An adjustable atomizing bucket based on water atomization method for powder production

An adjustable, water atomization technology, applied in the field of metal powder making, can solve problems such as difficult to meet the needs of the process, and achieve the effect of meeting the requirements of use, being easy to mass-produce, and inhibiting the oxidation reaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

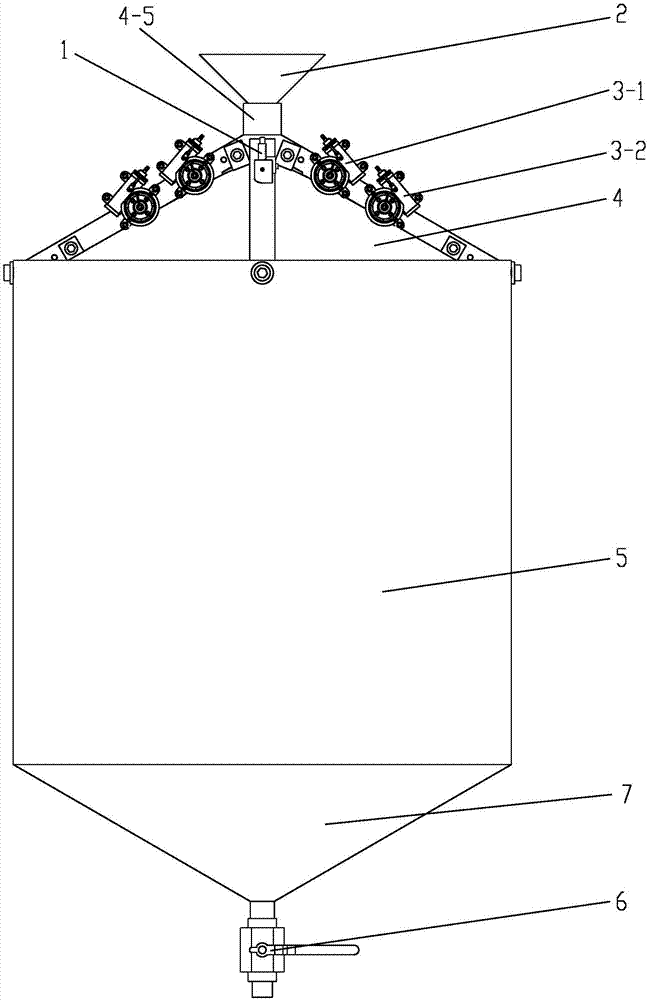

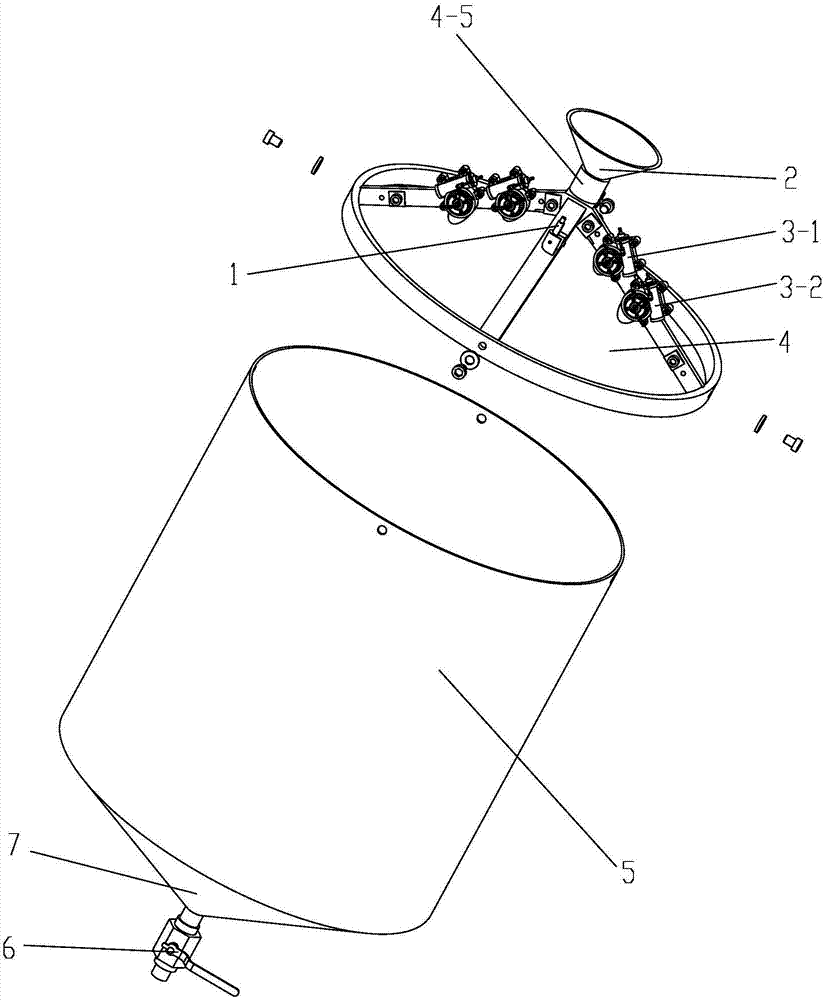

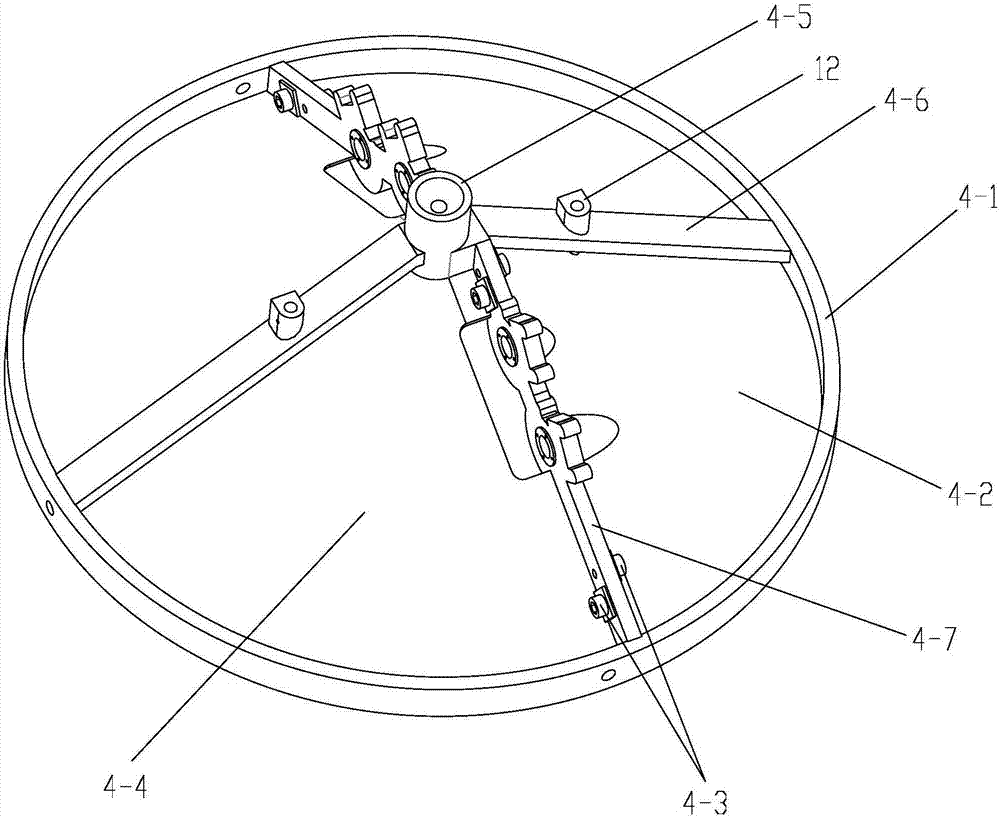

[0059] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the adjustable atomizing barrel based on the water atomization method of the present invention includes a barrel body 5 and a barrel cover 4 installed on the barrel body 5, and the barrel cover 4 includes an annular ring that matches the inner wall of the barrel body 5. Bracket 4-1, a ceramic crucible mounting frame 4-5 is arranged directly above the center of the annular frame 4-1, a funnel-shaped ceramic crucible 2 is installed on the ceramic crucible mounting frame 4-5, and the ceramic crucible is installed A first connection plate 4-6 and a second connection plate 4-7 are arranged between the frame 4-5 and the ring support 4-1, and the number of the first connection plate 4-6 and the second connection plate 4-7 is equal to Two, two first connecting plates 4-6 and two second connecting plates 4-7 are arranged at intervals, and two first connecting plates 4-6 and two second connecting plates 4-7 are ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com