A multi-point injection gas generator using ethanol as fuel

A gas generator and fuel technology, applied in the direction of liquid fuel supply/distribution, combustion methods, etc., to achieve the effect of small geometric size, avoid mutual interference of air flow, and solve the effect of volume flow increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the characteristics and advantages of the present invention clearer, the following description will be made in conjunction with specific embodiments.

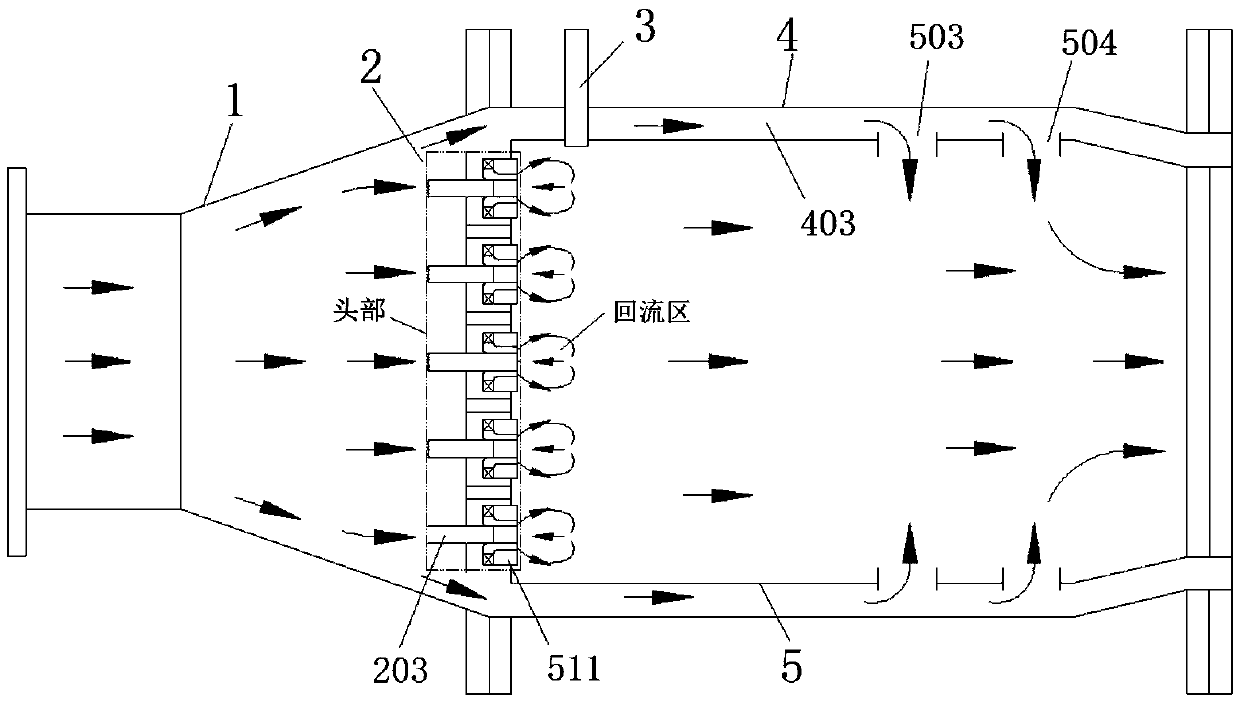

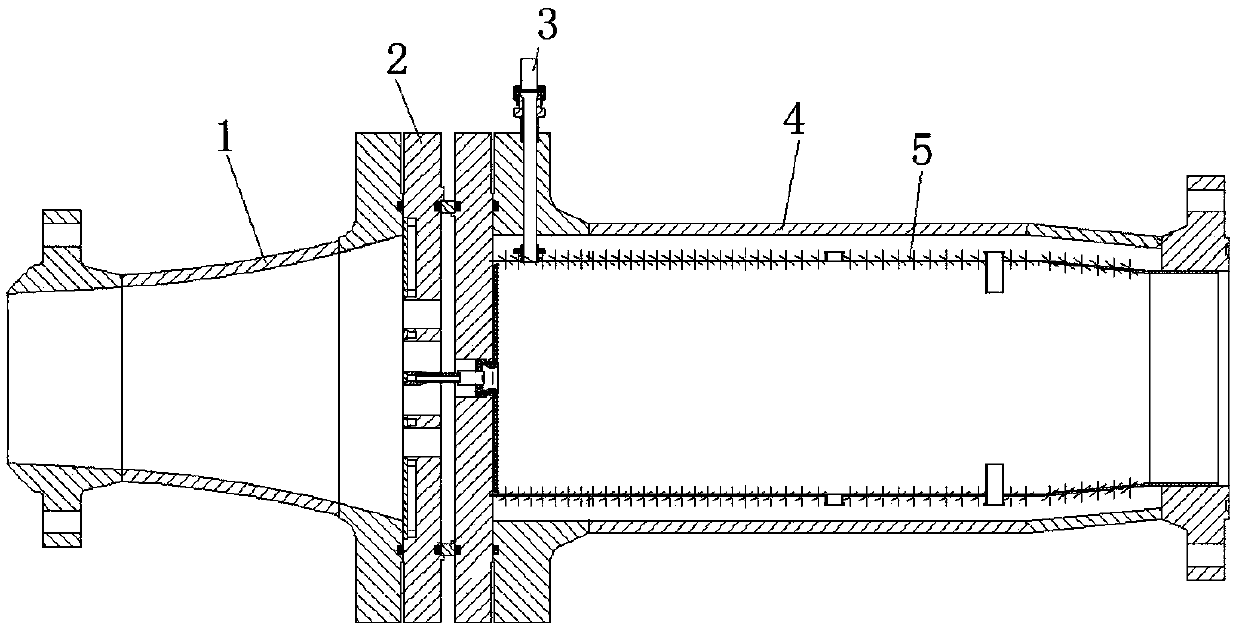

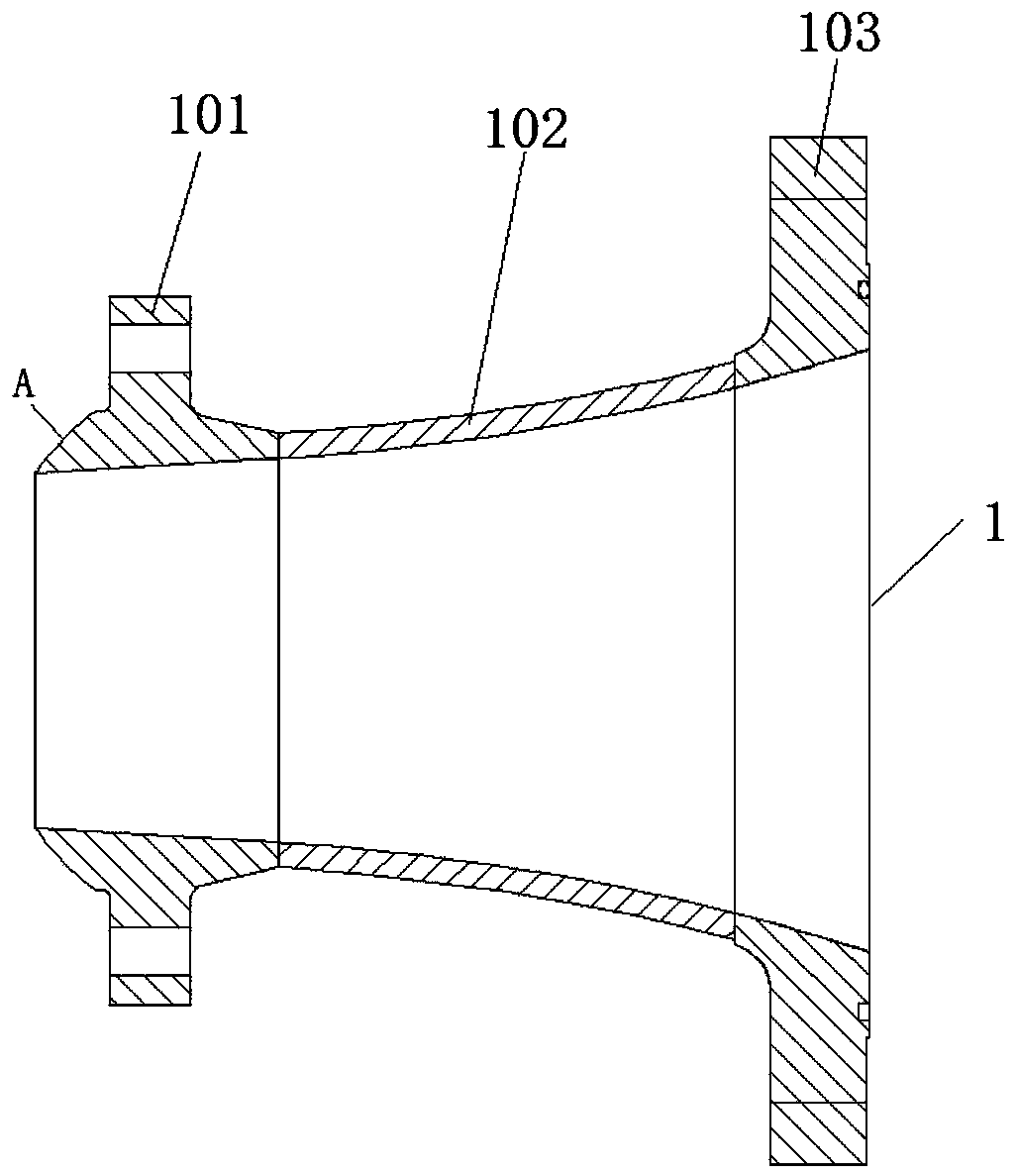

[0040] Such as Figure 1~16As shown, a multi-point injection gas generator using ethanol as fuel includes a diffuser 1, a fuel split atomization device 2, a high-energy plasma ignition nozzle 3, a housing 4, and a flame tube 5. The diffuser 1 consists of The front adapter flange 101, the diffuser section 102, and the rear flange 103 are composed of the shell 4. body 502, the fuel split atomization device 2 and the head adapter section 501 are fixed between the rear flange 103 and the front flange 401 of the housing, the end of the cylinder 502 is inserted into the rear connecting flange 402 of the housing, and the high-energy plasma The ignition nozzle 3 is fixed on the housing 4 and the barrel 502, an annular channel 403 is provided between the housing 4 and the barrel 502, and a floating ring mounting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com