Low-temperature high-speed flame spraying gun

A high-speed flame spraying, low temperature technology, applied in coating, melting spraying, metal material coating process and other directions, can solve the problems of high energy consumption of gas heating device, small adjustable range of oxygen-fuel ratio, and oxidation of coating material, etc. Achieve the effect of reducing flow requirements, avoiding high temperature tests, and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

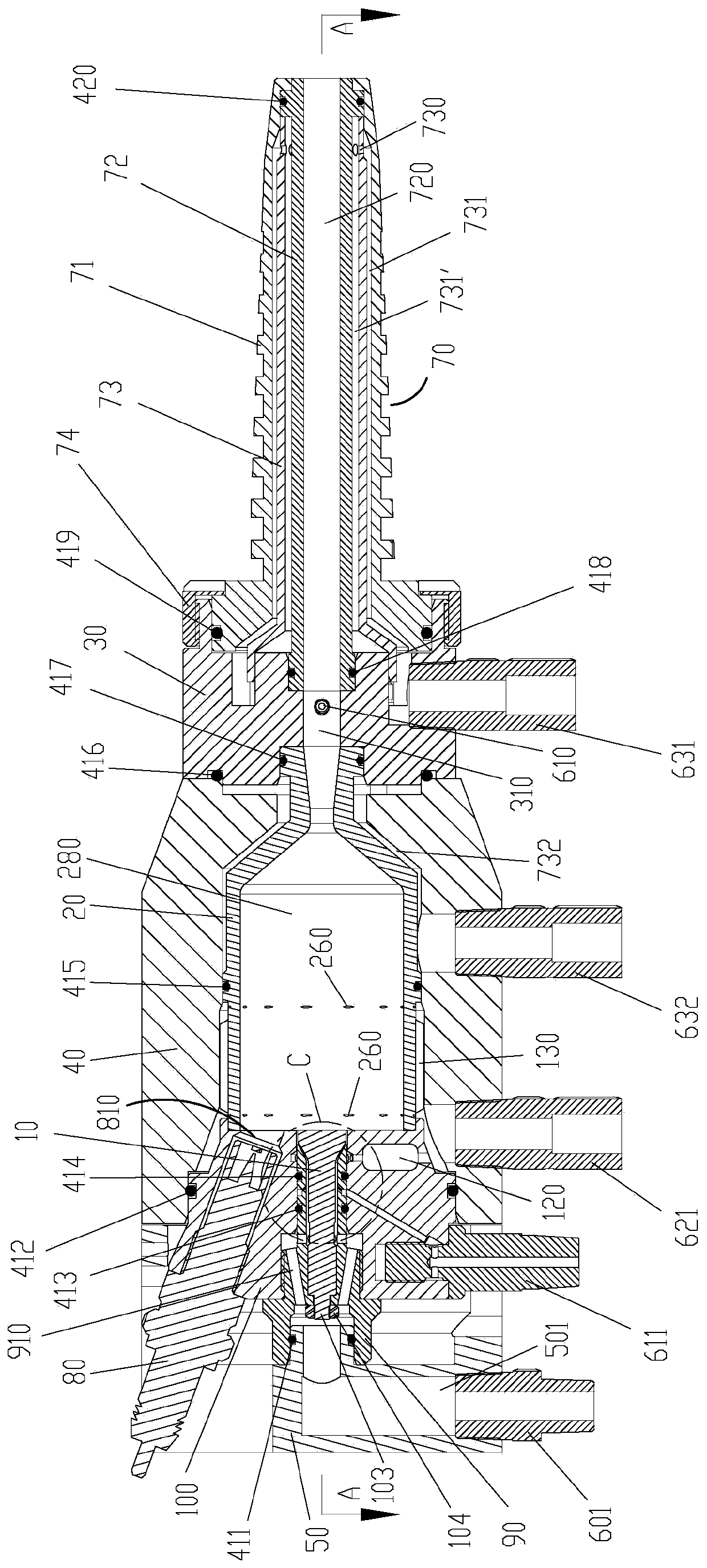

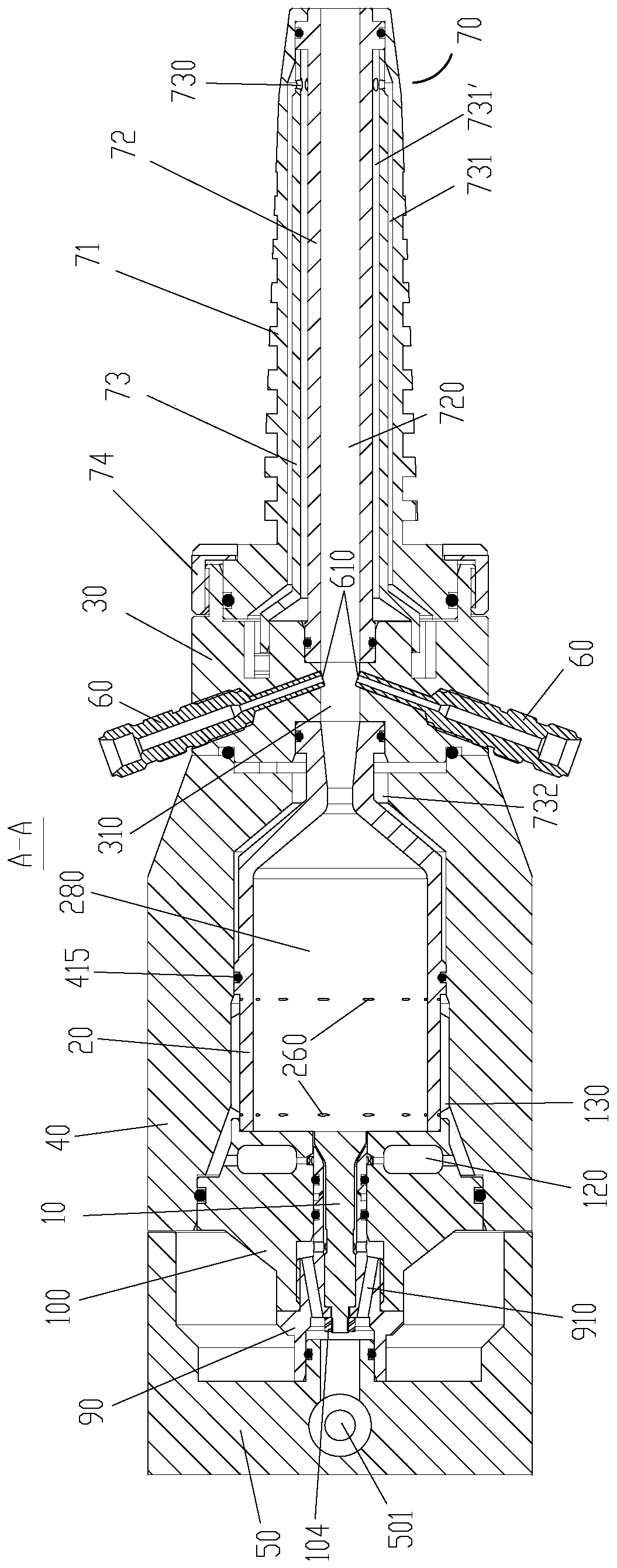

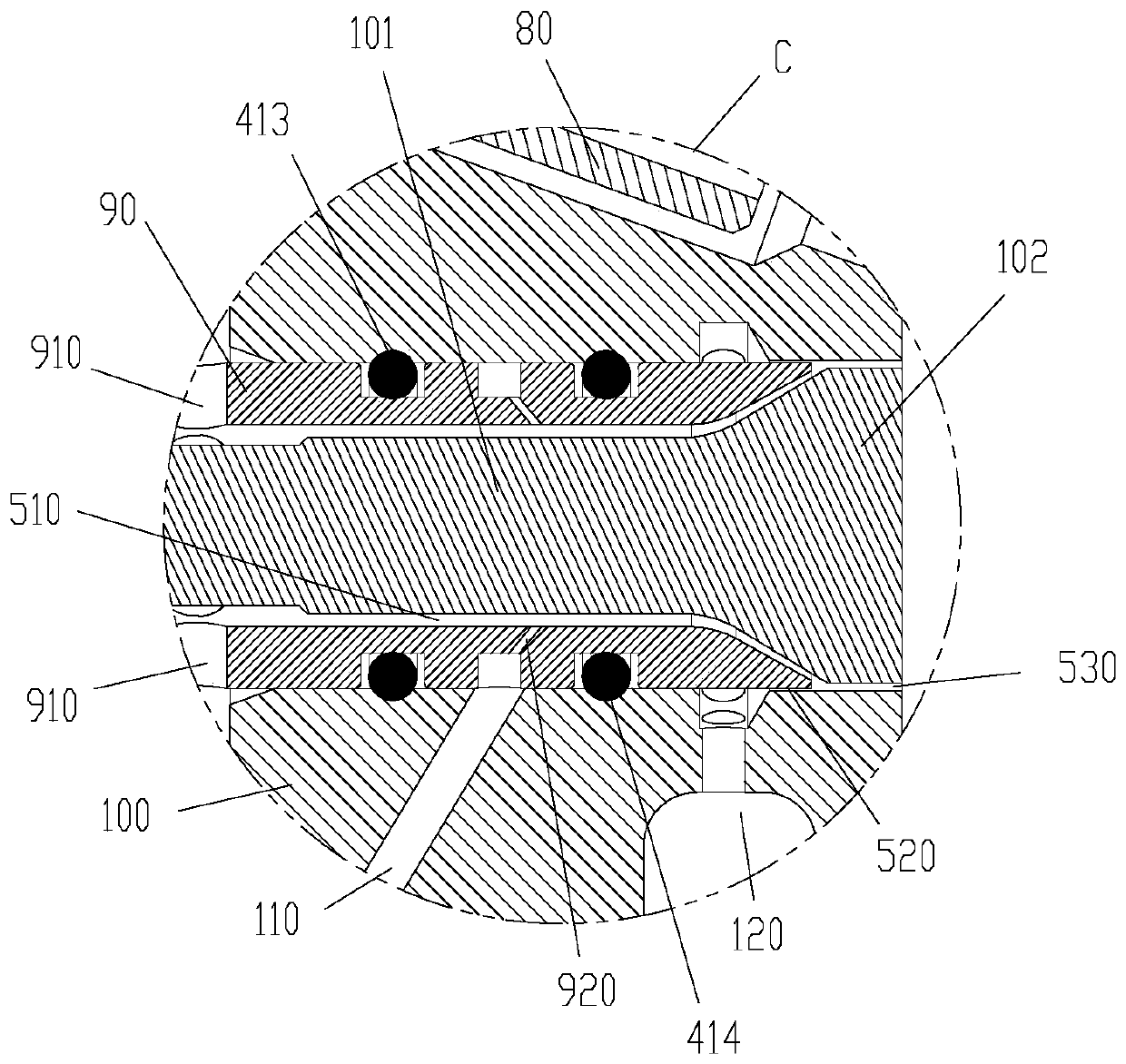

[0019] Such as Figure 1 to Figure 5 As shown, the low-temperature high-speed flame spraying gun of the present invention includes an outer gun body 40, wherein: the combustion chamber 20 of the contraction-expanding structure is installed in the through cavity of the outer gun body 40; There is a gun barrel body 70, and the outlet 240 of the combustion chamber 20 forming the combustion chamber 280 communicates with the flame flow straight channel 720 of the gun barrel body 70 via the intermediate connecting cavity 310 of the intermediate connecting body 30; The powder feeding nozzle 60 for spraying powder, and the spraying powder channel 610 formed by the powder feeding nozzle 60 communicates with the intermediate connecting cavity 310; the entrance 250 of the combustion chamber 20 is sealed by the combustion chamber head cover 100, and the combustion chamber head cover 100 is provided with a center Cone 10, the center cone 10 is provided with a fuel nozzle 90 outside, the fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com