Anaerobic carbonization dangerous solid wastes disposing apparatus

A hazardous waste and disposal device technology, applied in incinerators, lighting and heating equipment, combustion methods, etc., can solve the problems of ineffective prevention of dioxin regeneration, dust sticking to cloth bags, tail equipment corrosion, etc., to protect human beings Effects of health, environmental protection, and operating cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

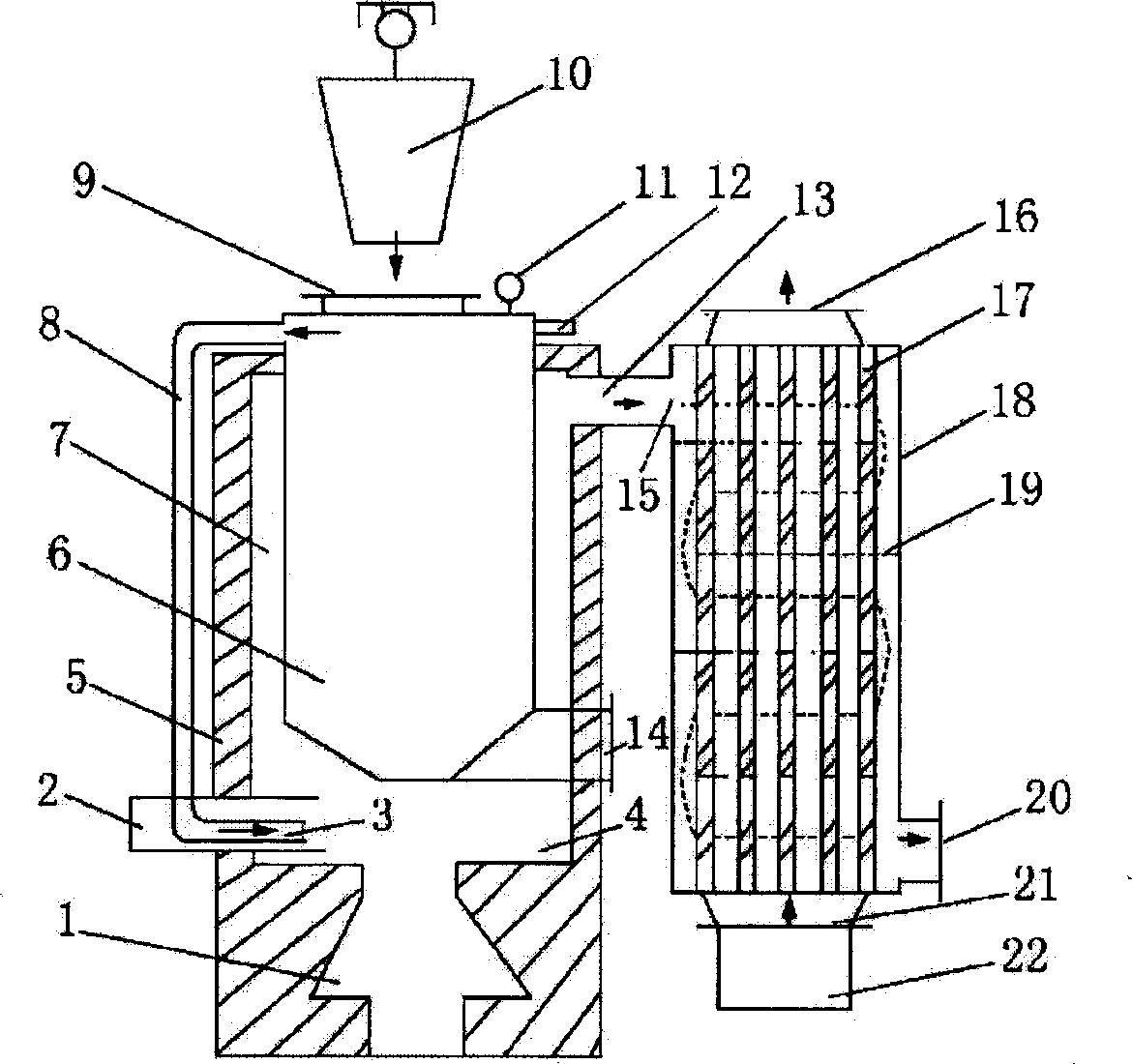

[0030] Examples see figure 1 , the present invention includes anaerobic pyrolysis zone and pneumatic quenching zone.

[0031] The anaerobic pyrolysis zone has a refractory heat preservation shell 5 made of refractory heat preservation material. The lower part of the refractory heat preservation shell 5 is the gas generator 1, the middle part is the combustible gas combustion chamber 4, and the upper part is the furnace fire path 7, the furnace fire path The inside of 7 suspends the pyrolysis tank 6, the top of the pyrolysis tank 6 is equipped with a pressure gauge 11 and a temperature measuring instrument 12, and protrudes from the top of the furnace body 5, and the sealing opening of the top of the pyrolysis tank 6 and the feeding port 9 and the upper feeding Corresponding to the device 10, the top side of the pyrolysis tank 6 communicates with the combustible gas discharge pipe 8, and the combustible gas injection port 3 at the lower end of the combustible gas discharge pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com