Internal combustion engine guide collision burning system

A technology of combustion system and internal combustion engine, applied in the direction of internal combustion piston engine, charging system, combustion engine, etc., can solve the problems of excessively rich circumferential distribution, unevenness, and short penetration distance of umbrella spray, and reduce soot. Emission volume, good atomization performance, and the effect of improving emission indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

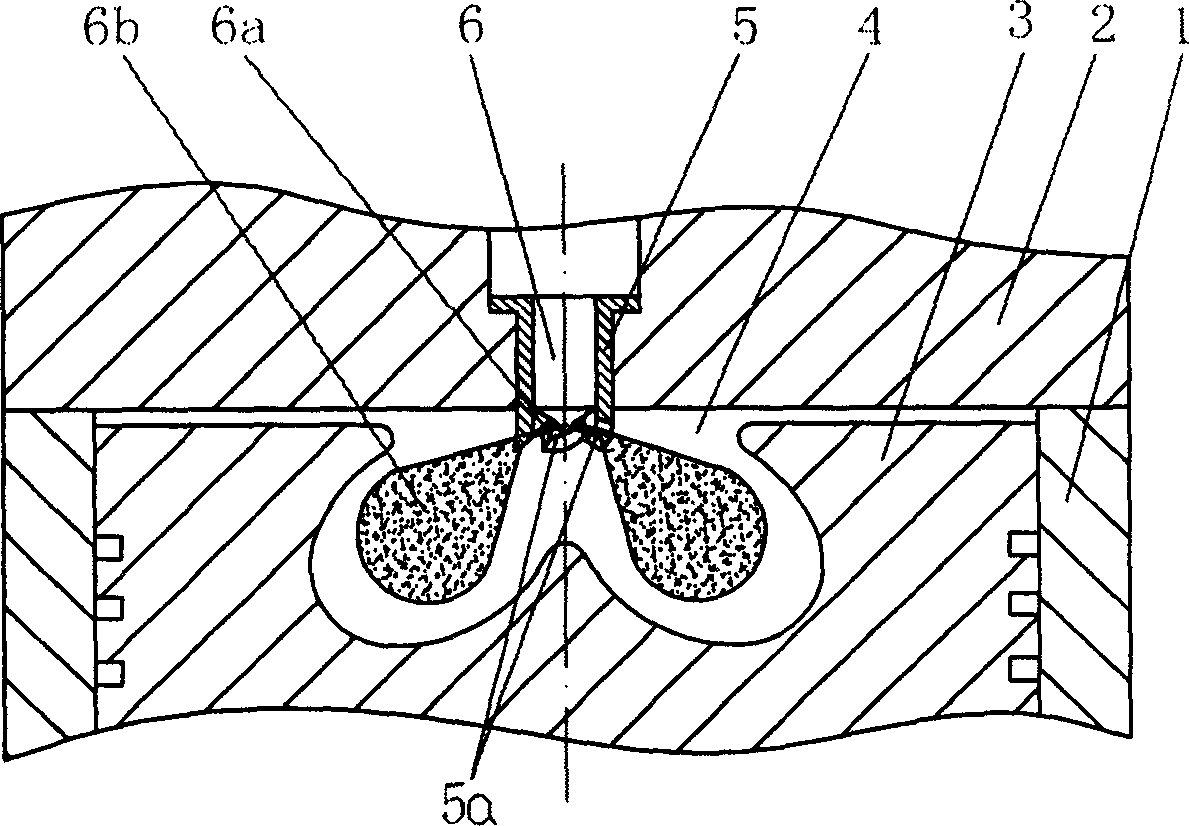

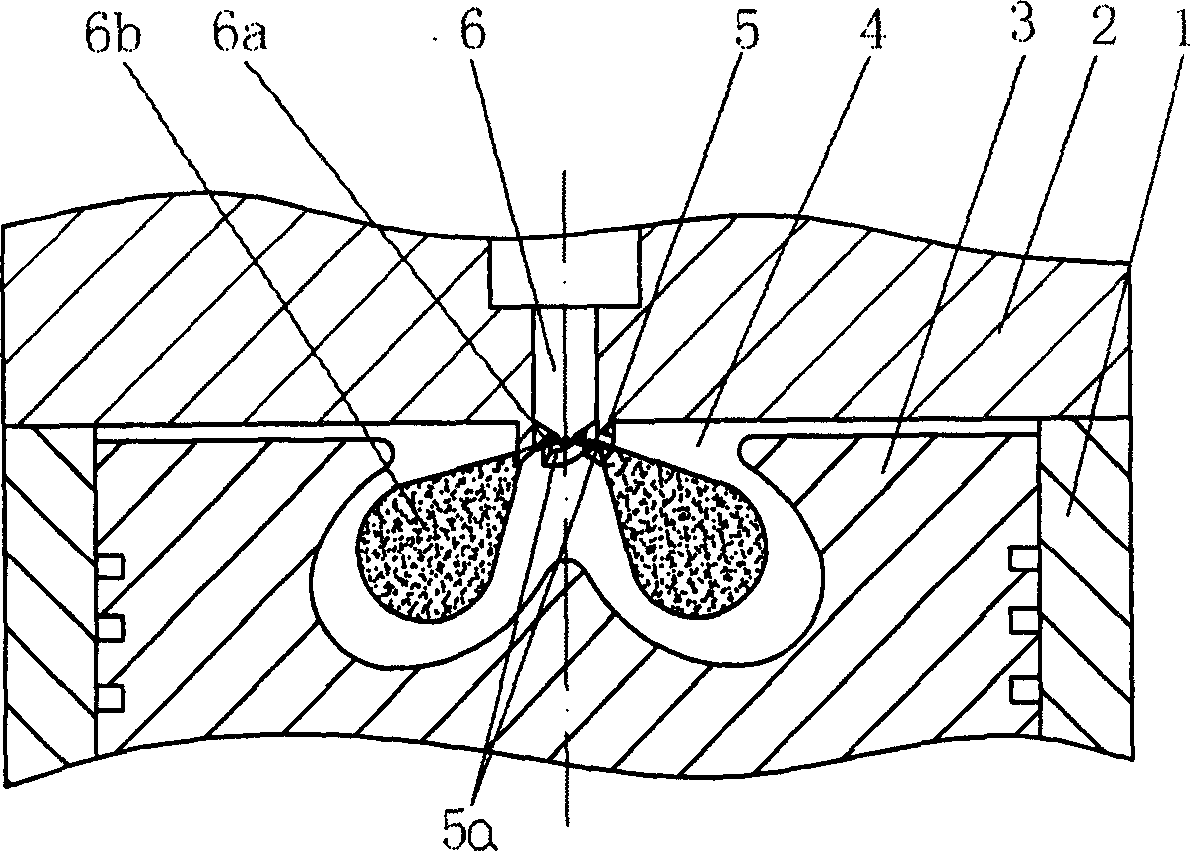

[0018] exist figure 1 , 2 In the shown embodiment, a main combustion chamber 4 is formed by the cylinder liner 1, the cylinder head 2 and the piston 3; a guide ring 5 is arranged on the periphery of the fuel injection nozzle 6, figure 1 The guide ring in is set separately, figure 2 The guide ring 5 is integrated with the cylinder head. The lower end of the guide ring 5 is provided with a planar guide surface 5a for the primary oil jet, and the planar guide surface 5a is located on the path of the primary oil jet 6a sprayed out by the fuel injection nozzle 6 . The fuel injection nozzle 6 ejects 6 primary oil jets 6a to the 6 planar guide surfaces 5a, and under the guidance of the planar guide surfaces 5a, 6 secondary oil jets 6b are formed, and the 6 secondary oil jets 6b can basically be Cover the whole main combustion chamber 4.

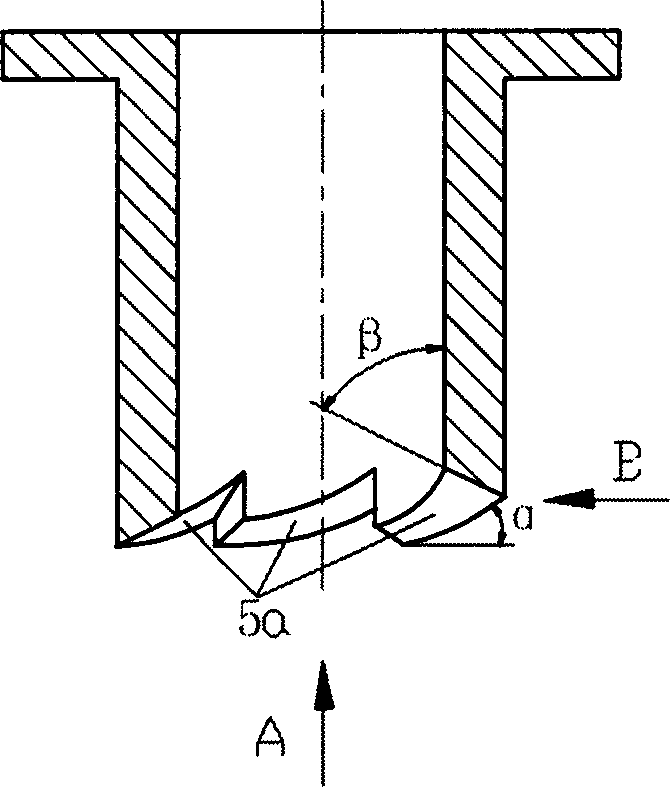

[0019] exist image 3 , 4 In the embodiment shown in , 5, and 6, the guide surface is a planar structure, and the lower part of the guide ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com