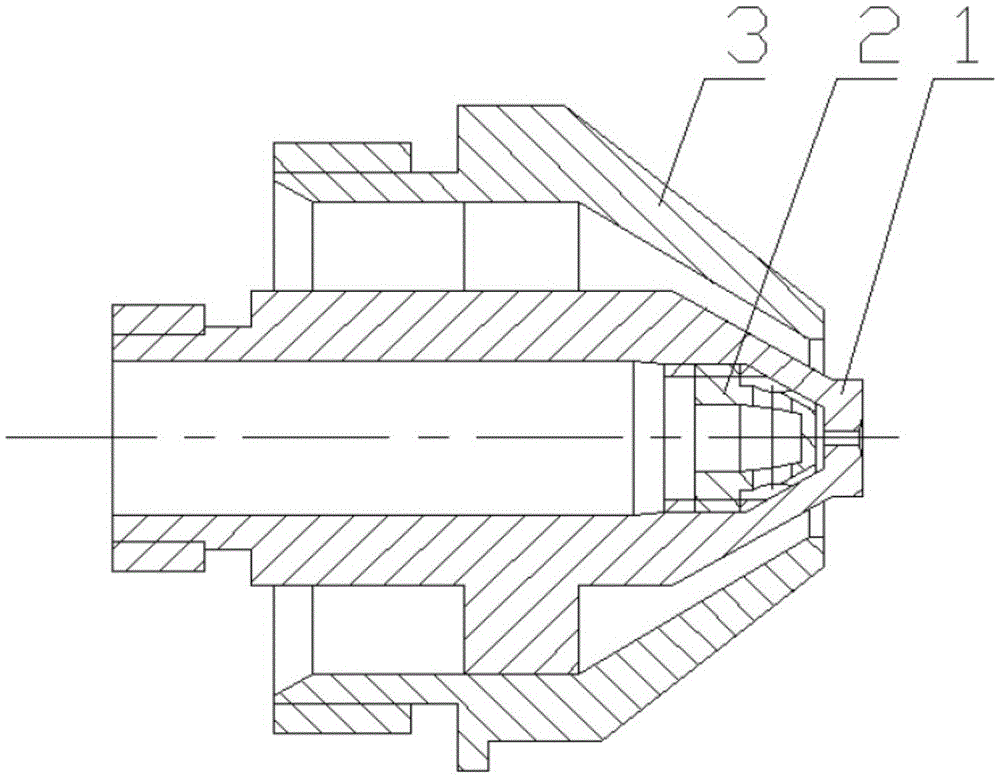

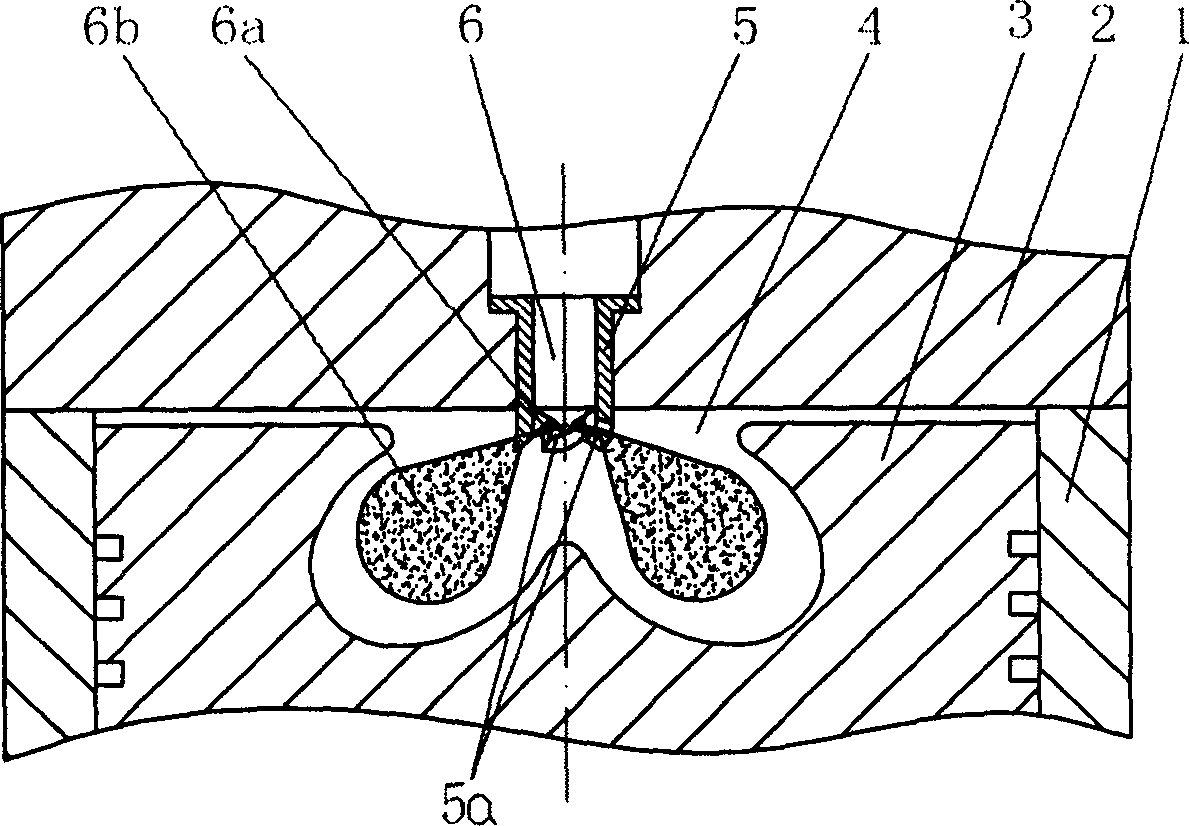

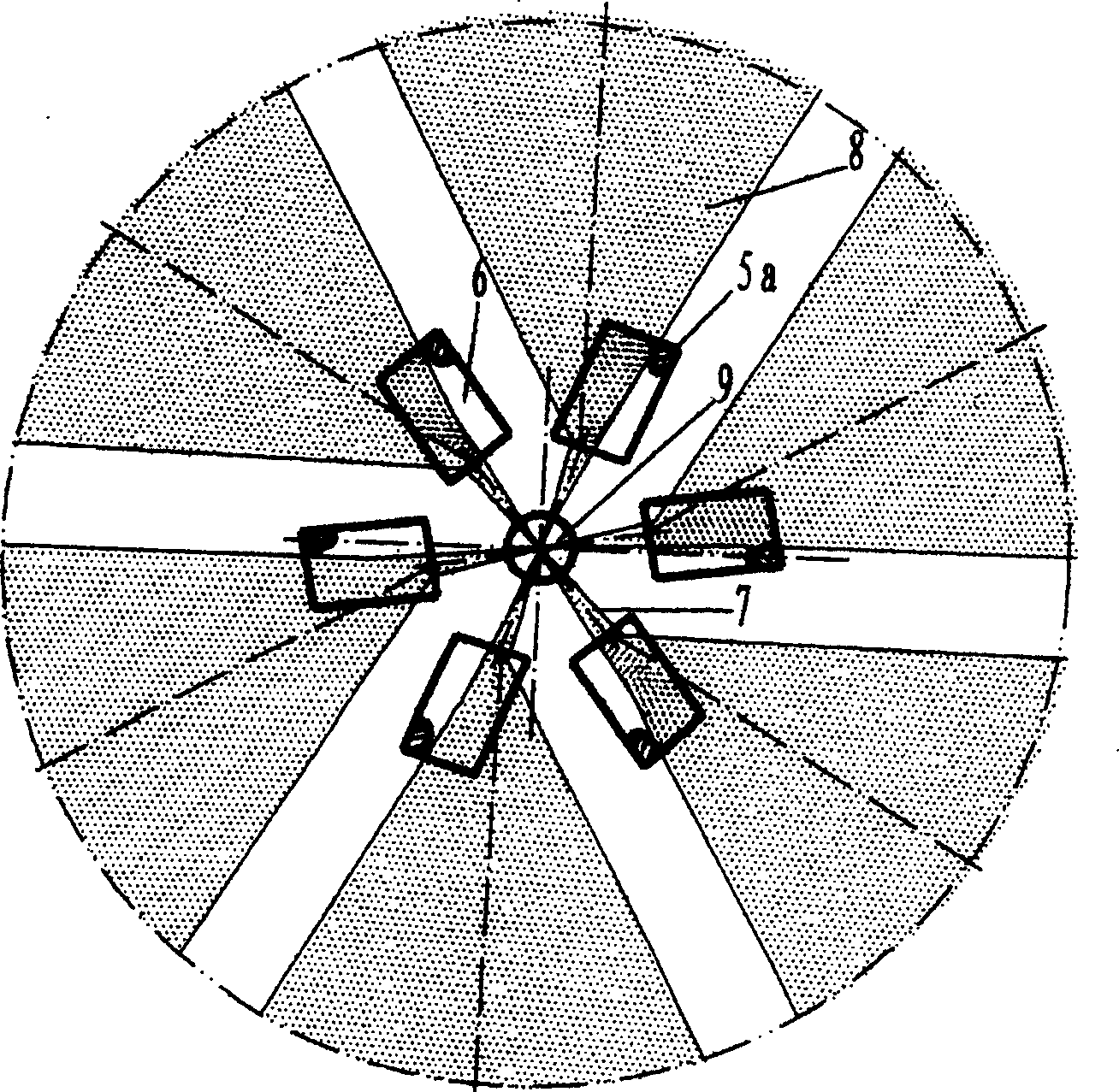

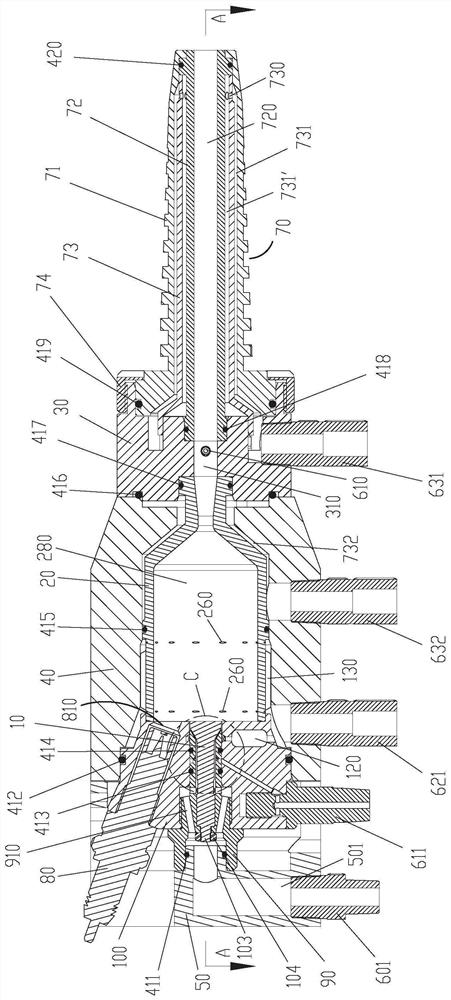

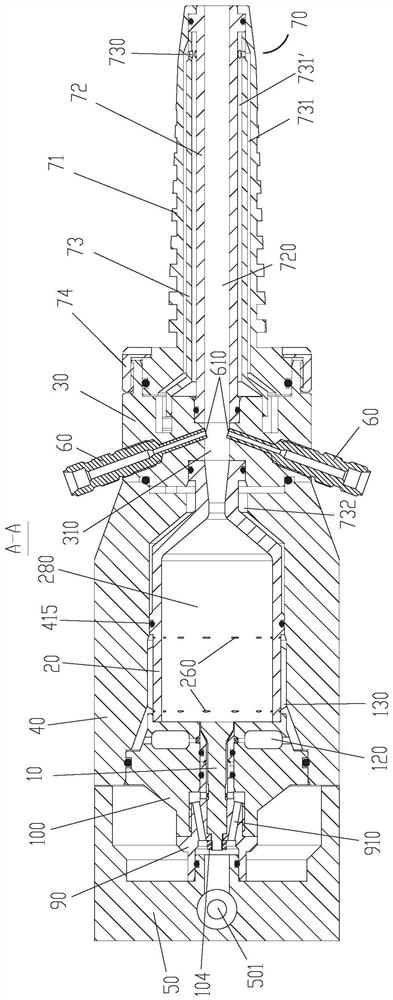

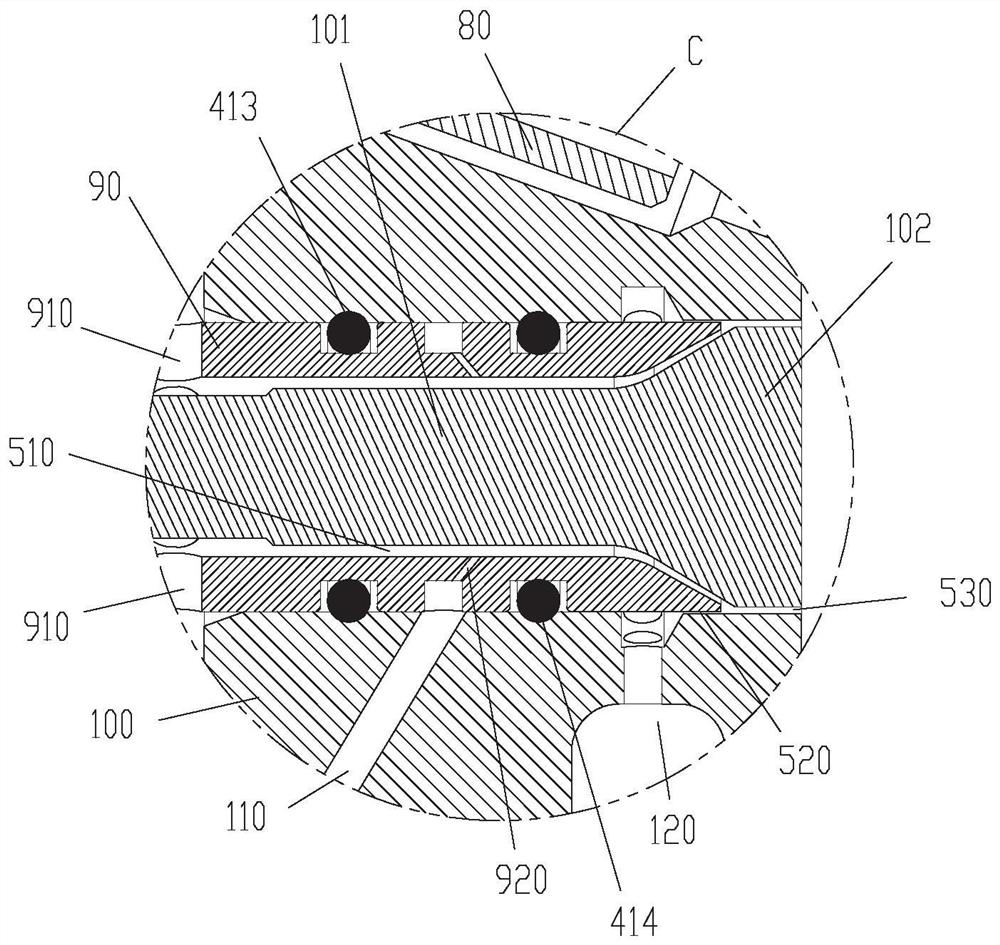

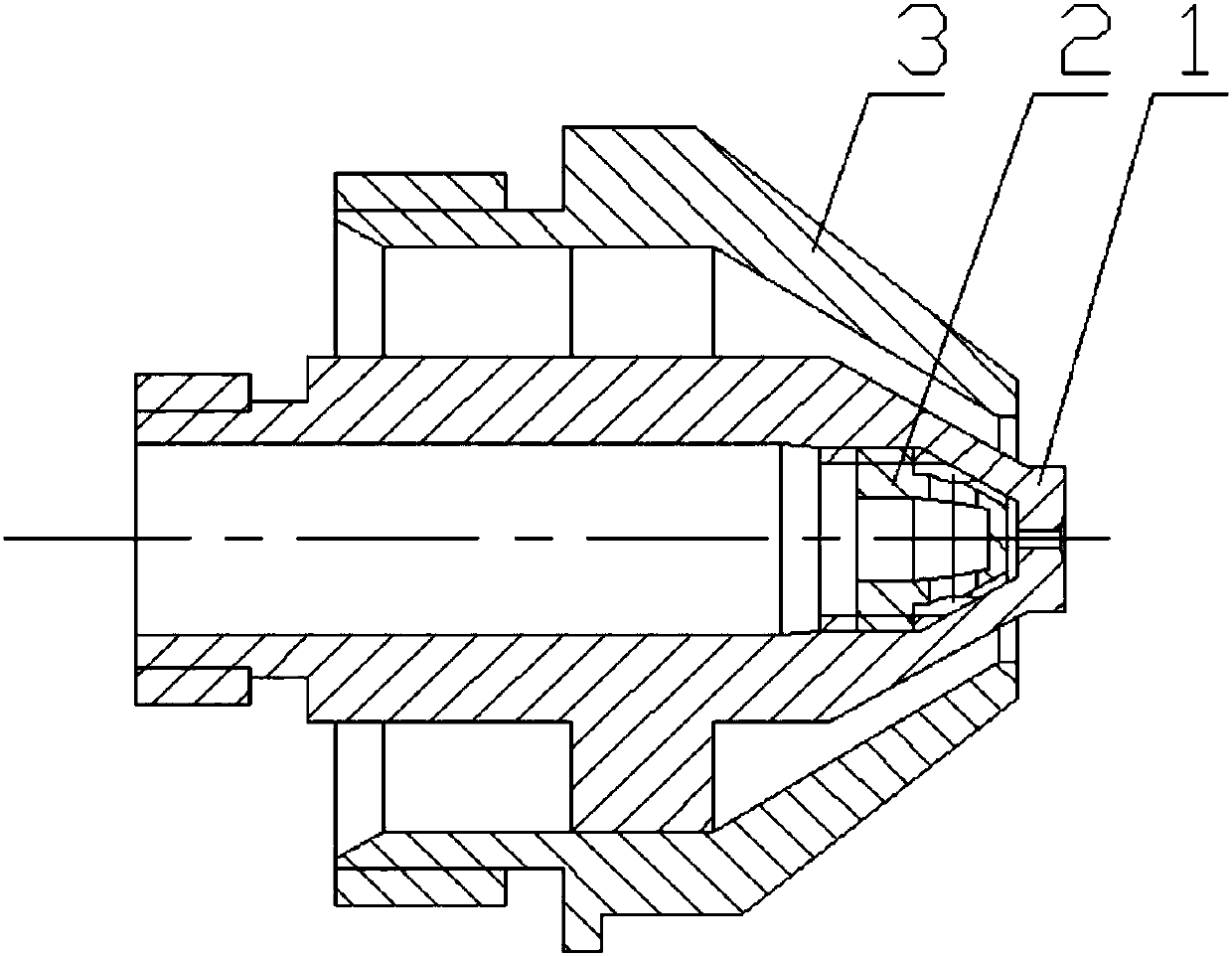

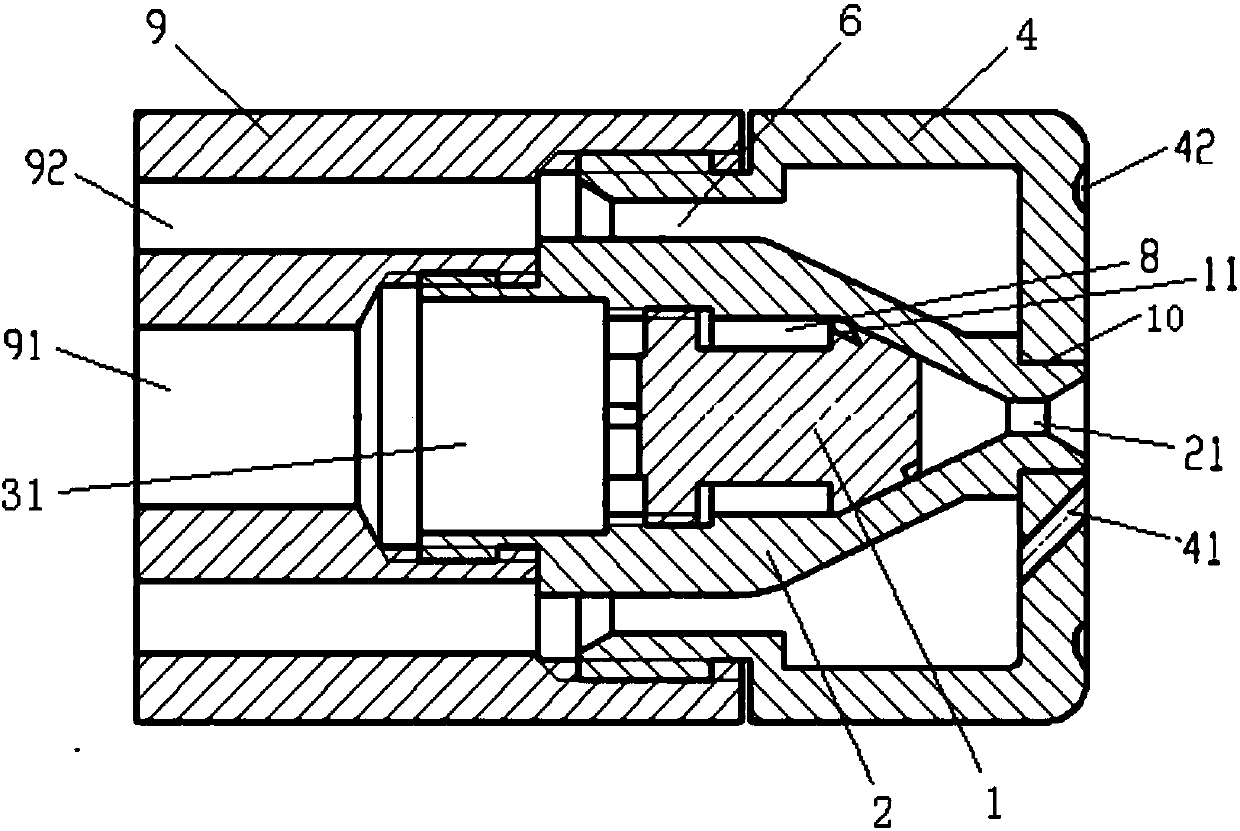

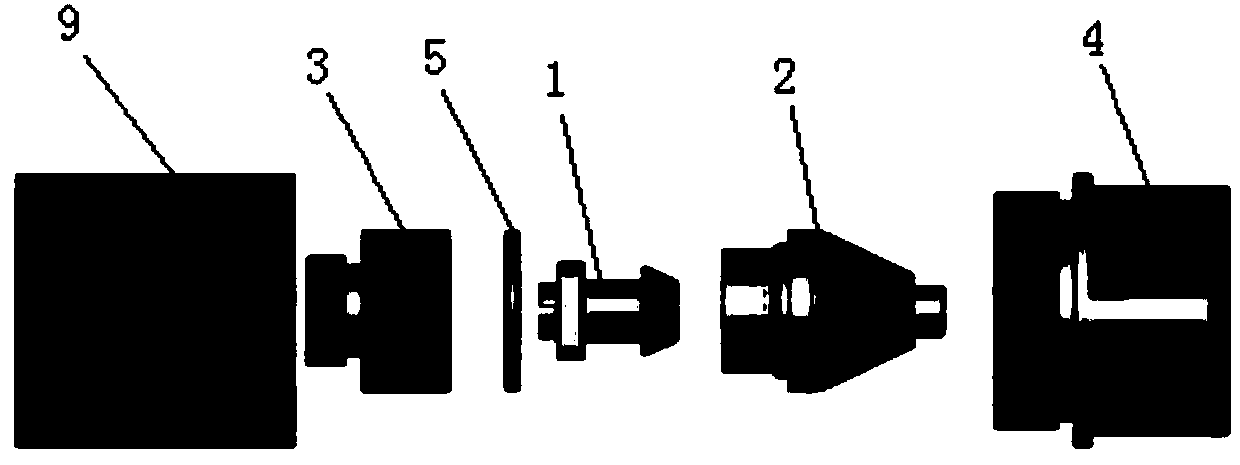

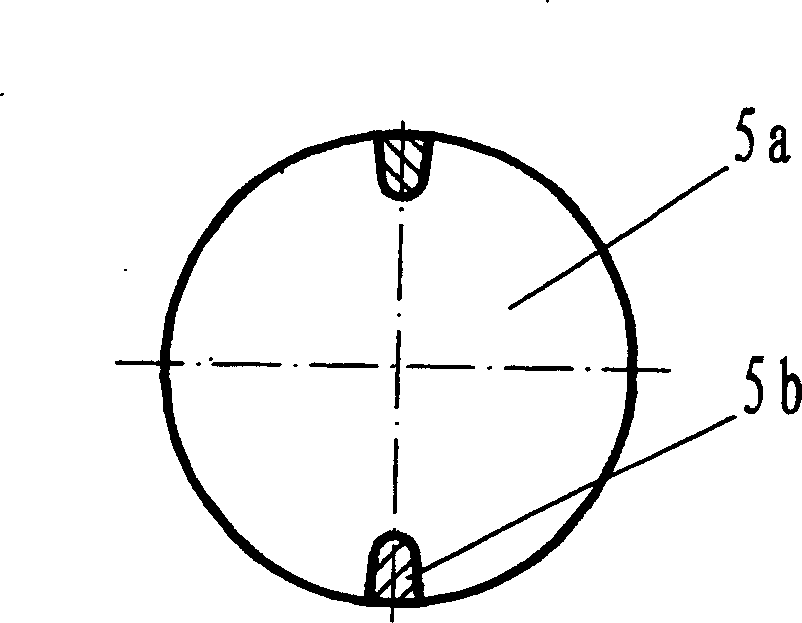

Novel centrifugal nozzle of combustion chamber of gas turbine

InactiveCN112879950ABlow out in favor ofBlow out guaranteeContinuous combustion chamberCombustion chamberFuel oil

The invention discloses a novel centrifugal nozzle of a combustion chamber of a gas turbine. Compared with a common centrifugal nozzle, the nozzle is characterized in that two paths of rotating fuel oil pass through oil path holes and are finally collided and broken at a certain part of a contraction section through rotation constraint of swirlers on double oil paths, primary atomization is achieved, the fuel oil is blown out of the nozzle through a middle air hole of an air passage finally, secondary atomization is achieved, and the atomization effect is enhanced finally. The swirlers of a main oil path and an auxiliary oil path are identical in rotating direction, it is guaranteed that two paths of fuel oil rotate and collide at the contraction section, the good atomization and crushing effect is achieved, the good atomization effect of the nozzle is beneficial to organized combustion in the combustion chamber of the gas turbine, the combustion condition can be enhanced, and the combustion efficiency is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

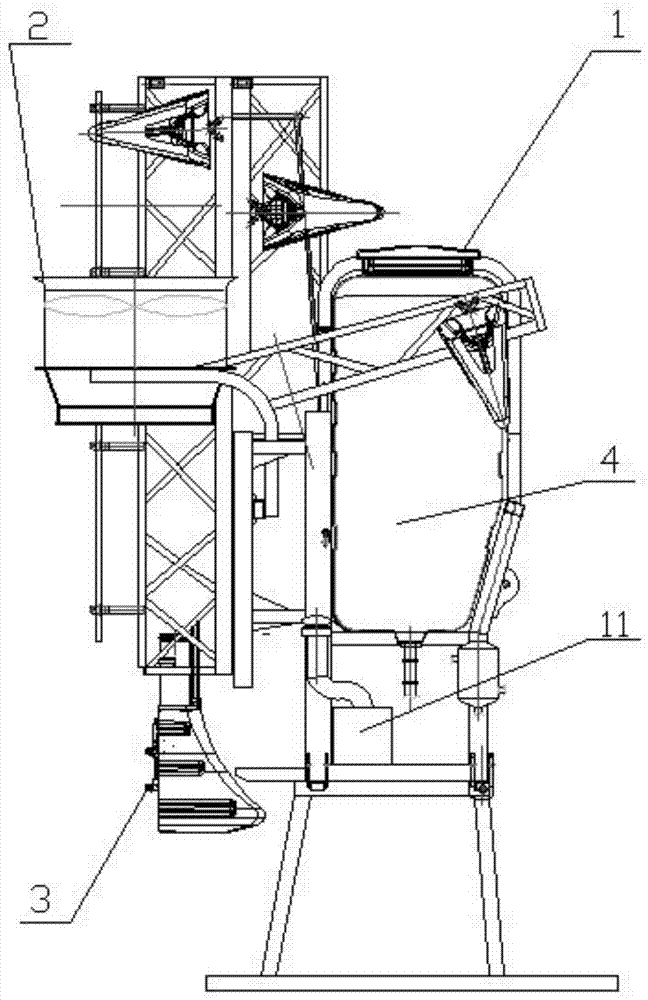

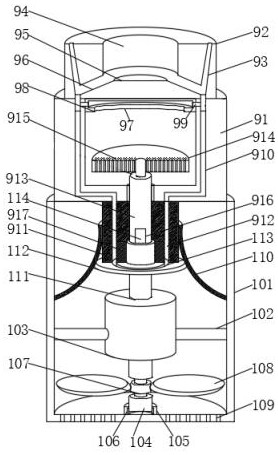

Supergravity type diesel engine tail gas collaborative purification device

InactiveCN111715072AImprove the mixing effectEnhanced mass transferEngine sealsGas treatmentDieselingEngineering

The invention discloses a supergravity type diesel engine tail gas collaborative purification device. The device adopts a rotating packed bed to enhance the gas-liquid mixing capacity and strengthen gas-liquid mass transfer, can achieve collaborative purification of various pollutants and is high in tail gas purification efficiency. A rotating shaft is a partially hollow shaft, a nozzle is installed in the hollow part of the shaft, and an absorption liquid enters the nozzle from the hollow part. The absorption liquid is sprayed out from nozzle spray holes through the rotation of the shaft to realize primary atomization, and then enters the rotary packed bed to form a supergravity state, so that secondary atomization is realized, and the absorption liquid is mixed with tail gas. A static liquid supply pipe and a rotating hollow shaft in the device are in contact connection through a rubber cover bearing, and the outer end face of the rotating shaft is fixed through a rubber cover and ascrew. A baffle is arranged on the right side of the rotor and can prolong the residence time of gas in a reactor. The purification device is provided with a damping device, and a tail gas inlet is connected by adopting a flexible body, so that the applicability of the tail gas purification device on a ship is greatly enhanced.

Owner:NANTONG UNIVERSITY

Low-temperature high-speed flame spraying gun

ActiveCN111549309ARealize secondary atomizationAvoid burnsMolten spray coatingCombustion chamberNitrogen gas

The invention discloses a low-temperature high-speed flame spraying gun. A combustion chamber is installed in an outer gun body. A gun barrel body is mounted at the head of the outer gun body througha middle connecting body. A powder feeding nozzle is mounted on the middle connecting body. A combustion chamber inlet is sealed through a combustion chamber head cover, a center cone penetrates through the combustion chamber head cover, and the center cone is sleeved with a fuel nozzle. A horn-shaped annular oxygen / fuel channel is formed between the fuel nozzle and a center cone body, and an annular primary nitrogen mixing straight channel is formed between a center cone head and the combustion chamber head cover. A spark plug is arranged on the combustion chamber head cover. An outer gun body tail cover is installed at the tail of the outer gun body. An oxygen inlet joint communicating with the oxygen / fuel channel is mounted on the outer gun body tail cover. A fuel injection joint communicating with the oxygen / fuel channel is mounted on the combustion chamber head cover. A nitrogen inlet joint communicating with the primary nitrogen mixing straight channel and a secondary nitrogeninjection eccentric hole is mounted on the outer gun body. According to the low-temperature high-speed flame spraying gun, a high flame flow speed can be obtained, and the flame flow temperature canbe in a reasonable low-temperature range and can be greatly adjusted.

Owner:NAT INNOVATION INST OF DEFENSE TECH PLA ACAD OF MILITARY SCI

Atomizer for uterus cold treatment in obstetrics and gynecology department

The invention discloses an atomizer for uterus cold treatment in the obstetrics and gynecology department, and belongs to the technical field of medical instruments. The atomizer for uterus cold treatment in the obstetrics and gynecology department comprises an inserting rod, three windows are formed in the side surface of the inserting rod at equal intervals, spraying plates are arranged in the windows in a sleeved mode, and the top of the inserting rod communicates with a spherical spraying head. According to the atomizer, the inserting rod is used, the inserting rod is of a columnar design and is made of a medical flexible silica gel material, and the outer end of the spherical spraying head is of a conical head, so that the inserting is more convenient to insert into the vagina of a patient, the vagina can be slowly dilated, and pain and injury in the inserting process are reduced; the silica gel material has elasticity, comfort of the patient in the treatment process can be improved, and liquid medicine sprayed by the spherical spraying head is in an umbrella shape and can be attached to the uterus and the cervix uterus; and the three spraying plates are additionally arranged, so that the effective attachment rate in the uterus can be improved.

Owner:王濛晗

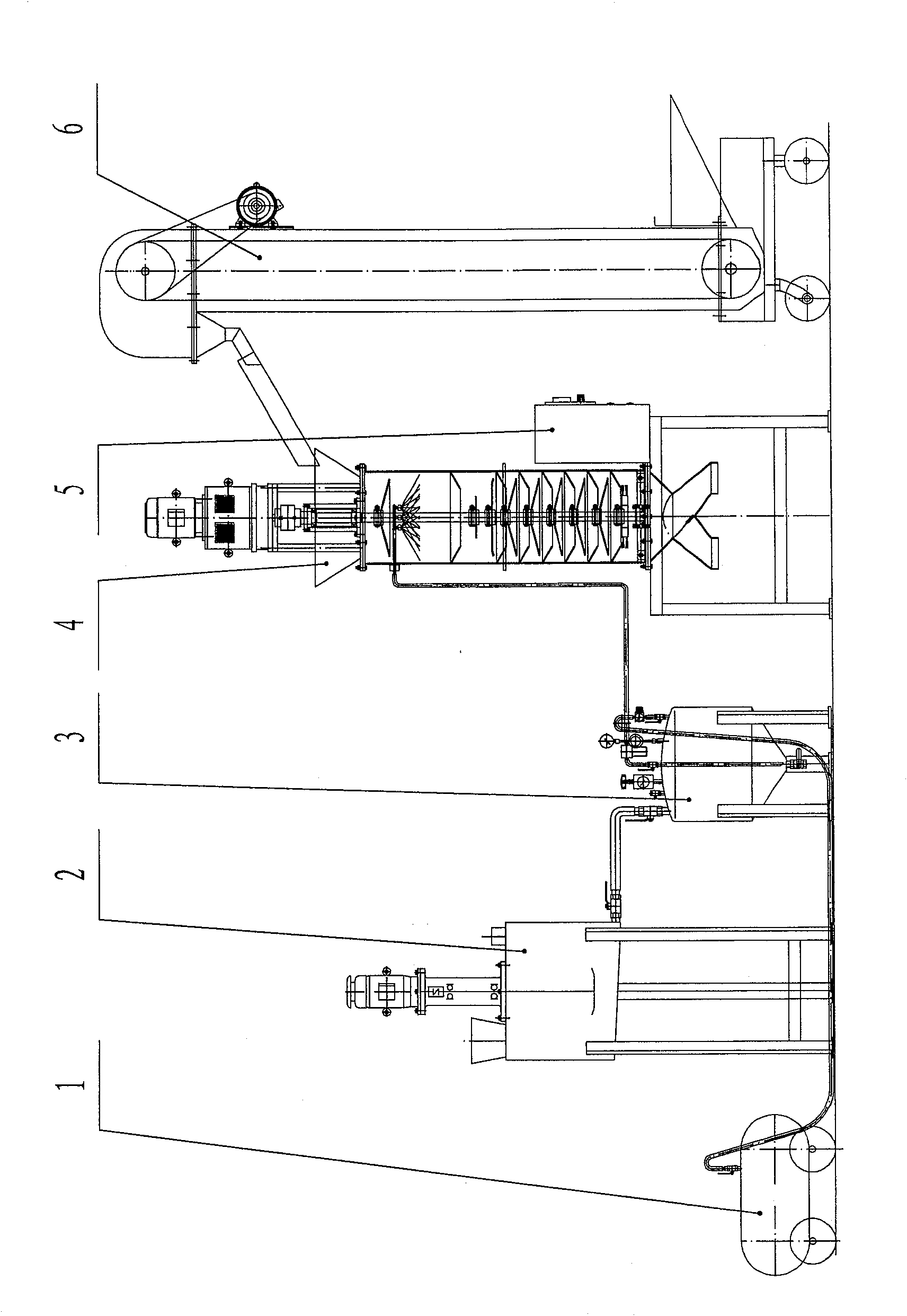

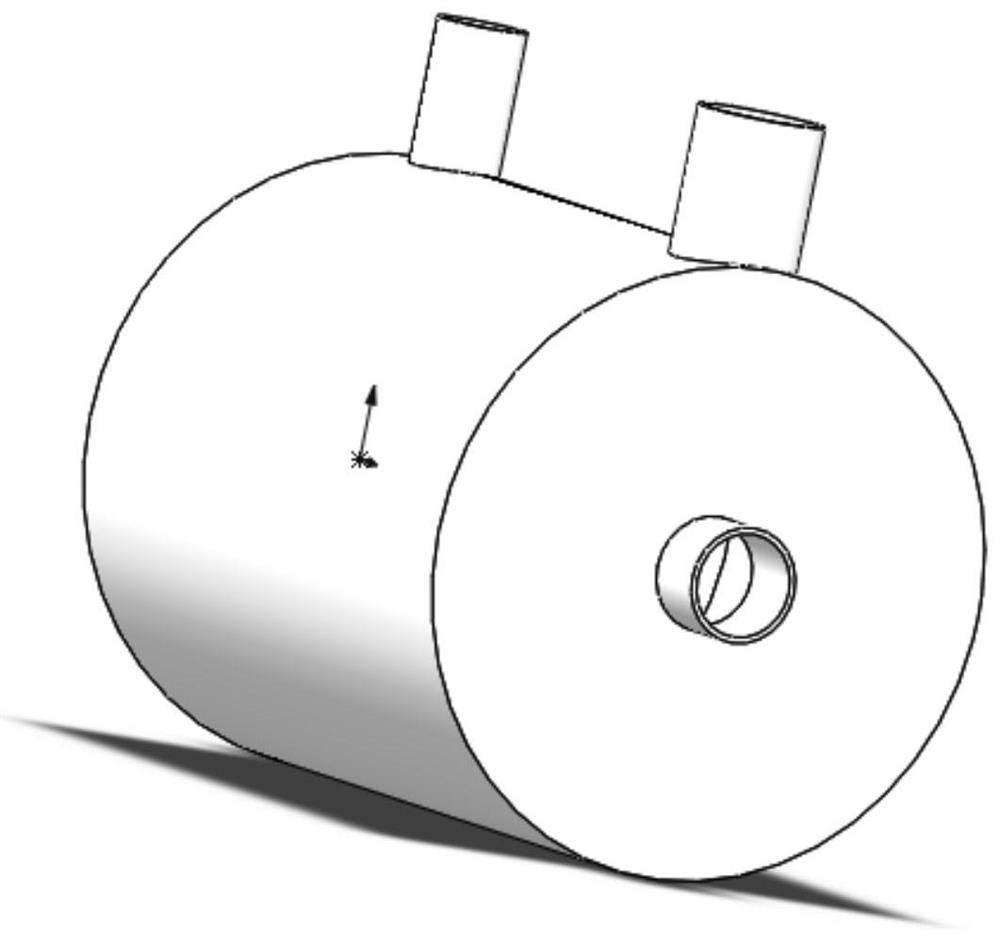

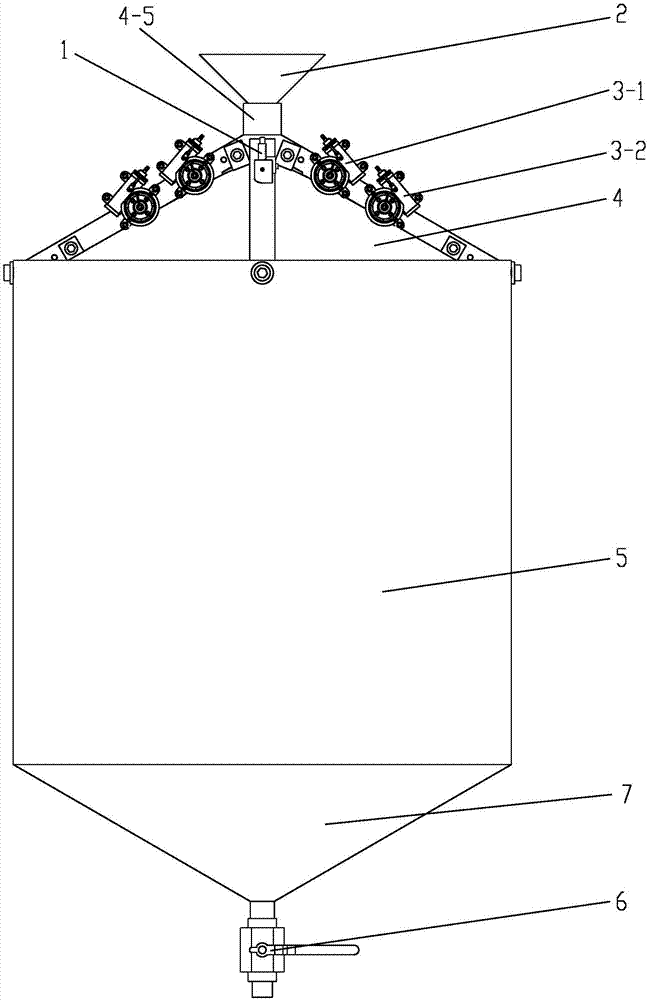

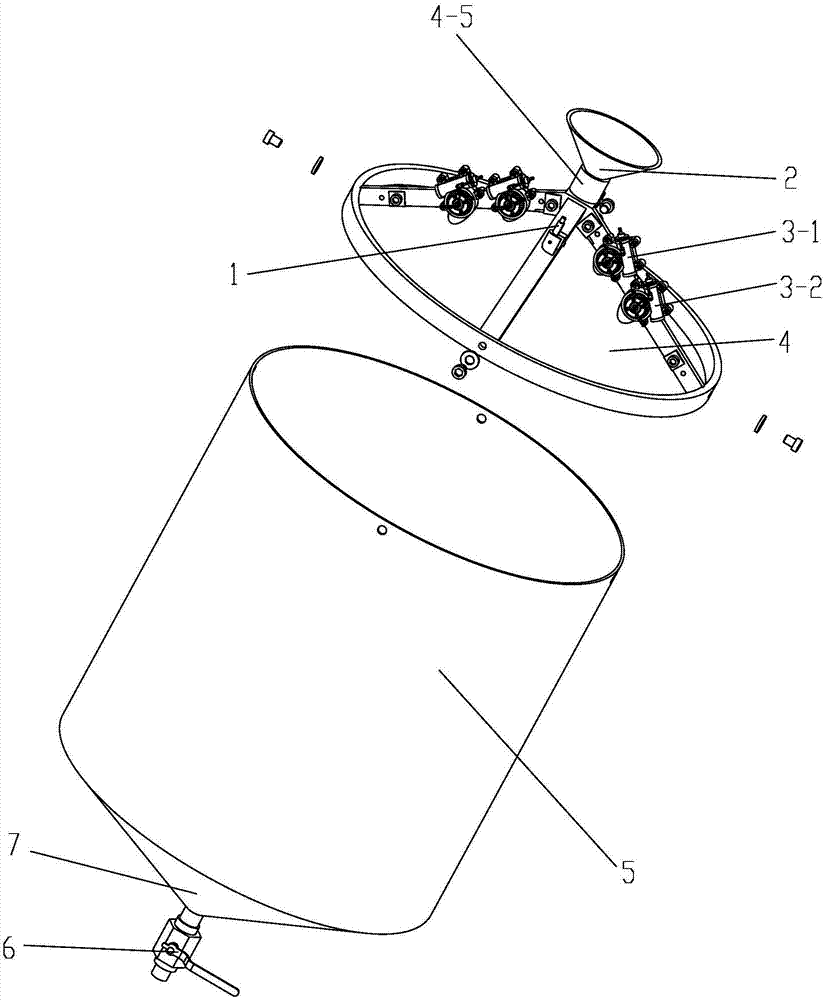

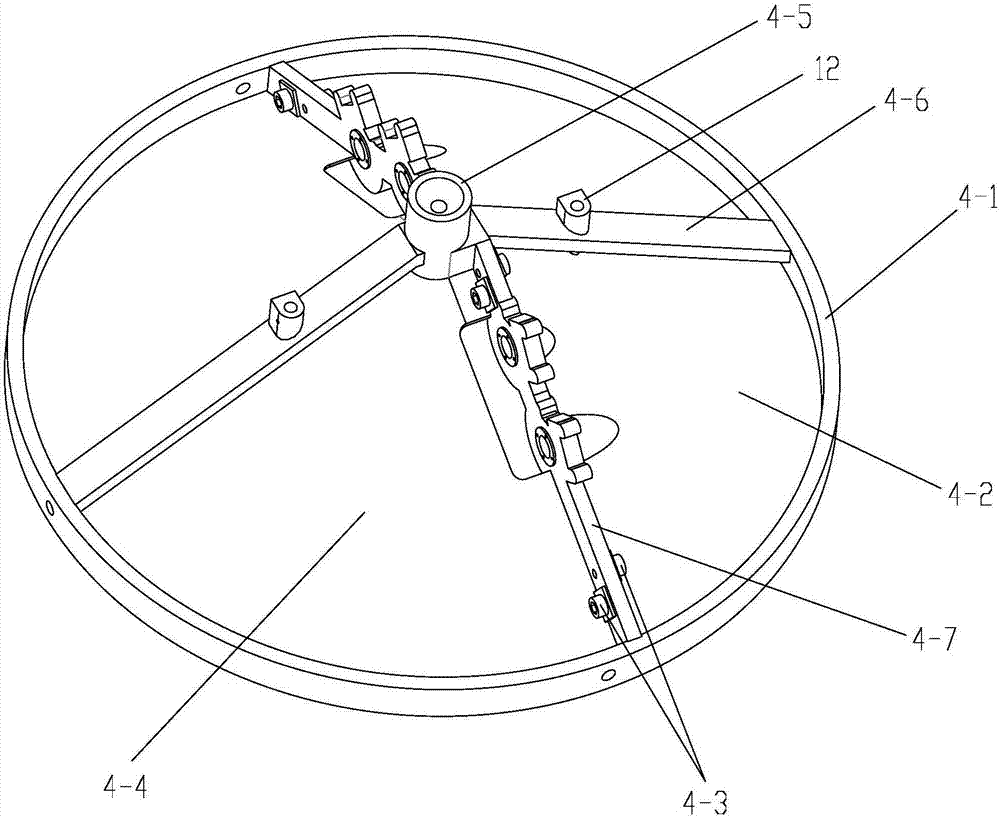

An adjustable atomizing bucket based on water atomization method for powder production

The invention discloses an adjustable atomizing barrel based on water atomization method powder making, which comprises a barrel body and a barrel cover installed on the barrel body, the barrel cover includes an annular bracket matched with the inner wall of the barrel, and the annular A ceramic crucible mounting frame is arranged directly above the center of the bracket, a funnel-shaped ceramic crucible is mounted on the ceramic crucible mounting frame, a first connecting plate and a second connecting plate are arranged between the ceramic crucible mounting frame and the ring support, The number of the first connecting board and the second connecting board is two, the two first connecting boards and the two second connecting boards are arranged at intervals, and an inert gas protection system is installed on the two first connecting boards The atomized water atomization angle adjustment system and the cooling water atomization angle adjustment system are installed on the two second connecting plates. The invention has the advantages of simple structure, novel and reasonable design, adjustable atomization angle as required, and simple and convenient operation.

Owner:XIAN UNIV OF SCI & TECH

Guide blade combustion system of internal combustion engine

InactiveCN1480641AImprovements in emission indicatorsEmission reductionFuel injection apparatusMachines/enginesCombustion systemCombustion

A combustion system with guide blade for IC engine features that the guide blades are arranged under the oil nozzle. When the oil beam is sprayed onto the guide blades, its surface can quickly spreadit for realizing secondary atomizing. Its advantages are uniform high-quality atomizing, and high combustion speed.

Owner:DALIAN UNIV OF TECH

A Fixed Bed Multiphase Atomizing Nozzle

The invention provides a fixed bed multiphase atomizing nozzle, comprising a whirlcone, an inner nozzle and an outer nozzle which are coaxially arranged in sequence; the head of the whirlcone is provided with multiple first whirling grooves; the outer wall of the whirlcone and the inner wall of the inner nozzle define a liquid phase channel; the head of the inner nozzle is provided with a liquid phase spray orifice; the liquid phase channel is communicated with the liquid phase spray orifice by the first whirling grooves; the area of the end face of the head of the outer nozzle is 1.5-5 times the cross sectional area of the greatest cross section of the inner nozzle; the middle of the end face of the head of the outer nozzle is provided with a fixing hole; the outer wall of the inner nozzle and the inner wall of the outer nozzle define a gas phase channel; the end face of the head of the outer nozzle is provided with multiple whirling holes around the fixing hole, and the gas phase channel is communicated with the whirling holes; on the end face of the head of the outer nozzle, the outer sides of the whirling holes are further provided with multiple gas phase spray holes around the fixing hole, and the multiple gas phase spray holes are communicated with the gas phase channel. According to the atomizing nozzle, the atomizing angle and the atomizing diameter are both increased greatly, the atomizing effect is better, and the atomizing range is larger.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

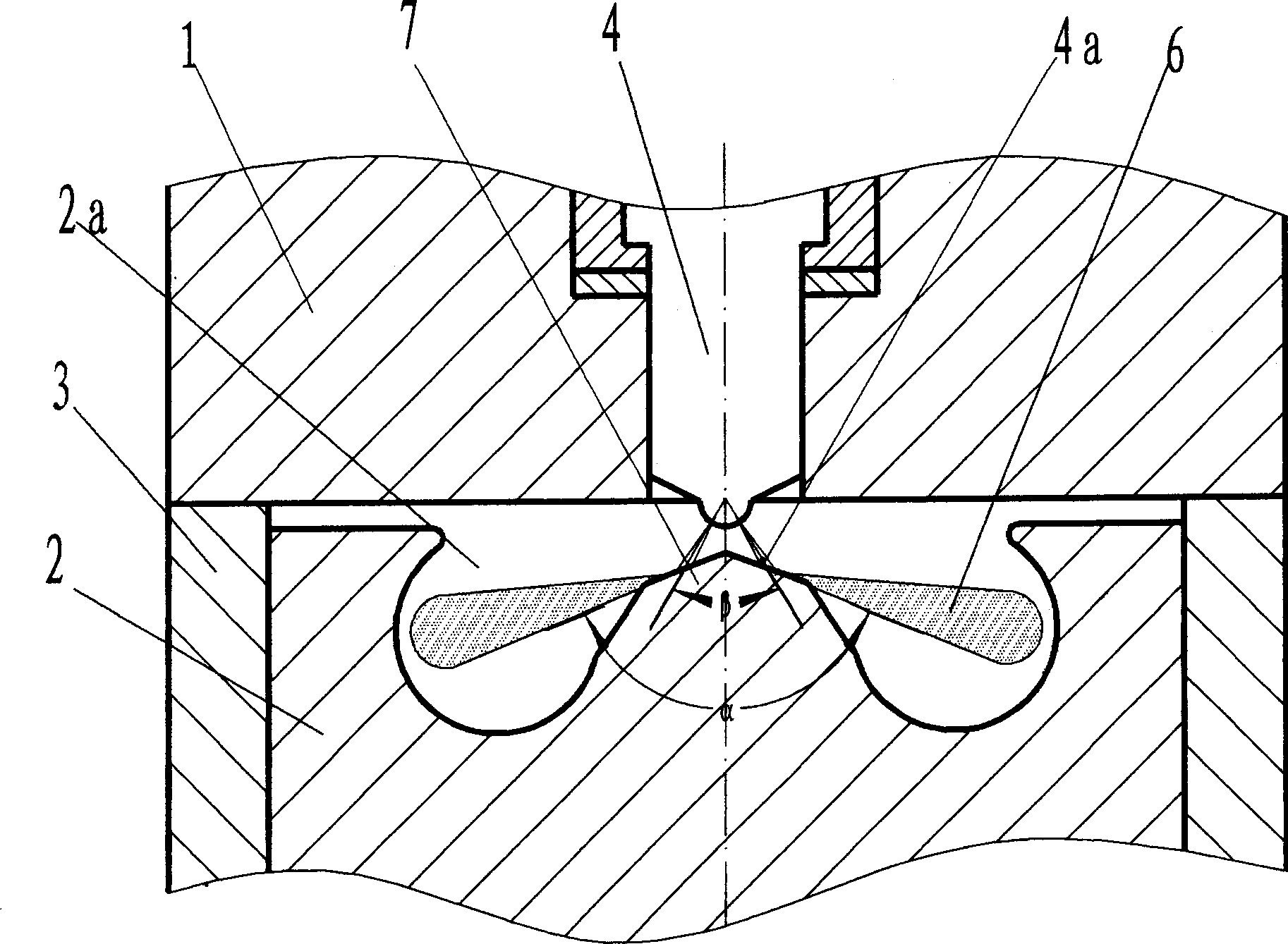

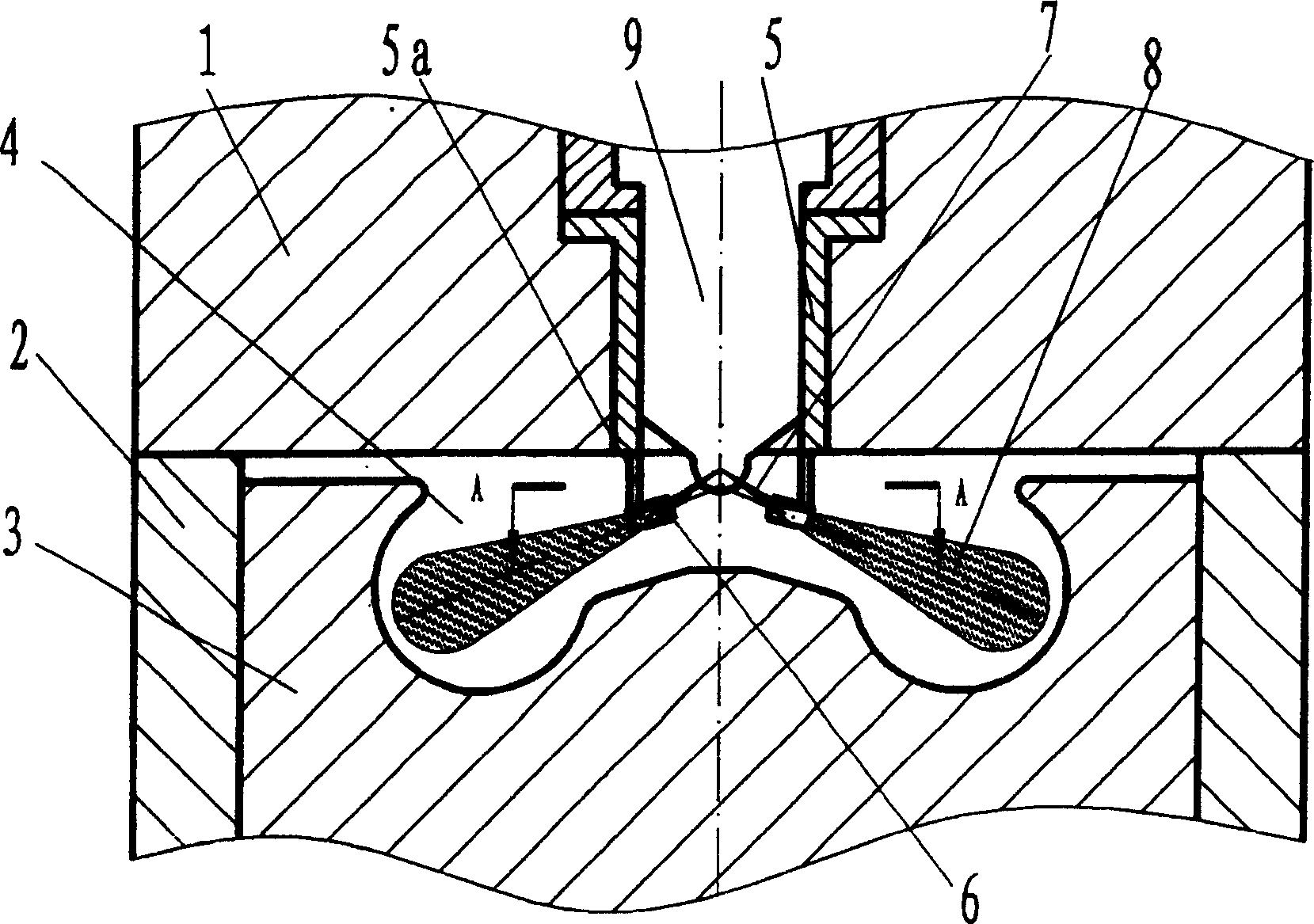

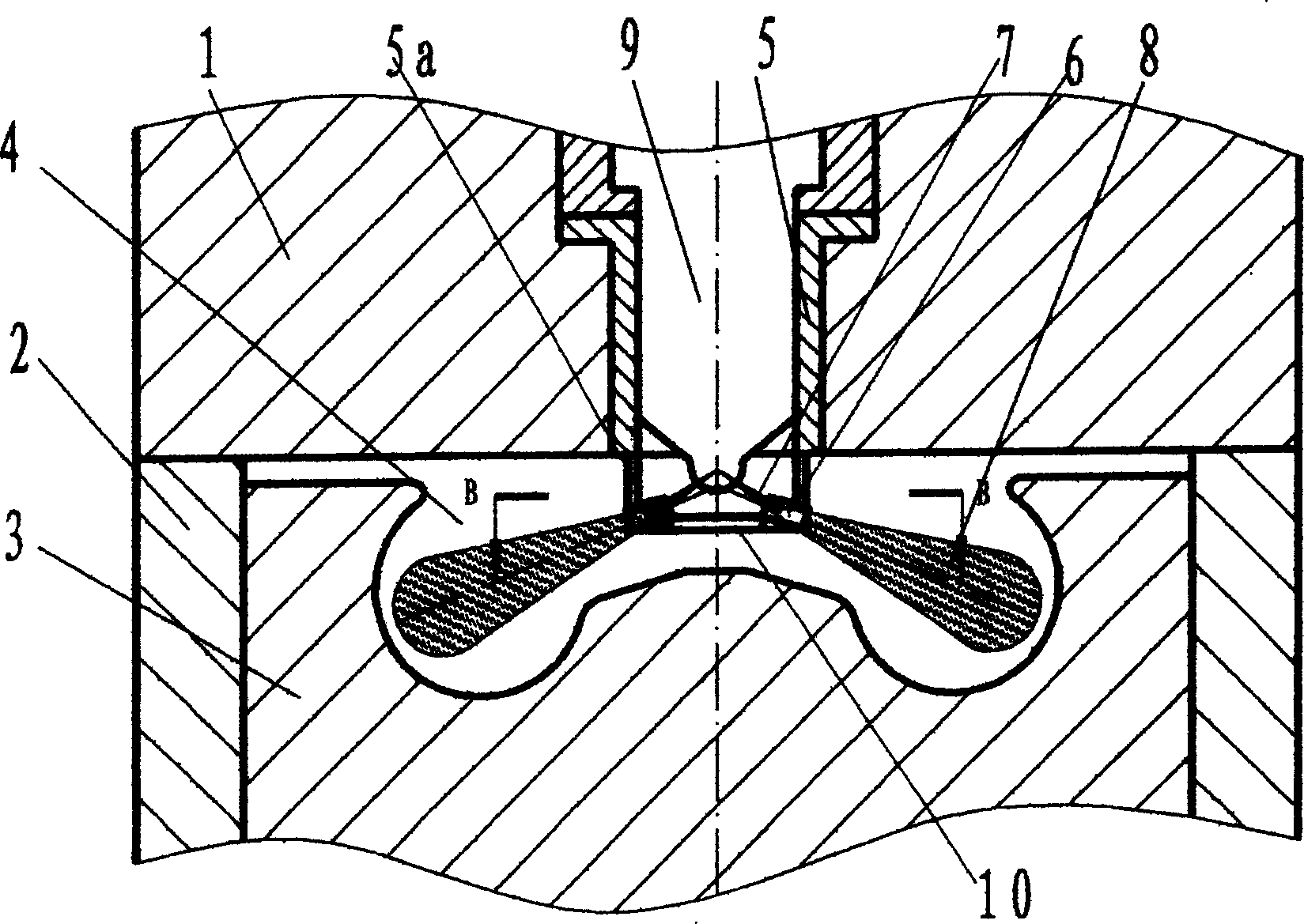

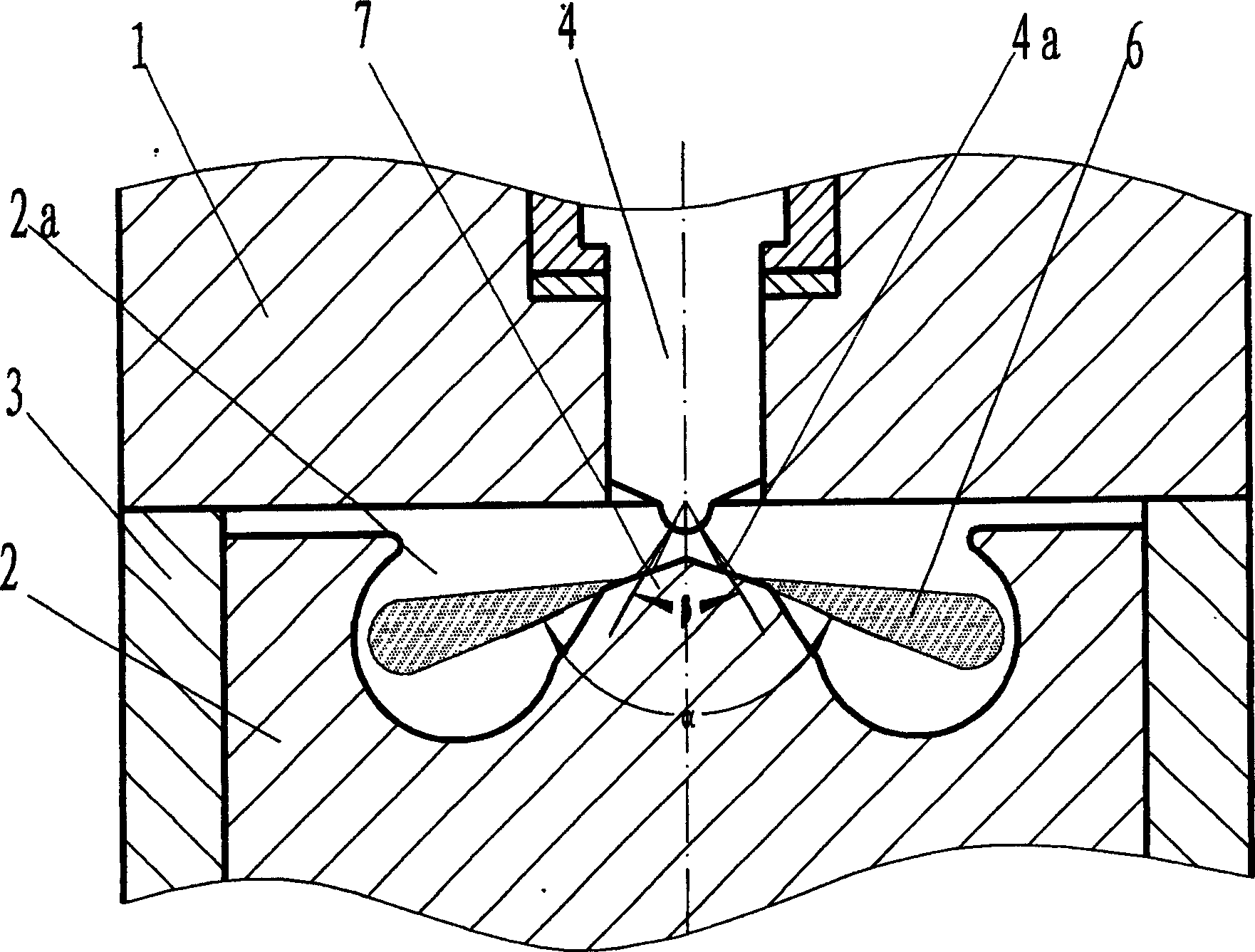

Internal combustion engine inner cone type atomization system

InactiveCN1285833CQuality improvementImprovements in emission indicatorsFuel injection apparatusMachines/enginesCombustible gasEngineering

The invention relates to an inner cone atomization system of an internal combustion engine which plays a guiding role and realizes secondary atomization, and belongs to the field of engine mixture gas formation and combustion. It is equipped with an inner cone guide cone directly above the fuel injector. When the oil beam ejected from the porous injector hits the guide cone, under the guidance of the inner cone surface, it forms a uniform distribution in the circumferential direction. The spray with good atomization and controllable penetration distance is very beneficial to the formation of combustible mixture, accelerates the combustion speed, and significantly improves the power, economy and emission indicators of the engine.

Owner:DALIAN UNIV OF TECH

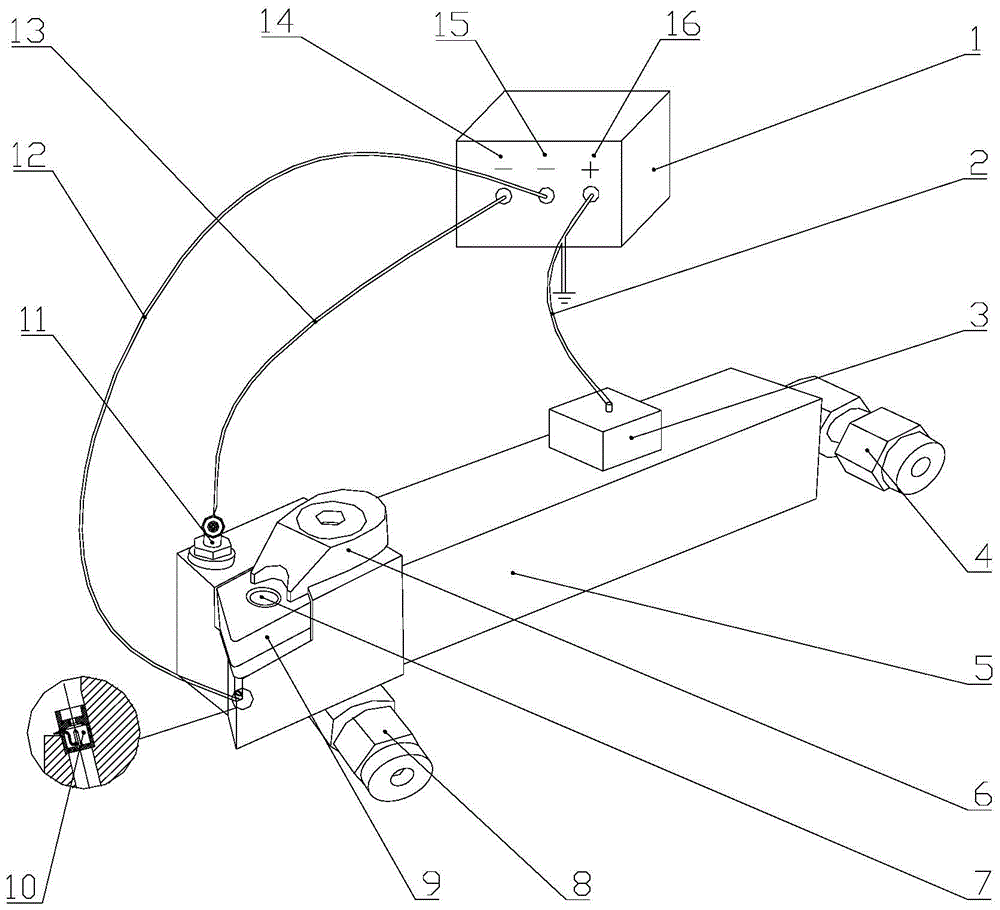

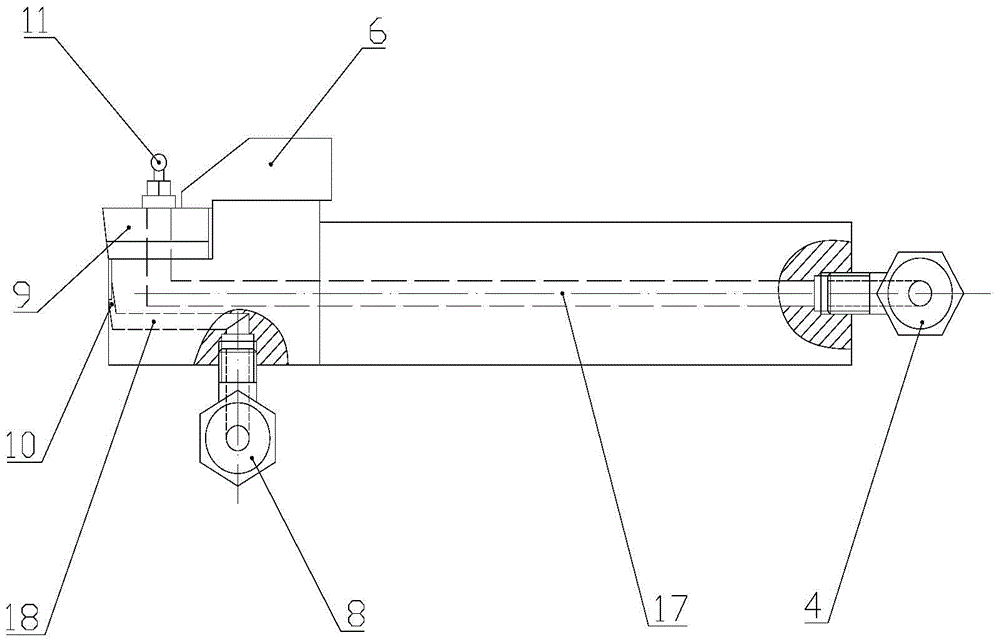

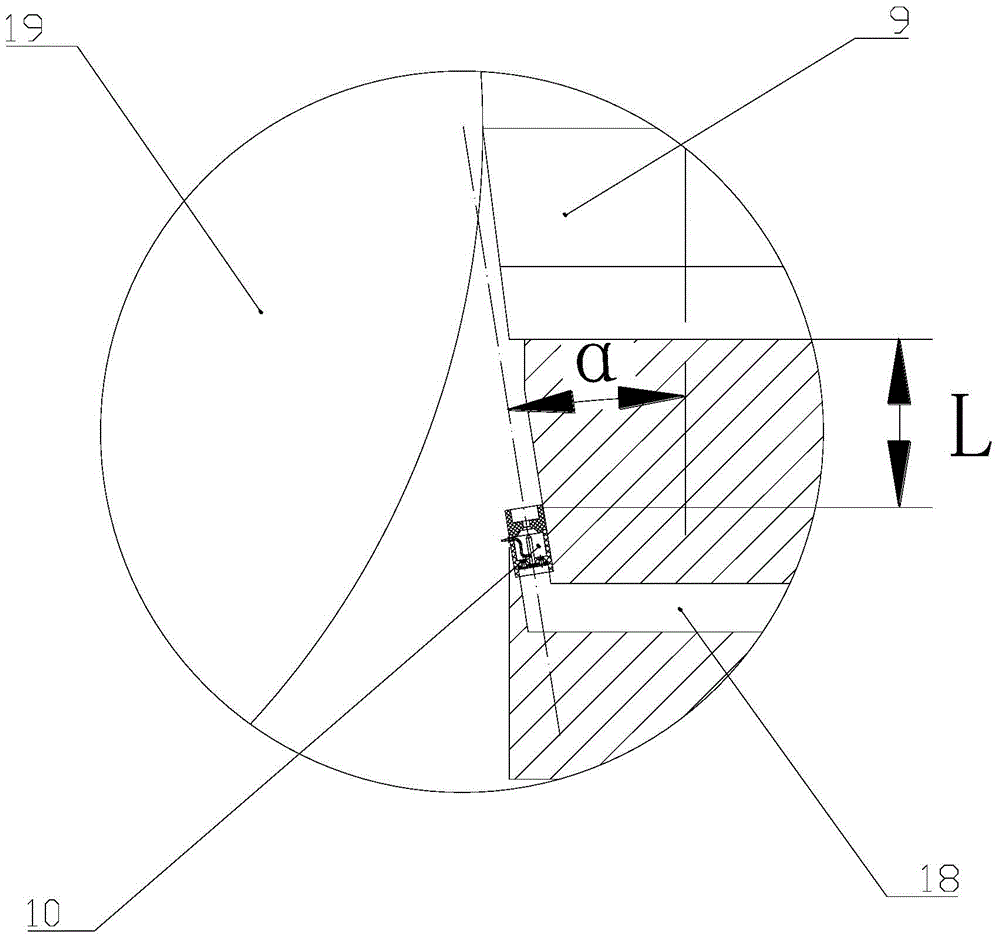

Nano fluid micro lubrication electrostatic atomization controllable jet turning system

ActiveCN104209806BIncrease profitOvercome surface tensionMaintainance and safety accessoriesJet flowInternal integration

The invention relates to a nanofluid micro-lubricating electrostatic atomization controllable jet turning system, which includes: an adjustable multi-negative power supply, the adjustable multi-negative power supply has a plurality of negative interfaces with different voltages and at least one positive interface, and the negative interfaces are connected to each other Work independently; the internal cooling turning tool is respectively equipped with a built-in integrated nozzle and an external integrated nozzle, and the two nozzles are distributed near the turning tool to provide a lubricating medium for turning; The cold hole is connected to the minimum quantity lubrication system to provide lubricating cutting fluid; at the same time, the two nozzles are also connected to different negative interfaces of the adjustable multi-negative power supply through wires; the electromagnetic joint is connected to the positive interface of the adjustable multi-negative power supply through wires, and installed On the turning tool with internal cooling, the wire is grounded at the same time. The invention realizes controllable distribution during the spraying process, improves the uniformity of the droplet spectrum, the deposition efficiency and the effective utilization rate of the liquid, controls the motion law of the droplet, and reduces the pollution to the environment.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

A mine-used multi-stage atomization two-phase flow fine water atomization device

Owner:LIAONING TECHNICAL UNIVERSITY

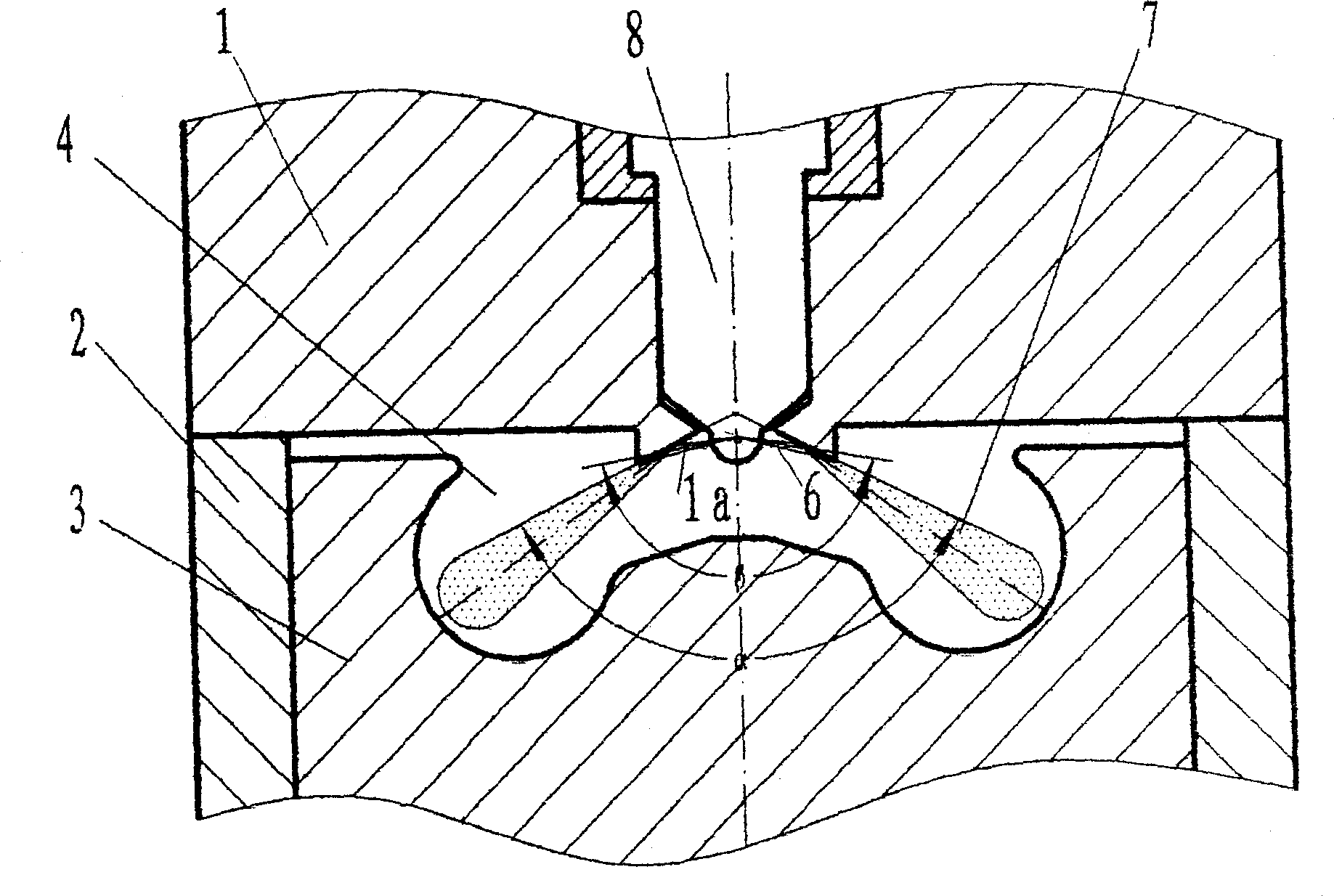

Diesel engine secondary atomization combustion system

InactiveCN1258039CQuality improvementImprovements in emission indicatorsFuel re-atomisation/homogenisationMachines/enginesCombustion systemDiesel combustion

A secondary atomization combustion system for a diesel engine belongs to the field of engine mixture gas formation and combustion. It is equipped with a guide cone directly below the fuel injector. When the oil beam ejected from the multi-hole injector hits the guide cone, under the guidance of the cone surface, it forms a uniform circumferential distribution, good atomization, The spray with controllable penetration distance is very beneficial to the formation of combustible mixture, which accelerates the combustion speed and significantly improves the power, economy and emission indicators of the engine.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com