Gas atomization device and method for secondary atomization and accelerated cooling

An accelerated cooling and secondary atomization technology, which is applied in the field of secondary atomization and accelerated cooling gas atomization devices, can solve the problems of reduced powder yield, increased oxygen content, and long-time cooling of powder, achieving Improve the yield of fine powder, improve the powder output rate, and avoid the effect of powder accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

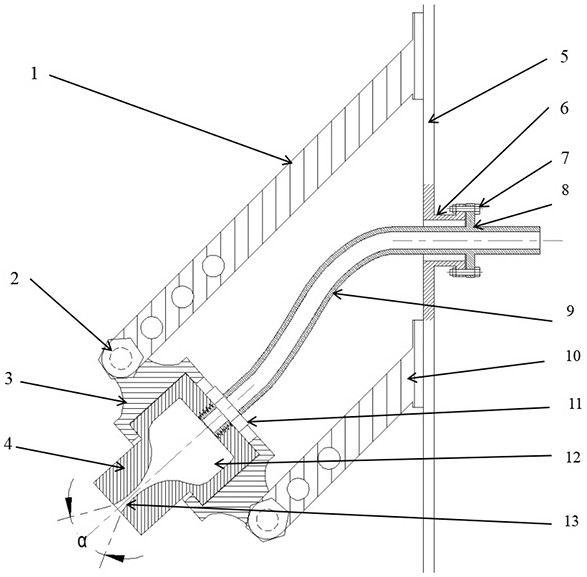

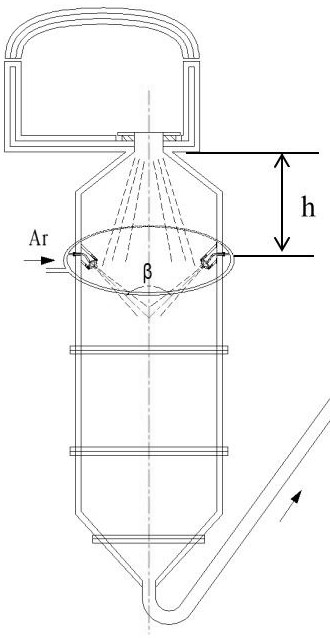

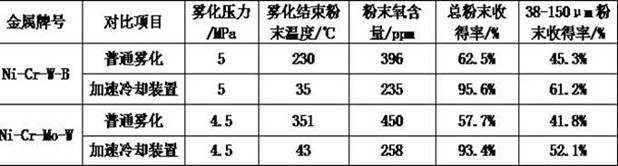

[0029] The Ni-Cr-W-B powder for laser cladding is prepared by using the patent application of the present invention. The specific process is: use 220kg Ni-Cr-W-B alloy bar as the raw material, vacuumize to 5Pa, and use the contact thermocouple thermometer to measure the temperature of the molten steel Fill the equipment with argon gas to 101kPa at 1750±20°C, turn on the back-end fan, wait for the fan to reach a stable suction condition, open the back-end exhaust valve, and start pouring atomization when the system pressure is 95kPa, atomization The pressure is 5MPa. After stable atomization in the primary atomization area, open the gas hand valve of the annular pipeline for secondary atomization and accelerated cooling.

[0030] Preferably, the high-pressure hose adopts DN25 pipe with a pressure resistance of 24MPa, and the hose is wrapped with fire-resistant cotton. The gas pressure of the secondary atomization pipeline is 1MPa, and the flow rate is 10m 3 / min.

[0031] Pr...

Embodiment 2

[0034] The Ni-Cr-Mo-W powder for laser cladding is prepared by using the patent application of the present invention. The specific process is: use 213kg of Ni-Cr-Mo-W alloy rod as raw material, vacuumize to 5Pa, and use a contact thermocouple thermometer When the temperature of molten steel is measured to be 1730±20°C, fill the equipment with argon to 101kPa, turn on the back-end fan, wait for the fan to reach a stable suction condition, open the back-end exhaust valve, and start pouring when the system pressure is 95kPa Atomization, the atomization pressure is 4.5MPa. After stable atomization in the primary atomization area, open the gas hand valve of the annular pipeline for secondary atomization and accelerated cooling.

[0035] Preferably, the high-pressure hose adopts DN25 pipe with a pressure resistance of 24MPa, and the hose is wrapped with fire-resistant cotton. The gas pressure of the secondary atomization pipeline is 0.8MPa, and the flow rate is 8m3 / min.

[0036] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com