Injection system for internal combustion engine

A technology of injection system and internal combustion engine, which is applied in the direction of fuel injection device, charging system, mechanical equipment, etc. It can solve the problems of short penetrating distance of umbrella-shaped spray, too thick circumferential distribution of mixed gas, unevenness, etc., and achieve atomization performance Good, fast burning and perfect, uniform circumferential distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

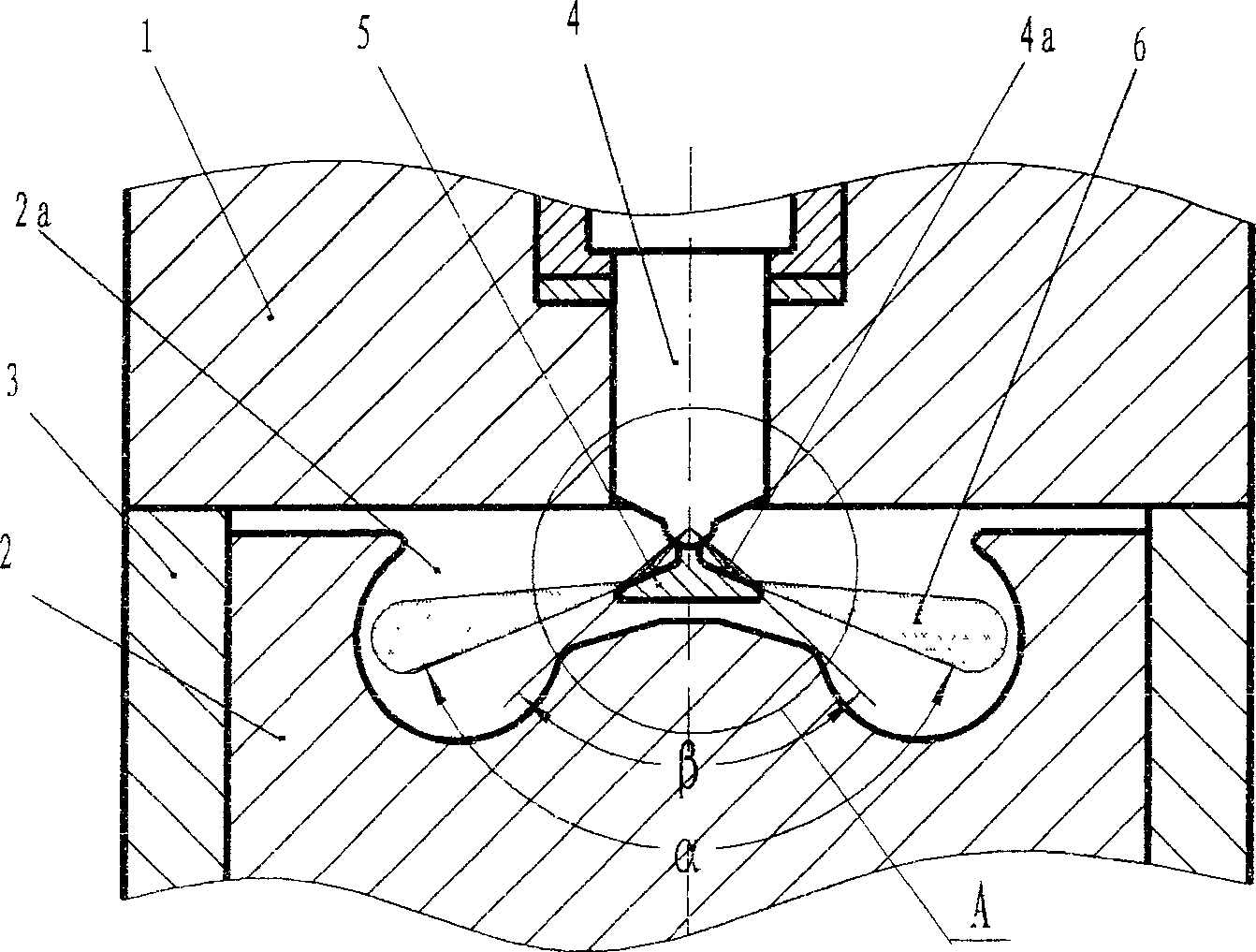

[0012] exist figure 1 In the shown embodiment, the cylinder head (1), the piston (2) and the cylinder liner (3) form an ω-shaped combustion chamber (2a), and the middle part of the cylinder head (1) is equipped with an oil injector (4), and the fuel injection The lower end of the mouth (4) is provided with a guide cone (5). When the nozzle (4) sprays the primary oil beam (4a) to the guide cone (5), the primary oil beam (4a) expands into a more evenly distributed secondary oil beam under the guidance of the guide cone surface (6), the secondary oil beam (6) forms a more homogeneous combustible mixture under the action of the airflow movement in the combustion chamber (2a).

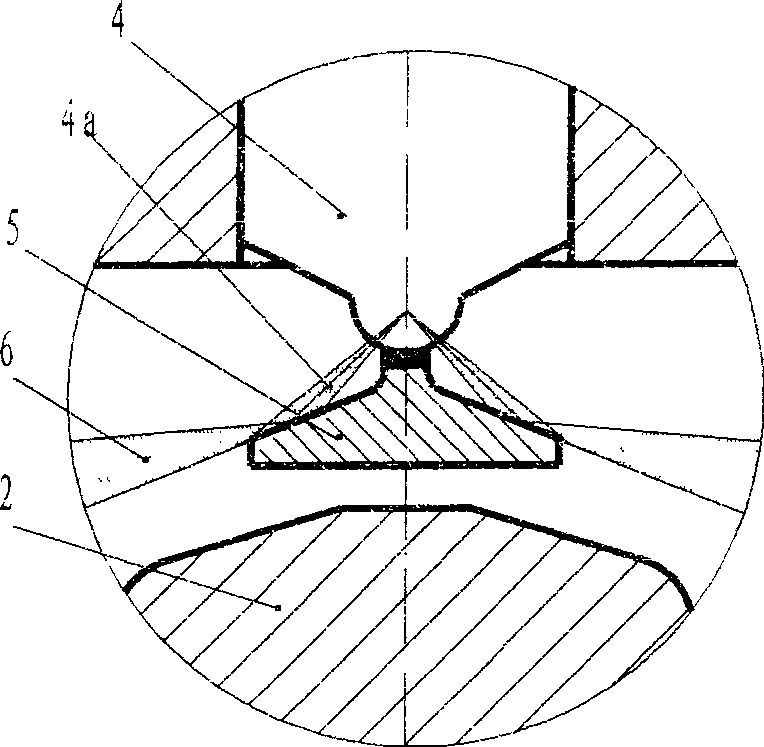

[0013] exist figure 2 The figure shows that the guide cone (5) is welded to the lower end of the fuel injection nozzle (4) and connected as a whole.

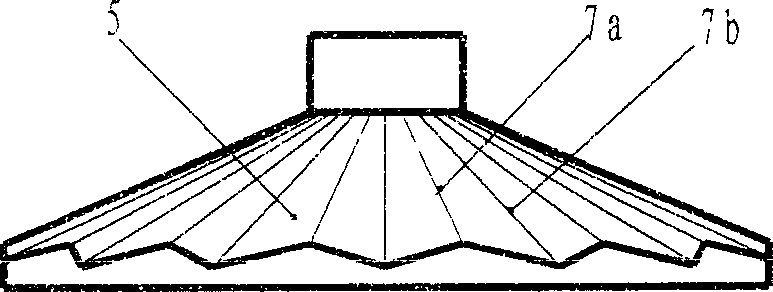

[0014] exist image 3 The guide cone (5) with a zigzag surface consisting of a top line (7a) and a bottom line (7b) is shown in .

[0015] exist Figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com