Vertical rotary spraying type seed dressing machine

A coating machine and spray technology, applied in the field of vertical rotary spray seed coating machine, can solve problems such as easy blocking of nozzles, and achieve the effects of accurate measurement, reduced quantity and low motor power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

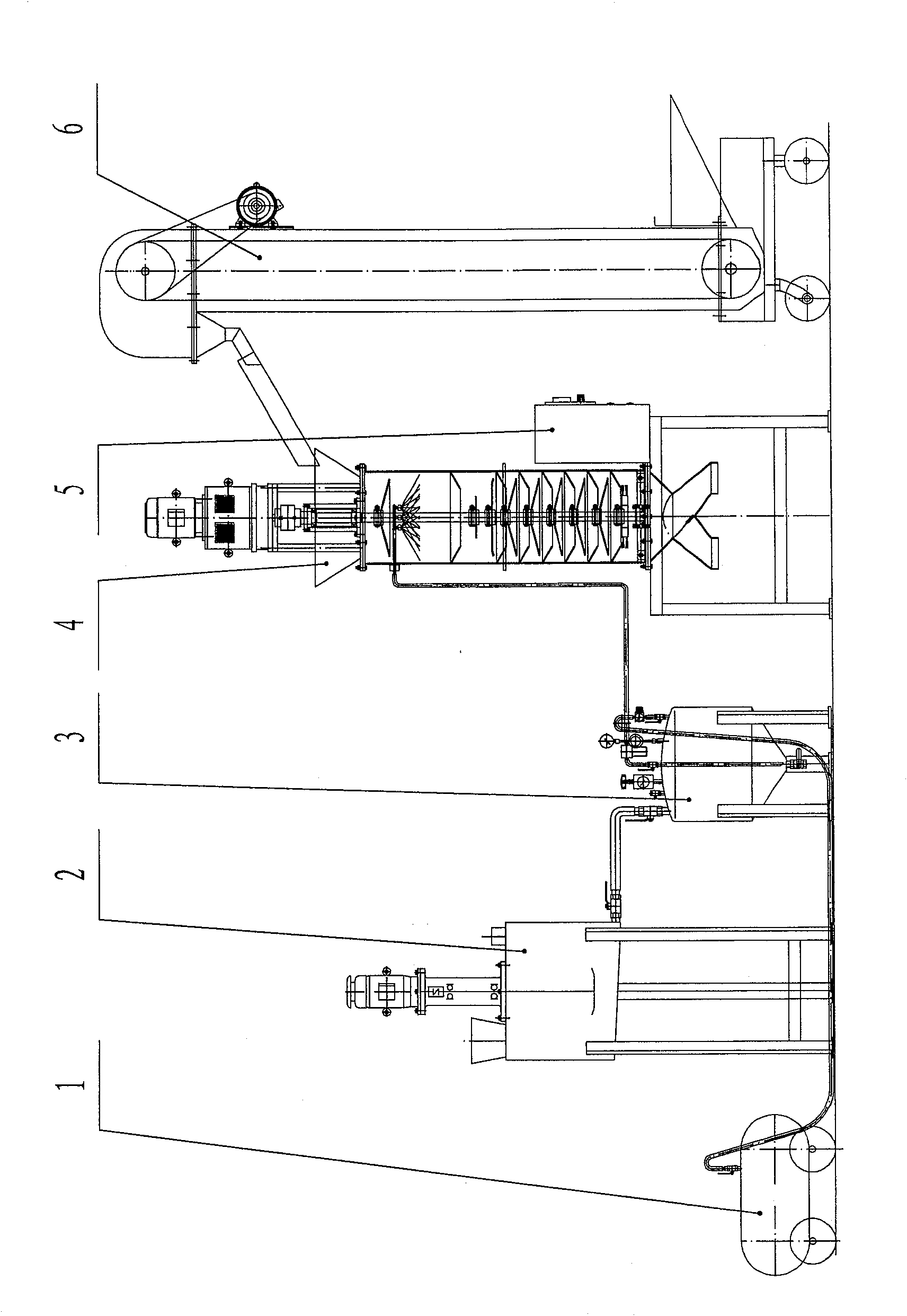

[0022] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

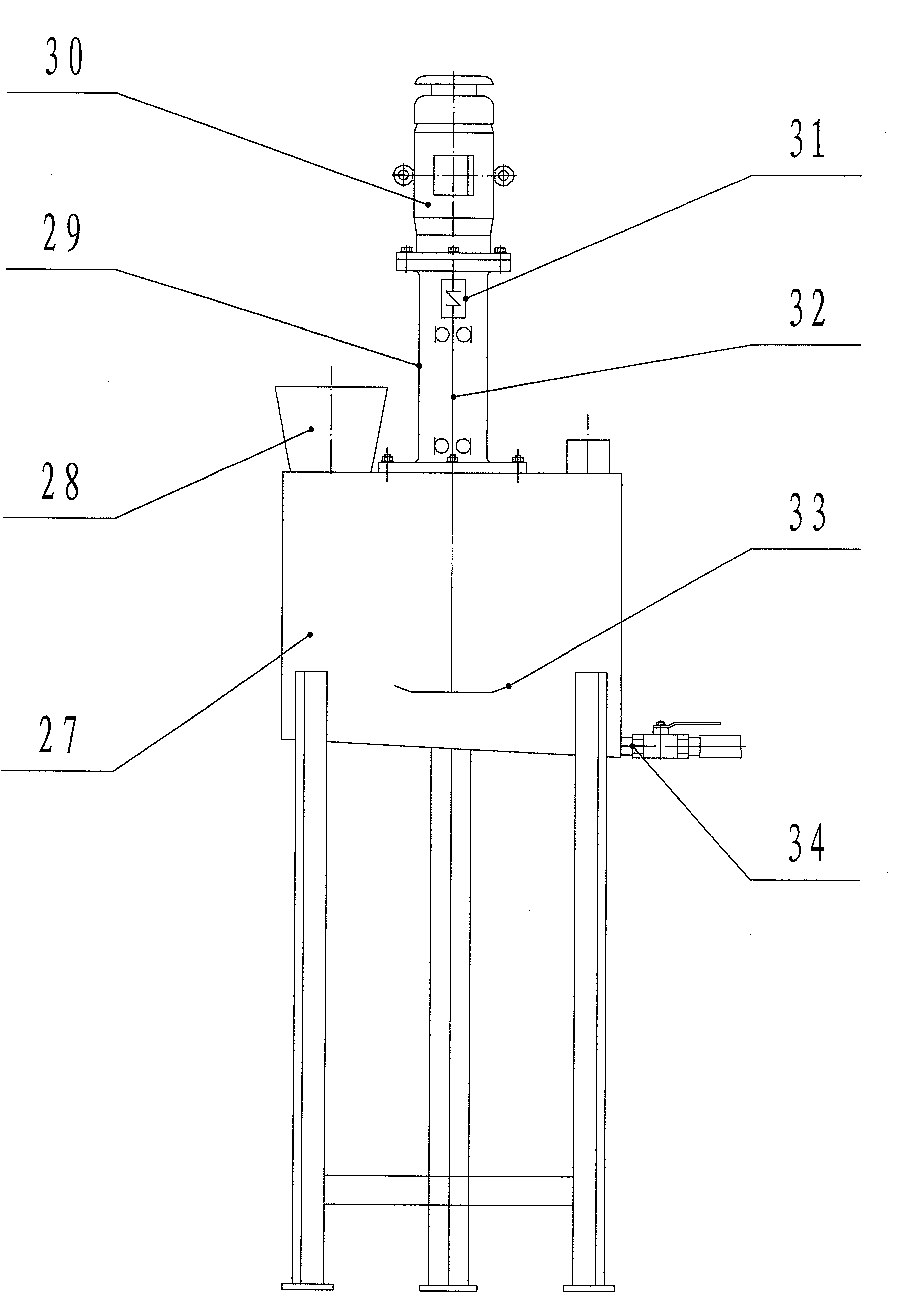

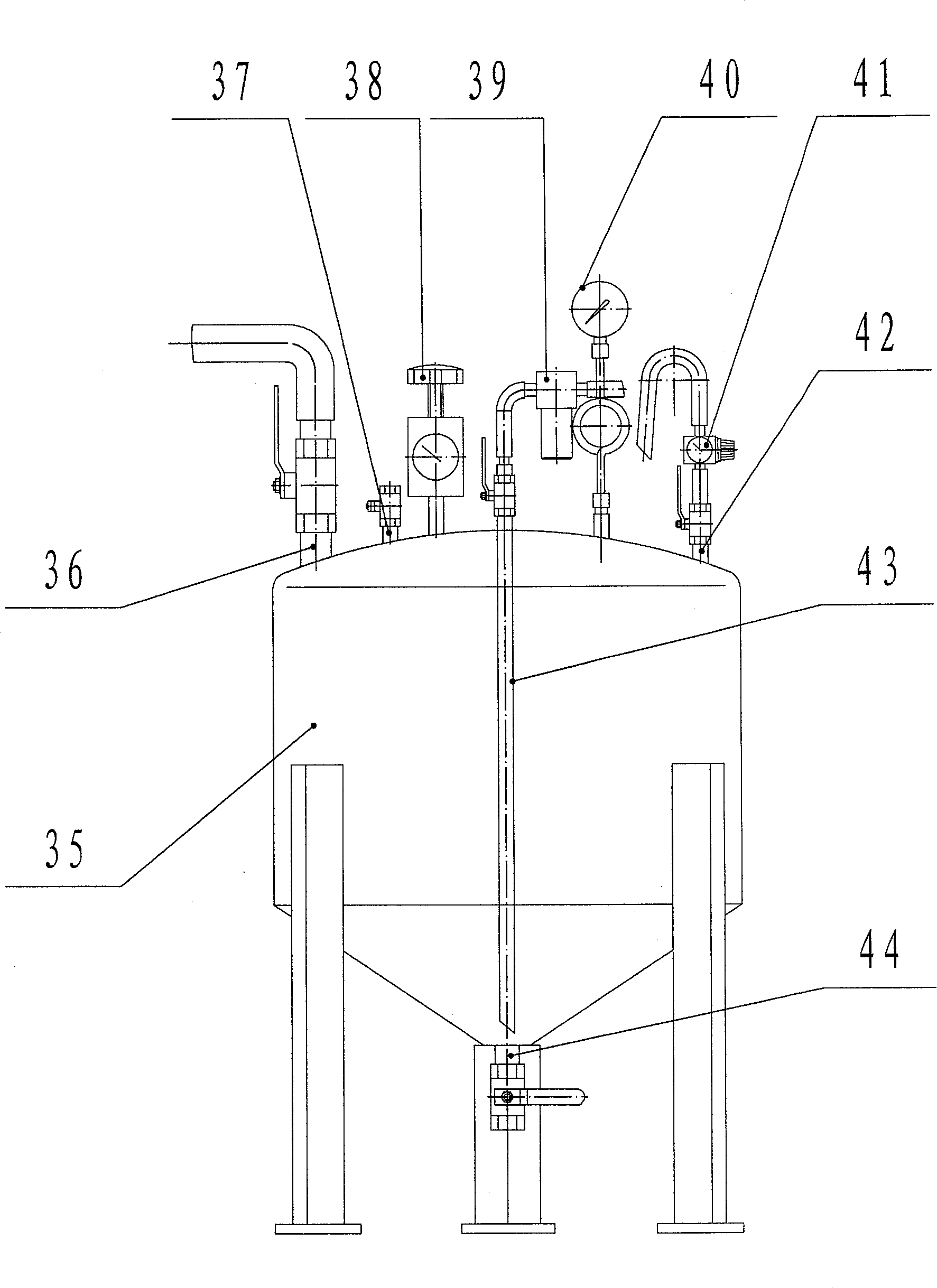

[0023] The present invention mainly consists of an air compressor 1, a modulation kettle device 2, a material pressing and metering kettle device 3, a host machine 4, an electrical control box 5, a lifting metering machine 6, a base 7, a discharge port 8, a material control device 9, and a swing gate 10. Bearing seat 11, gland 12, brush turntable 13, baffle plate 14, vertical turntable 15, spray pipe 16, speed regulating motor 17, coupling 18, support rod 19, hopper 20, bearing seat 21 , Spray head 22, transmission shaft 23, small flat rotary disc 24, large flat rotary disc 25, material barrel 26, seasoning barrel 27, hopper 28, bearing seat 29, motor 30, coupling 31, stirring shaft 32, stirring wheel 33, Discharge port 34, barrel 35, feed port 36, vent port 37, safety valve 38, filter 39, pressure gauge 40, decompression pressure regulating valve 41, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com