Supergravity type diesel engine tail gas collaborative purification device

A technology of purification device and diesel engine, applied in exhaust device, muffler device, exhaust gas treatment and other directions, can solve the problems of filter material replacement, bad operating conditions, easy failure of catalyst, etc., to achieve compact structure, enhanced applicability, The effect of enhancing the gas-liquid mixing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

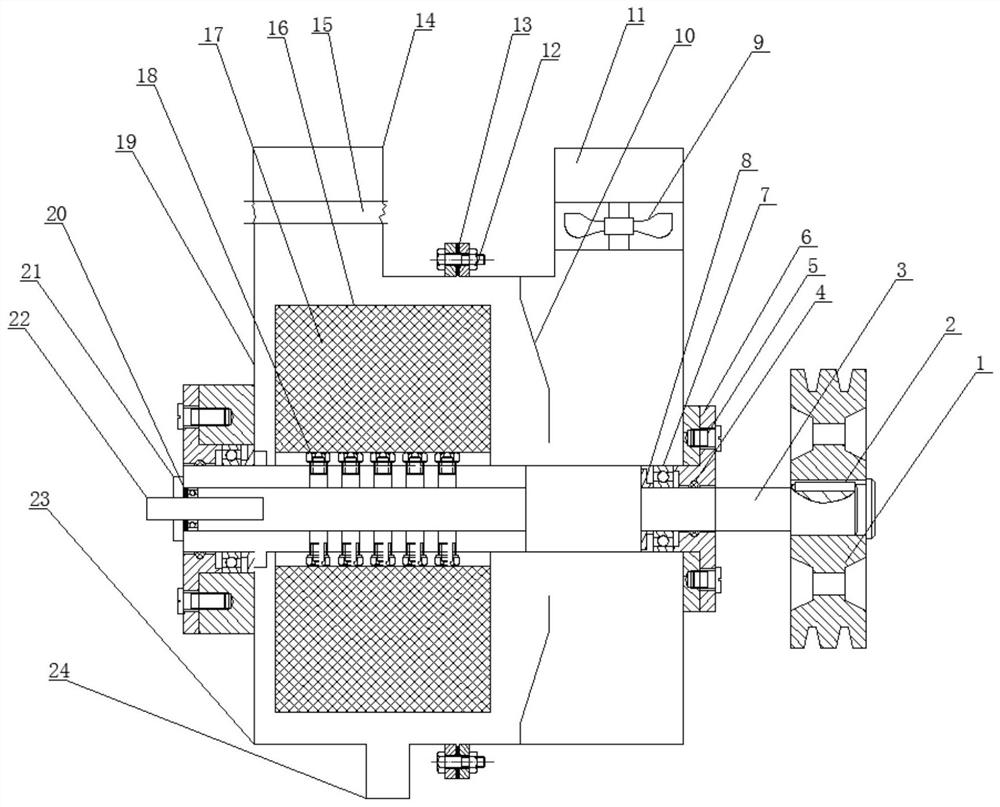

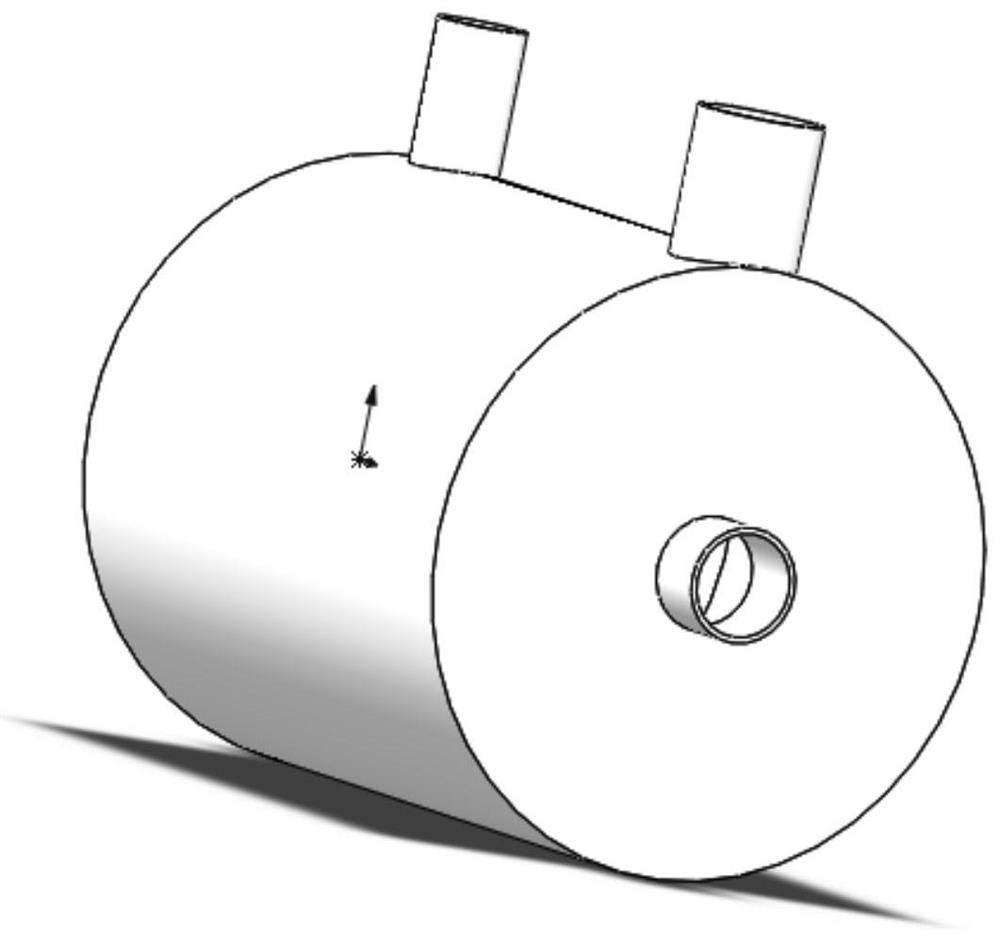

[0024] Such as Figure 1-2 As shown, a high-gravity diesel engine exhaust synergistic purification device includes a housing, a rotating packing bed and a liquid distributor; the rotating packing bed is mainly composed of a rotor 16, a packing 17 and a rotating shaft 3; the rotor 16 is a core component , which is mainly used to fix the packing 17 and drive the packing bed to perform rotary motion, thereby enhancing the contact and micro-mixing of gas and liquid. The rotor 16 is welded on the rotating shaft 3 . The left half of the rotating shaft 3 is hollow, which is used for the nozzle 18 and liquid supply. The right half of the rotation axis 3 is solid to improve the strength of the axis. The right end of the rotating shaft 3 is equipped with a pulley 1, which is connected to the motor through a belt, and the motor drives the rotating packing bed to rotate.

[0025] The liquid distributor adopts a pressure nozzle 18, which is installed in the hollow part of the rotating s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com