Guide blade combustion system of internal combustion engine

A technology of guide vanes and combustion systems, which is applied in charging systems, mechanical equipment, engine components, etc., can solve the problems of short penetration distance of umbrella spray, excessively concentrated circumferential distribution and unevenness of mixture, and achieve atomization performance. Good, reduce the amount of soot emissions, the effect of uniform circumferential distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

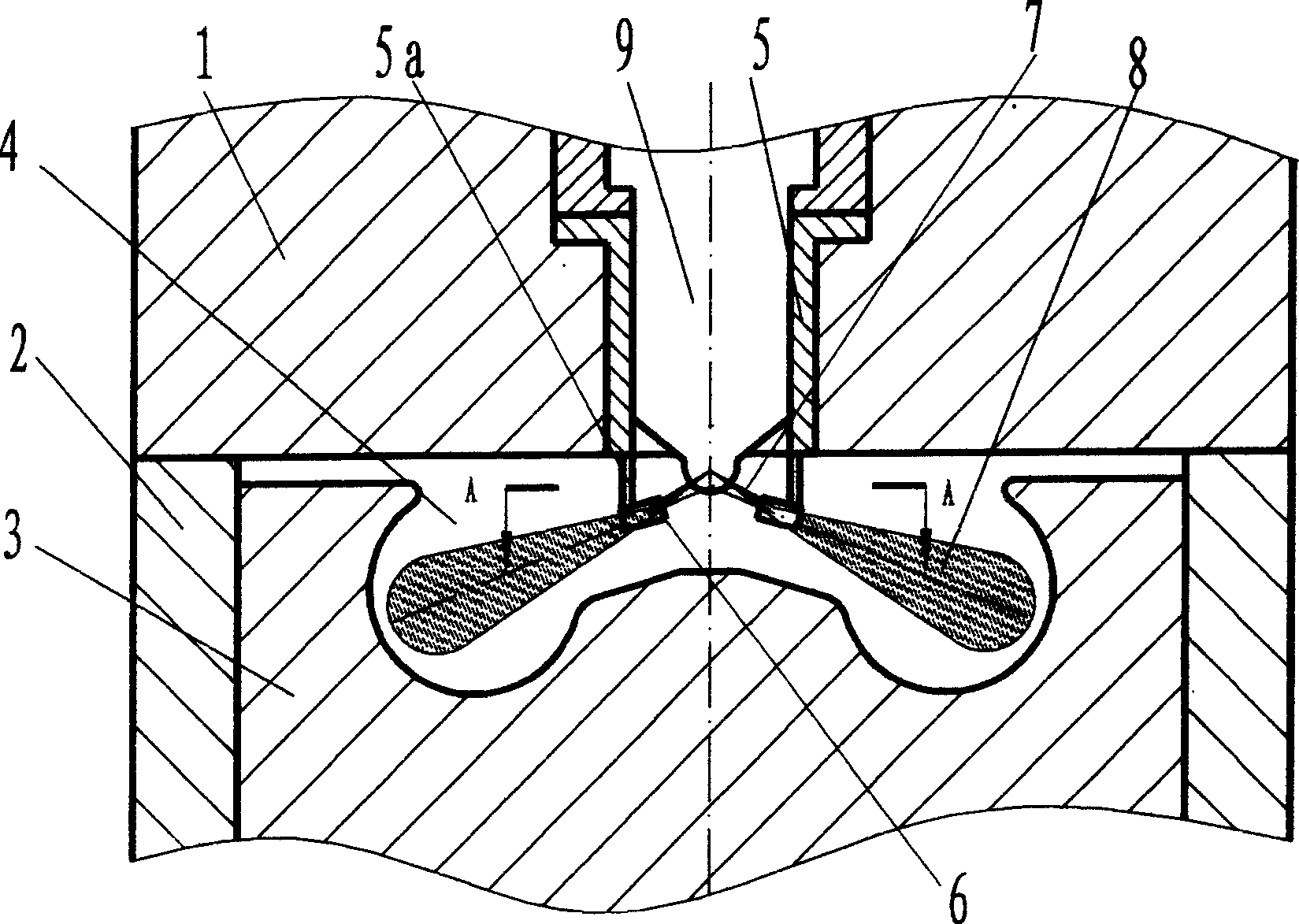

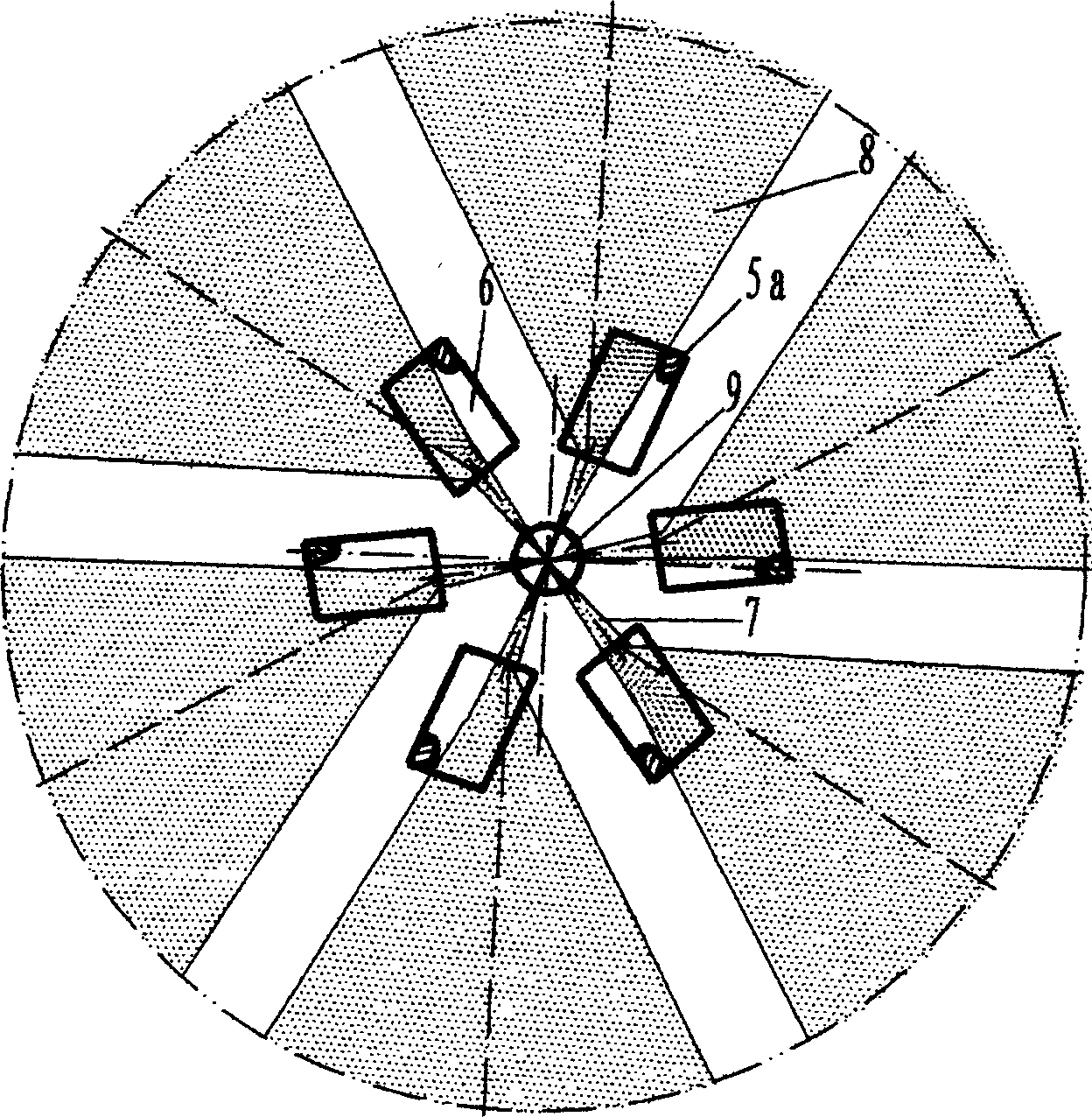

[0012] exist figure 1 , 2 In the shown embodiment, an ω-shaped combustion chamber (4) is formed by the cylinder head (1), the cylinder liner (2) and the piston (3). The oil injector (9) sprays 6 primary oil beams (7) to the 6 guide vanes (6), and under the guidance of the guide surface of the guide vanes (6), 6 secondary oil beams (8) are formed, and the 6 The secondary oil beam (8) can basically cover the entire combustion chamber (4). The guide vanes (6) are fixed on the casing (5) installed in the cylinder head (1) through connecting ribs (5a).

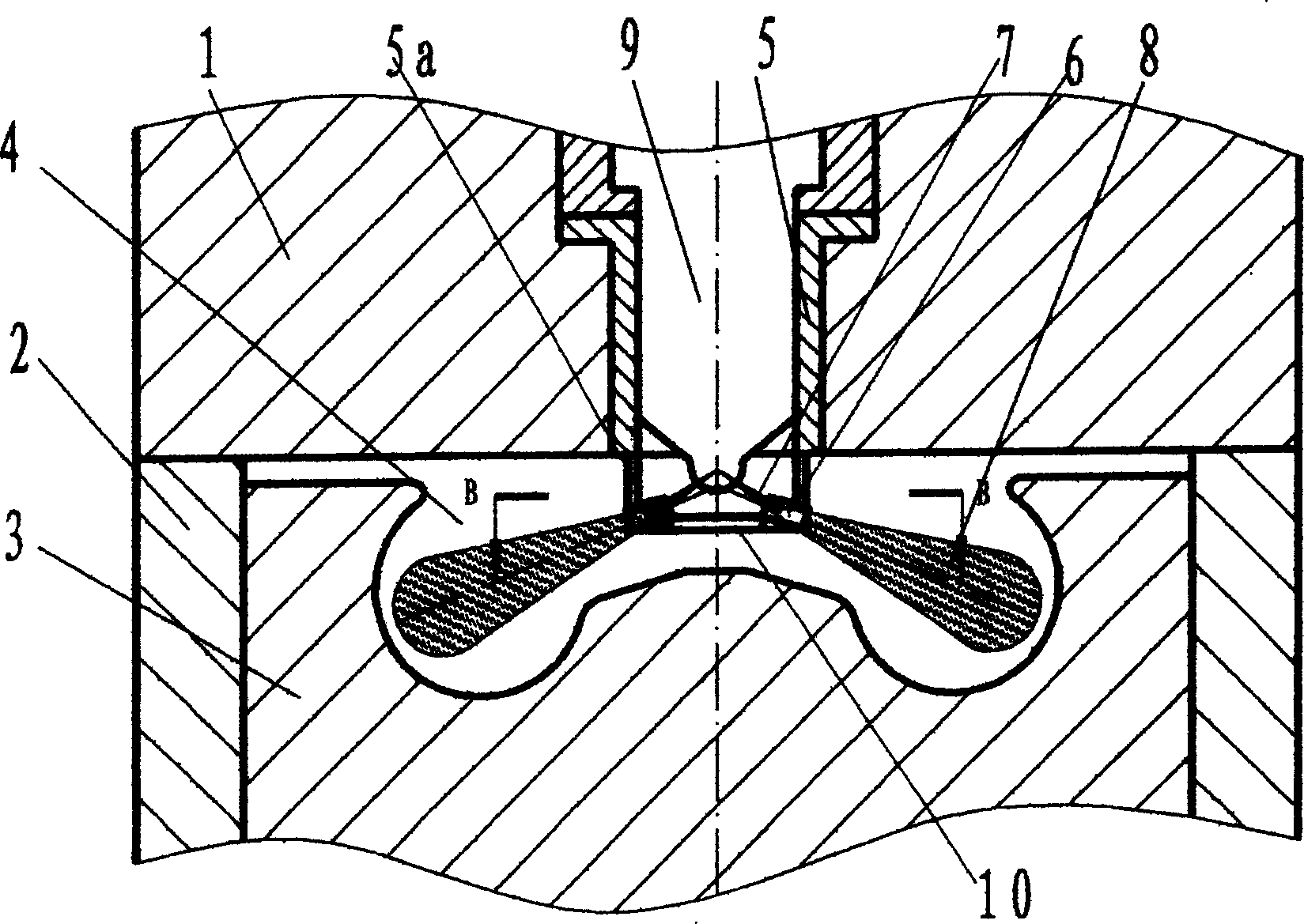

[0013] exist image 3 , 4 In another embodiment shown, an ω-shaped combustion chamber (4) composed of a cylinder head (1), a cylinder liner (2) and a piston (3), guide vanes (6) are connected together to form an annular body (10), the annular body (10) is fixed on the sleeve pipe (5) installed in the cylinder head (1) by 3 connecting ribs (5a). The oil injector (9) sprays 6 primary oil beams (7), and under the guidance of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com