Patents

Literature

72results about How to "Improvements in emission indicators" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

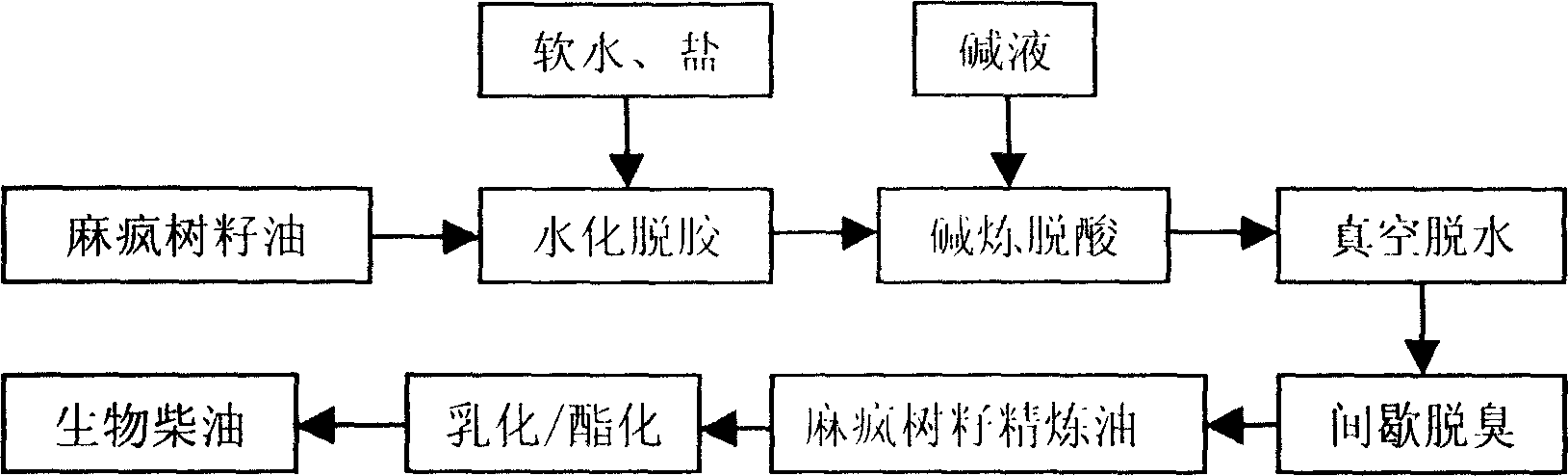

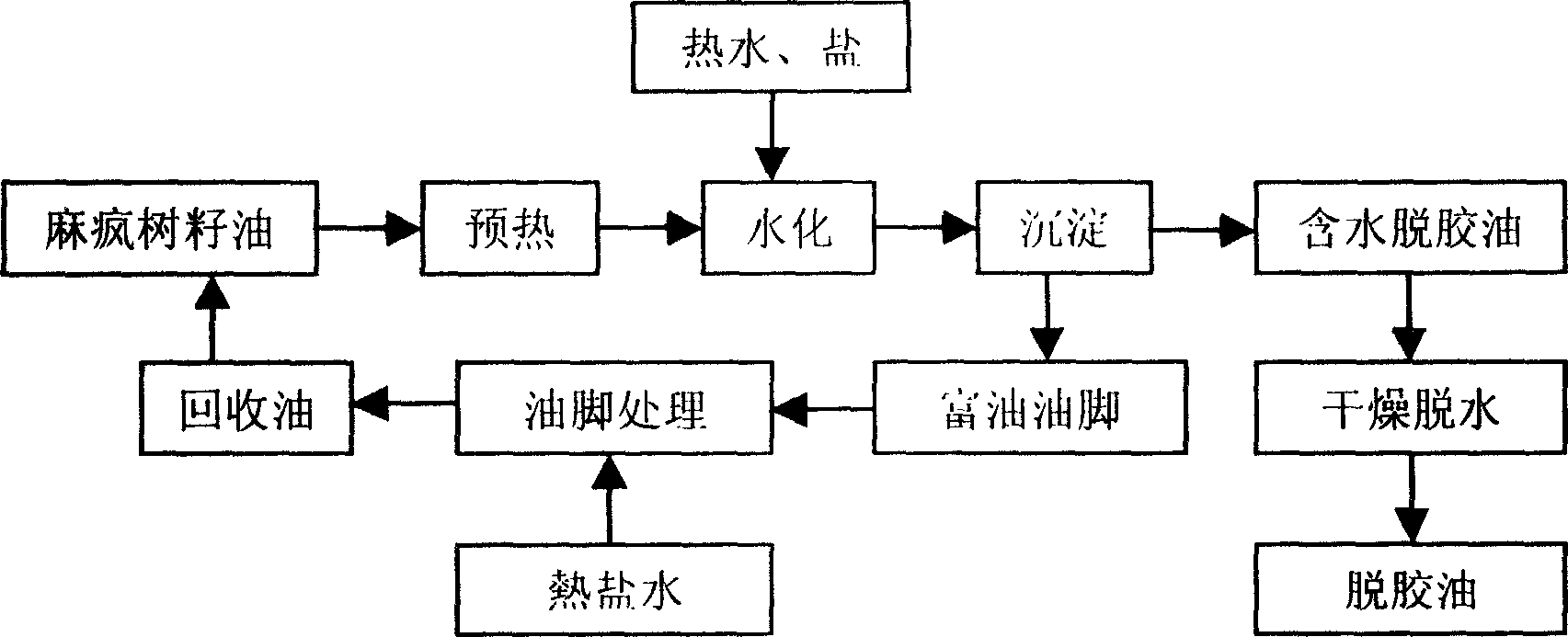

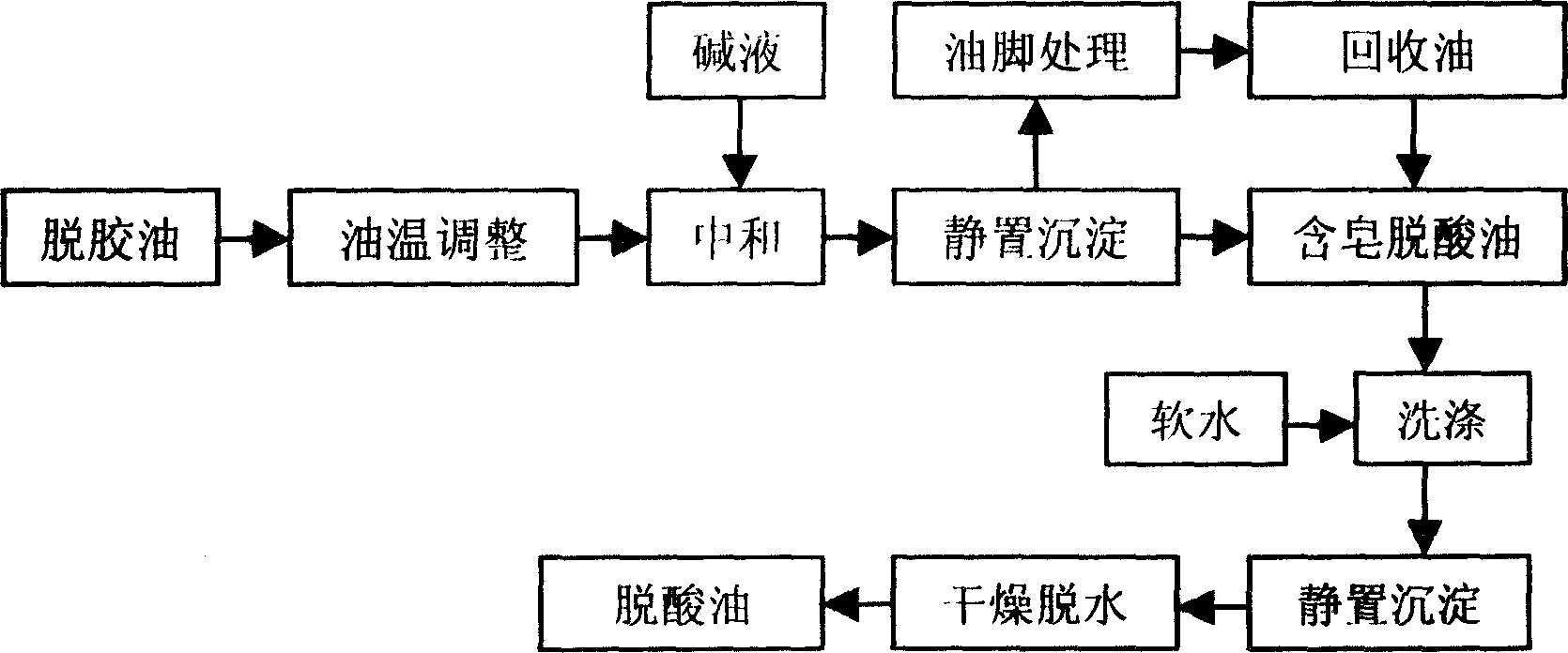

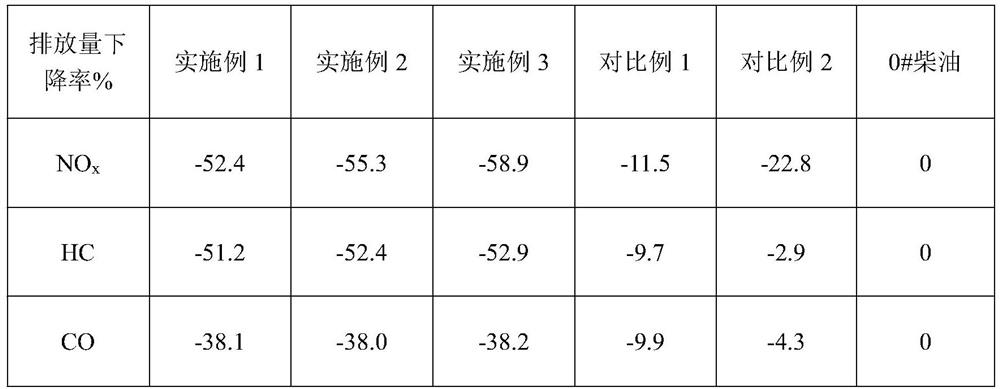

Biological diesel oil and method for preparing same

InactiveCN1557914AReduce stearic acid contentImprove combustion effectBiofuelsLiquid hydrocarbon mixture productionJatrophaEngineering

The present invention relates to biological diesel oil and method for preparing same. The technical program is the biological diesel oil contains Jatropha crucas L. seed oil; in said Jatropha crucas L. seed oil, stearic acid content is not more than 0.4 (wt) percents. The method for preparing biological diesel oil comprises production art of the biological diesel oil and refining, improving art of the biological diesel oil; said refining, improving art comprises steps of: a, hydrating and degumming; b, alkali refining and acid removing; c, dehydrating; d intermittent deodorizing; e, emulsification and esterification. The invention has good effect of recucing stearic acid content in the Jatropha crucas L. seed oil, eliminating aromatic compound such as phthalic acid etc., improving burning ability of the biological diesel oil, reducing carbon accumulation in motor cylinder, improving power ability of motor, and discharging index. And the invention has simple producing process and low producing cost.

Owner:罗羽林

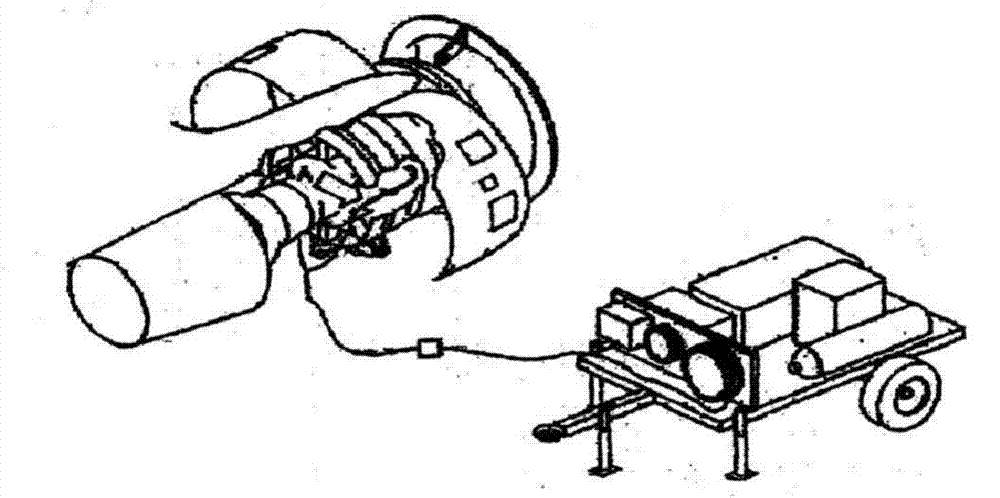

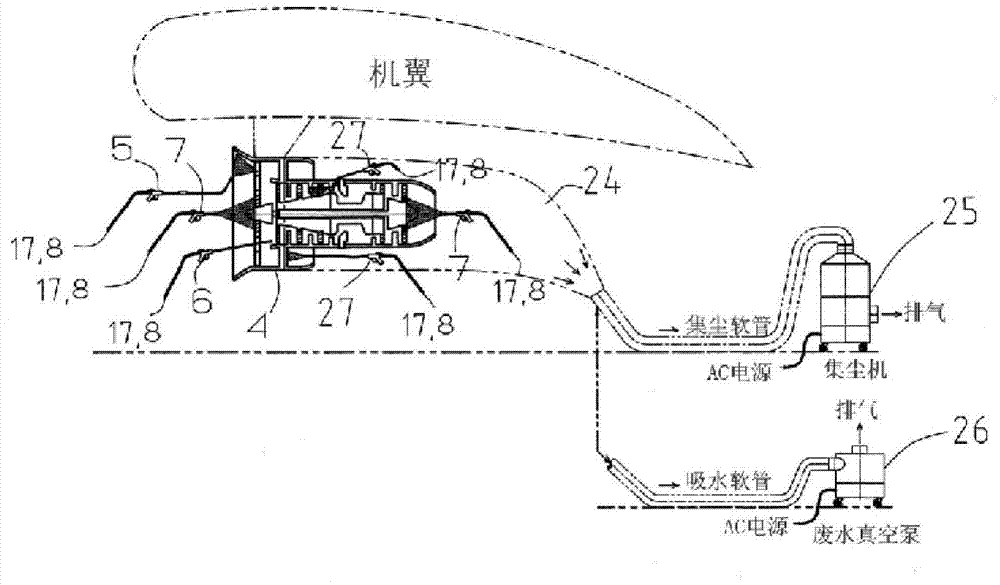

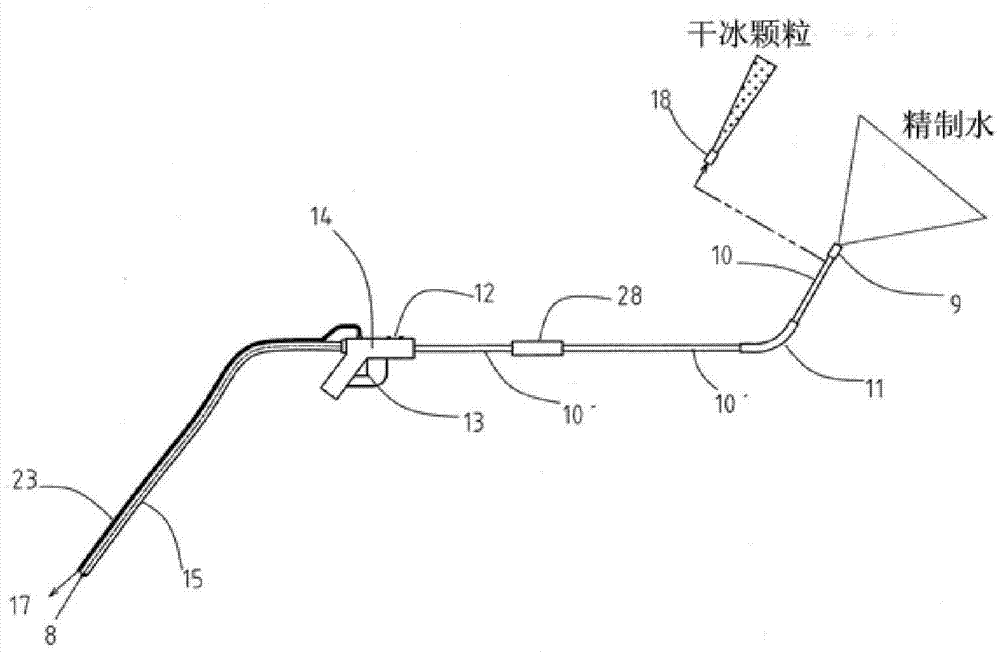

Jet engine cleaning method and cleaning apparatus

InactiveCN104763531AReduce processing costsImprove cleaning effectMachines/enginesEngine componentsCarbon dioxideDry ice

The invention discloses a jet engine cleaning method and a cleaning apparatus. High efficient cleaning cna be achieved in short time without the use of chemical cleaning agent and emissions of EGT, SFC and carbon dioxide can be reduced. The cleaning method comprises the following steps of injecting dry ice particles toward the jet engine as the to-be-cleaned object and installed on two sides of a wing. Shake and impact are caused to the surface of dirts due to a burst reaction when plenty of dry ice particles are sent into the engine with high speed engine blade rotation, so dirts break and the dry ice particles can enter the cracks; the dry ice particles can turn into air with expanded size due to the sublimation action of the dry ice; by the use of the above methods, dirts can be peeled off and blown off; and then refined warm water is sprayed, so all remained dirts can be removed.

Owner:洪圣涛 +1

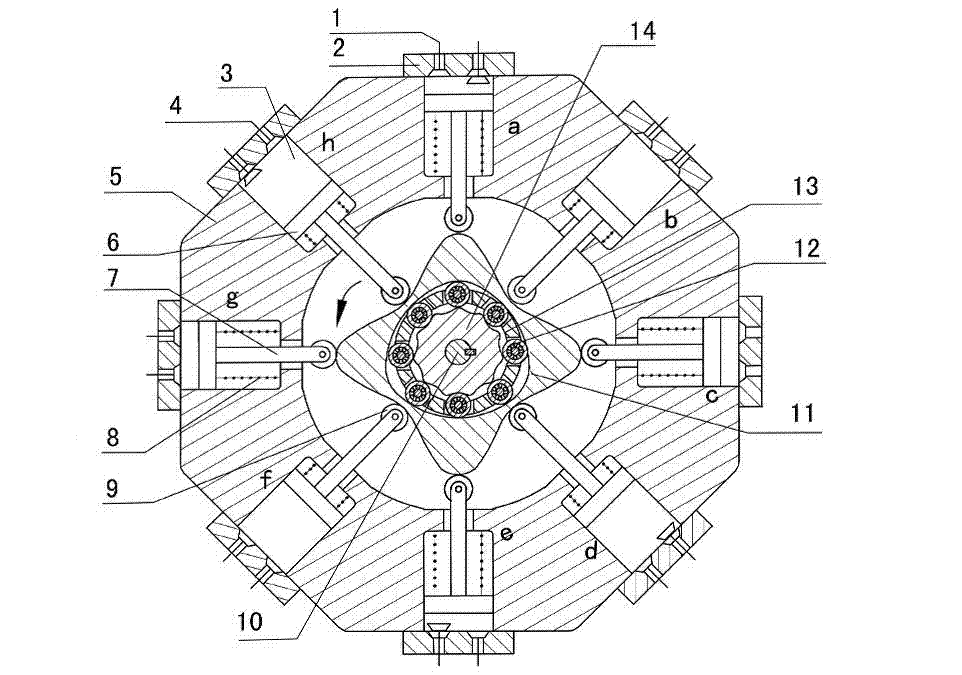

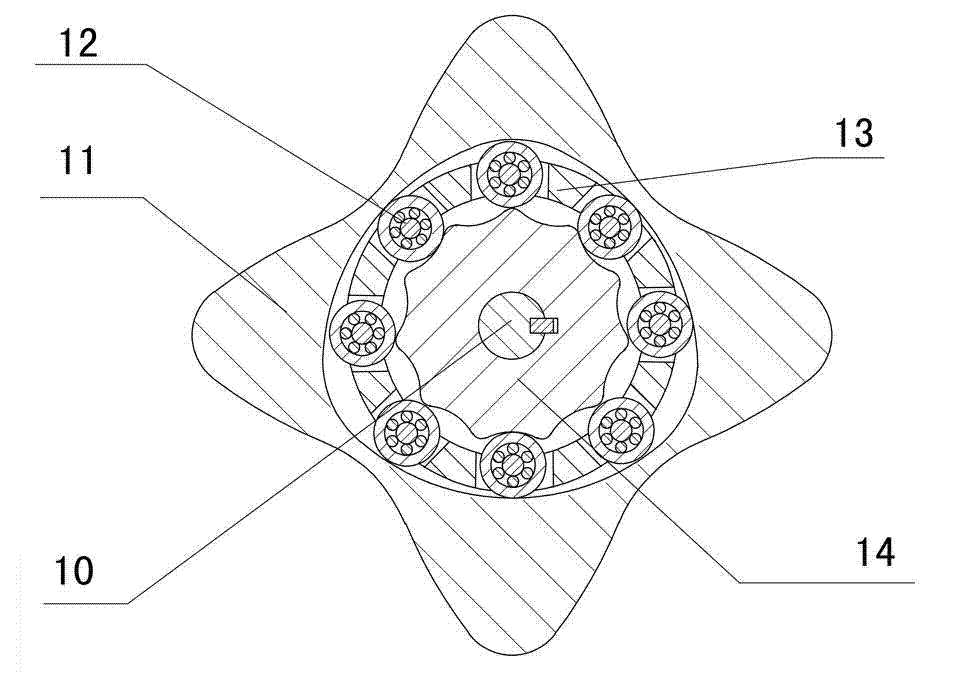

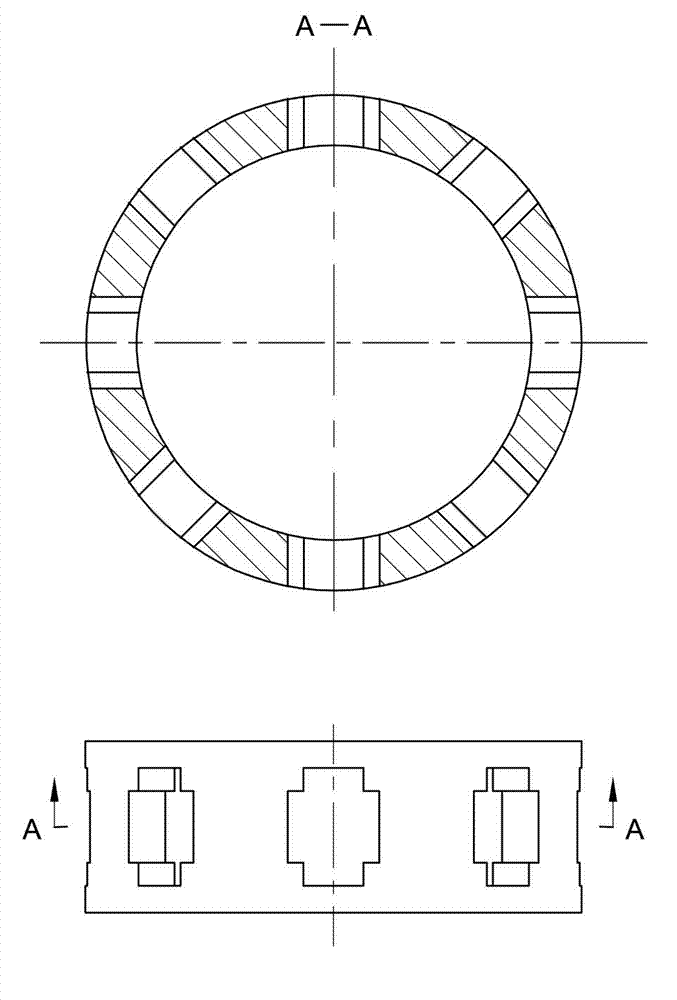

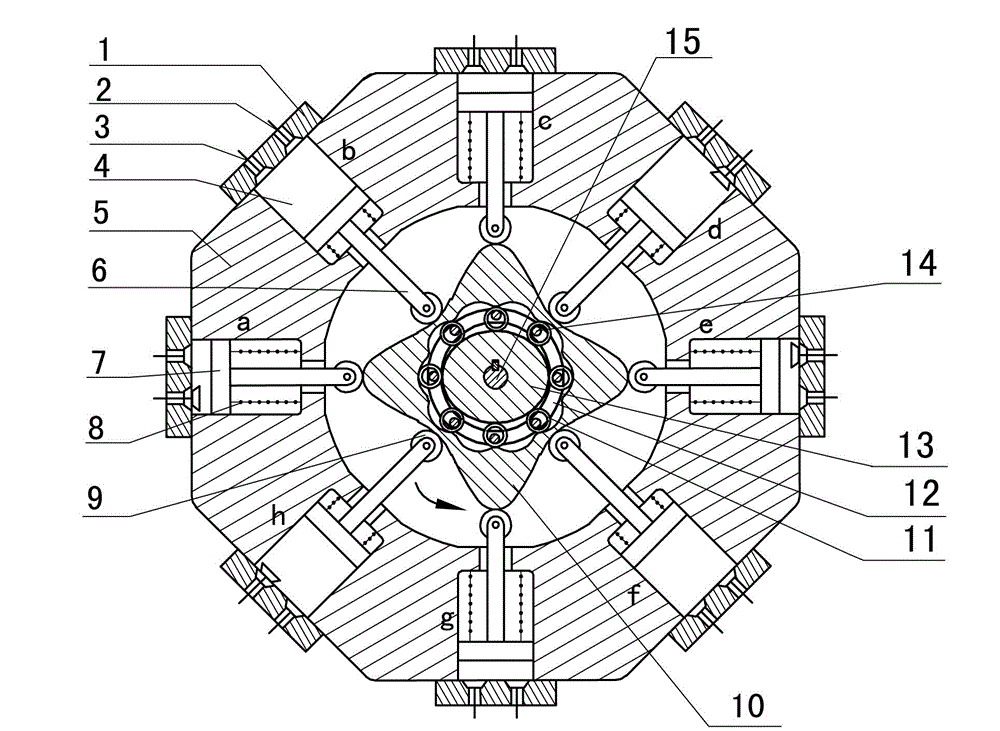

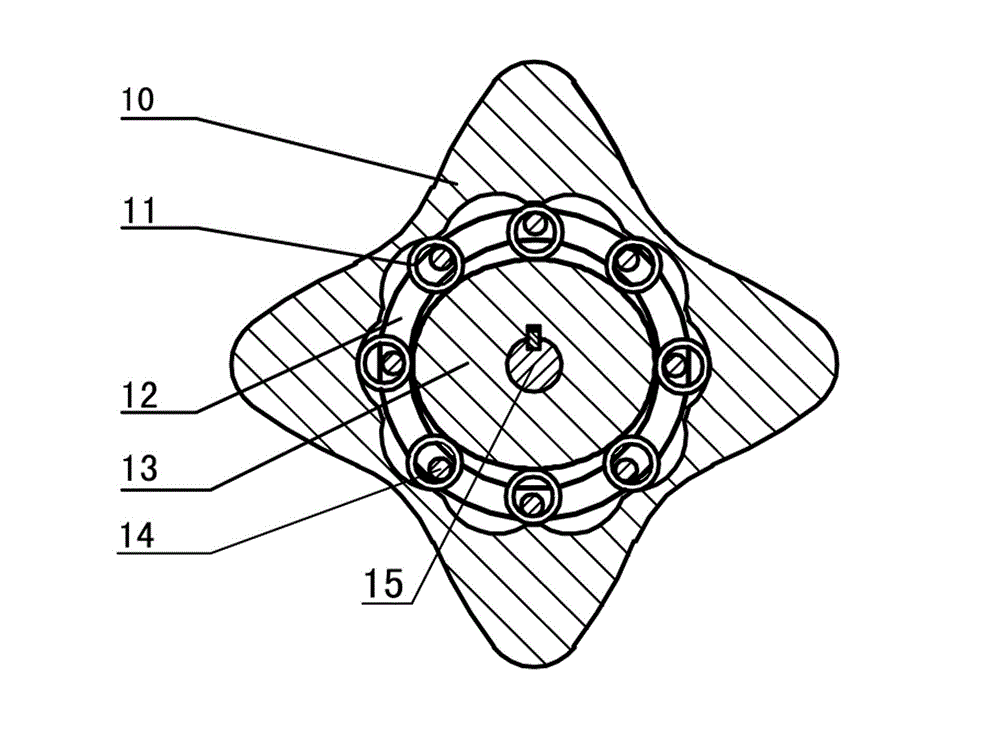

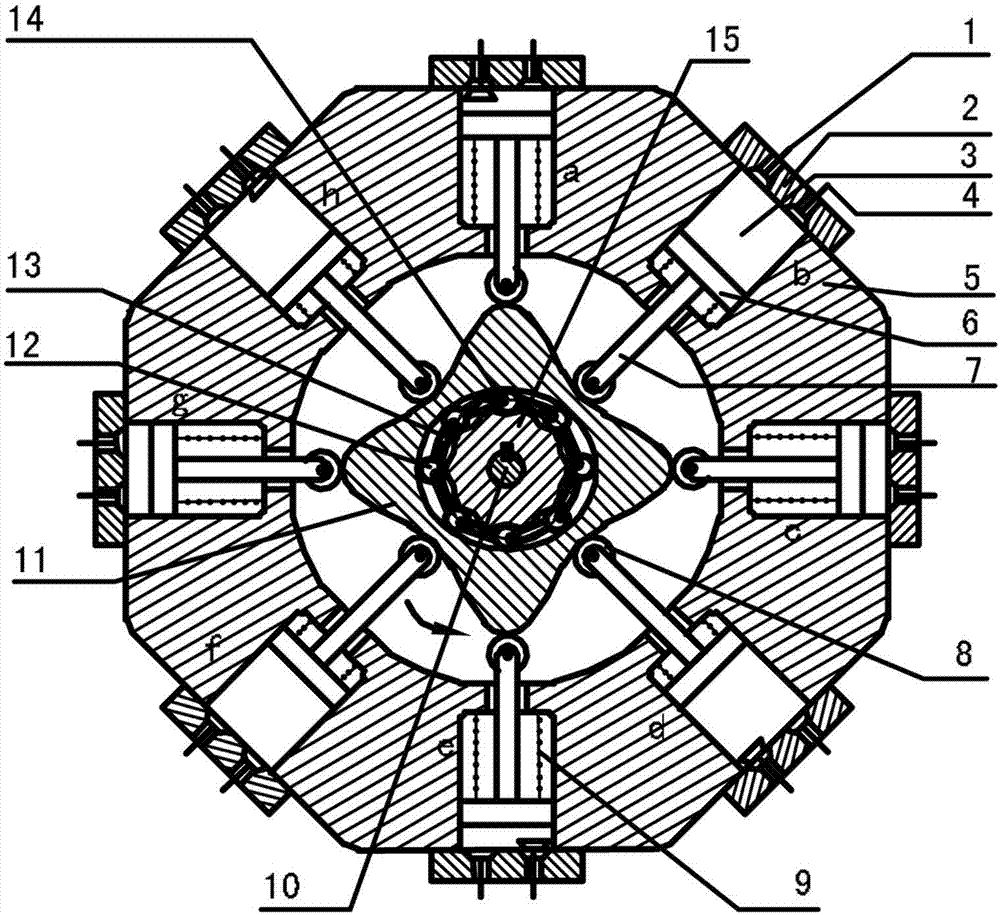

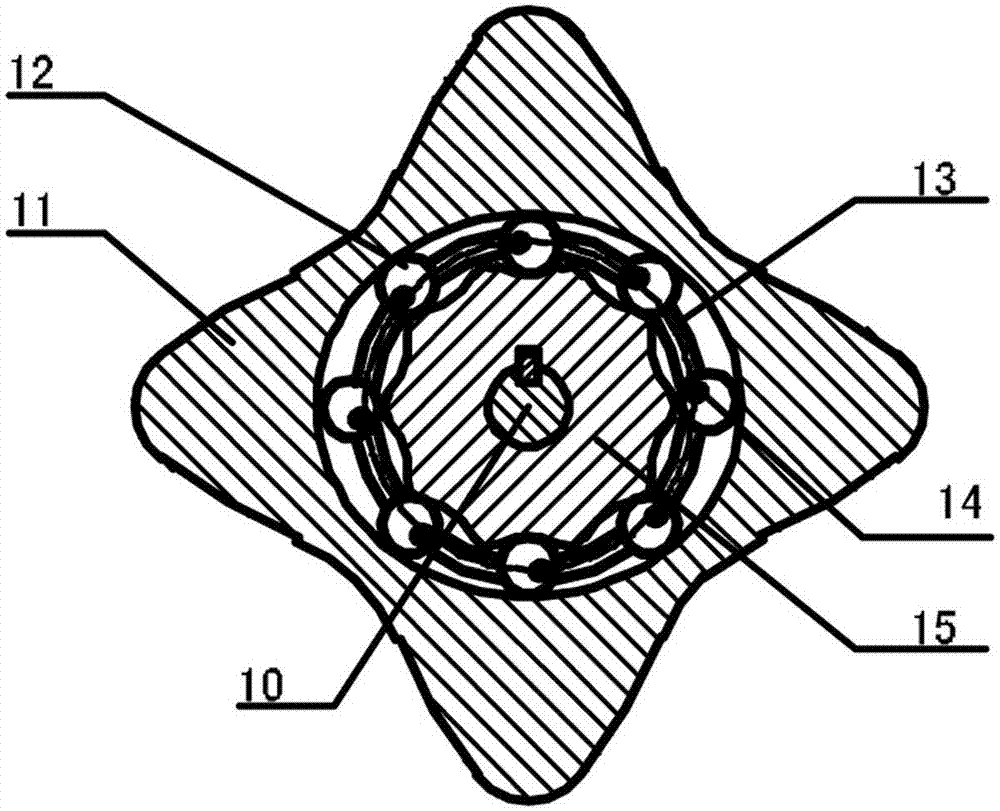

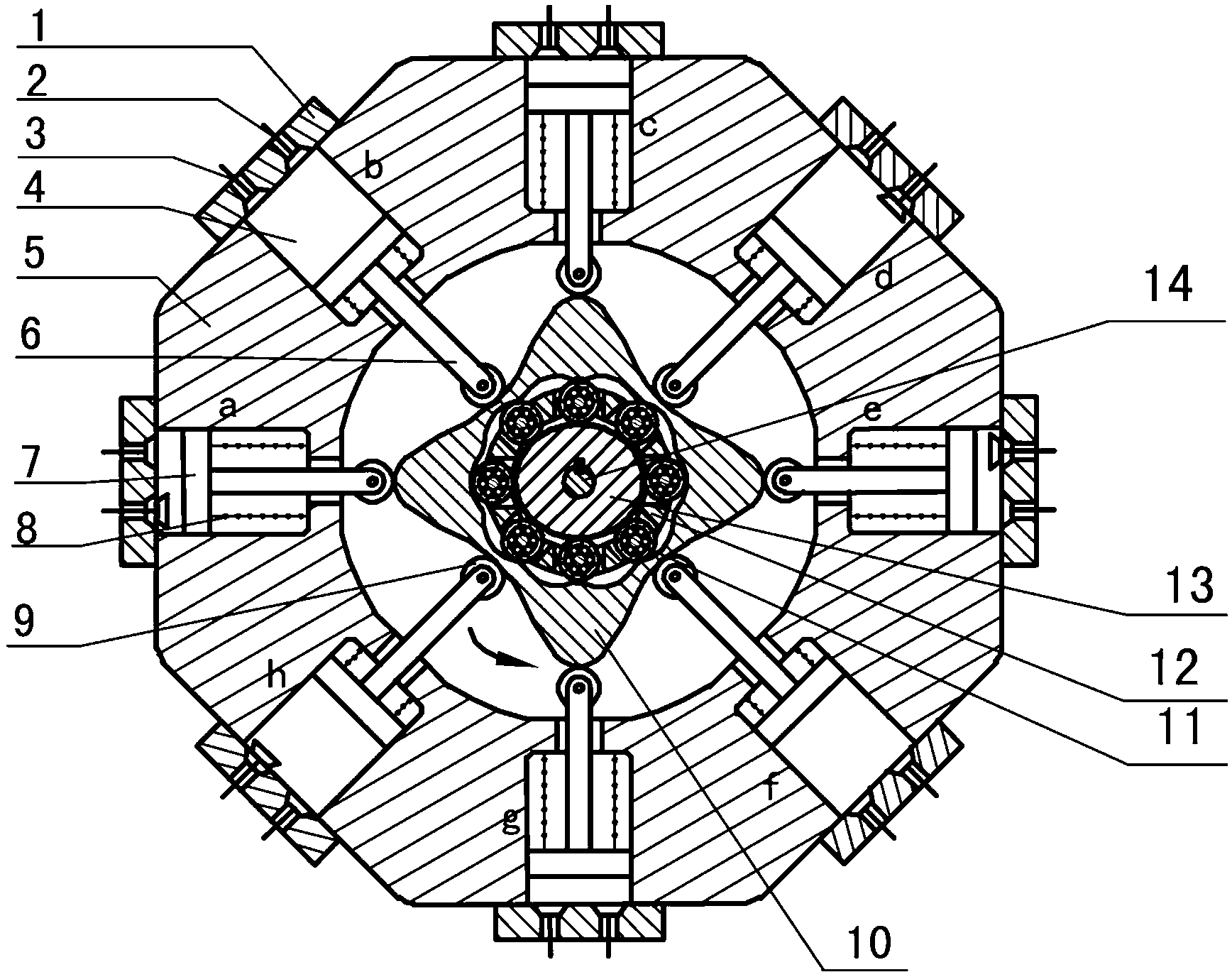

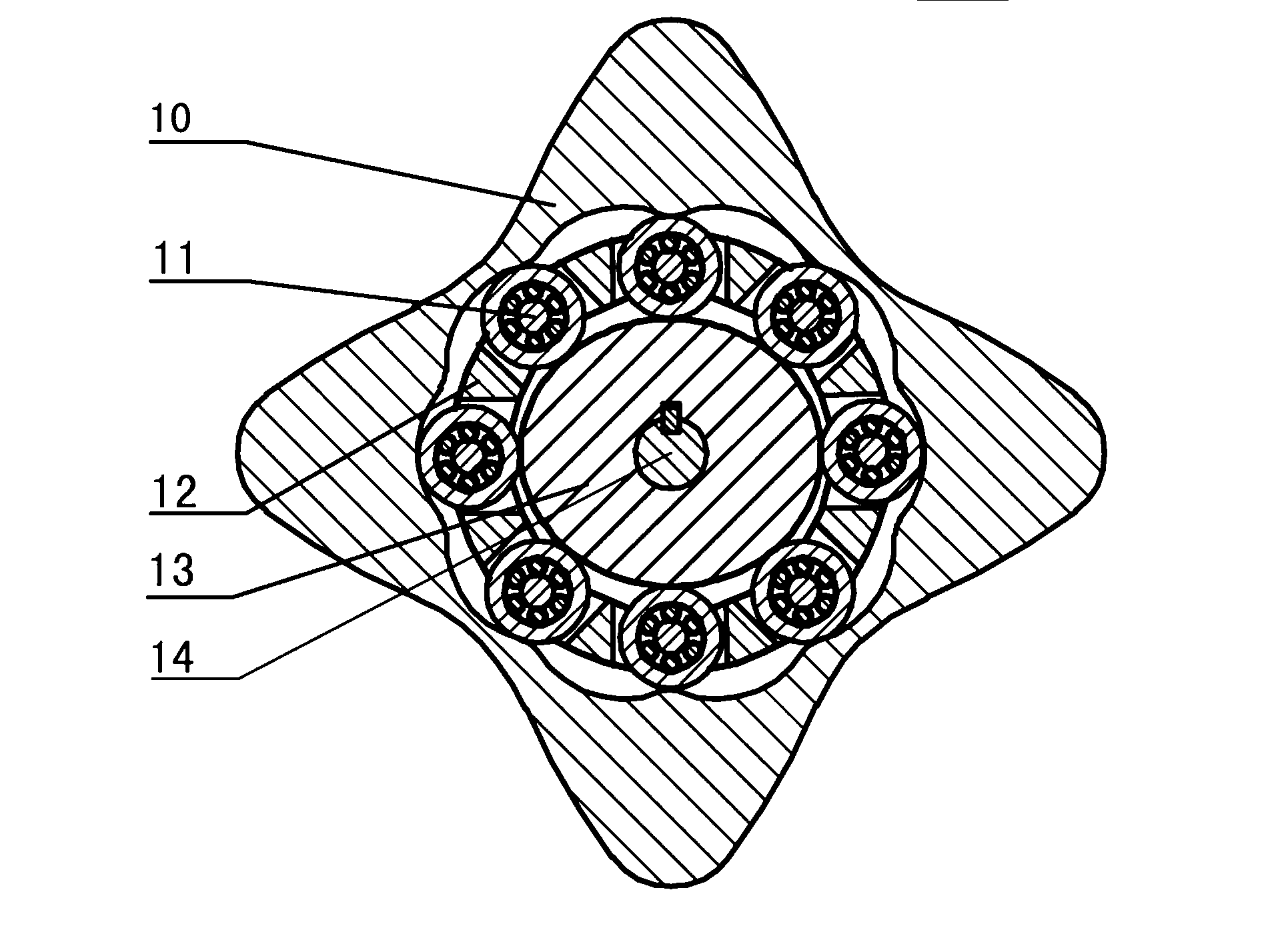

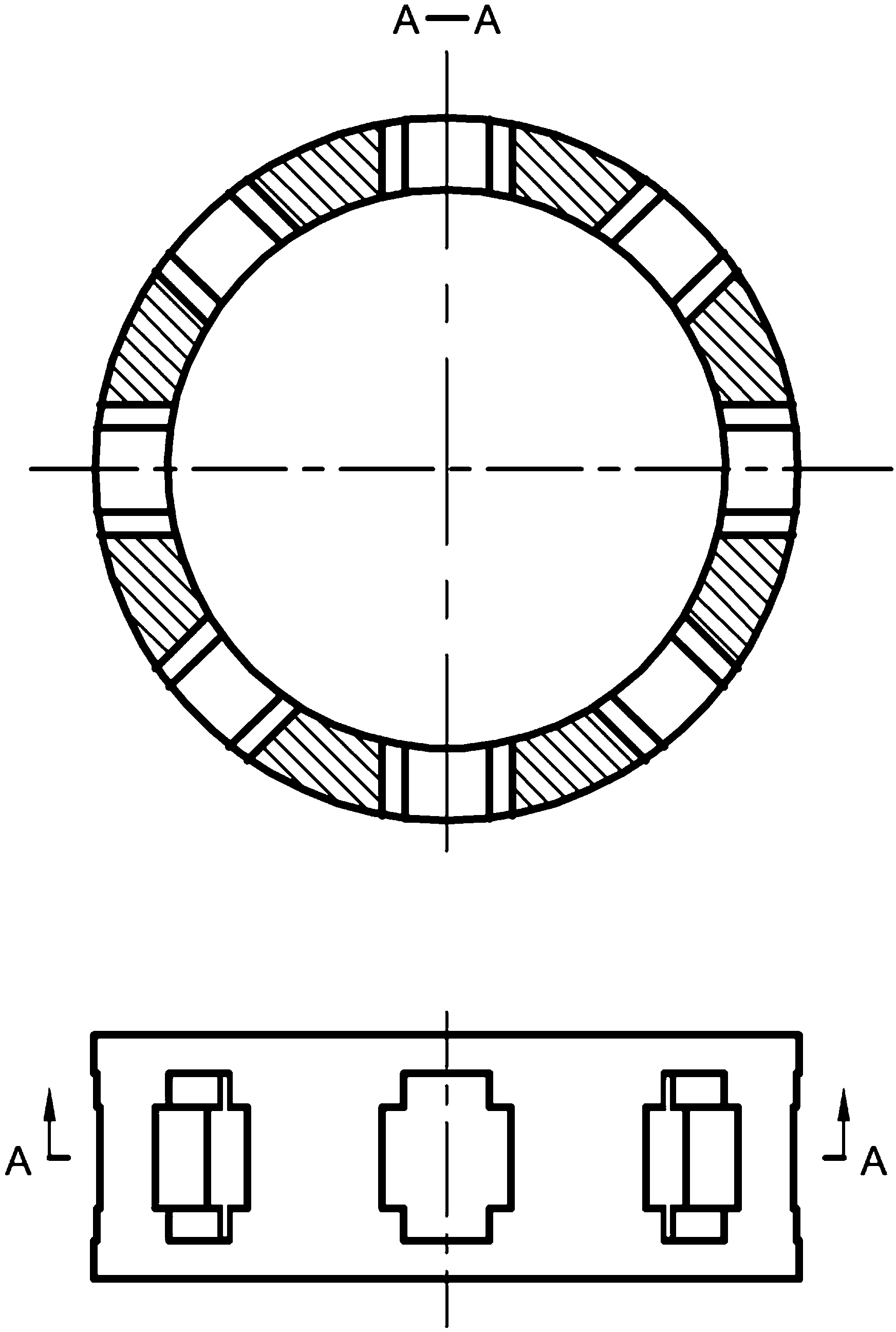

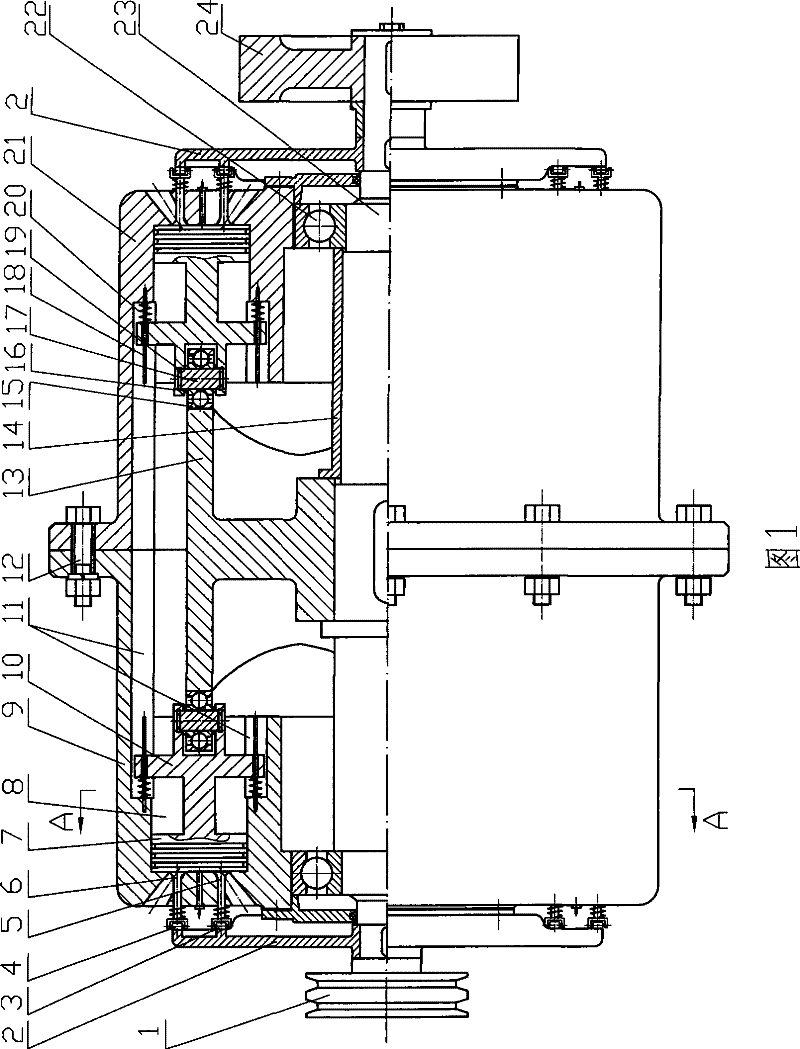

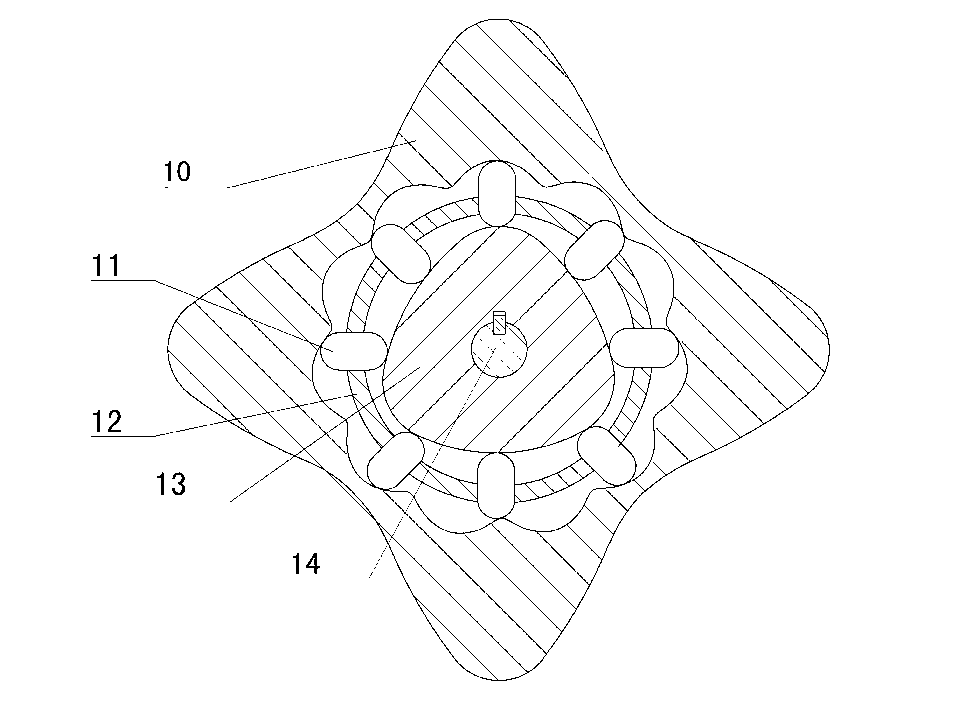

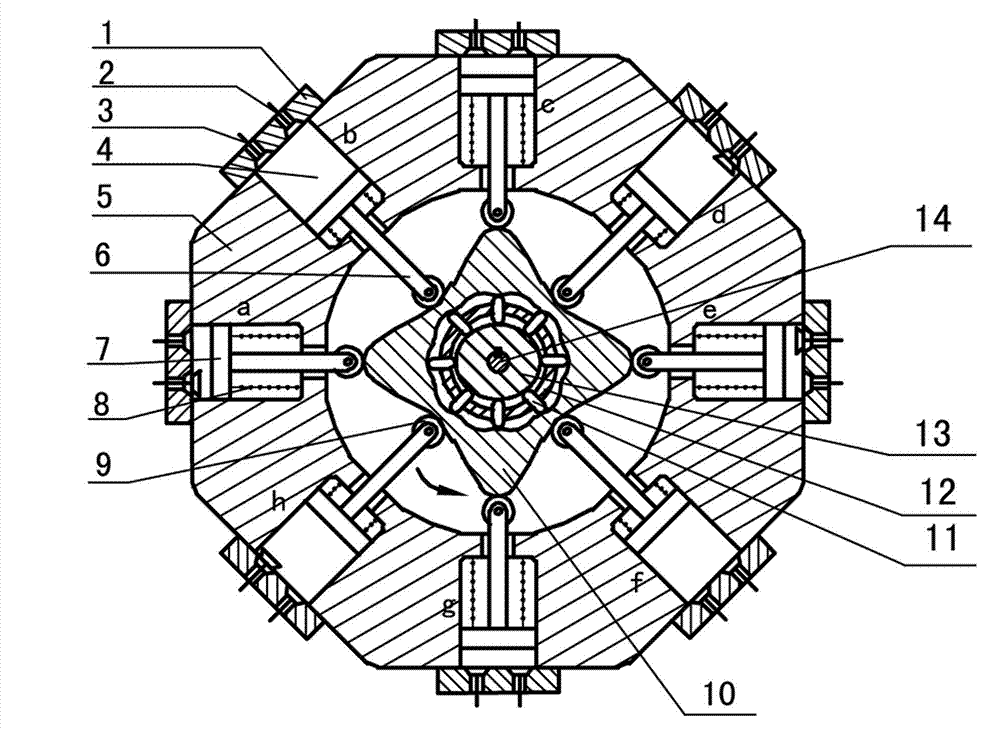

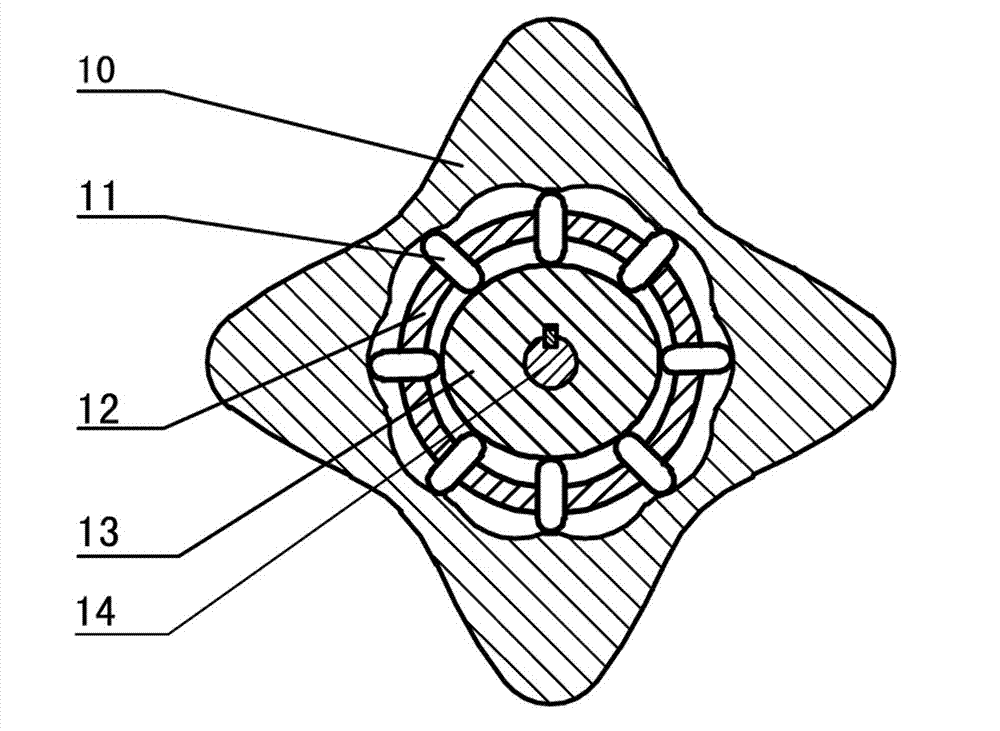

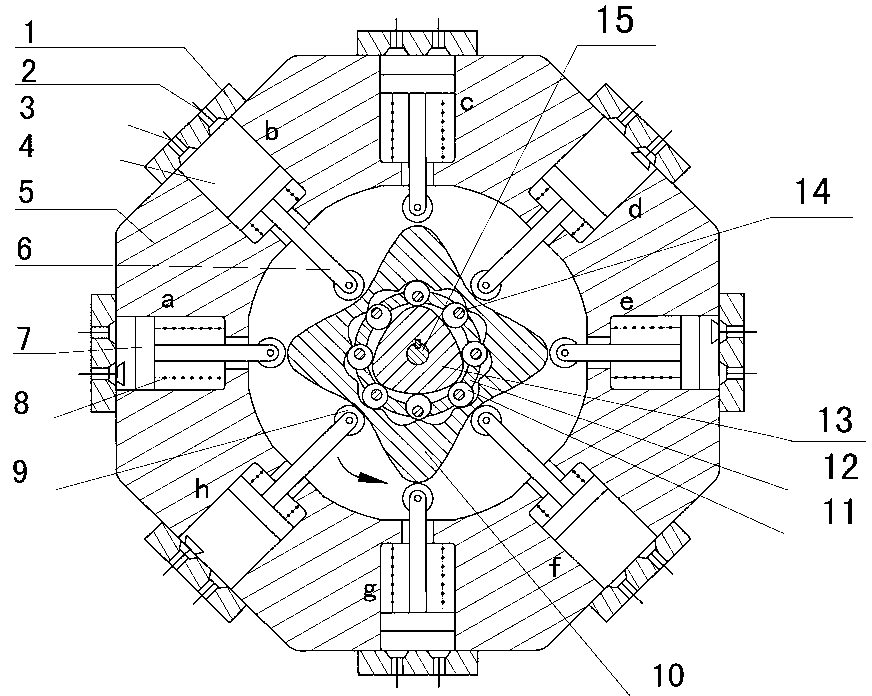

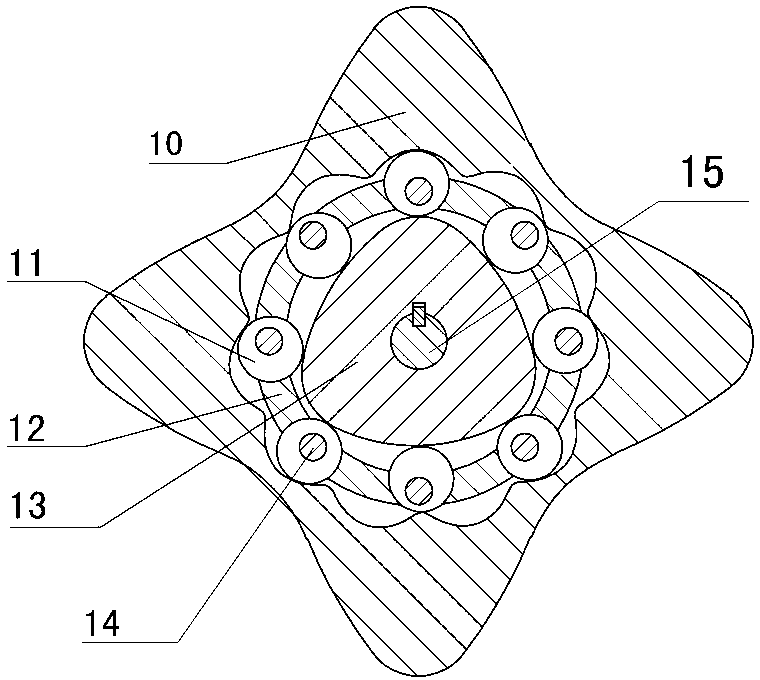

Outer convex inner arbitrary gear difference cam rolling moving transmission internal-combustion engine

The invention discloses an outer convex inner arbitrary gear difference cam rolling moving transmission internal-combustion engine, relating to the field of fuel gas power and belonging to a multi-cylinder internal-combustion engine. The invention provides a novel internal-combustion engine; eight cylinders are distributed on the periphery of an outer convex inner multiphase inner cam symmetrically in a ring shape, so that a resultant force of the outer convex inner multiphase inner cam is zero; each cylinder piston directly acts on the outer convex inner multiphase inner cam through a push rod; and power is transmitted to an output shaft connected with a central wheel key by the outer convex inner multiphase inner cam through arbitrary gear difference inner cam rolling moving movable gear transmission. With the adoption of the internal-combustion engine, a connecting rod and a crank shaft in the traditional internal-combustion engine are saved; an outer convex multiphase inner cam rolling moving transmission mechanism has the characteristics of having no eccentric mass, and having an inertia force and working load self-balancing; the rotating speed of the output shaft depends on transmission ratio of movable gear transmission; when a movable gear frame is fixed, output by a central wheel is in low speed and large torque; and the internal-combustion engine can be widely applied to the fields of high-power engineering machinery and military and the like, such as excavators and armored cars. The internal-combustion engine is simple and compact in structure, small in axial size, self-balancing in stress, and stable in rotating.

Owner:SICHUAN UNIV

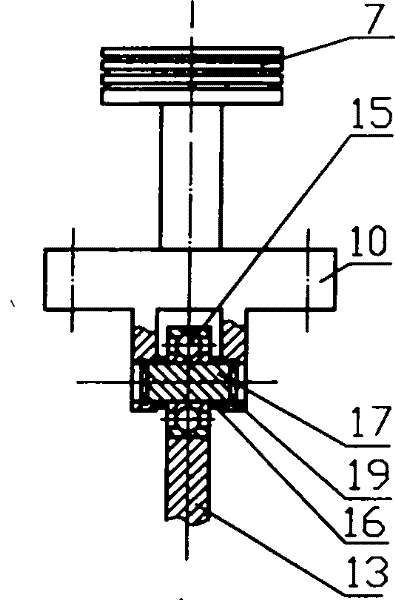

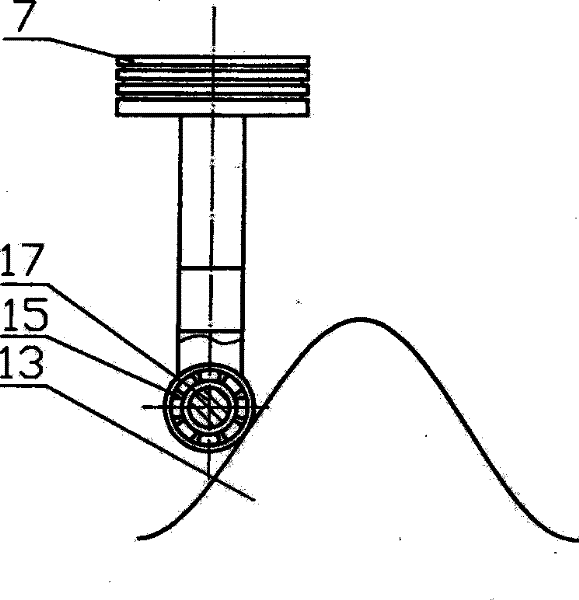

Camshaft assembly of engine with variable valve opening duration

ActiveCN102720592AGood inflation efficiencyImprove powerValve arrangementsInternal combustion piston enginesValve openingEngineering

The invention discloses a camshaft assembly of an engine with variable valve opening duration and aims to improve the inflating efficiency of the engine. The camshaft assembly comprises a group of valve opening duration control units of which the number is matched with that of cylinders of the engine, a camshaft and a variable gas distribution phase position control mechanism, wherein the valve opening duration control units are matched with the camshaft; the camshaft is a spline shaft; and the variable gas distribution phase position control mechanism is arranged at an input end of the camshaft. The camshaft assembly has the characteristics of stable performance and wide application range; and the valve opening duration and the opening and closing time can be adjusted according to working conditions of the engine, so that the inflating efficiency of the engine is optimal under various working conditions, and the dynamic property, economy and an emission index can be improved.

Owner:GREAT WALL MOTOR CO LTD

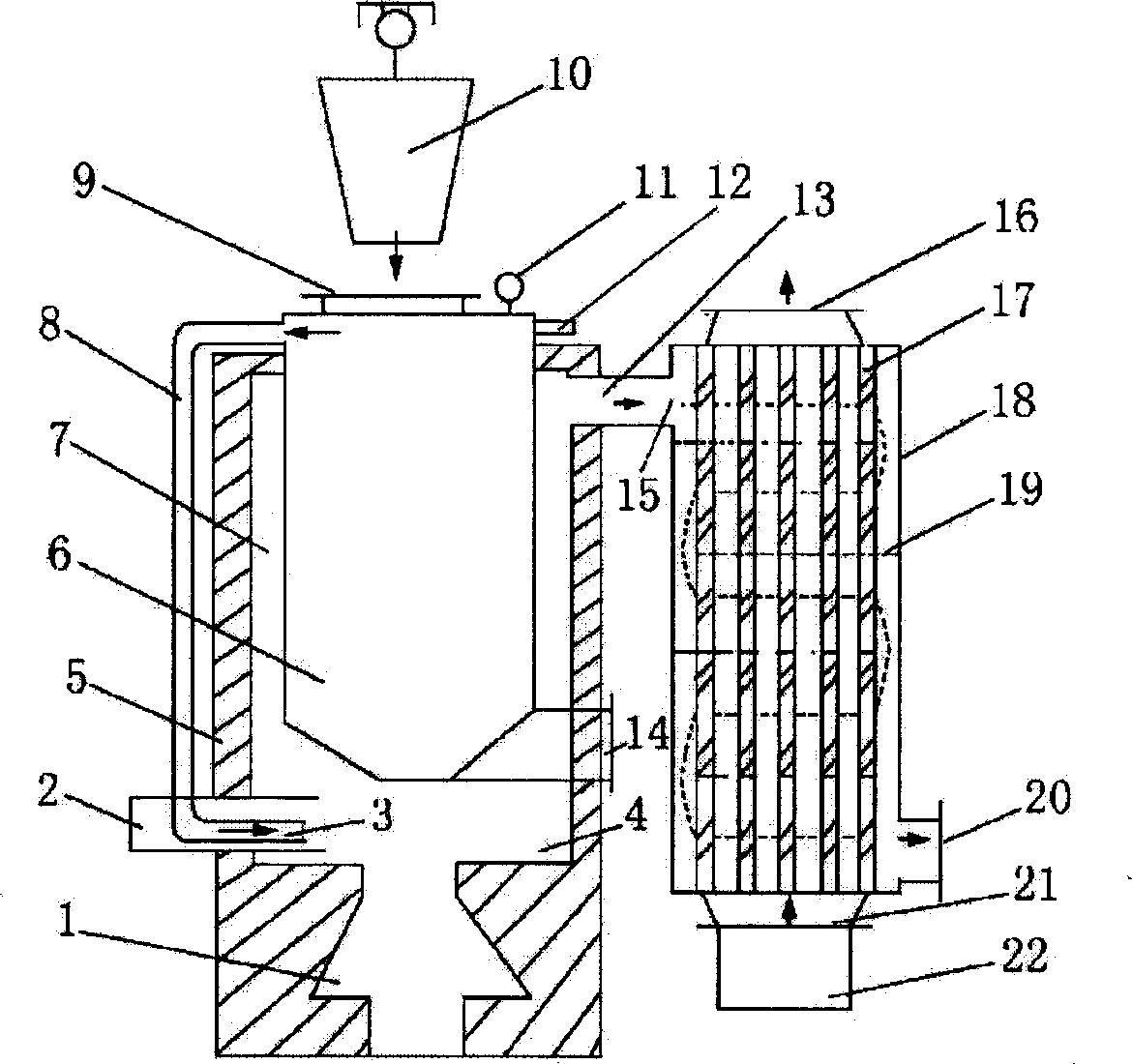

Anaerobic carbonization dangerous solid wastes disposing apparatus

ActiveCN1888535APrevent regenerationAvoid it happening againIncinerator apparatusCombustion chamberMedical waste

In the invention, a refractory insulated casing is disposed in the anacrobic pyrolyzation zone. A heating furnace is set in the tower part of the casing, a combustible gas combustion chamber is set in the middle part of the casing and in the upper part of the casing there is a hearth fire passage. In the hearth fire passage is suspended a pyrolyzation tank, on top of which a sealed charge door is corresponding to a above feeder and the top is in communication with the outlet pipe of the combustion gas and the bottom of the pyrolyzation tank is connected with a slagging means. On top of the refractory insulated casing is opened a flue outlet insulated casing is opened a flue outlet in communication with a pneumatic quench region, at the bottom of whose casing is set a fan and on its top is set an air-vent.

Owner:山东盛乙环保科技有限公司

Two-phase outer cam sleeve type high-rotational-speed internal-combustion engine

InactiveCN102877942AHigh speed outputReduce axial sizeGearingMachines/enginesEngineeringInternal combustion engine

The invention discloses a two-phase outer cam sleeve type high-rotational-speed internal-combustion engine, and relates to the field of power of fuel gas. The invention provides a novel internal-combustion engine. Eight cylinders are annularly, symmetrically and uniformly distributed around an outwards convex inner gear ring, so that resultant force from which the outwards convex inner gear ring is suffered is zero; pistons of the cylinders directly act on the outwards convex inner gear ring through push rods; and power is transferred to an output shaft connected with a symmetric two-phase cam through a key by the outwards convex inner gear ring through the drive of a two-phase outer cam type sleeve oscillating tooth. By using the internal-combustion engine, a connecting rod and a crankshaft in a conventional internal-combustion engine are omitted; a two-phase outer cam sleeve driving mechanism of the outwards convex inner gear ring of the internal-combustion engine does not have an eccentric mass; the internal-combustion engine has the characteristic of the self balancing of inertia force and a working load; the rotational speed of the output shaft depends on the drive ratio of the drive of the oscillating tooth; if a dowel pin frame is fixedly arranged, the symmetric two-phase cam carries out output at a high speed; the internal-combustion engine can be widely applied to the field of high rotational speeds, such as engines of helicopters, and miniature engines; and when an output rotational speed is constant, the emission of harmful gas can be reduced. The internal-combustion engine is simple and compact in structure, small in axial dimension and self-balancing in stress, and is stable to run.

Owner:SICHUAN UNIV

Two-phase inner cam type swinging transmission internal combustion engine

InactiveCN102828824AForce self-balancingLarge transmission ratioGearingMachines/enginesLow speedEngineering

The invention provides a two-phase inner cam type swinging transmission internal combustion engine, which relates to the field of gas motive power and belongs to a multi-cylinder internal combustion engine. The invention provides a novel internal combustion engine, eight air cylinders are annularly, symmetrically and uniformly distributed around an outer convex inner two-phase inner cam, the resultant force of the outer convex inner two-phase inner cam is zero, an air cylinder piston directly acts on the outer convex inner two-phase inner cam through a push rod, and the motive power is transferred to an output shaft connected with a center wheel key through a two-phase inner cam type swinging movable tooth via the outer convex inner two-phase inner cam. The internal combustion engine has the characteristics that a connecting rod and a crankshaft in the traditional internal combustion engine are omitted, and an outer convex inner two-phase inner cam type swinging transmission mechanism does not have the eccentric mass, and has the inertia force and work load self balance characteristic. The rotating speed of the output shaft depends on the transmission ratio of the movable tooth transmission, when the movable tooth frame is fixed, a center wheel realizes low-speed and large-torque output, and the internal combustion engine can be widely applied to engineering machinery, armored car and the like with high-powder requirements. The internal combustion engine has the advantages that the structure is simple and compact, the axial dimension is small, the self balance of the stress is realized, and the operation is stable.

Owner:SICHUAN UNIV

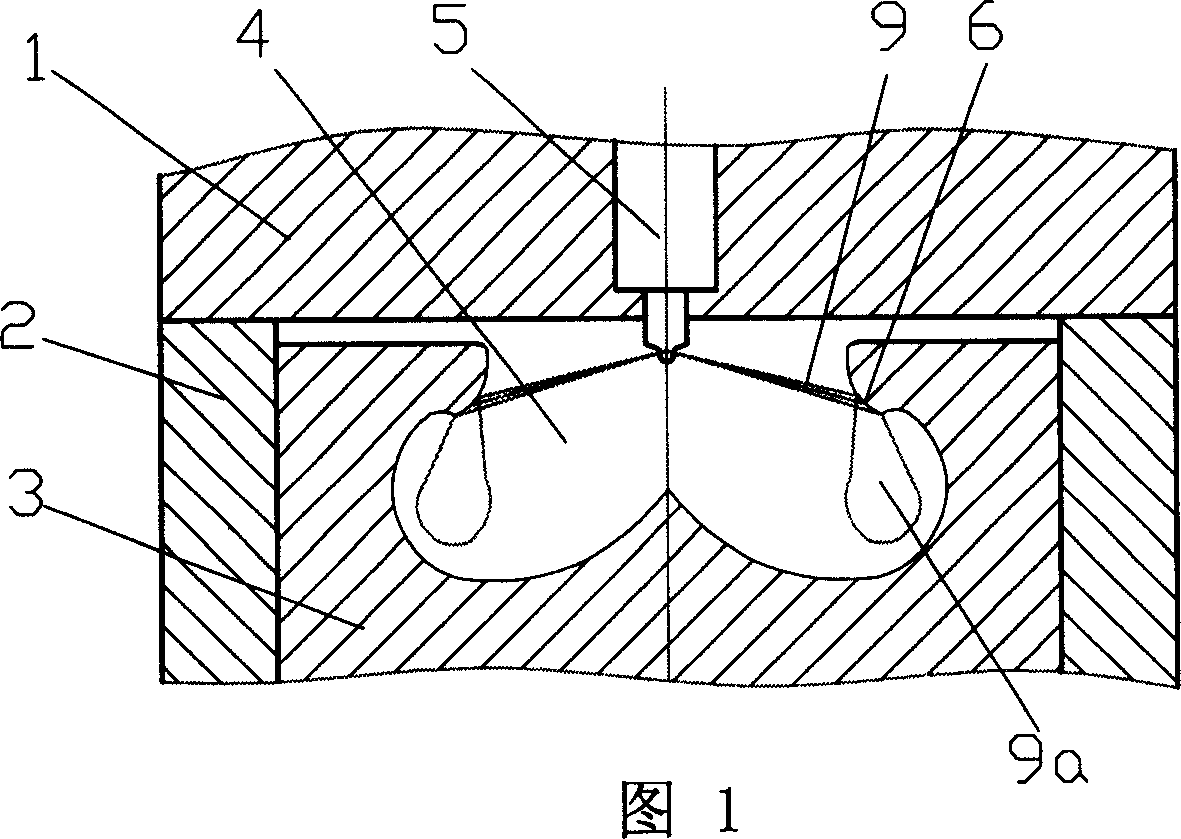

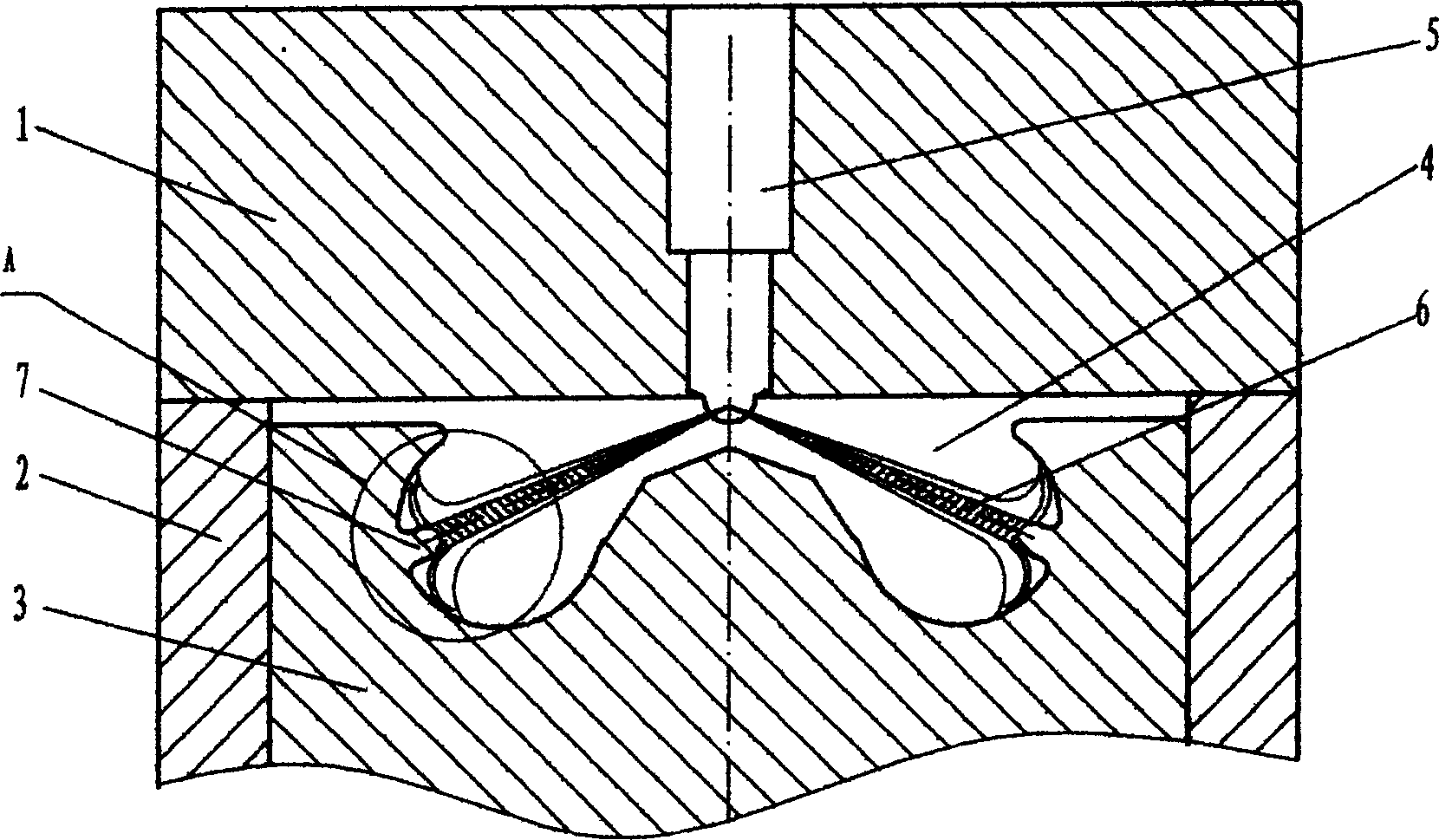

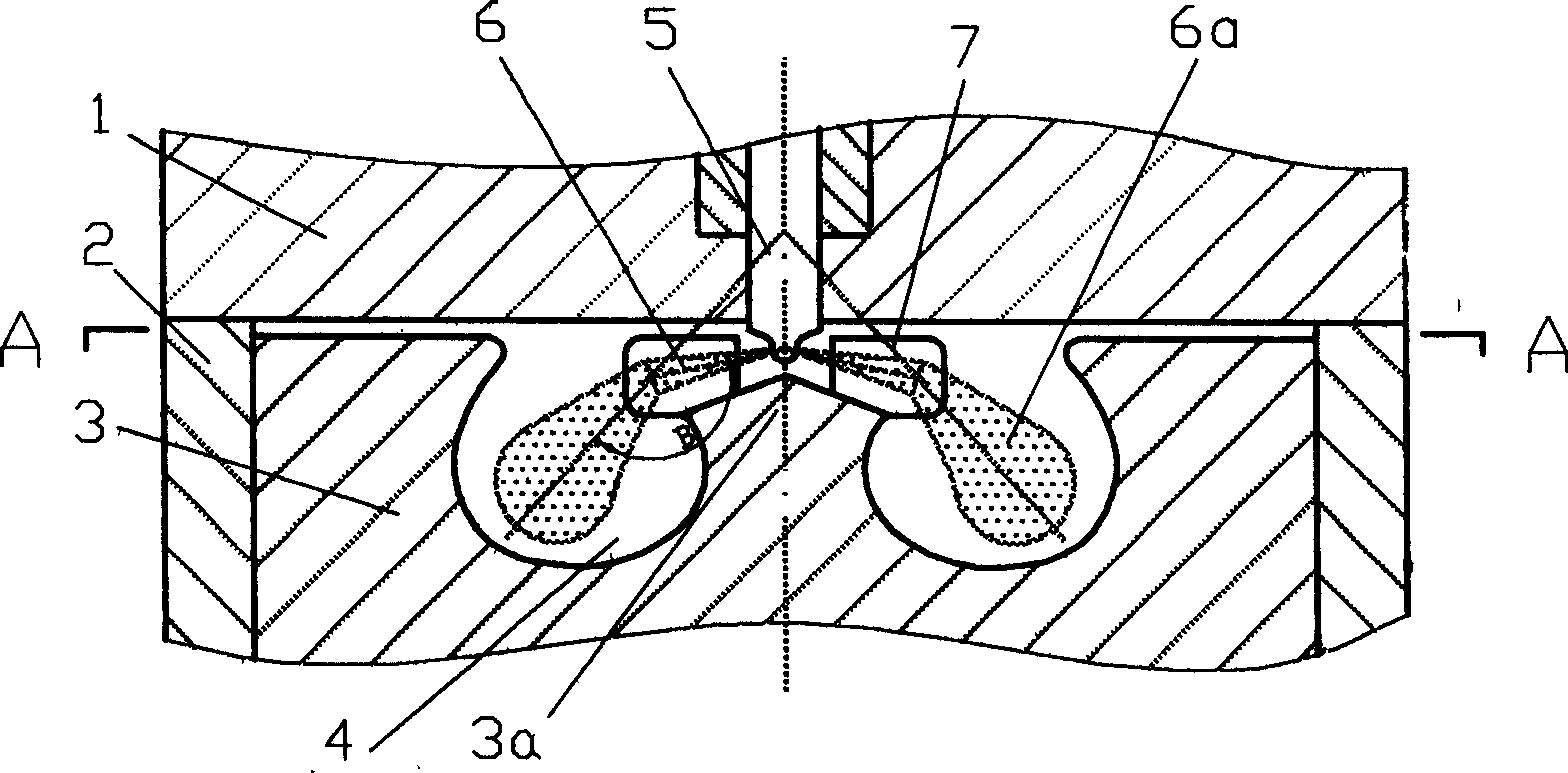

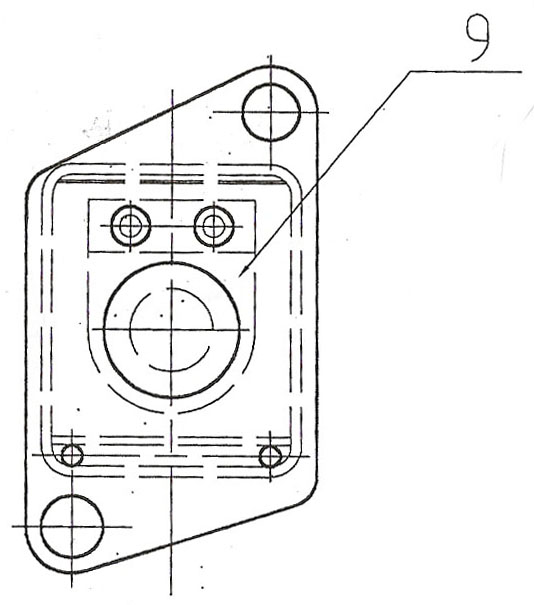

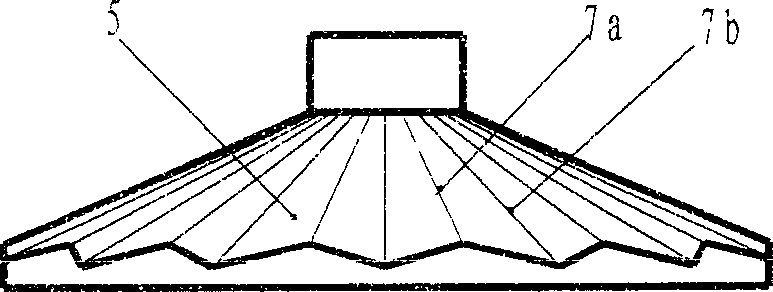

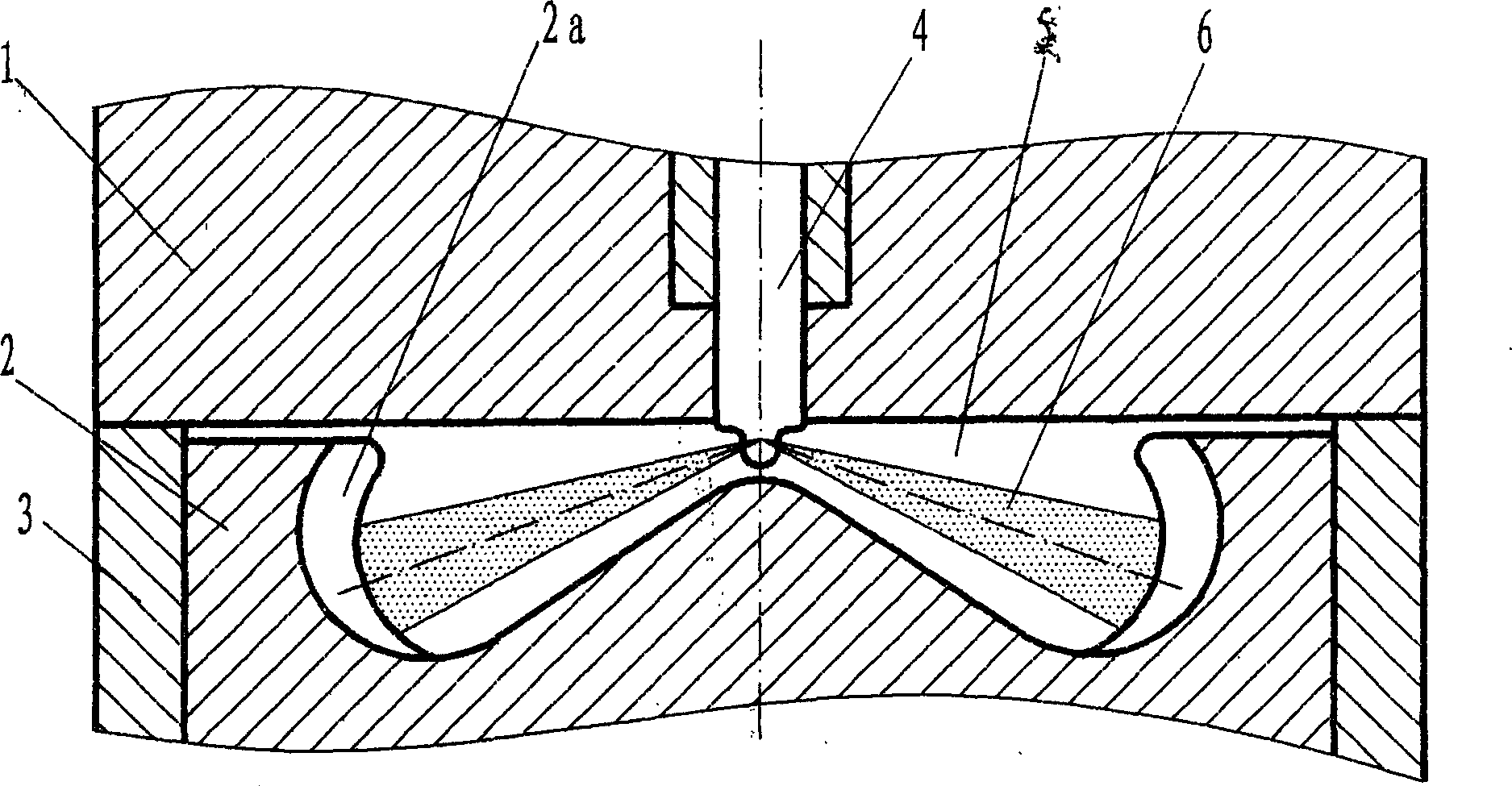

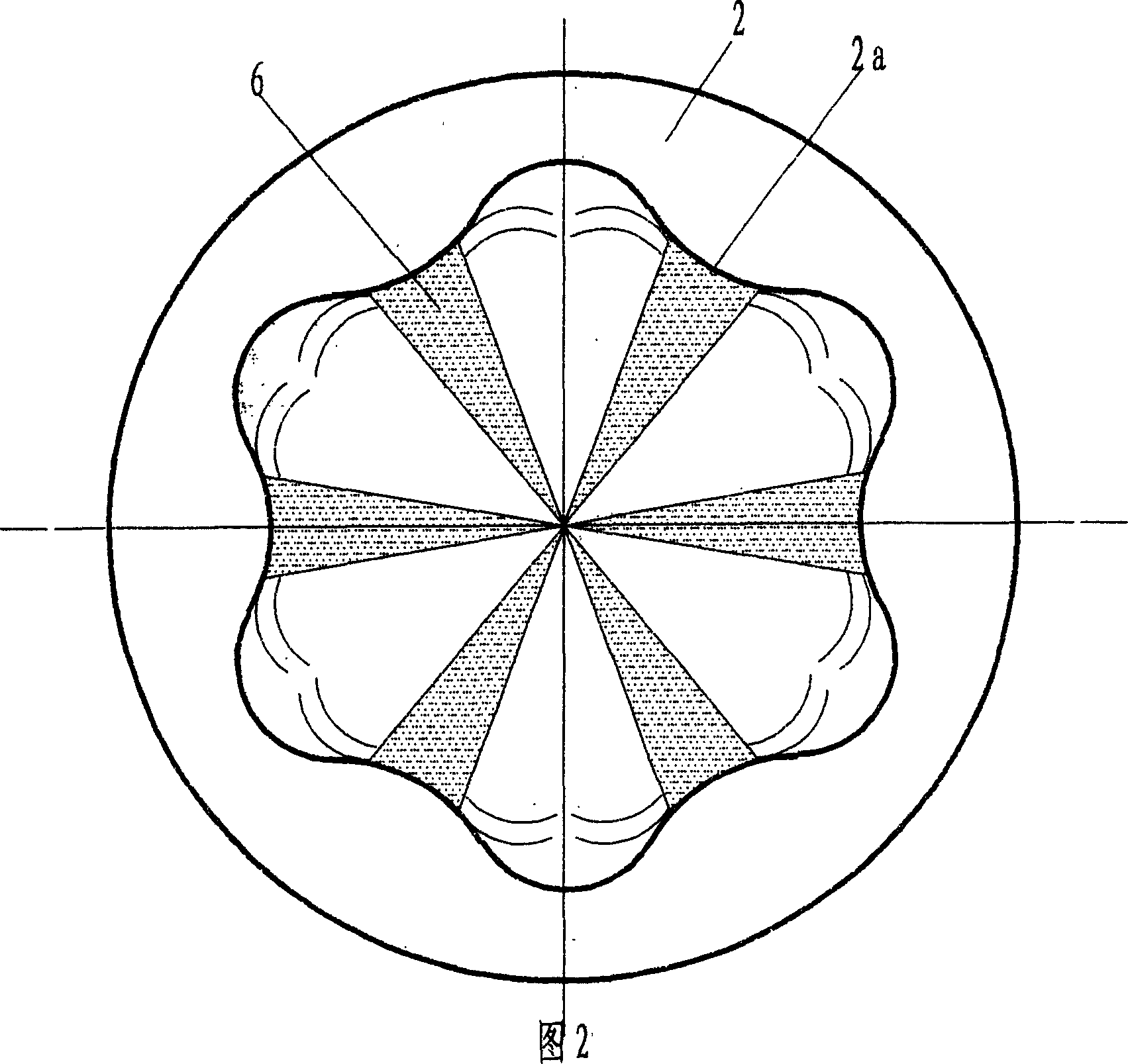

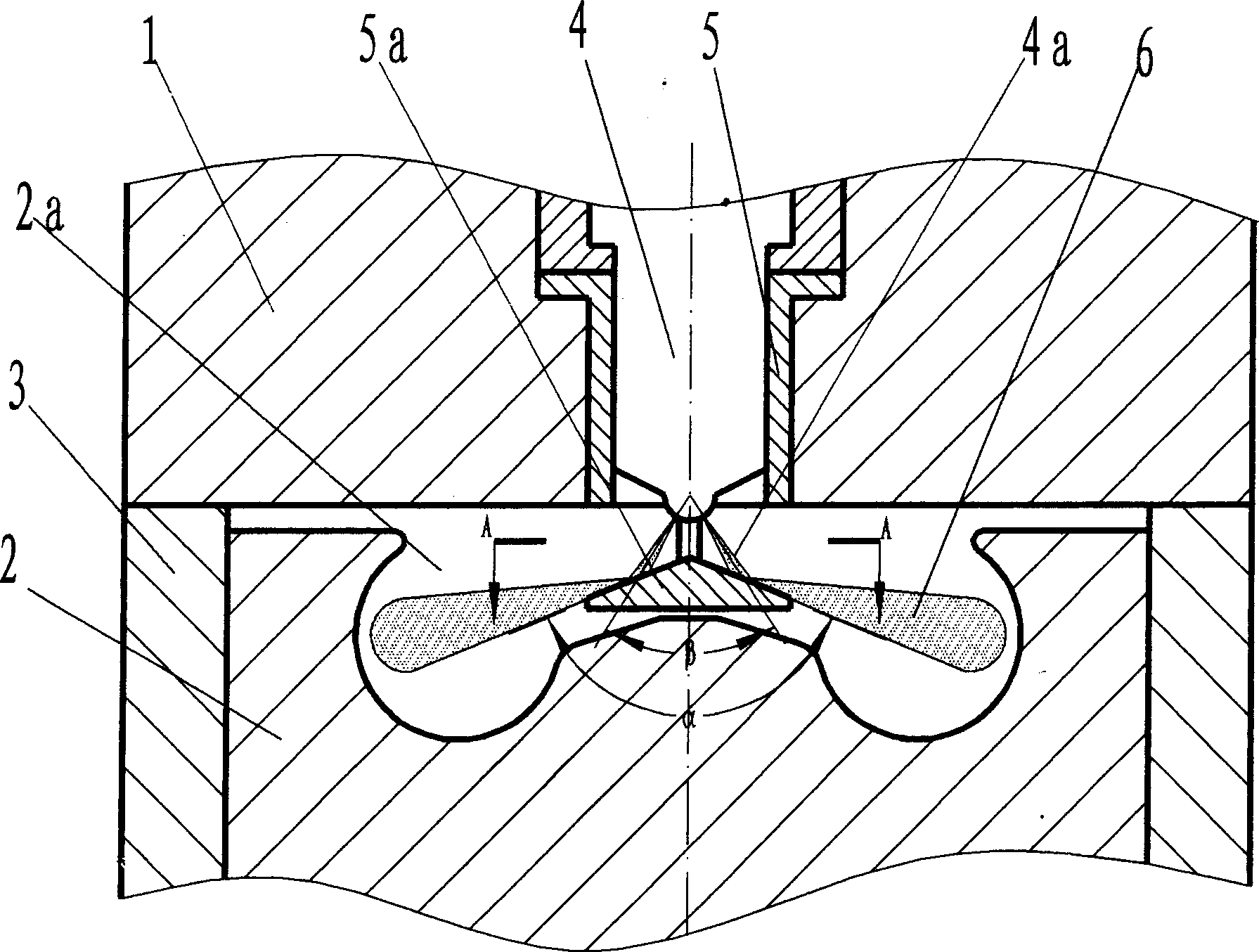

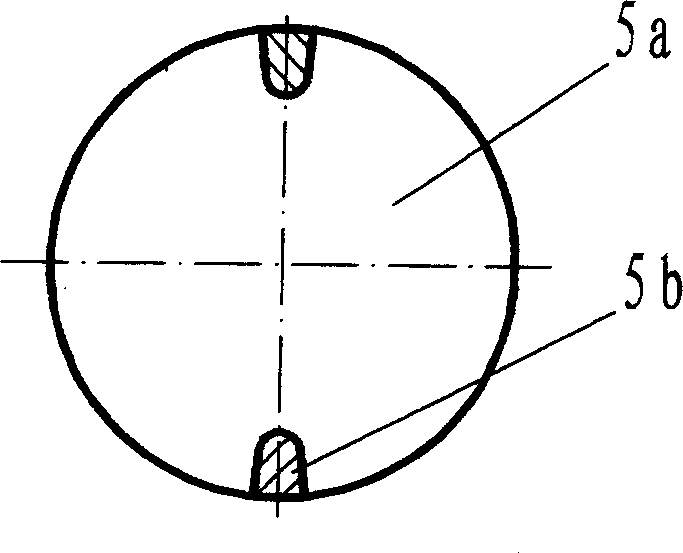

Spraying and diffusing combustion system of IC engine

InactiveCN1614209AFast spray dispersionThe spatial range of the distribution is largeInternal combustion piston enginesFuel injection apparatusCombustion chamberEngineering

A spray diffusion-type combustion system for IC engine features that a spray diffusing arc surface is arranged at the diameter-reduced position of combustion chamber for spraying the oil beam from the oil sprayer directly to the arc surface, so generating an oil beam diffused in wide range and quickly forming a relatively uniform gas mixture. Its advantages are quick and full combustion, low oil consumption, high power and less pollution.

Owner:DALIAN UNIV OF TECH

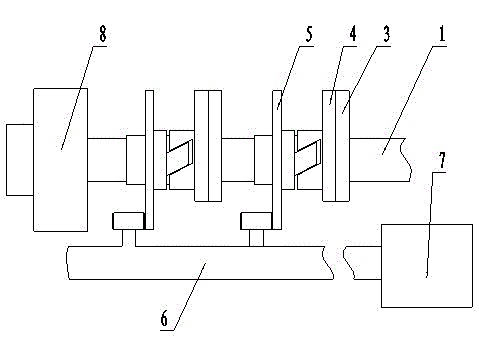

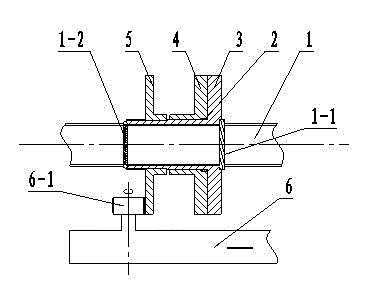

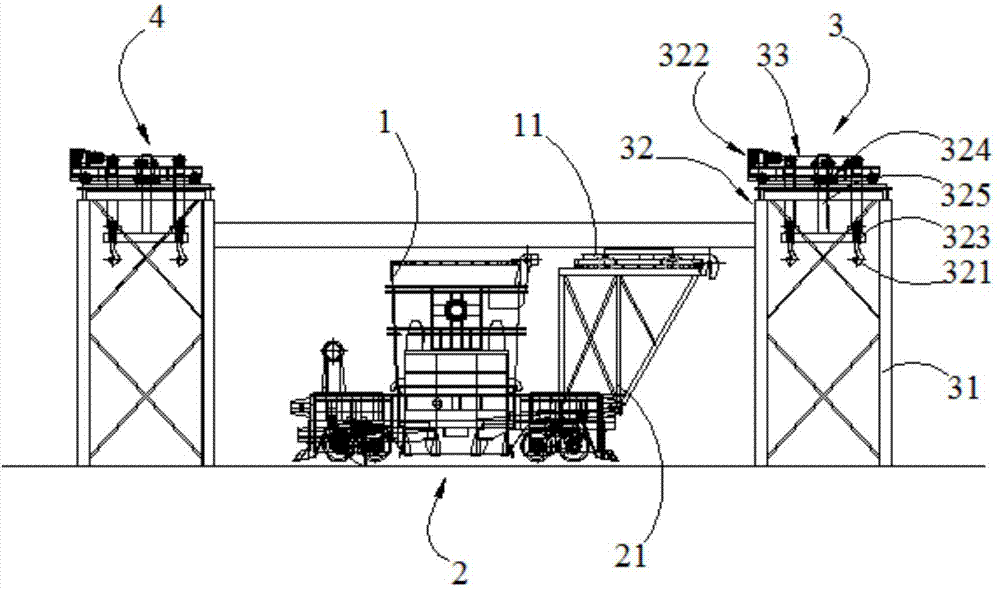

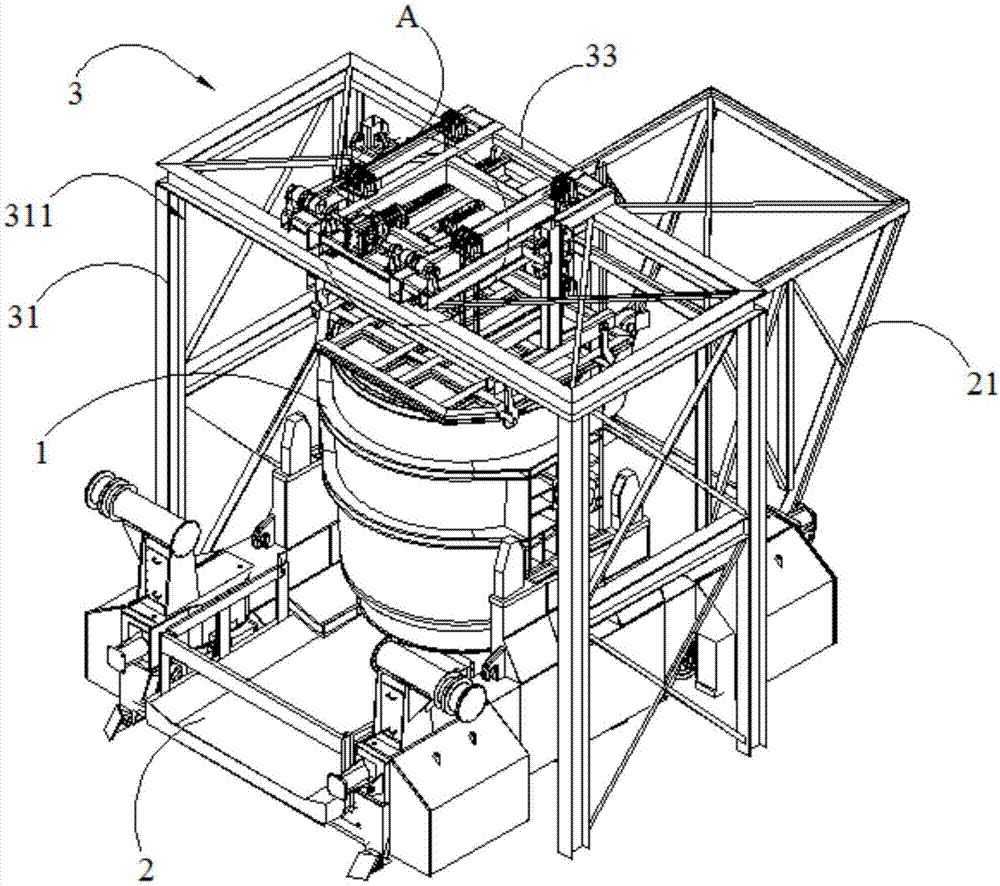

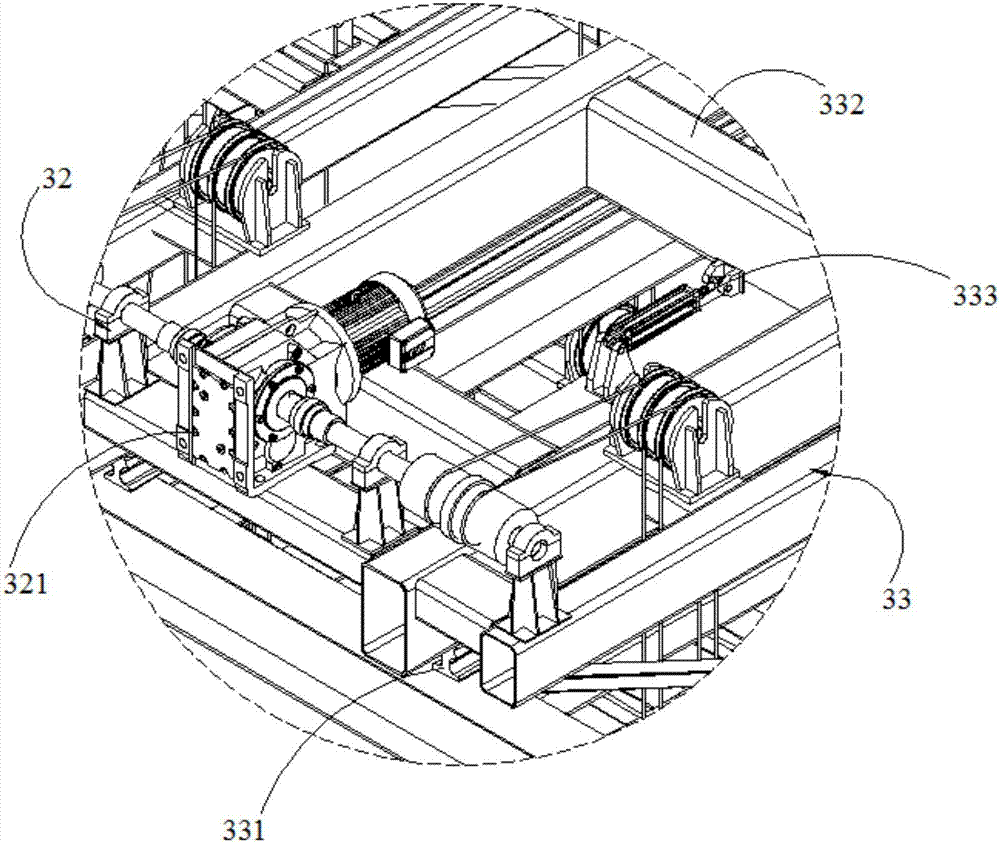

Cover adding and uncovering method and device for ladle in processing station

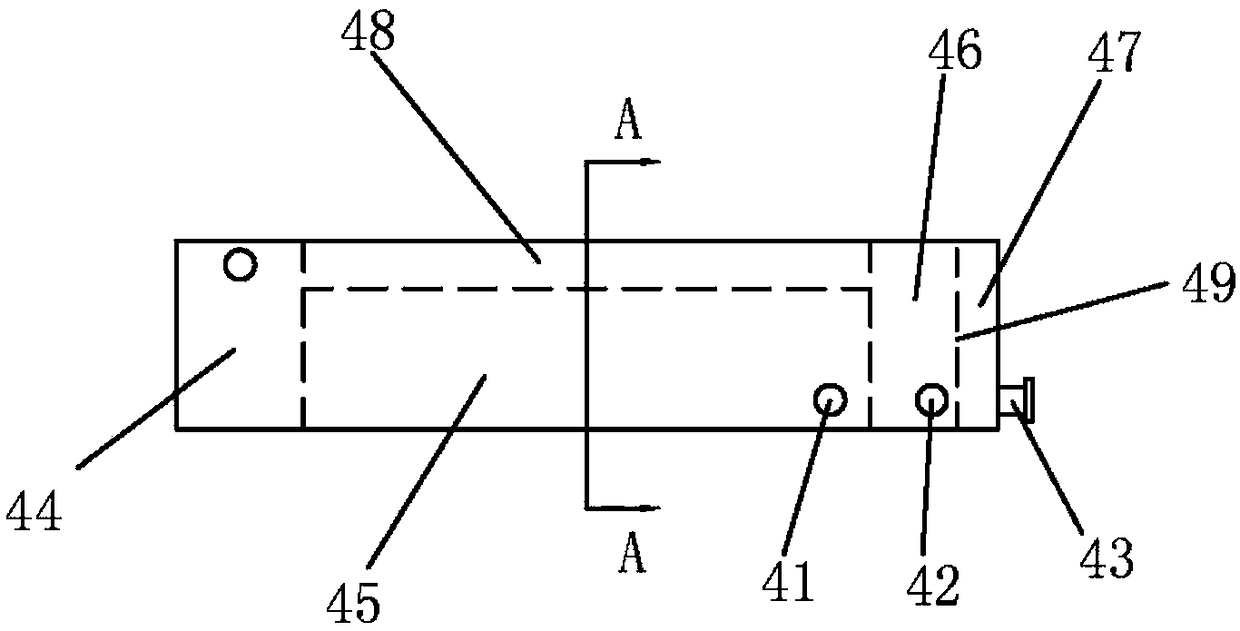

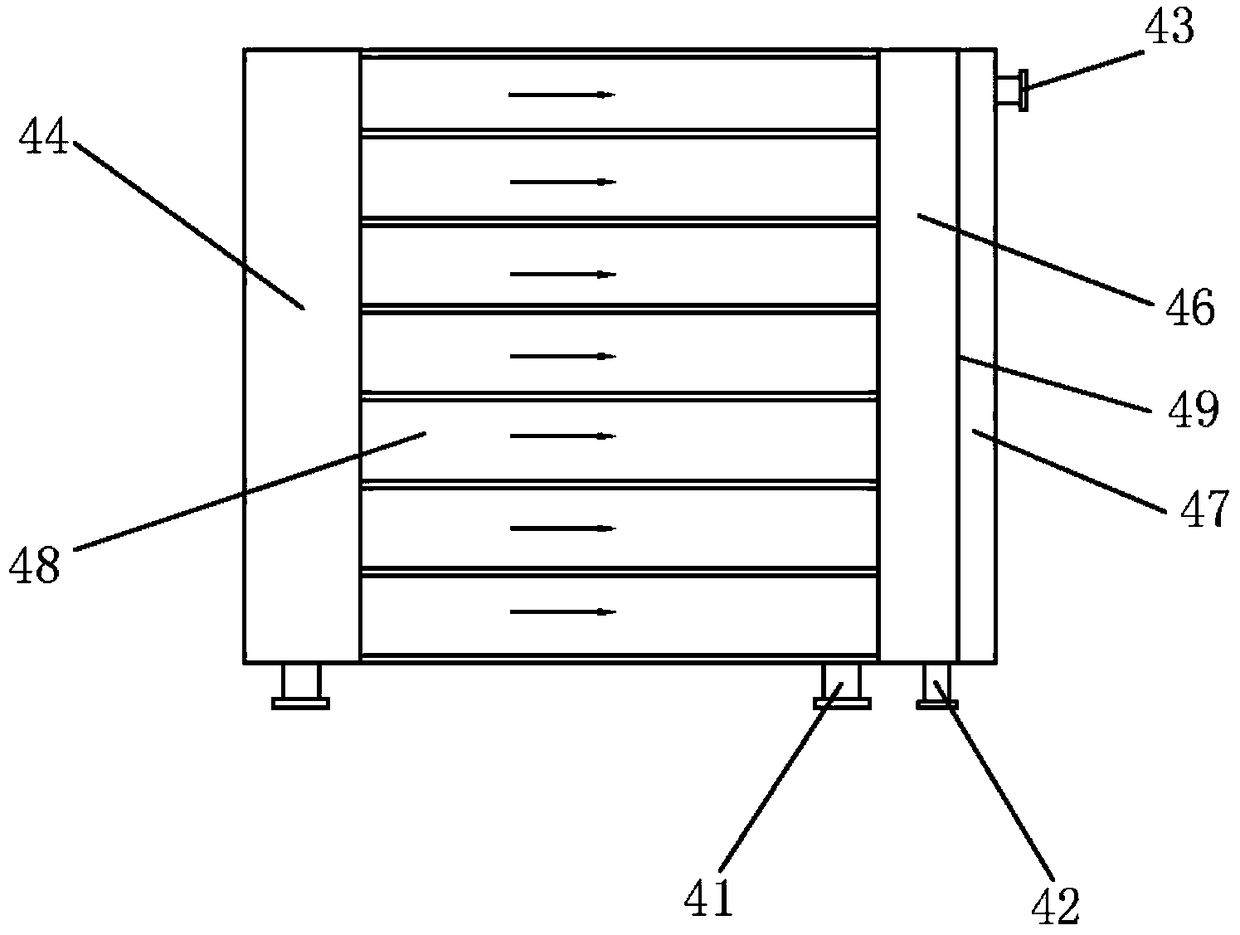

ActiveCN107262702AReduce consumptionImprovements in emission indicatorsMelt-holding vesselsEngineering

The invention relates to a ladle and provides a cover adding and uncovering method for a ladle in a processing station. The cover adding and uncovering method comprises the steps that before the ladle is transported to the processing station, a ladle cover is taken down through a cover uncovering mechanism in a cover uncovering station and then placed on a storage rack of a ladle car; and after processing is completed in the processing station, the ladle cover is buckled on the ladle from the storage rack through a cover adding mechanism in a cover adding station. The invention further provides a cover adding and uncovering device. The cover adding and uncovering device comprises the ladle car and further comprises the cover uncovering mechanism and the cover adding mechanism. A moving path of the ladle car is arranged between the cover uncovering mechanism and the cover adding mechanism. The processing station of the ladle is located on the moving path. The ladle car is provided with the storage rack for containing the ladle cover. According to the cover adding and uncovering method and device for the ladle in the processing station, the cover uncovering station and the cover adding station are separately arranged, and under the matching action of the storage rack of the ladle car, the clearance requirement in the processing station is very low, that is, the cover adding and uncovering method can adapt to the low clearance environment in the processing station; and in addition, the cover adding and uncovering method can further meet the occasions where ladles need to penetrate through processing stations along with covers and adapts to any old factory ladle cover adding project reconstruction.

Owner:WISDRI ENG & RES INC LTD

Two-phase outer cam shock wave rolling transmission internal combustion engine

InactiveCN102937048AReduce axial sizeCompact structureValve drivesMachines/enginesShock waveExternal combustion engine

The invention provides a two-phase outer cam shock wave rolling transmission internal combustion engine and relates to the field of gas power. According to the novel internal combustion engine, eight cylinders are annularly symmetrically evenly distributed around a convex inner tooth ring, the resultant force which the convex inner tooth ring is subjected to is zero, and a cylinder piston directly acts on the convex inner tooth ring through a push rod, power is transmitted to an output shaft connected with a two-phase outer cam key by two-phase outer cam shock wave rolling oscillating tooth transmission through the convex inner tooth ring. According to the internal combustion engine, a connecting rod and a crankshaft in a traditional internal combustion engine are not required, a convex inner two-phase shock wave rolling transmission mechanism does not have eccentric mass and has the advantages of self balancing of inertia force and working load, and the rotating speed of the output shaft depends on the transmission ratio of oscillating tooth transmission. If an oscillating tooth brace is fixed, a two-phase outer cam performs high-speed output and can be widely applied to the fields requiring for high rotating speeds, such as helicopter engines and small generators, and discharge of harmful gas can be reduced when the output rotating speed is fixed. The internal combustion engine is simple and compact in structure, small in axial dimensions self-balancing in stress and runs stably.

Owner:SICHUAN UNIV

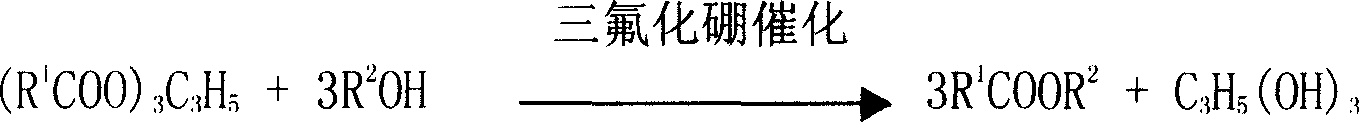

Method for preparing biologic diesel oil by using halophytic vegetation as raw material

InactiveCN1696247AHigh fat contentImprove applicabilityLiquid hydrocarbon mixture productionBio-feedstockHalophyteAlcohol

A process for preparing the biologic diesel oil from halophyte includes mixing the seeds of halophyte with short-chain alcohol, strong stirring, adding BF3 as catalyst, slow stirring, while esterifying reaction under reflux, cooling, filter, distilling for recovering alcohol, laying the liquid aside for phase separation to obtain lower layer of coarse glycerine and upper layer of methylester of fatty acid and ethylester of fatty acid, vacuum distilling of said upper layer, and purifying.

Owner:THE FIRST INST OF OCEANOGRAPHY SOA

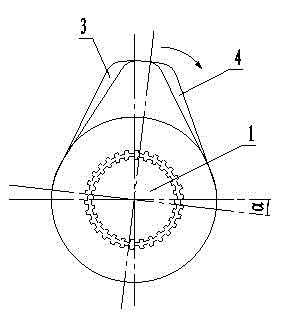

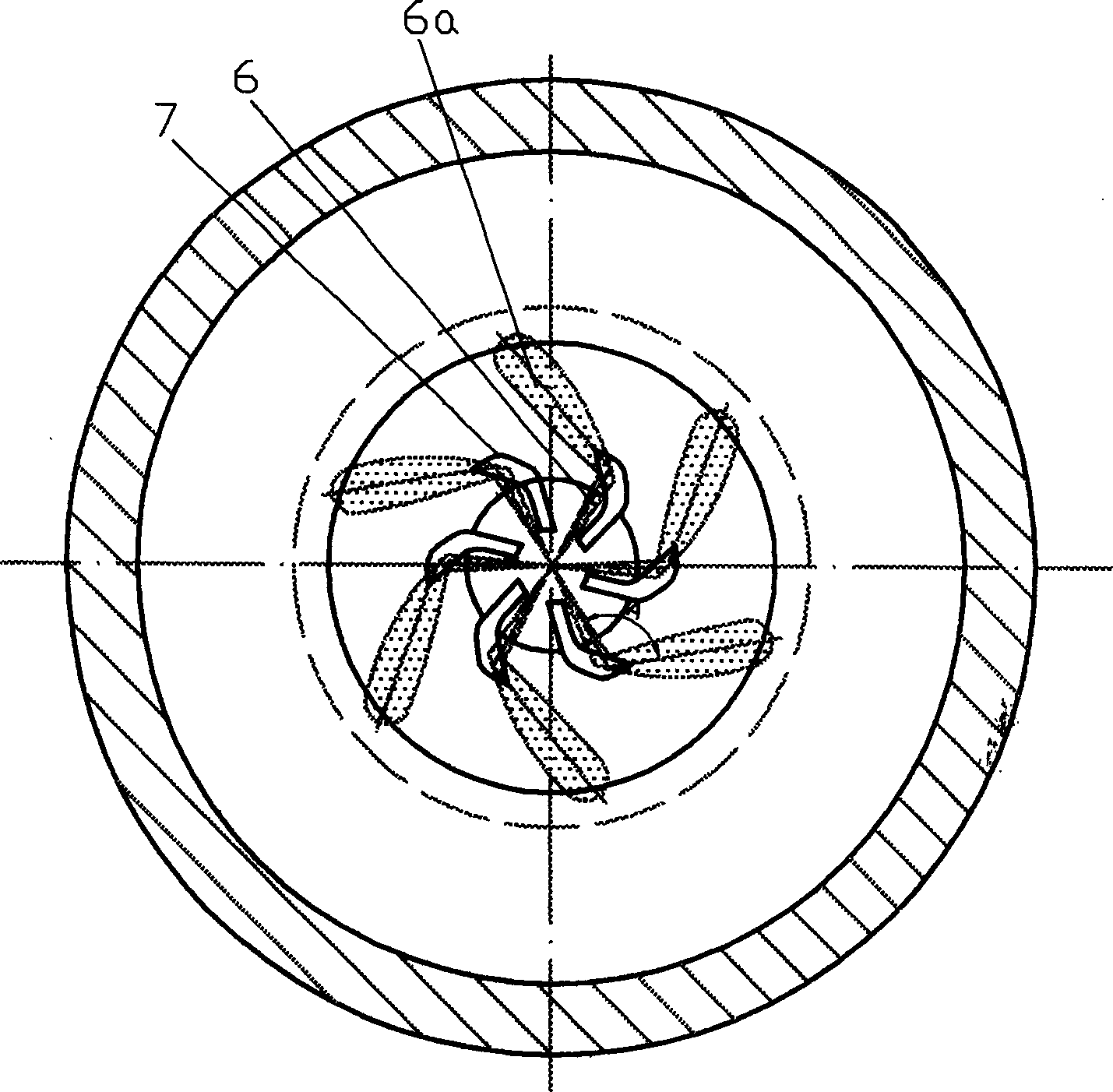

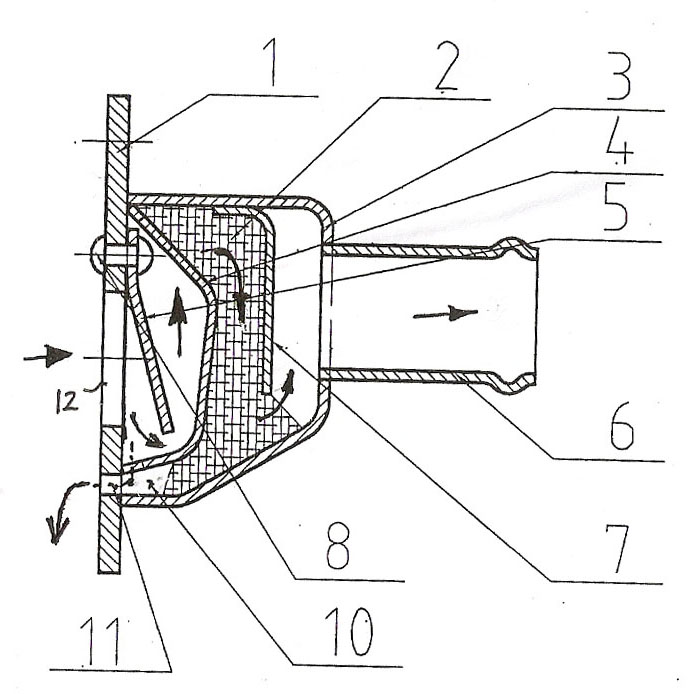

Spraying guidance system of internal combustion engine

InactiveCN1480642AIncrease involvementQuality improvementInternal combustion piston enginesFuel injection apparatusGuidance systemCombustion chamber

A spray guide system of IC engine features that a spray guide step is made on the inner surface of omega-type combustion chamber. When the pistor is raising up in the primary spray phase, the oil beam is sprayed onto said guide step, which can reflect part of the oil beam and quickly disperse the rest along its guide arc, so realizing secondary atomizing.

Owner:DALIAN UNIV OF TECH

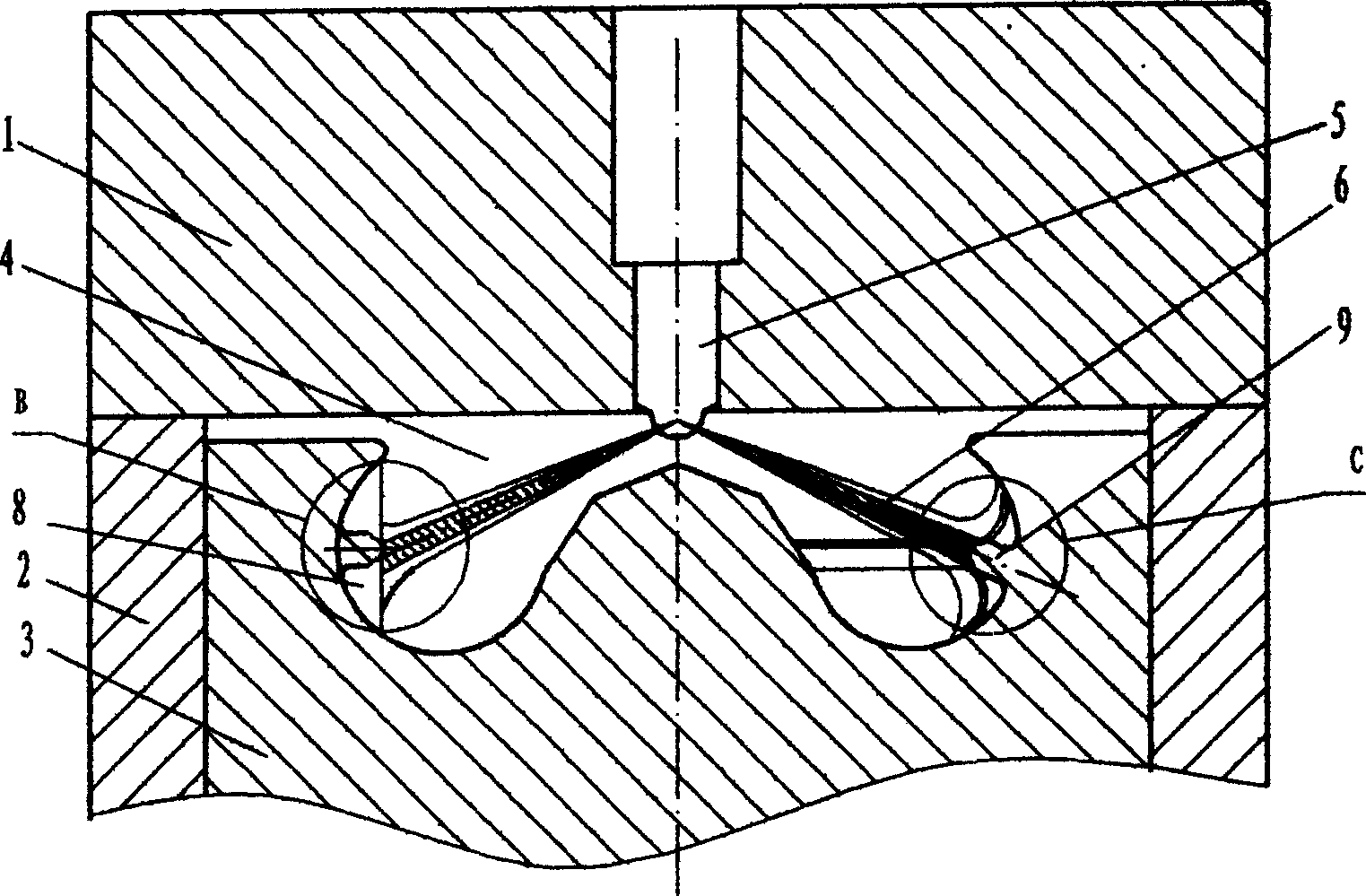

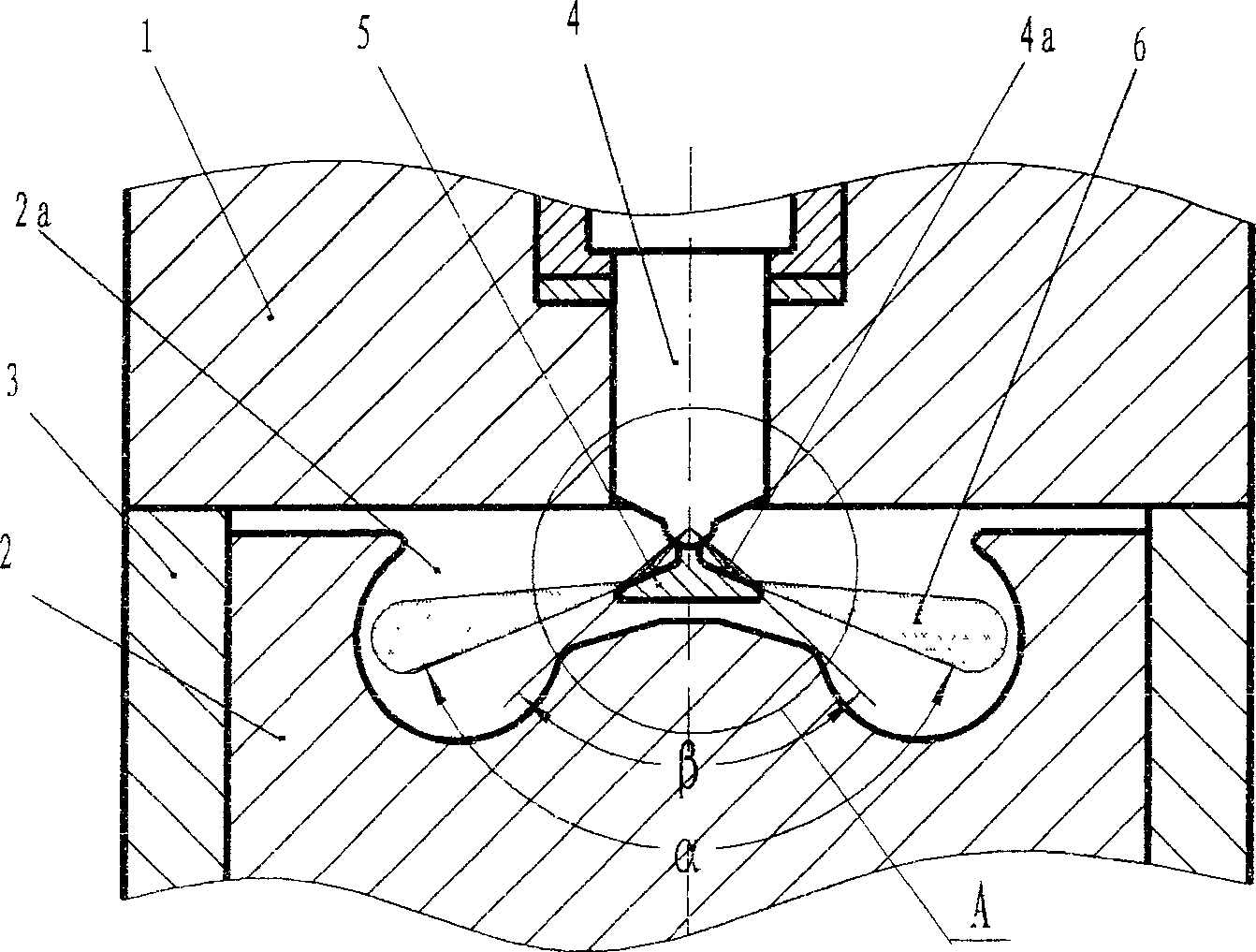

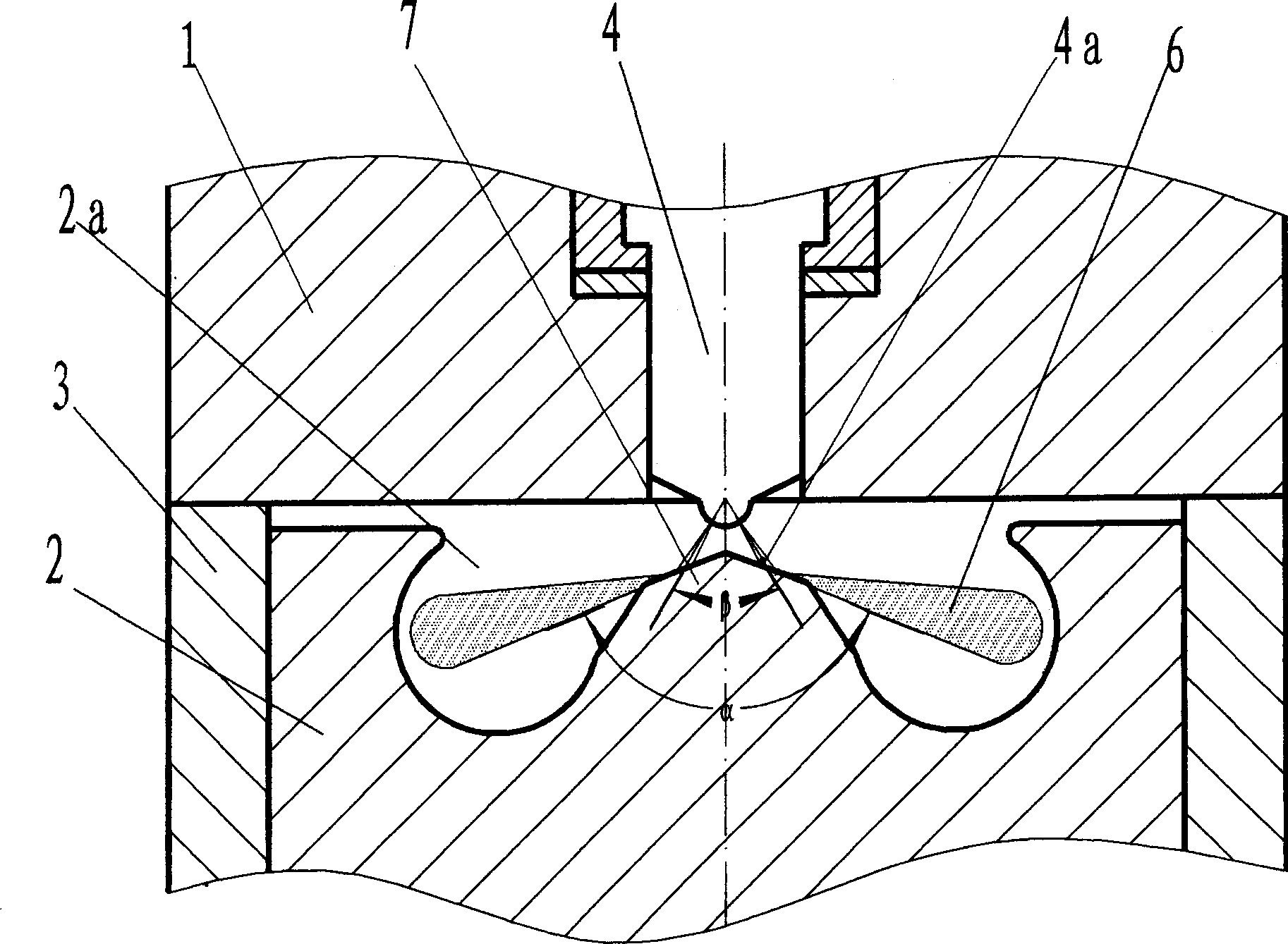

Collision spray burning system of internal combustion engine

InactiveCN1558094AFast dispersionIncrease involvementInternal combustion piston enginesCarburettorsCombustorCombustion chamber

The present invention is collision atomizing burning system for internal combustion engine and belongs to the field of the formation and combustion of mixed gas in internal combustion engine. The collision block makes the primary oil beam develop along the collision plane without deposition in the falling point in high dispersion speed, large distribution space range separated from the combustor, increased involved air amount and fine atomized particle, so as to form homogeneous mixed gas fast, improve the quality of the inflammable gas mixture in internal combustion engine and perfect the combustion without needing great air eddy current. The present invention can improve obviously the fume exhaust index of internal combustion engine and raise the kinetic and economic indexes.

Owner:DALIAN UNIV OF TECH

Cylinder double-face cam axial piston type crankless internal combustion engine

InactiveCN101392684BReduce noiseSmall shock and vibrationValve drivesMachines/enginesExhaust valveCombustion

The invention discloses a cylindrical double-track cam axial piston type crankless internal combustion engine, which relates to the technical field of internal combustion engines and is a multi-cylinder internal combustion engine. The invention provides a novel internal combustion engine; when pistons drive rollers arranged on the bottoms of the pistons for reciprocating movement, the rollers push a double-track cam fixed on a main shaft to rotate, and the power is output from the double-track cam through the main shaft. Outlines of two end surfaces of the double-track cam are in the form that wave crests correspond to wave crests, wave troughs correspond to wave troughs, and the two end surfaces are circumferentially symmetrical. Two groups of cylinders are symmetrically arranged at bothends of the double-track cam, and axis lines of the cylinders have equal distance to an axis line of the main shaft and are parallelly, circularly and evenly distributed. The pistons which have the same axis line and are symmetrically arranged with the spacing of 180 DEG C have the same working state, which ensures that the axial and radial composite force of the double-track cam and the main shaft are zero. A sliding rod at the bottom of each piston slides in a guide groove, which ensures that the side pressure of the piston is zero. Intake and exhaust valves of all the cylinders are intensively controlled by two distributing cams. The internal combustion engine has the characteristics of simple and compact structure, small volume, small impact vibration, steady operation, high power, long service life and so on.

Owner:SICHUAN UNIV

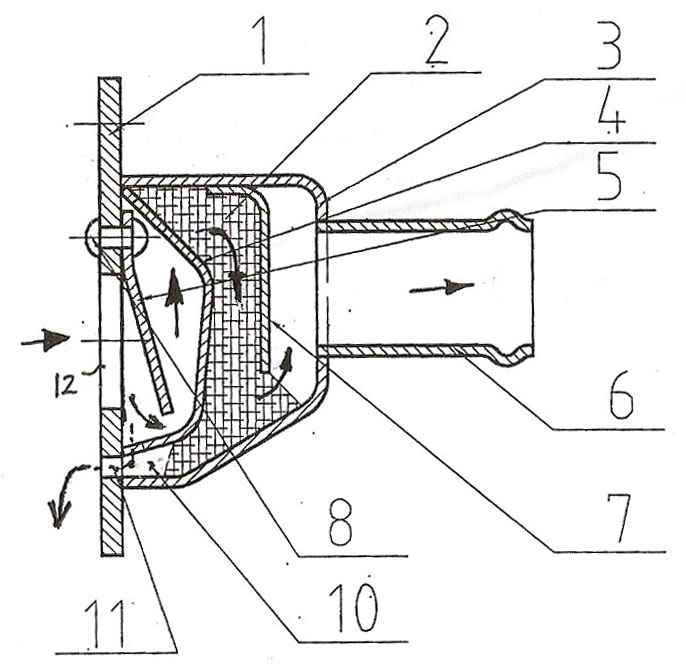

Energy-saving breather for engine

InactiveCN102146822AReduce consumptionReasonable structureMachines/enginesPressure lubricationFilter materialOil consumption

The invention discloses an energy-saving breather for an engine, comprising a baseplate. An air inlet communicated with an inner cavity of the engine is arranged on the baseplate, a breathing plate device covers the air inlet, a filtering device is arranged at the outer side of the breathing plate device, and an air outlet of the filtering device is communicated with an air outlet pipe. The energy-saving breather has a reasonable structure, realizes ideal oil-gas separation during ventilation of the original breather by utilizing vibration of diaphragms and reasonable airflow distribution and adopting a filtering material and achieves the purposes of greatly reducing engine oil consumption and improving emission.

Owner:南通紫金全昶节能科技有限公司

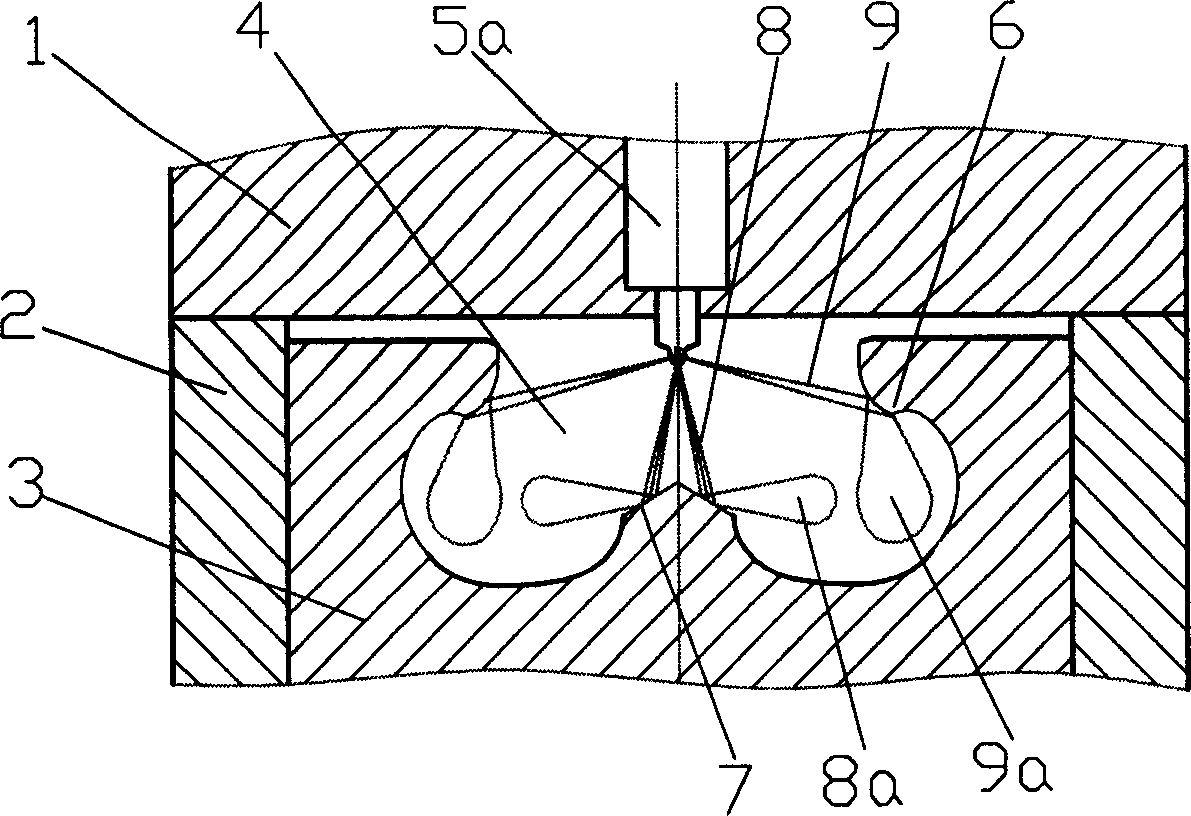

Injection system for internal combustion engine

InactiveCN1529049AQuality improvementImprovements in emission indicatorsFuel injection apparatusMachines/enginesCombustionExternal combustion engine

The invention is a kind of combustion spraying system, which belongs to engine mixed gas forming and combustion field. It sets a guiding cone under the oil sprayer, the guiding cone and the oil sprayer is connected together, forms a integral body. When the oil ejected from the multi-hole oil sprayer reaches the cone, under the guiding of cone surface, by using the secondary oil beam, forms pulverization with even distribution, good pulverization, controllable penetration distance, it speeds up the combustion of gas, thus the power, and economic performance and discharging index of engine are improved prominently.

Owner:DALIAN UNIV OF TECH

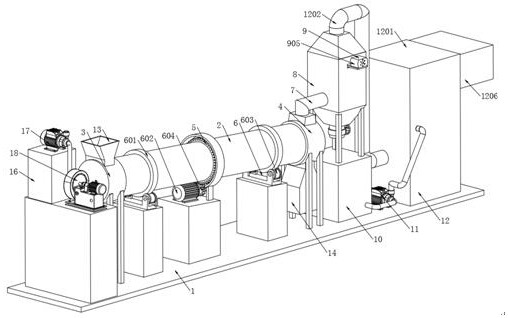

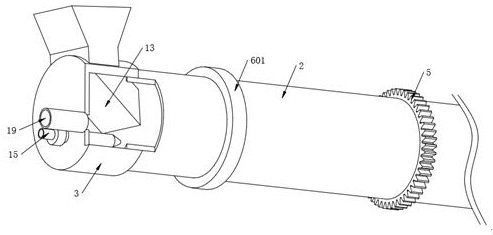

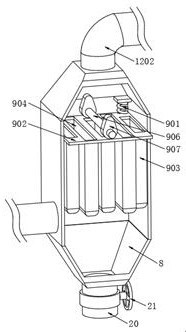

Desulfurization device in drying kiln for smelting ferronickel by using RKEF method

PendingCN114307445AReduce loadImprove purification effectTransportation and packagingDispersed particle separationDust controlProcess engineering

The invention belongs to the technical field of ferronickel smelting, and particularly relates to an in-kiln desulfurization device of a drying kiln for smelting ferronickel through an RKEF method, the in-kiln desulfurization device comprises a bottom plate, a barrel is arranged above the bottom plate, and the two ends of the barrel are rotationally communicated with a kiln head cover and a kiln tail cover through bearings; the surface of the kiln head cover and the surface of the kiln tail cover are fixed to the top of the bottom plate through supporting legs. By arranging the smoke outlet pipe, the dust removal box and the dust removal mechanism, dust contained in smoke can be firstly filtered and accumulated in the dust removal box, and by arranging the dust discharge pipe and the valve, workers can collect and secondarily treat the dust, so that metal elements still existing in the dust are prevented from being wasted; by arranging the water tank, the water pump and the desulfurization mechanism, gas subjected to dust removal can be desulfurized and then filtered again, and then is conveyed into the chimney to be discharged, so that the load of subsequent purification is reduced, meanwhile, the purification effect can be obviously improved, and the emission index is qualitatively improved.

Owner:扬州一川镍业有限公司

Method for extracting polynitrotoluene from nitrotoluene acid wastewater

ActiveCN109627170AReduce contentIncrease contentOrganic chemistryOrganic compound preparationNitro compoundFiltration

The invention relates to the technical field of nitrotoluene preparation, in particular to a method for extracting polynitrotoluene from nitrotoluene acid wastewater, mononitrotoluene, acid wastewater, a mixed nitrification in a collection tank and refluent emulsified acidic water are mixed and conveyed to a cooler for two-time cooling by a delivery pump, then the liquid is subjected to primary separation to obtain a mixed nitrification and acidic water, the acidic water is subjected to secondary separation to obtain a mixed nitrification, clear acidic water and emulsified acidic water, the clear acidic water flows to a wastewater treatment system for treatment, the emulsified acidic water flows back to the delivery pump, the primary separation is gravity settling separation, the secondaryseparation is gravity settling separation after filtration, the mixed nitrifications obtained through primary separation and secondary separation are placed into the collection tank, partial nitrification is delivered to the delivery pump, and the other mixed nitrifications are extracted polynitrotoluene products. According to the method for extracting the polynitrotoluene from the nitrotoluene acid wastewater, the content of the nitro-compound in wastewater is reduced, and the method is economic, environment-friendly, safe and convenient.

Owner:HUBEI DONGFANG CHEM IND

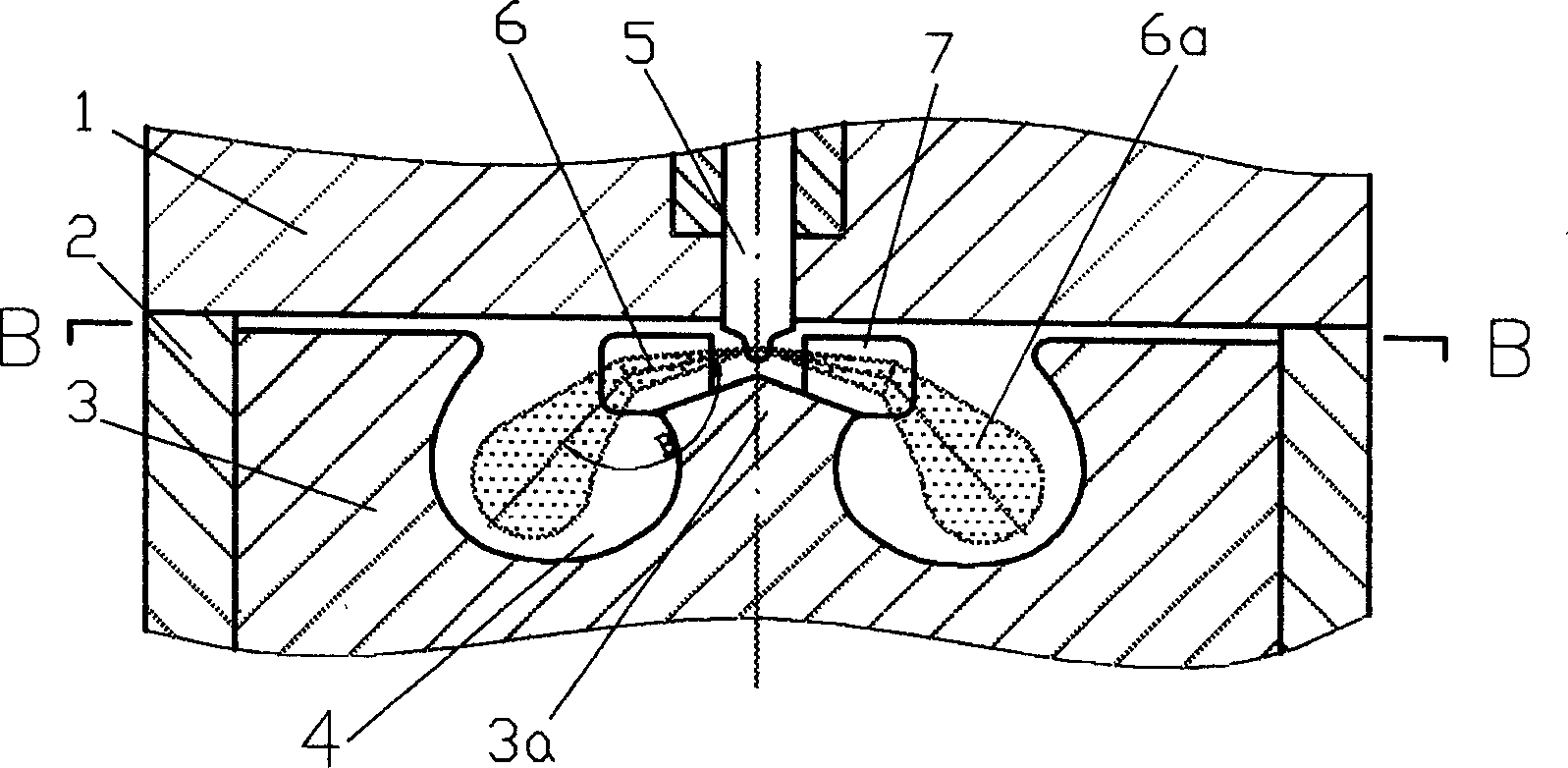

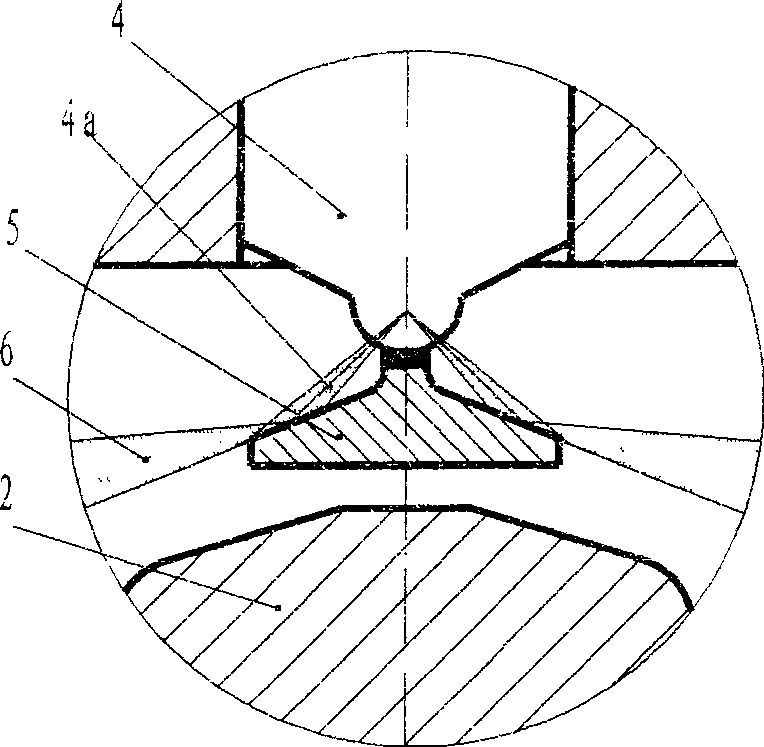

Burning chamber of IC engine

InactiveCN1554861AIncrease involvementQuality improvementInternal combustion piston enginesCombustion chamberEngineering

The present invention relates to a kind of burning chamber of internal combustion engine and belongs to the field of engine mixed gas formation and combustion. The burning chamber has in the inner wall of piston top spraying collision ridges in the number corresponding to the jetted oil beams, and the collision ridges have proper profile for spraying flow, so that one part of the spray is dispersed fast along the guide arc to atomize for the second time while the other part is rebounded. So, homogeneous inflammable mixed gas is formed fast for complete and fast combustion without needing great air eddy current. The engine is improved in exhaust performance obviously while the economic performance and power indexes are raised.

Owner:DALIAN UNIV OF TECH

Any-tooth-difference movable type high rotation speed internal combustion engine

InactiveCN103047008ACompact structureReduce axial sizeGearingMachines/enginesThrough transmissionElectric generator

The invention provides an any-tooth-difference movable type high rotation speed internal combustion engine and relates to the field of combustion gas power. Eight cylinder are annularly and evenly distributed around an outward-protruding inner gear to enable the outward-protruding inner gear to be subjected to zero stress, cylinder pistons directly act on the outward-protruding inner gear through pushing rods, and power is transferred to an output shaft connected with a multiple-phase shock wave cam key through transmission of the outward-protruding inner gear and a multiple-phase cam type moving oscillating teeth. A connecting rod and a crankshaft in a traditional internal combustion engine are omitted, an outward-protruding inner multiple-phase cam type moving transmission mechanism has the advantages of being free of eccentric mass and having inertia force and working load self balance, the rotating speed of the output shaft depends on the transmission ratio of the oscillating teeth, if an oscillating tooth frame is fixed, a multiple-phase shock wave cam performs high-speed output, and the high rotation speed internal combustion engine can be widely applied to the field of machines needing high rotation speed, such as a helicopter engine, a small power generator and the like. When the output rotation speed is fixed, emission of harmful gas can be reduced. The any-tooth-difference movable type high rotation speed internal combustion engine is simple and compact in structure, small in axial size, self-balancing in stress and stable in operation.

Owner:SICHUAN UNIV

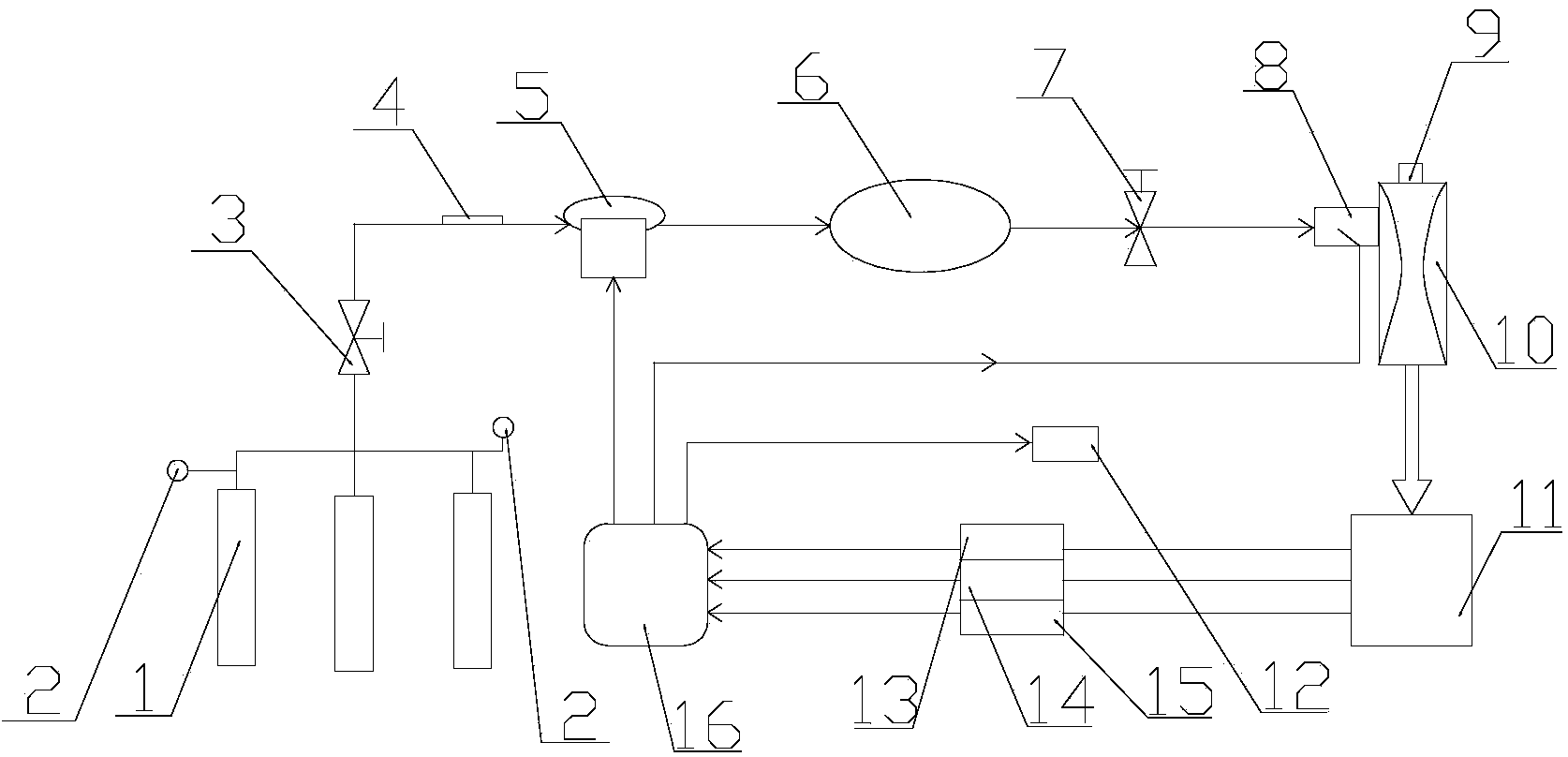

Electronic control system for dual-fuel engine

InactiveCN104251160AFlexible controlImprovements in emission indicatorsInternal combustion piston enginesEngine controllersCompressed natural gasEngineering

The invention relates to engine control technologies, in particular to an electronic control system and a control method for a diesel and natural gas hybrid dual-fuel engine. The electronic control system comprises CNG (compressed natural gas) cylinders, gas cylinder pressure gauges, a regulating valve, a natural gas heater, a high-pressure stop valve, a pressure reducing valve, a linear load valve, a stepper motor valve, an air inlet, a mixer, the engine, a fuel capacity limiting electromagnetic valve, a gas inlet pressure sensor, a gas inlet temperature sensor, an engine rotation speed sensor and an electronic control unit. The electronic control system and the control method have the advantages that the natural gas capacity and the ignition fuel capacity can be flexibly controlled by the electronic control system for the dual-fuel engine, and the dual-fuel engine has good emission indexes and can work by the aid of pure diesel during starting and idling; instructions can be emitted by the control system for the engine when the rotation speed of the engine is higher than a certain set value, so that the engine can be automatically switched to work in a dual-fuel working mode.

Owner:JIANGSU NINGGONG HEAVY MACHINERY

Two-phase shock wave movable type high-rotation speed internal combustion engine

InactiveCN102900524AReduce axial sizeCompact structureMachines/enginesExternal combustion engineInternal combustion engine

The invention discloses a two-phase shock wave movable type high-rotation speed internal combustion engine, relates to the field of fuel gas power and provides a novel internal combustion engine. According to the internal combustion engine, eight cylinders are symmetrically arranged at the periphery of an externally raised inner gear ring uniformly, so that resultant force applied to the externally raised inner gear ring is zero; pistons of the cylinders directly act on the externally raised inner gear ring through push rods; and power is transmitted by the externally raised inner gear ring through a two-phase shock wave movable teeth transmission mechanism to an output shaft which is in keyed connection with a two-phase shock wave device. By the internal combustion engine, connection rods and crank shafts in the conventional internal combustion engine are eliminated, so that an externally raised inner two-phase shock wave movable transmission mechanism does not have eccentric mass, and the internal combustion engine has the characteristics that inertia force and working load are self-balanced; the rotation speed of the output shaft depends on a movable teeth transmission ratio; if movable teeth frames are fixed, the two-phase shock wave device outputs power at high speed; the internal combustion engine can be widely applied to field such as helicopter engines and small engines in which high rotation speed is required; when the output rotation speed is fixed, emission of harmful gas can be reduced; and besides, the internal combustion engine is simple and compact in structure, has a small axial size and stably runs, and stress is self-balanced.

Owner:SICHUAN UNIV

Method for producing waste plastic oil through normal-pressure hydrofining

InactiveCN112725016AImprovements in emission indicatorsOvercome the technical difficulties of poor emission indicatorsHydrocarbon oils refiningHydrocarbon oils treatmentFiberCarbon fibers

The invention provides a method for producing waste plastic oil through normal-pressure hydrofining. The method comprises the following steps: by using waste plastic oil obtained by pyrolyzing waste plastic as a raw material, and carrying out a gas-phase hydrogenation reaction on the waste plastic oil under the action of a heterogeneous catalyst under the reaction conditions of one atmospheric pressure and 350-400 DEG C, thereby obtaining ether hydrocarbon fuel after the reaction is completed, wherein the catalyst is prepared from the following components in parts by weight: 3 parts of cerium dioxide, 3 parts of titanium dioxide, 1 part of zirconium oxide, 5 parts of zeolite and 5 parts of carbon fibers. The invention provides the simple and efficient method, the waste plastic oil can be hydrogenated at normal temperature and normal pressure to obtain the ether hydrocarbon fuel with excellent emission indexes, the technical problems that high-pressure hydrogenation is needed and the emission indexes of the obtained diesel oil are poor in the prior art are solved, and the method has good market application prospects.

Owner:成都前成科技有限公司

Diesel oil engine secondary atomization combustion system

InactiveCN1479008AQuality improvementImprovements in emission indicatorsFuel re-atomisation/homogenisationMachines/enginesCombustion systemCombustion

A secondary-atomizing conbustino system for diesel engine features that a guiding conic body is arranged under the oil nozzle, and when the oil sprayed by multi-hole nozzle is in touch with said conic body, it is further atomized and uniformly distributed to form a combustible mixed gas. Its advantage is high combustion speed.

Owner:DALIAN UNIV OF TECH

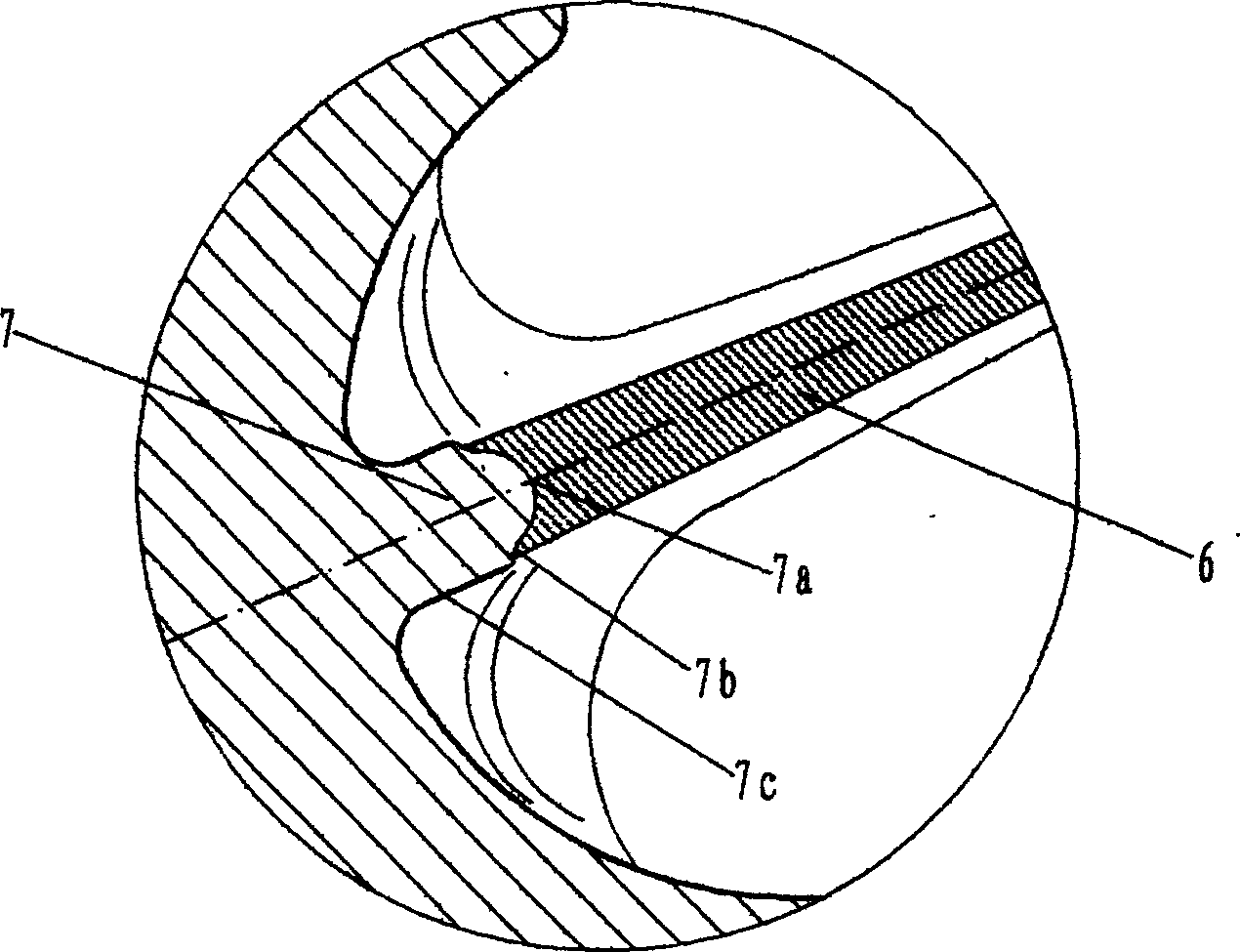

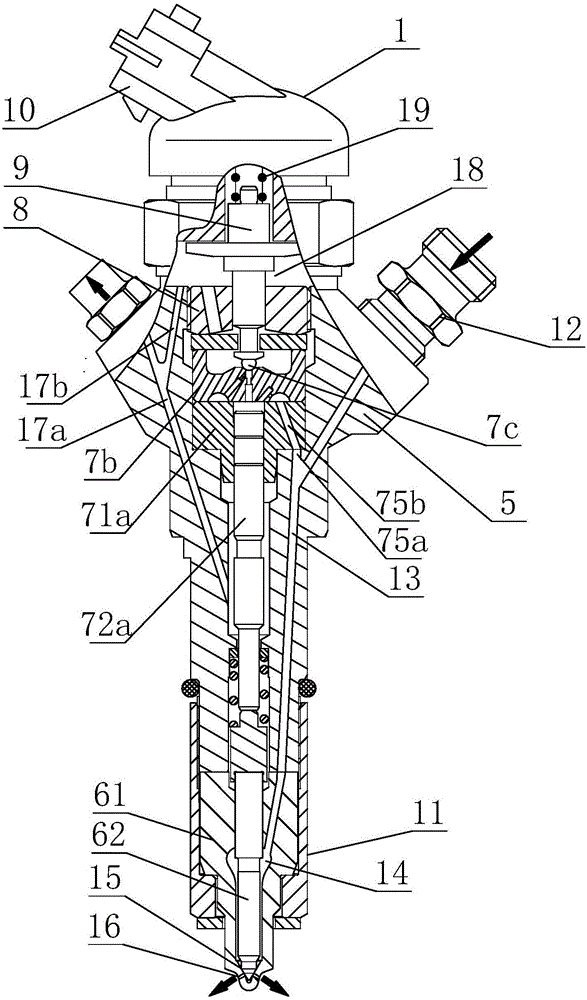

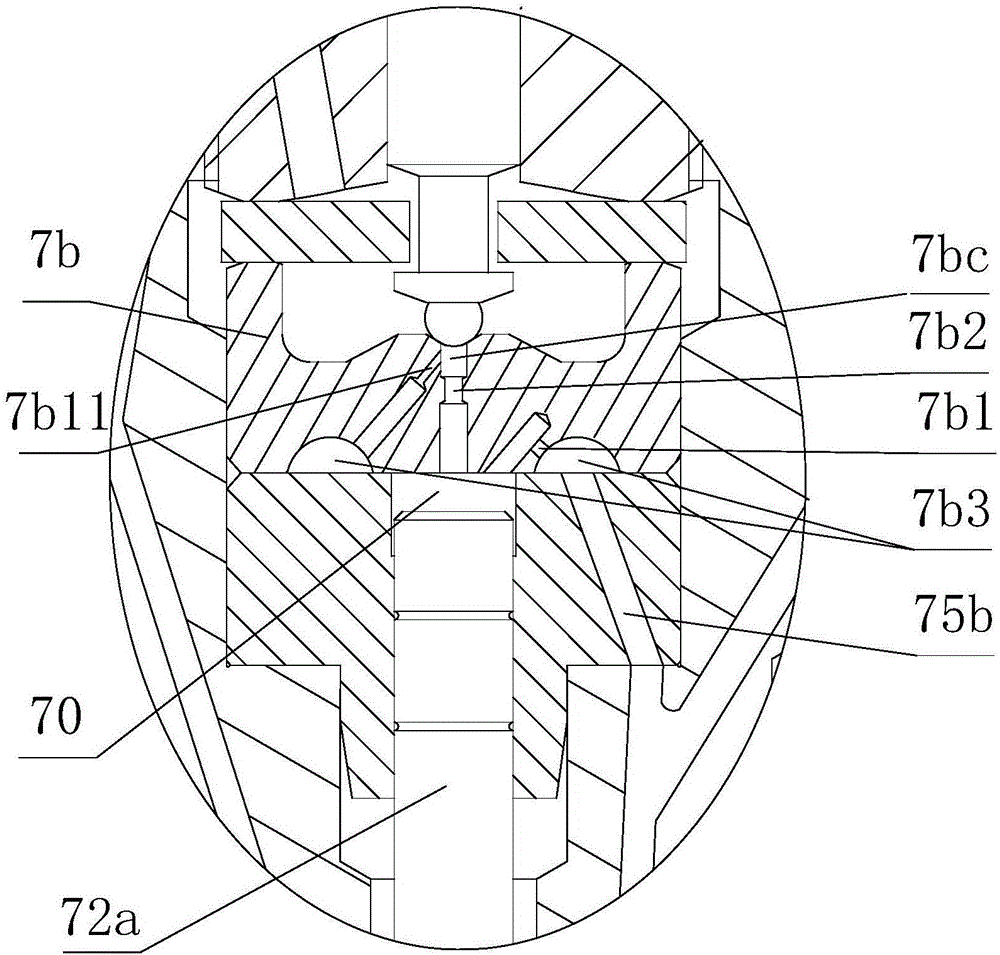

Electrically controlled high-pressure fuel injector for realizing quick fuel cut

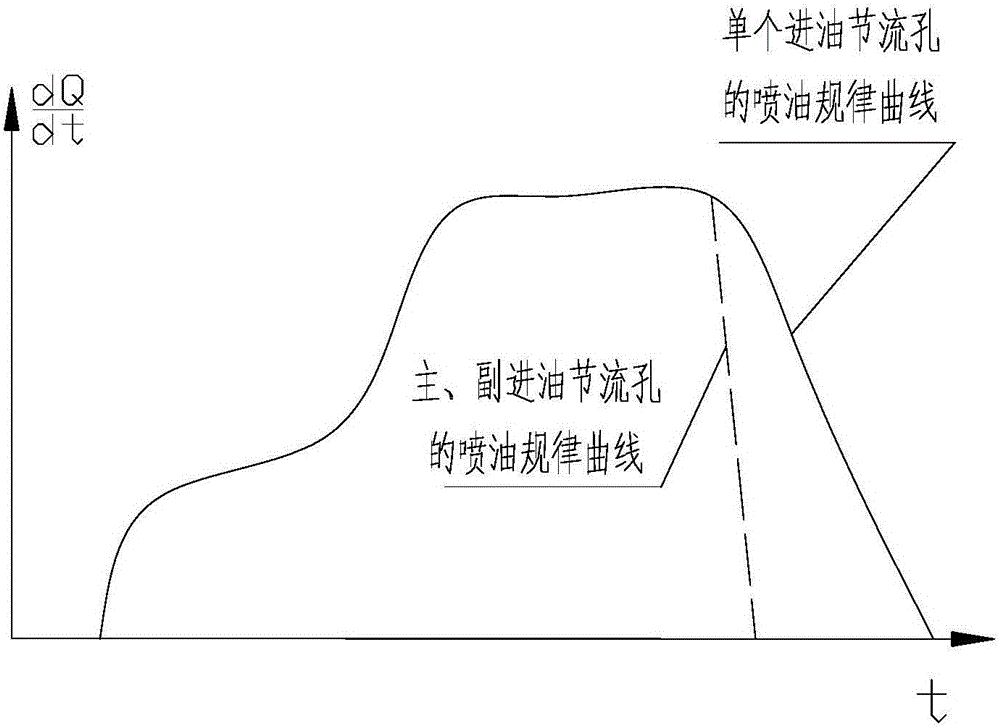

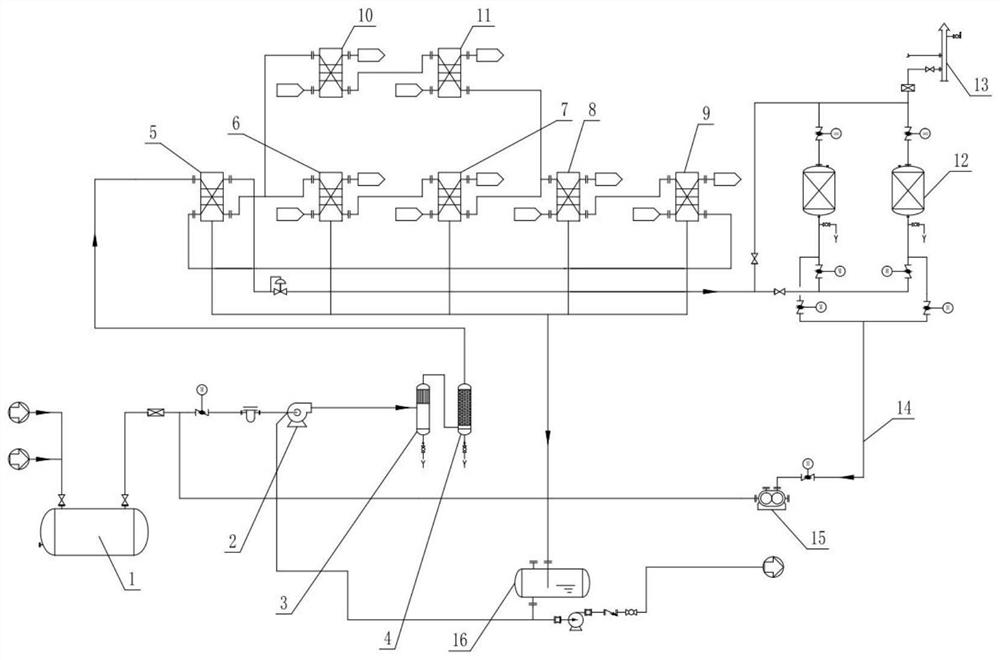

ActiveCN105971793AAfterburn suppressionImprove economyFuel injection apparatusMachines/enginesAviationFuel oil

The invention provides an electrically controlled high-pressure fuel injector for realizing quick fuel cut. The electrically controlled high-pressure fuel injector is characterized in that a main fuel intake orifice (7b1) and a fuel drainage passage are formed in a control valve body (7b); one end of the main fuel intake orifice (7b1) is communicated with a high-pressure fuel passage (75b), and the other end of the main fuel intake orifice (7b1) is communicated with a pressure control room (70) and used for supplying fuel for the pressure control room (70); one end of the fuel drainage passage is communicated with the pressure control room (70), and the other end of the fuel drainage passage is communicated with an opening and closing element sealed part of the control valve body (7b) and used for draining fuel in the pressure control room (70) when the opening and closing element sealed part is unsealed; and an auxiliary fuel intake orifice (7b11) is also formed in the control valve body (7b), one end of the auxiliary fuel intake orifice (7b11) is communicated with the fuel drainage passage, and the other end of the auxiliary fuel intake orifice (7b11) is communicated with the high-pressure fuel passage (75b). By virtue of the reasonably matched aperture, the electrically controlled high-pressure fuel injector can obtain the ideal fuel injection rule that the fuel cut curve sharply drops, effectively prevents an aviation heavy-oil piston engine from post-combustion and greatly improves the economic indicators and emission allowances.

Owner:TSINGHUA UNIV

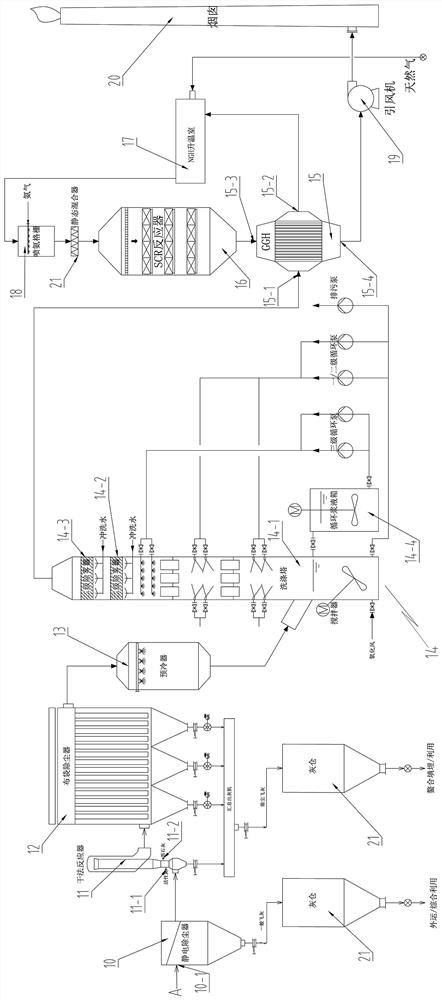

High-pressure cryogenic combined VOCs gas recovery device and recovery method

PendingCN113440886AIncrease operating pressureMeet emission standardsGas treatmentDispersed particle filtrationVapor–liquid separatorBuffer tank

A high-pressure cryogenic combined VOCs gas recovery device comprises a buffer tank, a compressor unit and a heat exchange mechanism, the inlet end of the buffer tank is communicated with an external VOCs gas collection pipeline, the inlet end of the compressor unit is communicated with the outlet end of the buffer tank through a gas filter, the outlet end of the compressor unit is communicated with a gas-liquid separator. The gas phase outlet end of the gas-liquid separator is communicated with a liquid remover; the heat exchange mechanism comprises a pre-heat exchanger and four stages of heat exchangers which are sequentially connected in series, the heat inlet end of the pre-heat exchanger is communicated with the outlet end of the liquid remover, the heat outlet end of the pre-heat exchanger is communicated with the heat inlet ends of the four stages of heat exchangers, and the heat outlet ends of the four stages of heat exchangers are communicated with the cold inlet end of the pre-heat exchanger; and the cold inlet ends and the cold outlet ends of the four stages of heat exchangers are respectively communicated with low-temperature refrigerants under different design temperature conditions. The device is high in safety, environment-friendly and energy-saving, and can perform stable standard treatment on the VOCs gas.

Owner:连云港市拓普科技发展有限公司

Optional tooth difference swing type high-rotation-speed internal-combustion engine

An optional tooth difference swing type high-rotation-speed internal-combustion engine relates to the field of gas power. The tooth difference swing type high-rotation-speed internal-combustion engine is characterized in that eight air cylinders are annularly evenly distributed on the periphery of a protruding inner gear ring to allow resultant force borne by the inner gear ring to be zero. An air cylinder piston directly acts on the protruding inner gear ring through a push rod. Power is transmitted by protruding inner gear ring to an output shaft connected with a multi-phase shock wave wheel key through transmission of a multi-phase cam swing movable tooth. A connecting rod and a crankshaft in traditional internal-combustion engines are omitted, and the protruding inner multi-phase cam swing transmission mechanism has no eccentric weight, and has the advantages that self-balancing of inertia force and work load. Rotation speed of the output shafts depends on transmission ratio of movable tooth transmission. If a movable tooth frame is fixed, high-speed output of the multi-phase shock wave wheel is achieved. The internal-combustion engine is widely applicable to fields, which need high rotation speed, such as helicopter engines and small power generators. When rotation speed is fixed, emission of harmful gas can be reduced. The internal-combustion engine is simple and compact in structure, low in axial size, self-balancing in stress, and stable in operation.

Owner:SICHUAN UNIV

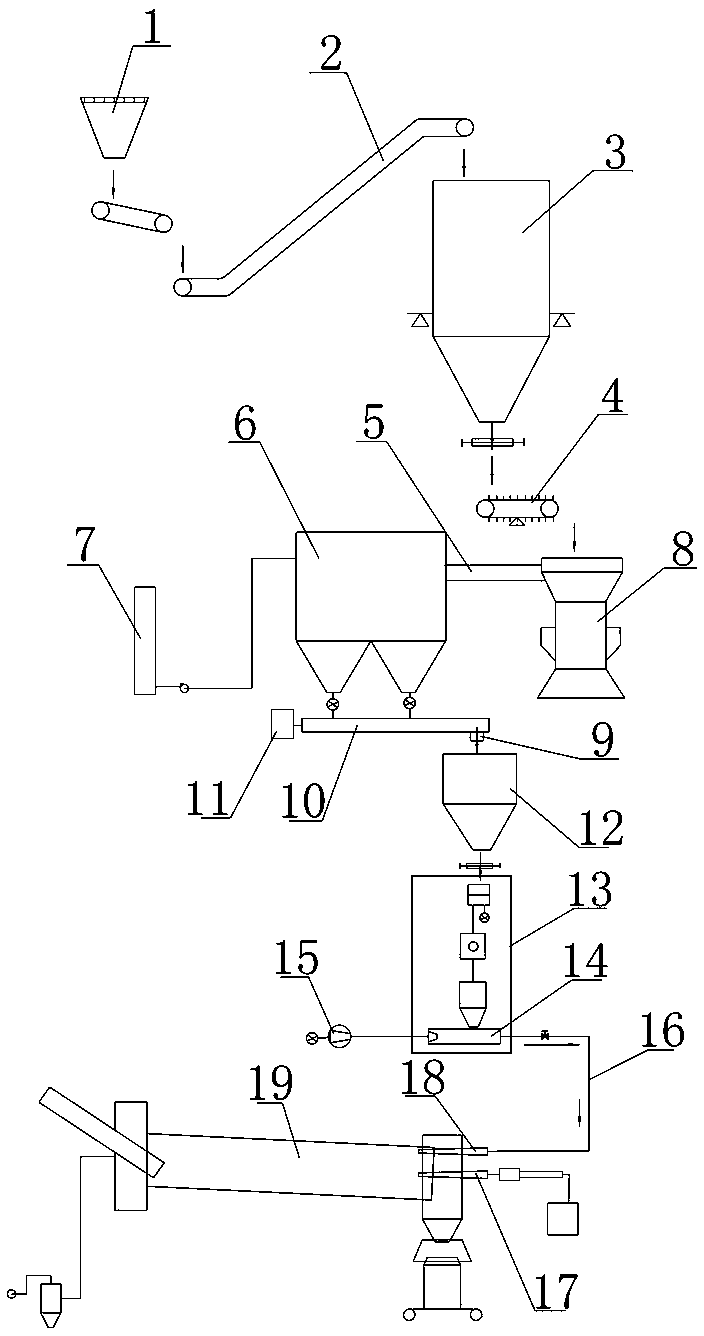

Internal pre-reduction desulfurization device for rotary kiln during ferronickel smelting by virtue of RKEF process

The invention discloses an internal pre-reduction desulfurization device for a rotary kiln during ferronickel smelting by virtue of an RKEF process. The internal pre-reduction desulfurization device comprises a massive material bin, wherein a quantitative feeding conveyer belt is arranged below the massive material bin; the tail end of the quantitative feeding conveyer belt corresponds to a feeding hole of a vertical mill machine; a discharging hole of the vertical mill machine is communicated with a feeding hole in the upper part of a powder collecting machine; the bottom of the powder collecting machine is communicated with a material conveying pipe; a discharging hole in the tail end of the material conveying pipe corresponds to a feeding hole in the top of a finished product bin; the finished product bin is communicated with a feeding hole of a quantitative feeding machine; one end of the quantitative feeding machine is communicated with a roots blower, and the other end of the quantitative feeding machine is communicated with a material nozzle; and a material nozzle is communicated with the rotary kiln. A desulfurizer and a reducer are ground and conveyed together and are finally blown into the interior of the rotary kiln, reaction is carried out when a burner jets flame into the rotary kiln, pre-reduction desulfurization is carried out in a high temperature and water vapor environment, desulfurization treatment can be carried out in the rotary kiln, a subsequent purification load is reduced, and purification effect also can be obviously improved, so that emission indexes are essentially improved.

Owner:临沂鑫海新型材料有限公司

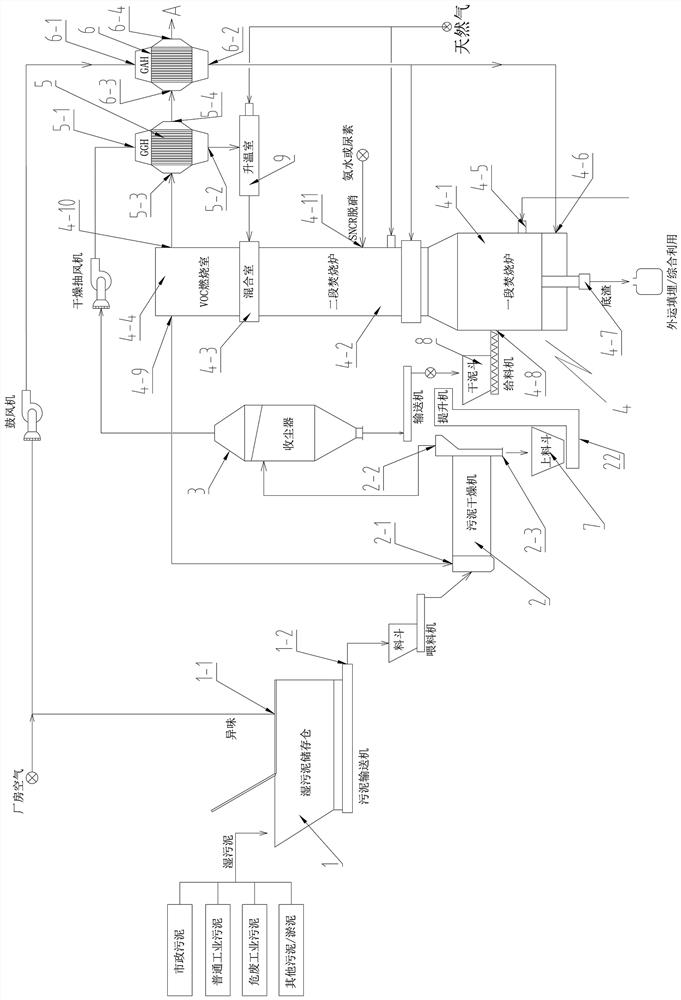

System and method for harmlessly treating sludge

PendingCN113587117AImprovements in emission indicatorsIncrease incineration rateIncinerator apparatusCombustionFlue gas

The invention provides a system for harmlessly treating sludge, which is simple in structure, low in investment, operation and maintenance cost and suitable for wide popularization and application. High-temperature flue gas exhausted by an integrated incinerator is directly used as a drying heat source of a sludge drying machine, damp and hot peculiar smell waste gas generated by sludge drying of the sludge drying machine is directly fed into the integrated incinerator to be subjected to high-temperature incineration, to-be-treated sludge is subjected to incineration treatment in a primary incineration section, odor is subjected to secondary combustion in a secondary incineration section, deodorization processing is conducted, and the integrated incinerator is provided with a secondary incineration section, namely the primary incineration section and the secondary incineration section, so that the retention time of waste gas generated by combustion in a high-temperature incineration state is ensured. Meanwhile, the invention also discloses a method for harmlessly treating the sludge.

Owner:WUXI XUELANG ENVIRONMENTAL TECH CO LTD

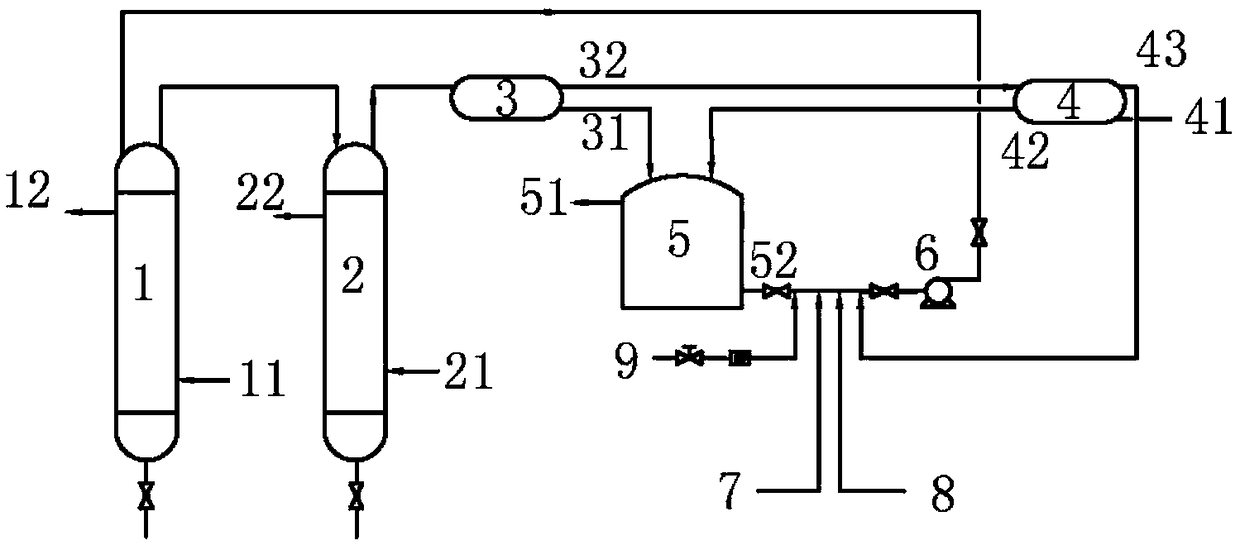

Device for extracting poly-nitrotoluene from acidic wastewater

PendingCN109320422AReduce solubilityImprove solubilityOrganic chemistryOrganic compound preparationNitro compoundWater flow

The invention relates to the technical field of nitrotoluene preparation, in particular to a device for extracting poly-nitrotoluene from acidic wastewater. The device comprises a cooler A, a cooler B, a separator A, a separator B, a collecting tank and a conveying pump; mononitrotoluene, the acidic wastewater, a mixed nitrated compound in the collecting tank and refluent emulsified acidic water are mixed and conveyed to the coolers through the conveying pump to be cooled; then liquid is primarily separated to obtain a mixed nitrated compound and acidic water; the acidic water is secondarily separated to obtain a mixed nitrated compound, clear acidic water and emulsified acidic water; the clear acidic water flows into a wastewater treatment system to be treated; the emulsified acidic waterflows back to be conveyed to the conveying pump; the mixed nitrated compounds obtained by primary separation and secondary separation are stored in the collecting tank; and parts of the mixed nitrated compounds are conveyed to the conveying pump, and the other mixed nitrated compounds are extracted poly-nitrotoluene products. The device is scientific in structure, safe and convenient, and the content of nitro-compounds in the wastewater is decreased.

Owner:HUBEI DONGFANG CHEM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com