Patents

Literature

138results about How to "Increase the degree of atomization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

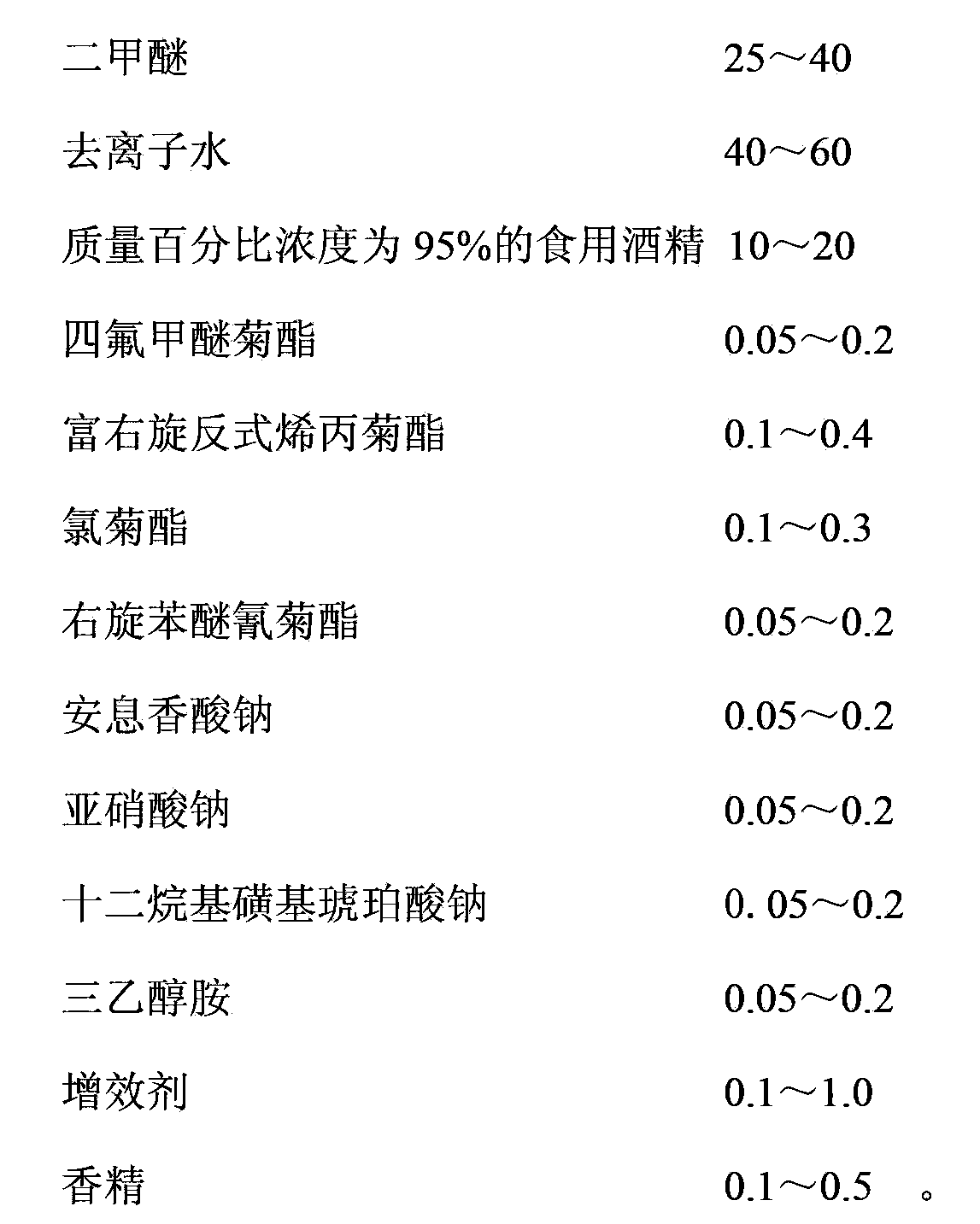

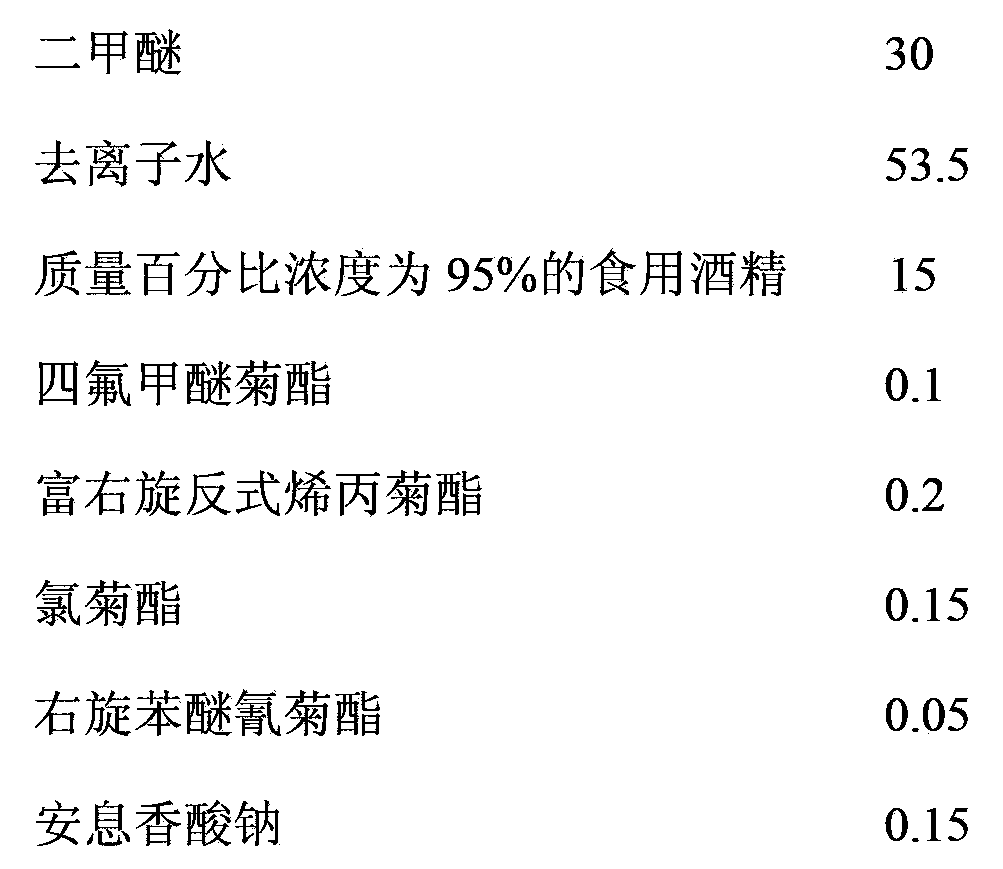

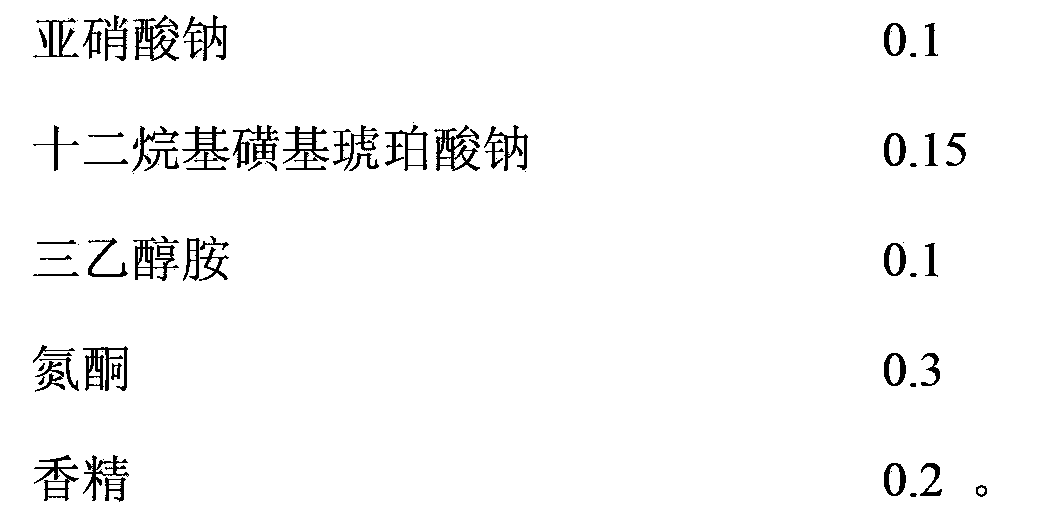

Homogeneous and high-efficient water-based pesticide aerosol with low VOC (Volatile Organic Compounds) content

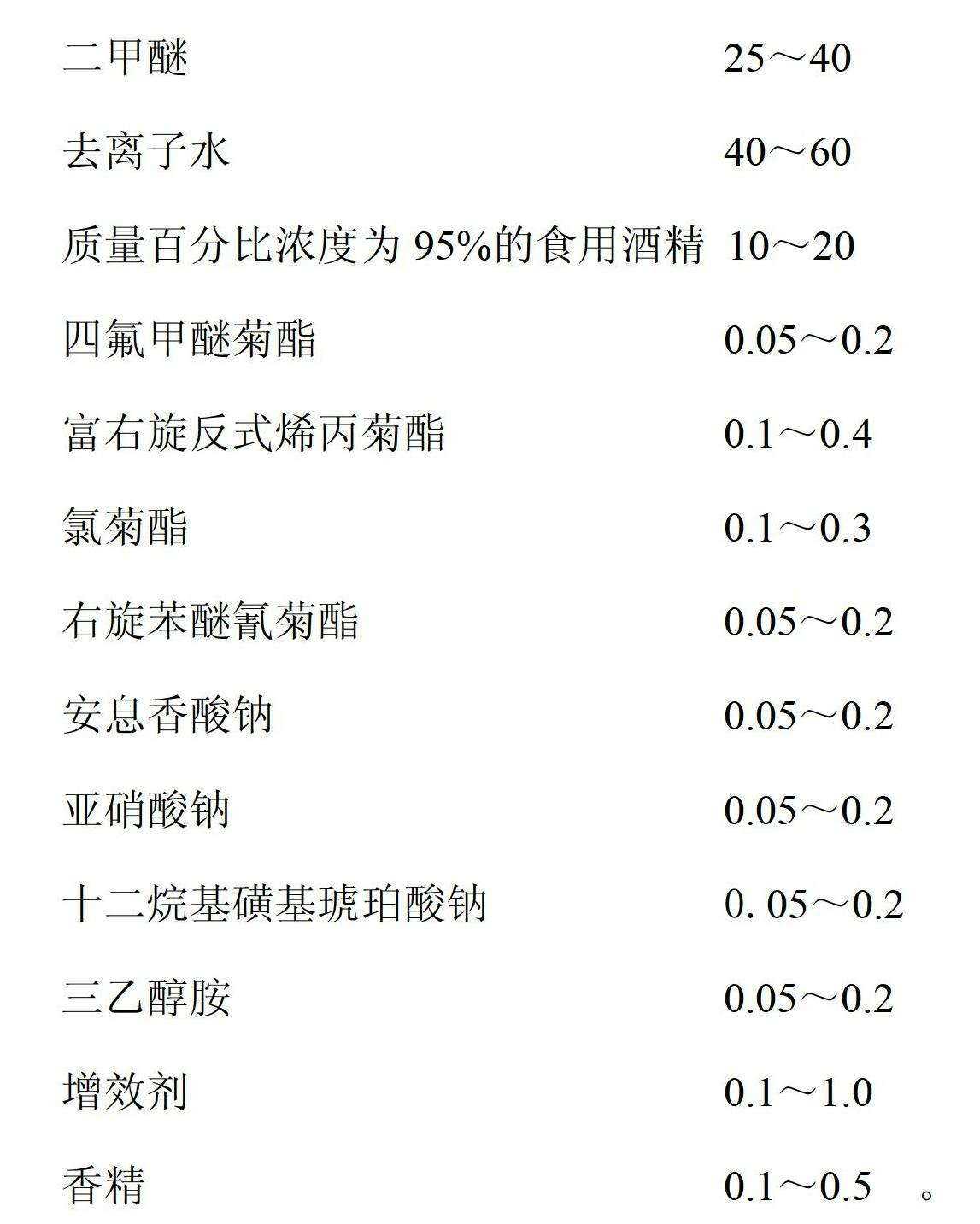

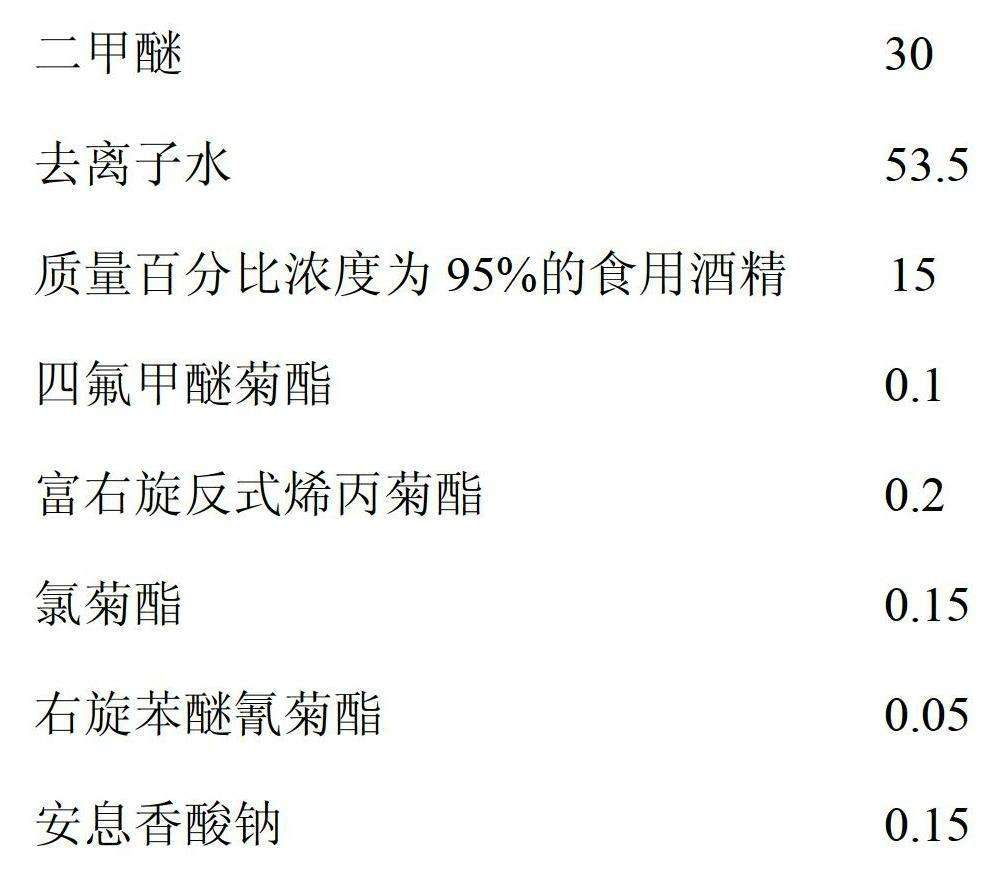

The invention provides homogeneous and high-efficient water-based pesticide aerosol with low VOC (Volatile Organic Compounds) content. The homogeneous and high-efficient water-based pesticide aerosol comprises the following components in parts by weight: 25-40 parts of dimethyl ether, 40-60 parts of de-ionized water, 10-20 parts of edible alcohol with mass-percentage concentration of 95 percent, 0.05-2 parts of dimefluthrin, 0.1-0.4 part of rich-d-transallethrin, 0.1-0.3 part of permethrin, 0.05-0.2 part of d-trans-cyphenothrin, 0.05-0.2 part of sodium benzoate, 0.05-0.2 part of sodium nitrite, 0.05-0.2 part of sodium dodecyl sulfate succinate, 0.05-0.2 part of triethanolamine, 0.1-1.0 part of synergist and 0.1-0.5 part of essence. According to the homogeneous and high-efficient water-based pesticide aerosol with low VOC content, disclosed by the invention, the advantages of good atomizing effect and insert-killing effect can be achieved without vibration and shaking before use.

Owner:山东美多包装有限公司

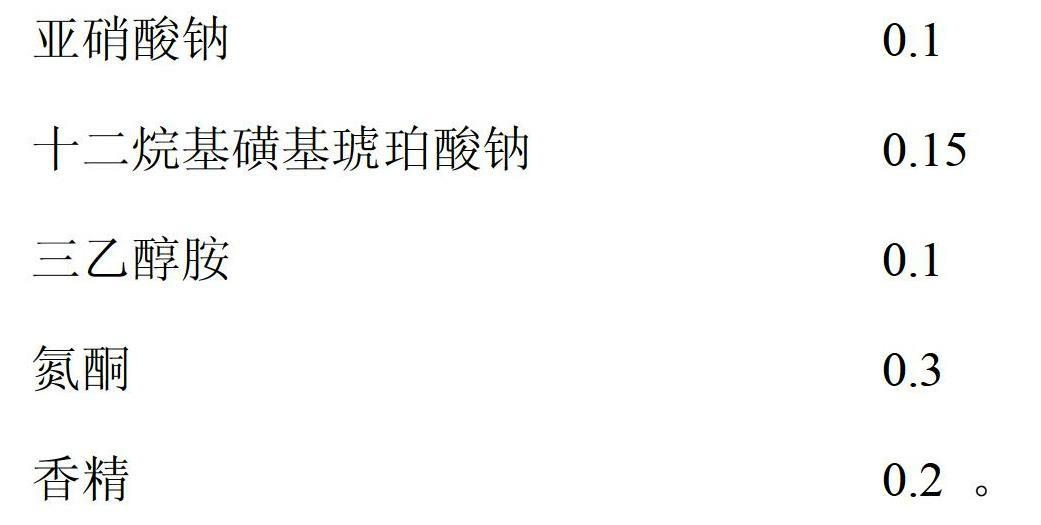

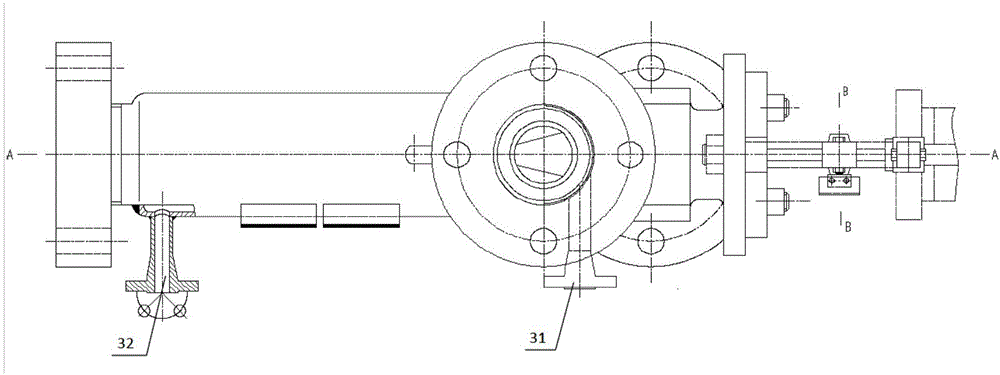

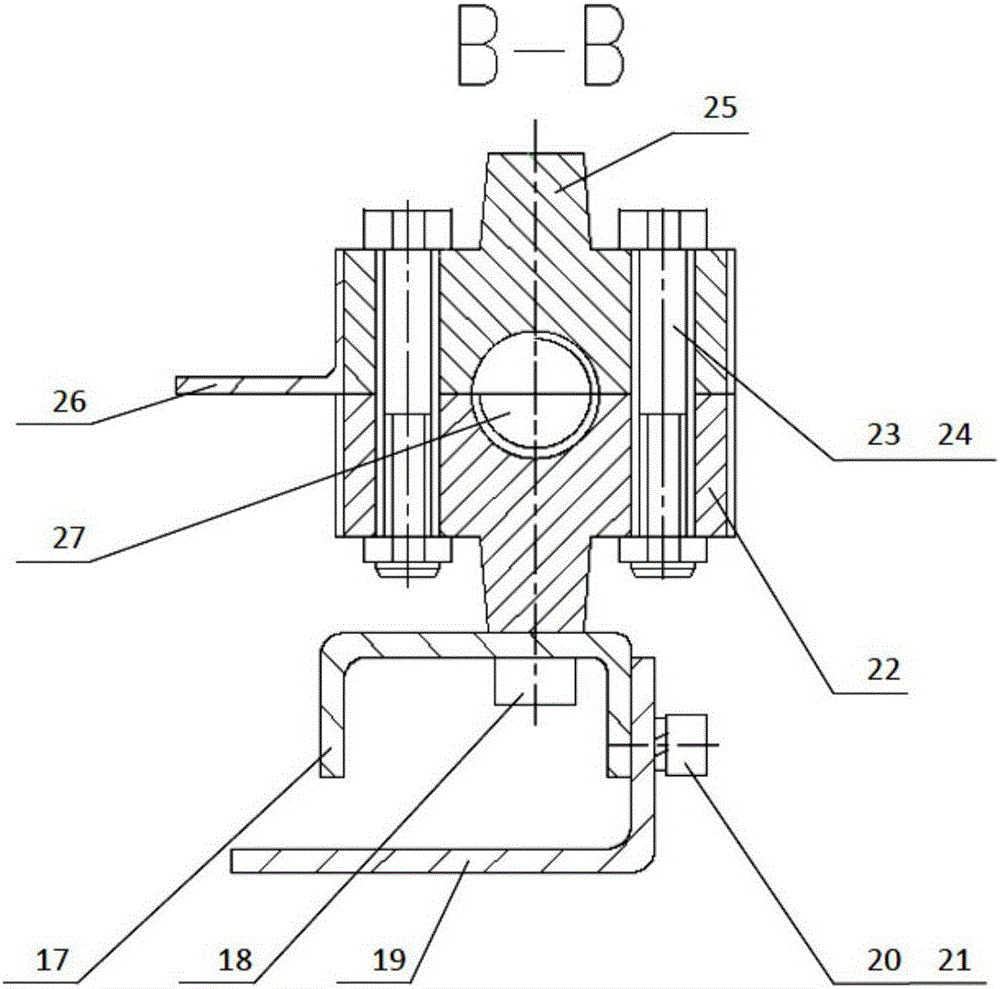

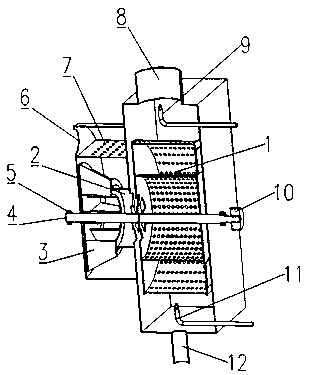

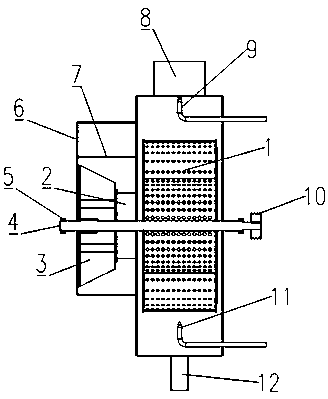

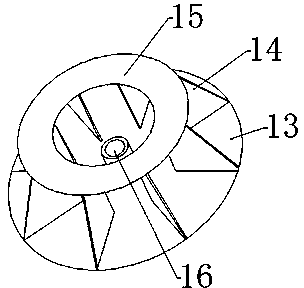

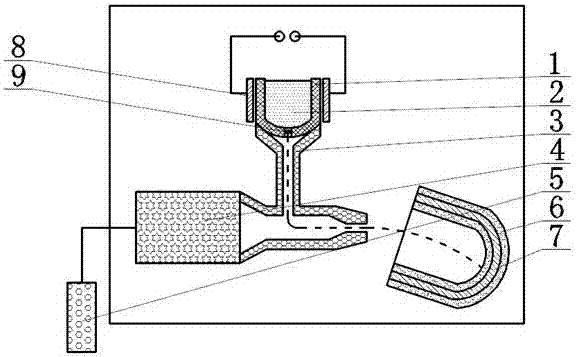

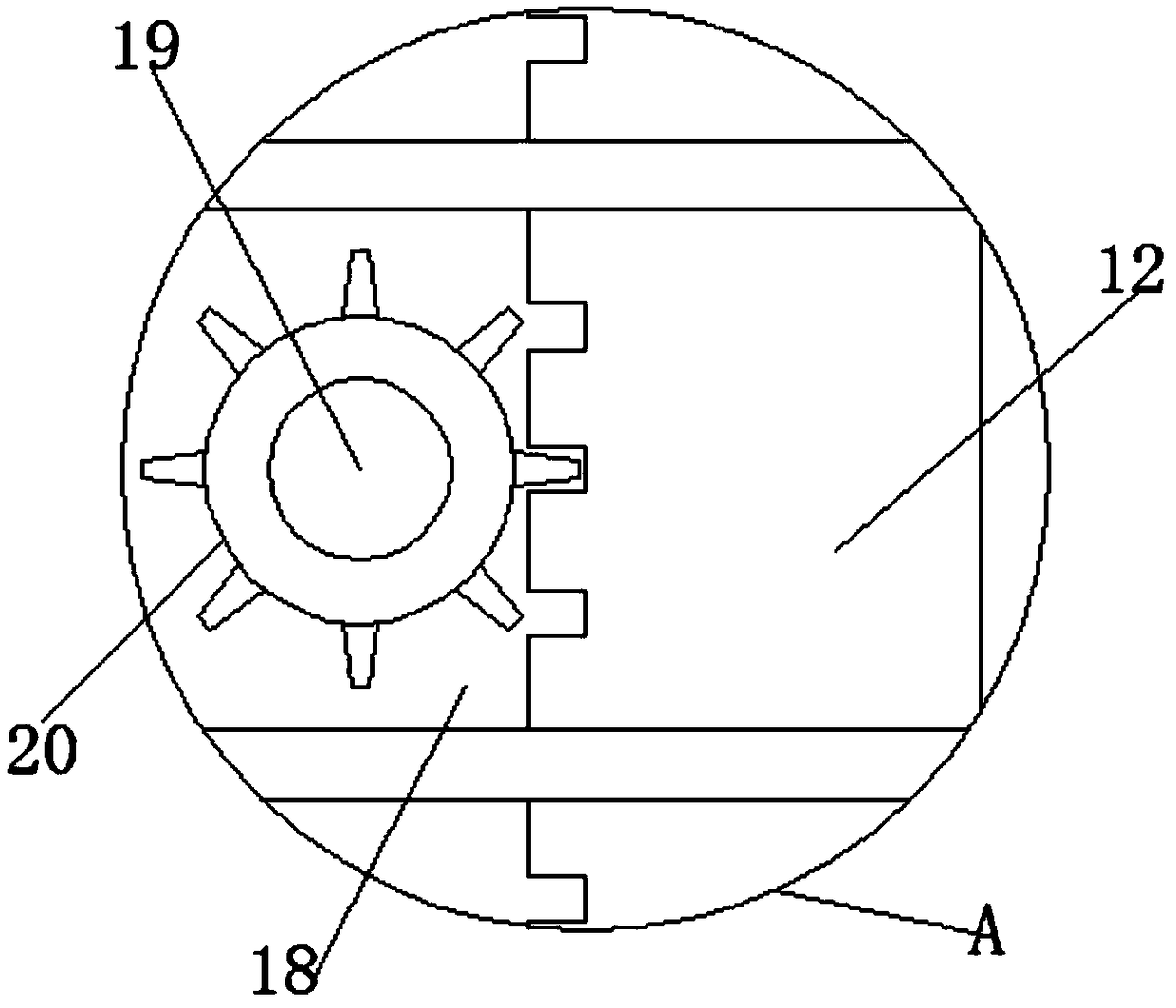

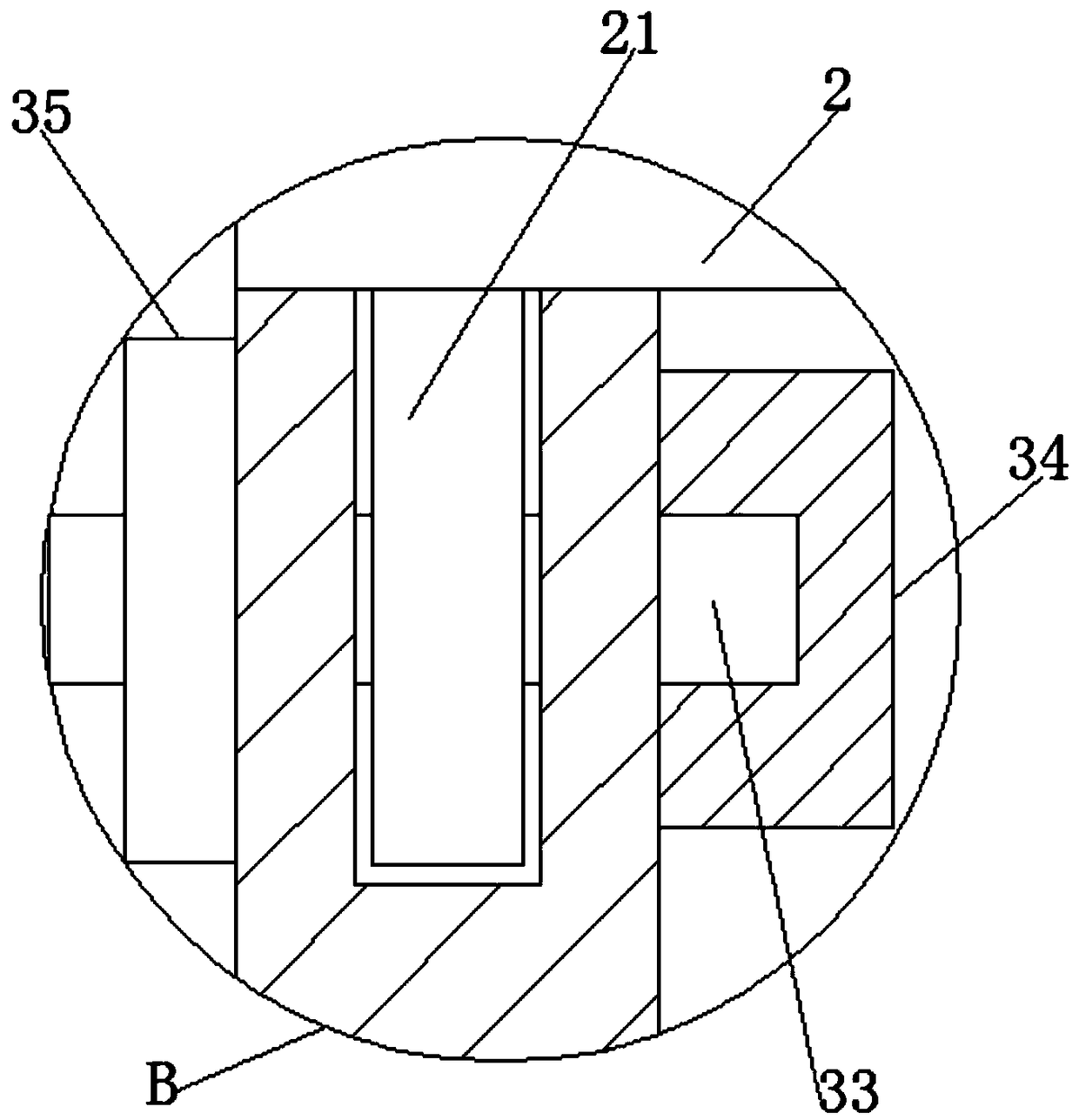

Ultrasonic-pneumatic electrostatic nozzle

InactiveCN104549813AIncrease the degree of atomizationImprove adsorption capacityLiquid spraying apparatusSpray discharge apparatusElectricityHigh pressure

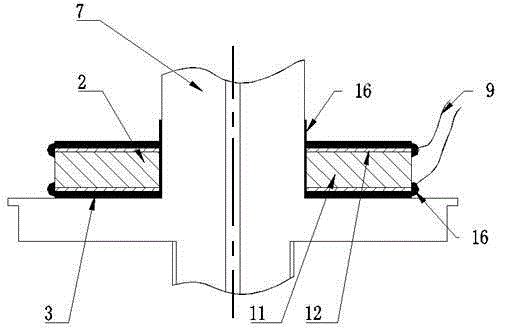

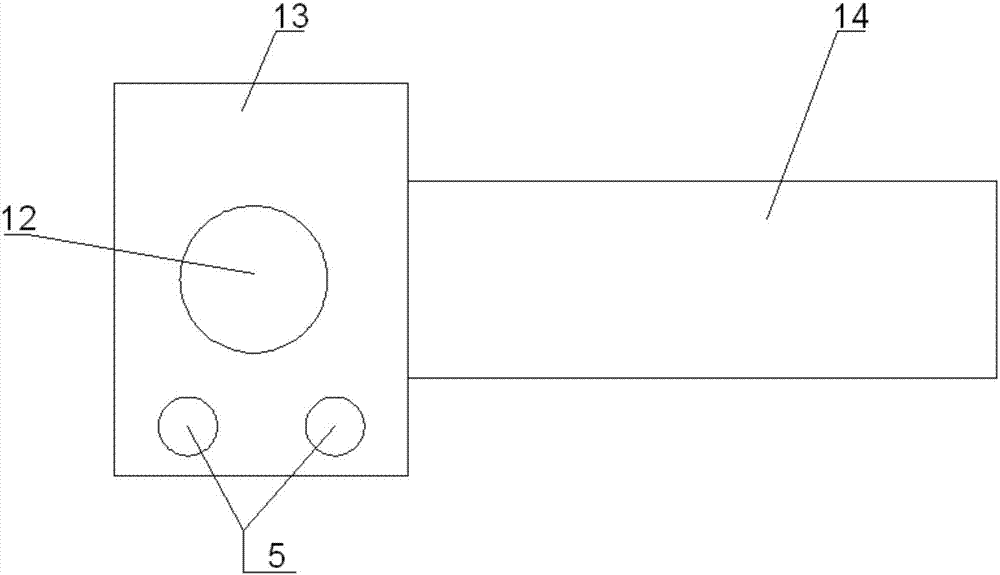

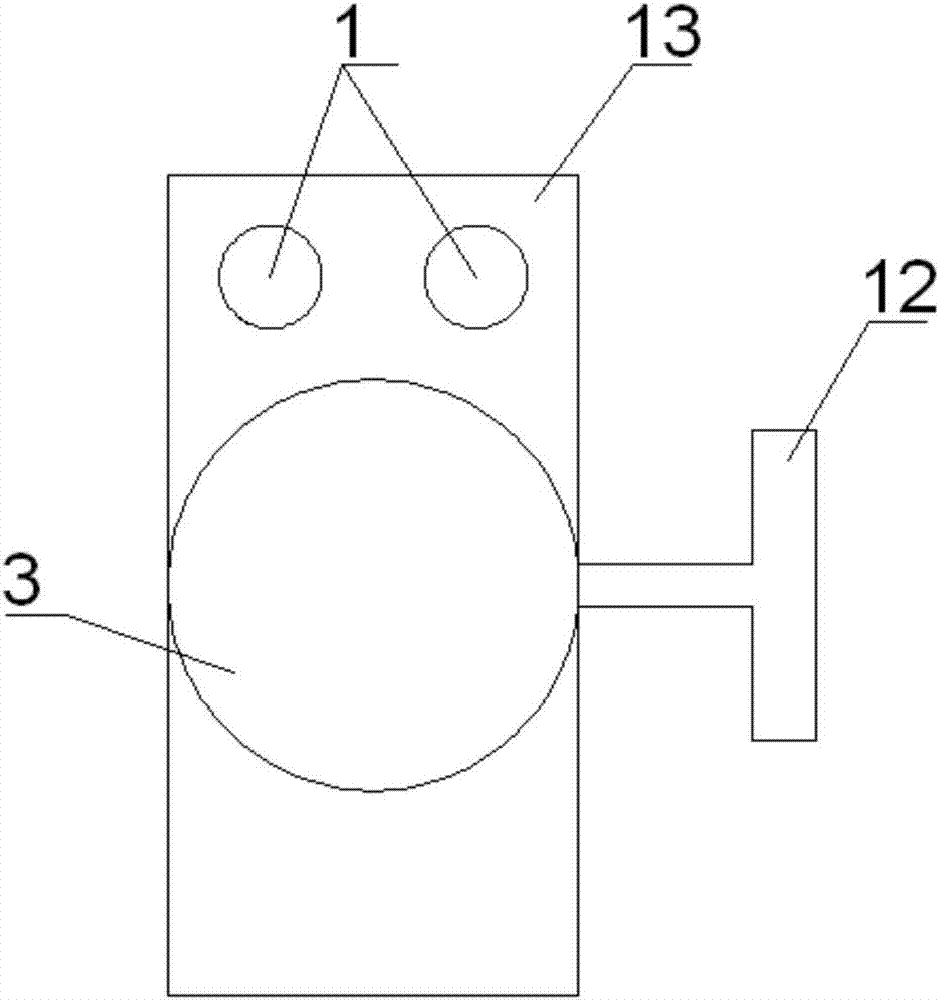

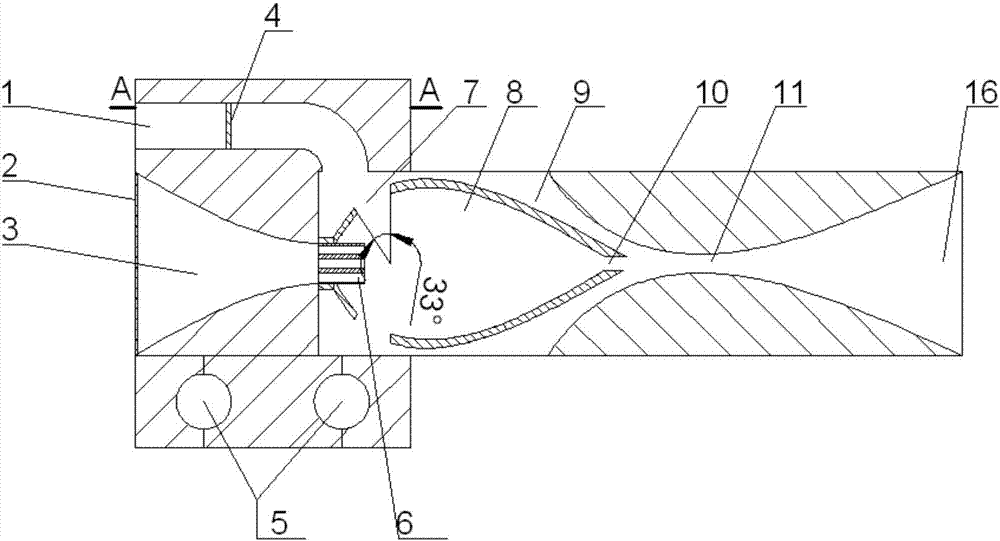

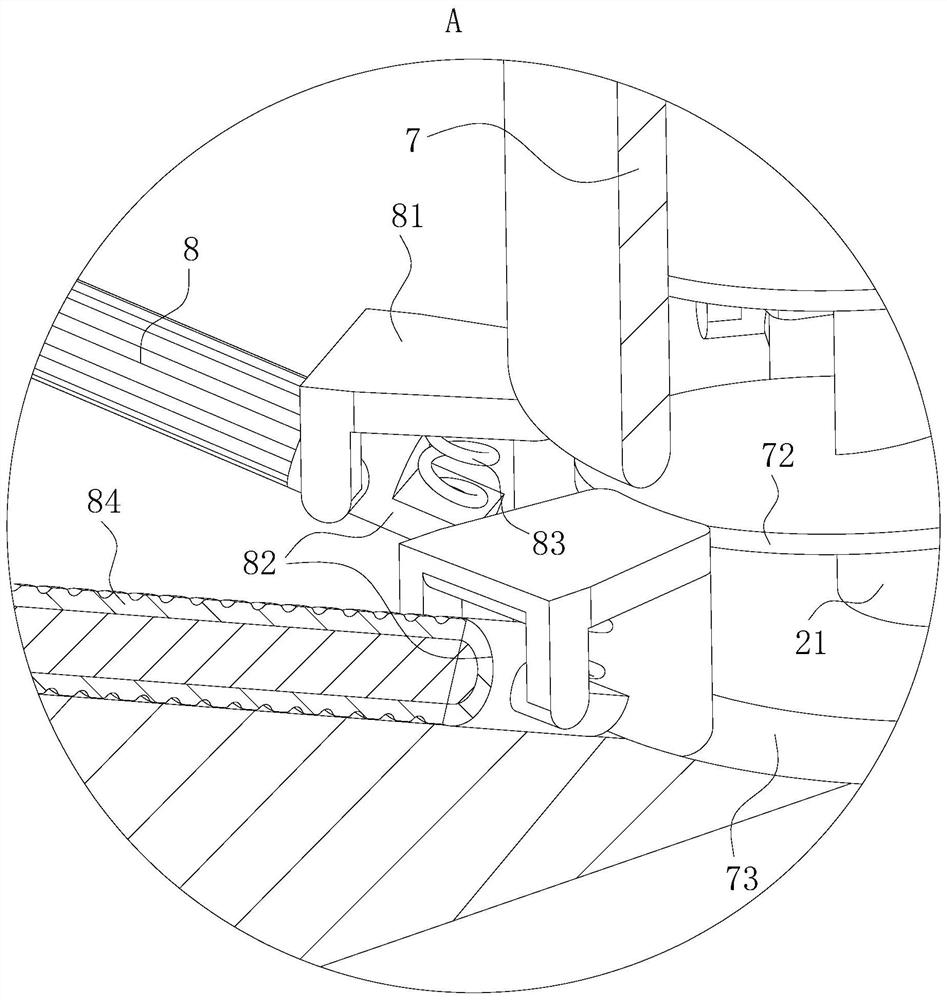

An ultrasonic-pneumatic electrostatic nozzle comprises a spray rod with a tiny liquid flow channel processed in the axis, an ultrasonic generator, a nozzle air tap, a high-voltage electrostatic generator. The nozzle air tap surrounds the end of the spray rod to form the nozzle, a support device is arranged in the middle of the spray rod, the ultrasonic generator and the high-voltage electrostatic generator are pressed and fixed on one side face, away from the nozzle, of the support device through a fastening device, the ultrasonic generator is provided with a piezoelectric wafer, a backseat and a lead, the lead is connected to the piezoelectric wafer, short pulse of voltage acts on two poles of the piezoelectric wafer through the lead, the piezoelectric wafer elastically deforms so as to generate elastic oscillation, the high-voltage electrostatic generator is provided with an electrode to be connected with the liquid flow channel in the axis of the spray rod, and the high-voltage electrostatic generator applies high voltage static on liquid passing through the liquid flow channel of the spray rod. The nozzle is simple in structure, convenient to operate, safe and reliable, adjustable in spray flux and distance and the like, and is of great significance to spray effect improvement and reduction of chemical waste.

Owner:YANGZHOU UNIV

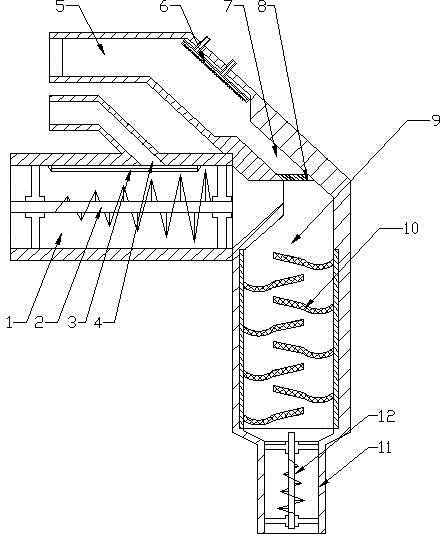

Multi-level atomization bi-phasic flow water mist atomization generating device for mine

Provided is a multi-level atomization bi-phasic flow water mist atomization generating device for a mine. The device comprises a rectification canister and a multi-level atomization canister, the rectification canister is internally provided with two gas guiding channels and one liquid guiding channel, the rear end of the liquid guiding channel is provided with a porous nozzle, the porous nozzle enters an impact atomizing chamber, the rear end of the impact atomizing chamber is provided with a Venturi mixing channel, liquid enters the porous nozzle through the liquid guiding channel, primary atomized jet is generated, negative pressure is formed in the impact atomizing chamber, partial gas of the gas guiding channels is sucked into the atomizing chamber, the gas is collided with the primary atomized jet, secondary atomization is achieved, water mist of the secondary atomization is mixed with gases in a gas side channel at a jet opening portion, and is atomized again in the Venturi mixing channel, during extinguishment, fast extinguishment and cooling are achieved through the multi-level atomization of nitrogen and water. Through the multi-level atomization bi-phasic flow water mist atomization generating device for the mine, after the extinguishment and before a pit is opened, air is automatically switched in the gas guiding channels, heat exchange and cooling are achieved through the multi-level atomization of the air and water, unnecessary waste of the nitrogen can be avoided, and the device is high in atomization degree and economical and practical.

Owner:LIAONING TECHNICAL UNIVERSITY

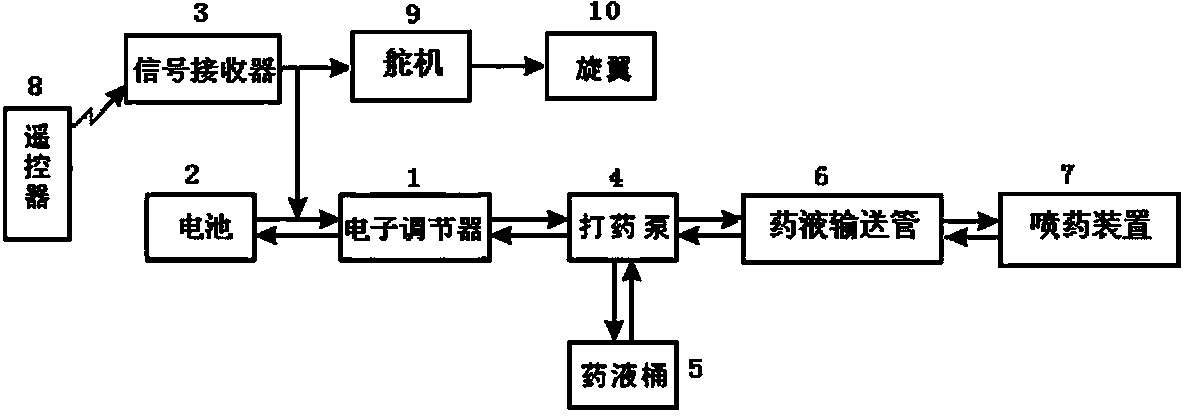

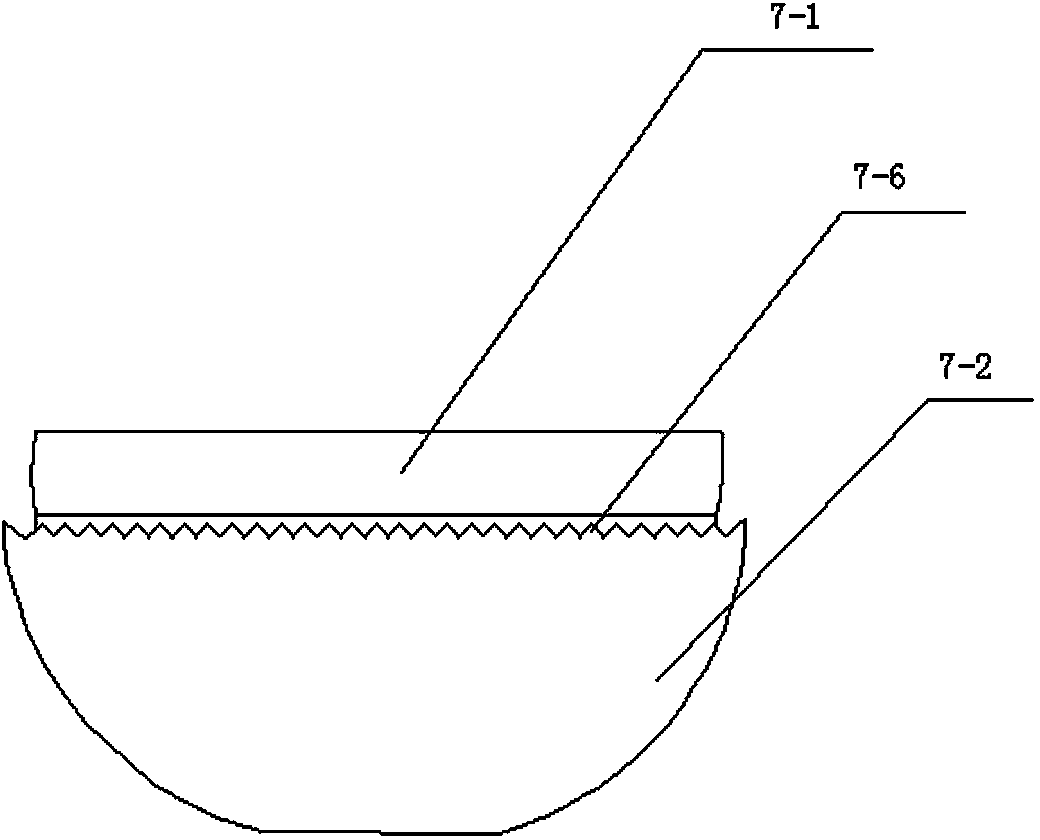

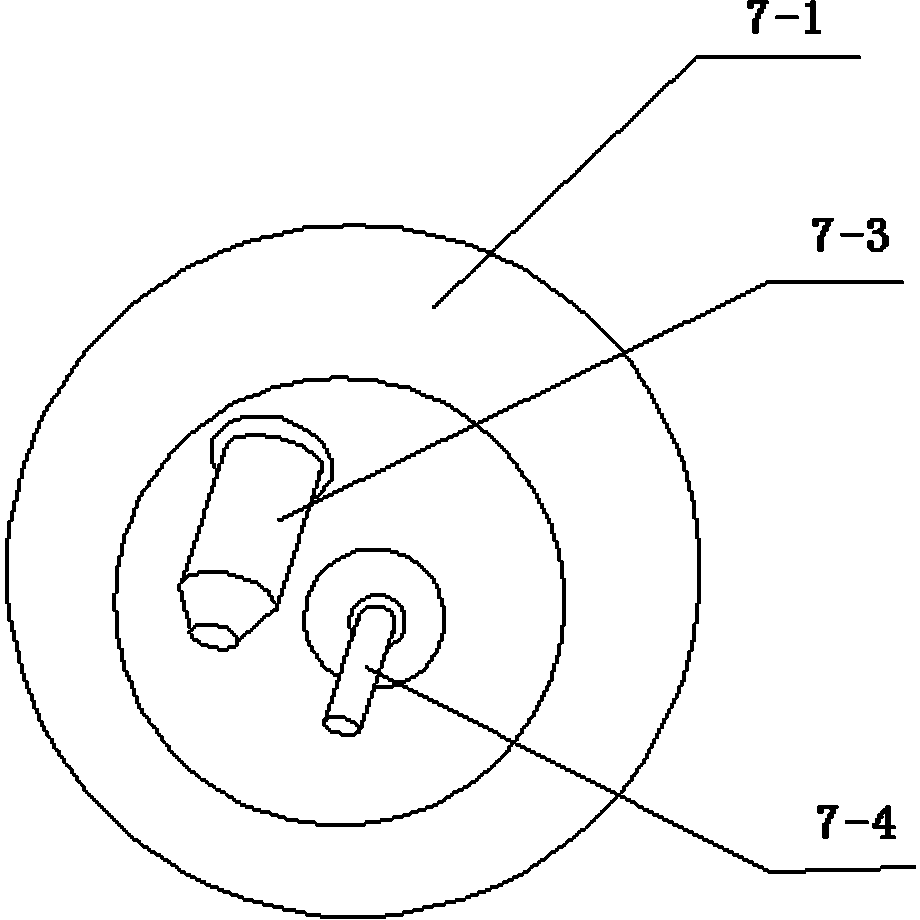

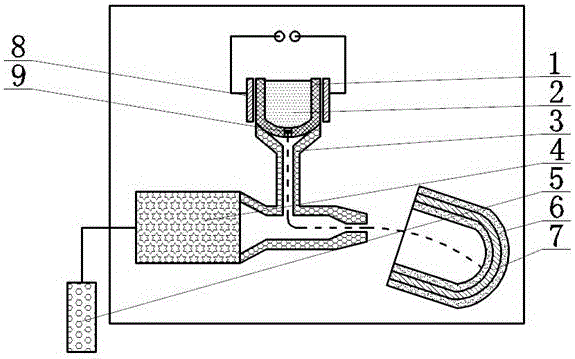

Remote-control flight plant protection machine pesticide spaying system

ActiveCN104041477AAchieve supply changeSimple structureInsect catchers and killersElectricityRemote control

A remote-control flight plant protection machine pesticide spaying system comprises an electronic regulator, wherein a power source end of the electronic regulator is externally connected with a battery, an input end of the electronic regulator is electrically connected with a signal receiver, an output end of the electronic regulator is electrically connected with a power source end of a pesticide pump, an input end of the pesticide pump is connected with a pipette, an end of the pipette is arranged in a pesticide barrel, an output end of the pesticide pump is connected with a pesticide spraying device through a pesticide conveying pipe, and the signal receiver is connected with a remote controller in a wireless mode. The remote-control flight plant protection machine pesticide spaying system is simple and compact in structure, the electricity volume supplied to the pesticide pump is regulated through the electronic regulator, the amount of pesticide sucked by the pesticide pump changes while the flight speed of a plane changes, and therefore supply change of the pesticide amount of the pesticide spraying device is achieved.

Owner:湖南精飞智能科技有限公司

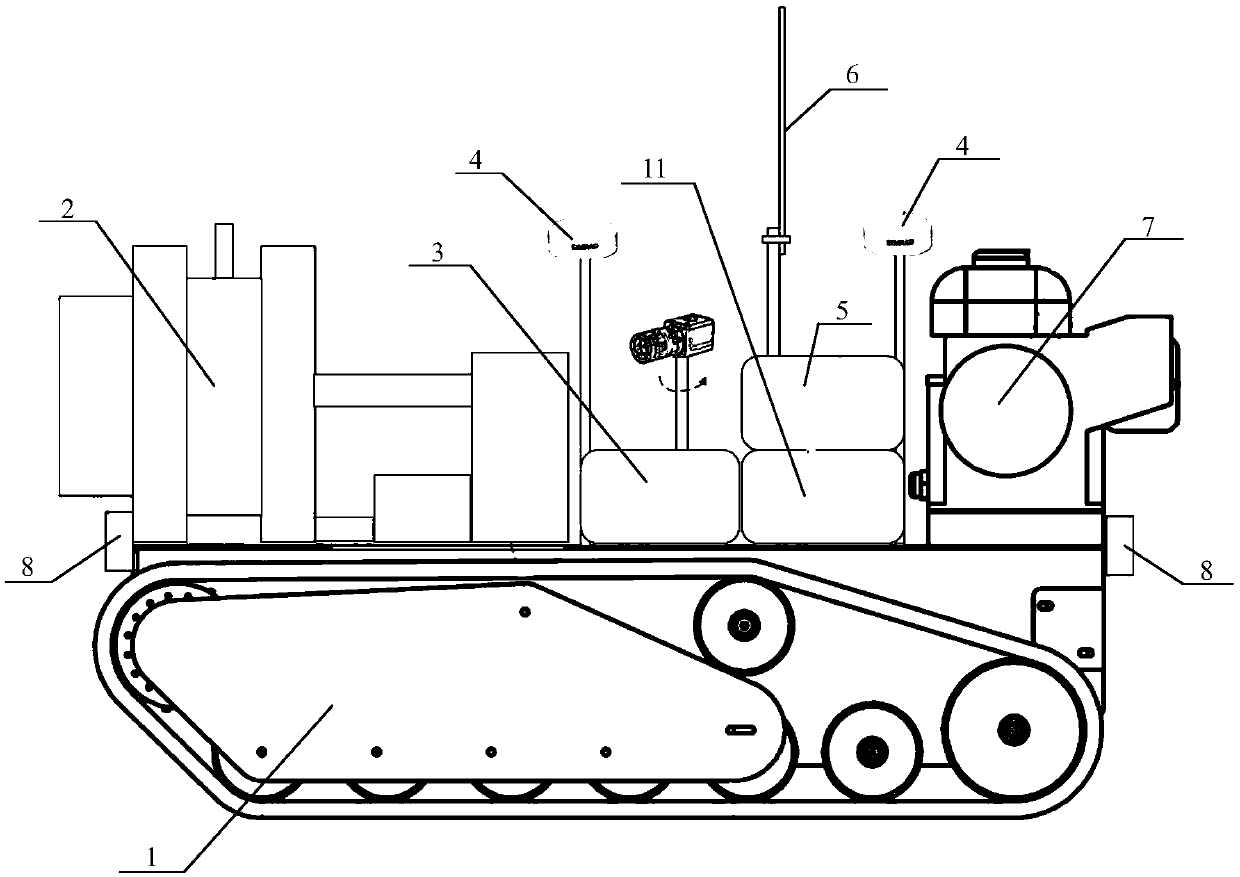

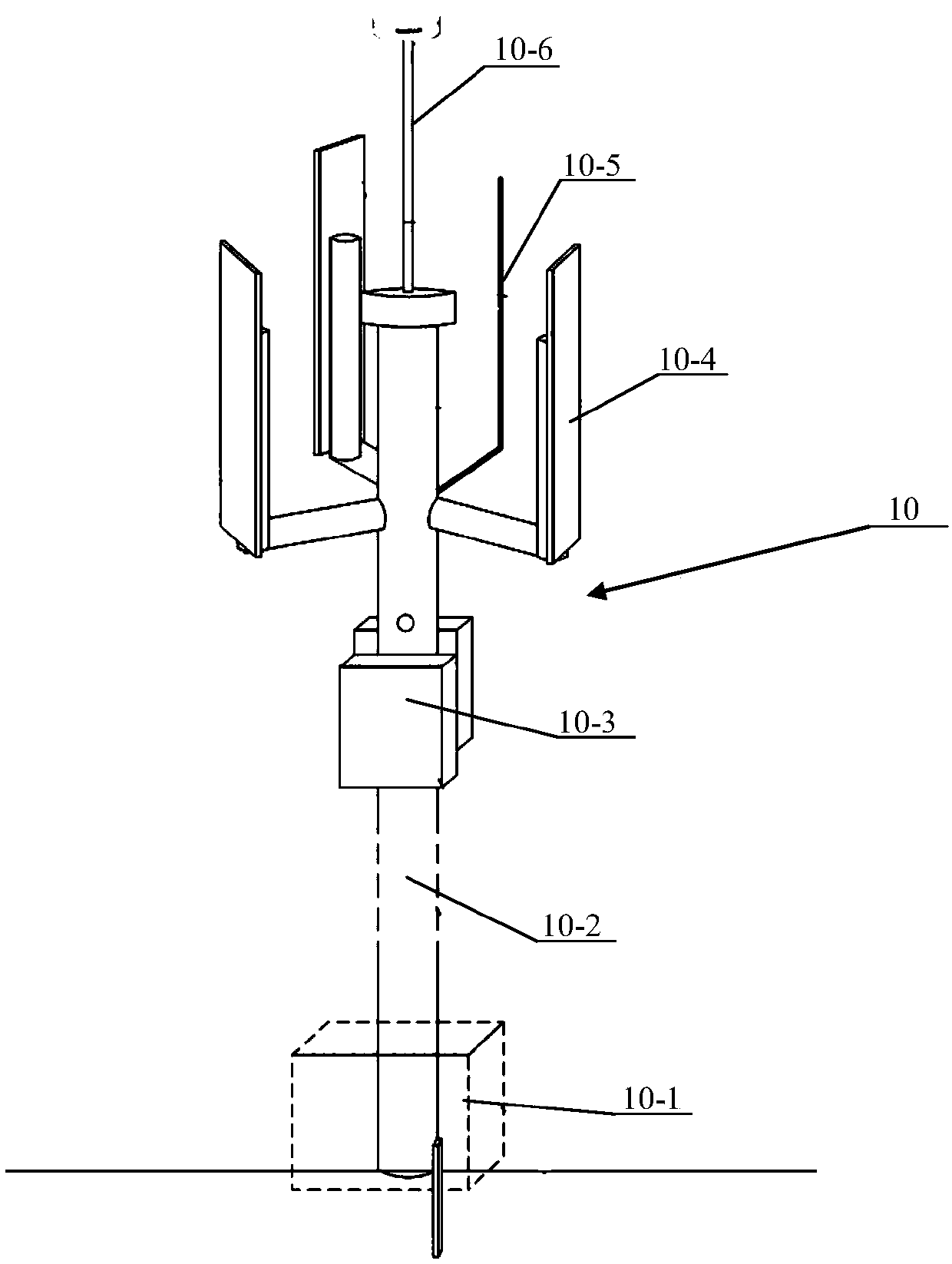

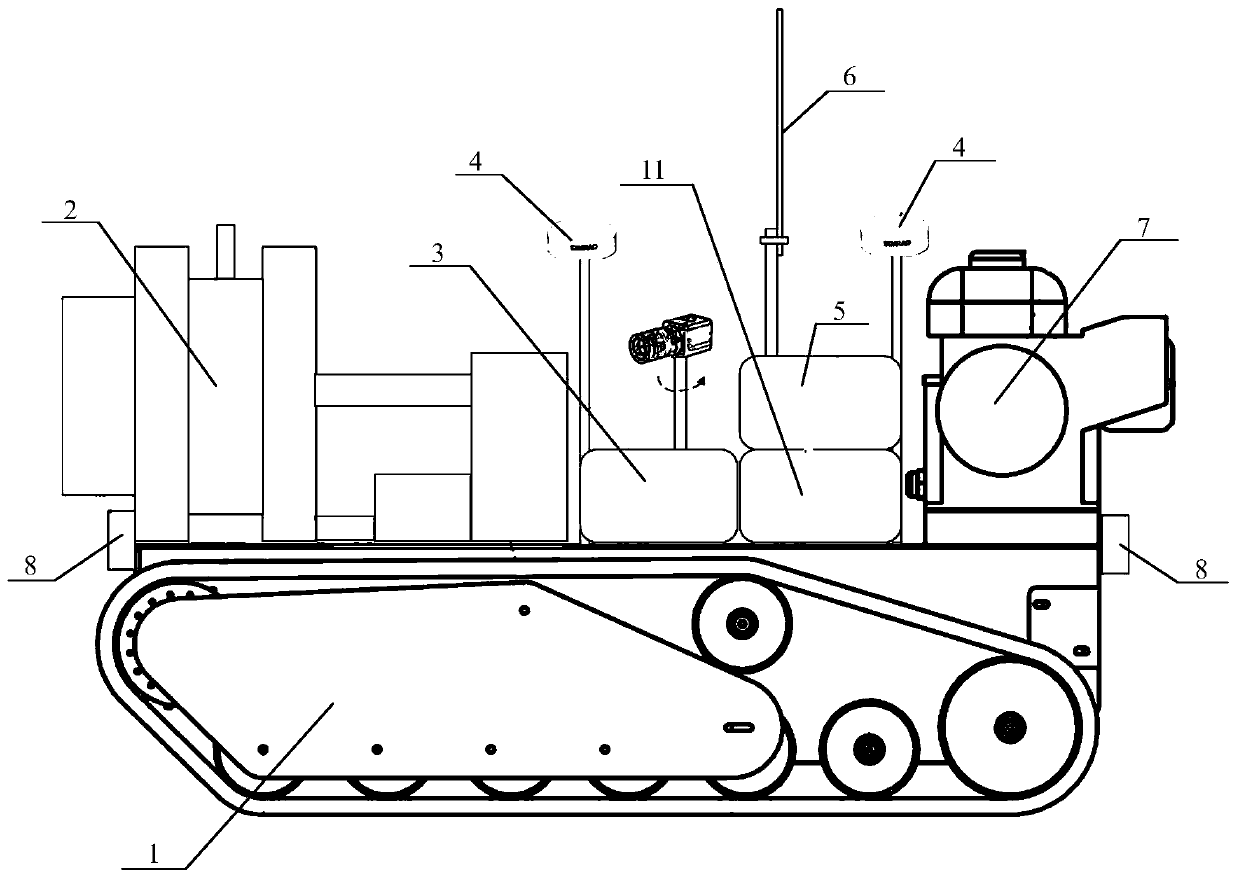

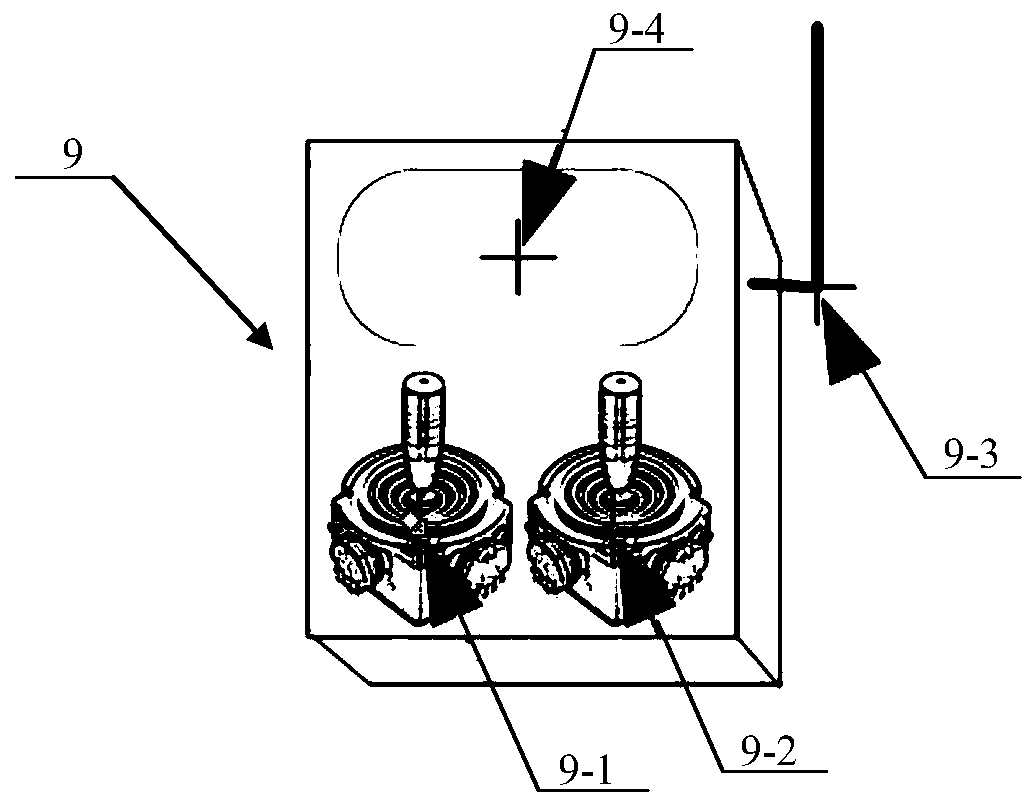

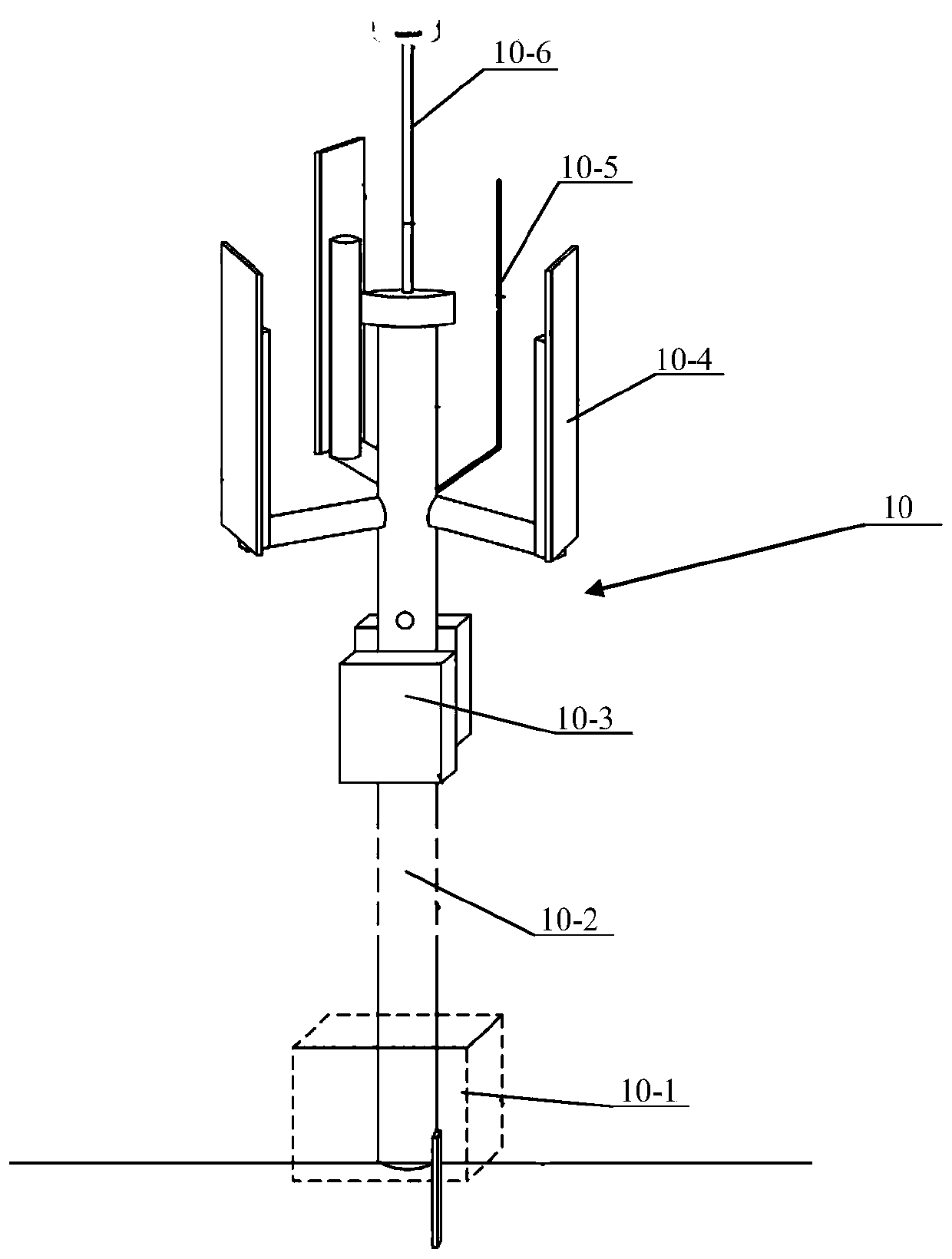

Autonomous navigation spraying robot for orchard work and working method thereof

InactiveCN109090087ARealize the spraying operationHas statusInsect catchers and killersAgricultural engineeringThe Internet

The invention relates to an autonomous navigation spraying robot for orchard work and a working method thereof, and belongs to the field of agricultural intelligent equipment. The robot comprises a robot body and accessory equipment, wherein the robot body comprises a mobile type chassis, an air feed spraying device, an inertial navigation device, a satellite positioning device, a control system,a remote communication device and an energy power system; radar obstacle avoidance devices are arranged at the front and rear ends of the robot body; the accessory equipment comprises a remote controller and a communication base station; the air feed spraying device, the inertial navigation device, the satellite positioning device, the energy power system and the radar obstacle avoidance devices are all connected with the control system; the control system is connected with the remote communication device; the remote communication device is connected with the Internet through the communicationbase station; and the remote communication device is further wirelessly connected with the remote controller. The autonomous navigation spraying robot disclosed by the invention can obviously reducethe number and the intensity of labors for orchard spraying work and has important significance for improving the quality and the efficiency of the modern fruit industry and converting new and old kinetic energy.

Owner:济南钰成霖信息科技有限公司

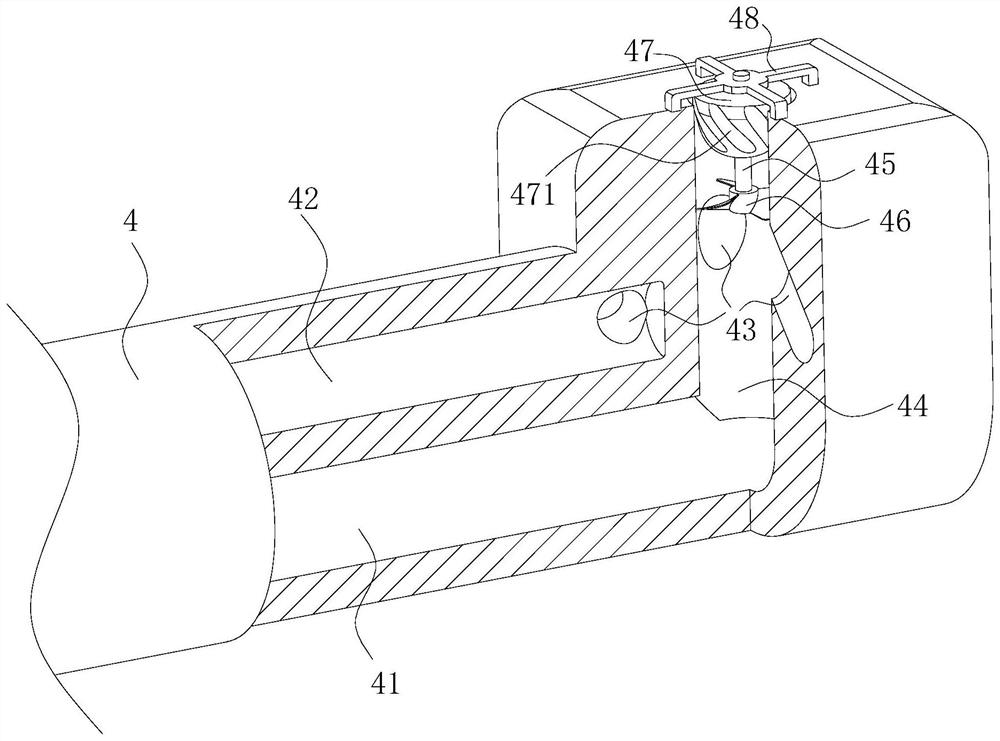

Pneumatic atomizing nozzle with function of adjusting sizes of atomizing particles

The invention provides a pneumatic atomizing nozzle with the function of adjusting the sizes of atomizing particles. The pneumatic atomizing nozzle comprises a nozzle body. An air inlet and a liquid inlet are formed in the outer side of the nozzle body. A tapered nozzle orifice is formed in one end of a hollow cavity of the nozzle body. The aperture of the tapered nozzle orifice is increased from inside to outside. A cylindrical cavity is formed in the middle of the nozzle body. A tapered spray nozzle and a tapered bushing are sequentially arranged at the other end of the hollow cavity. A part between the outer part of the tapered spray nozzle and the inner wall of the nozzle body is sealed. A cavity between an outer taper surface of the tapered spray nozzle and the inner wall of the hollow cavity communicates with the liquid inlet. A cavity defined by the inner taper surface of the tapered spray nozzle, the inner wall of the hollow cavity and the outer side of the tapered bushing communicates with the air inlet. A part between the tapered bushing and the inner wall of the hollow cavity is sealed. A cylindrical through hole is formed in the center of the tapered bushing. A core shaft capable of moving in the axial direction to adjust the size of an air outlet of the tapered spray nozzle is arranged in the cylindrical through hole through a bushing and a sealing sleeve. A fastening sleeve is mounted on the core shaft to fix the bushing in the axial direction. A gland, which has an axial pressing effect, is arranged on the end surface of the tapered bushing. According to the pneumatic atomizing nozzle provided by the invention, the air spraying rate is adjusted by adjusting the core shaft so as to adjust the sizes of sprayed liquid drops. The pneumatic atomizing nozzle is suitable for various productions.

Owner:厦门精世环保科技有限公司

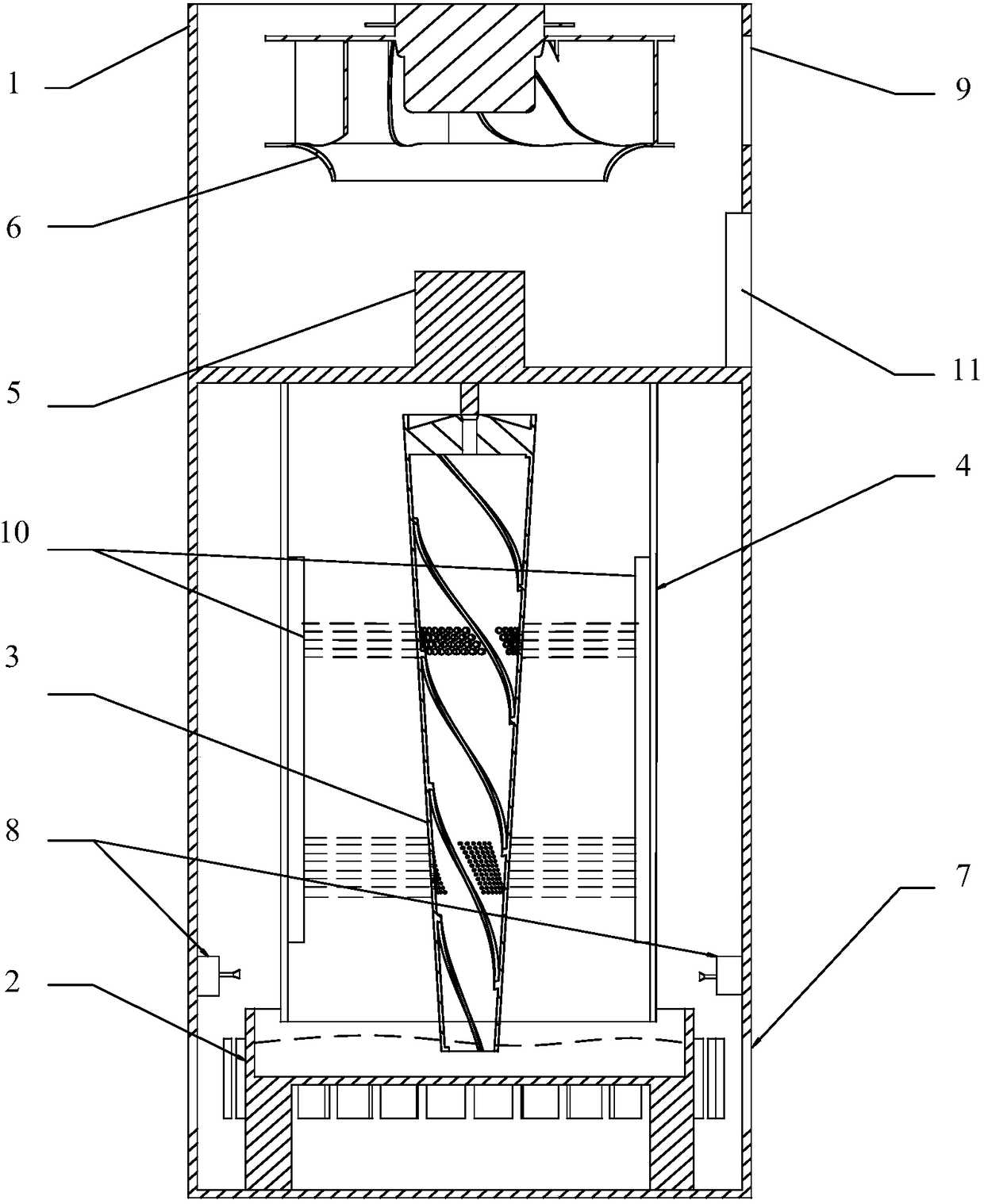

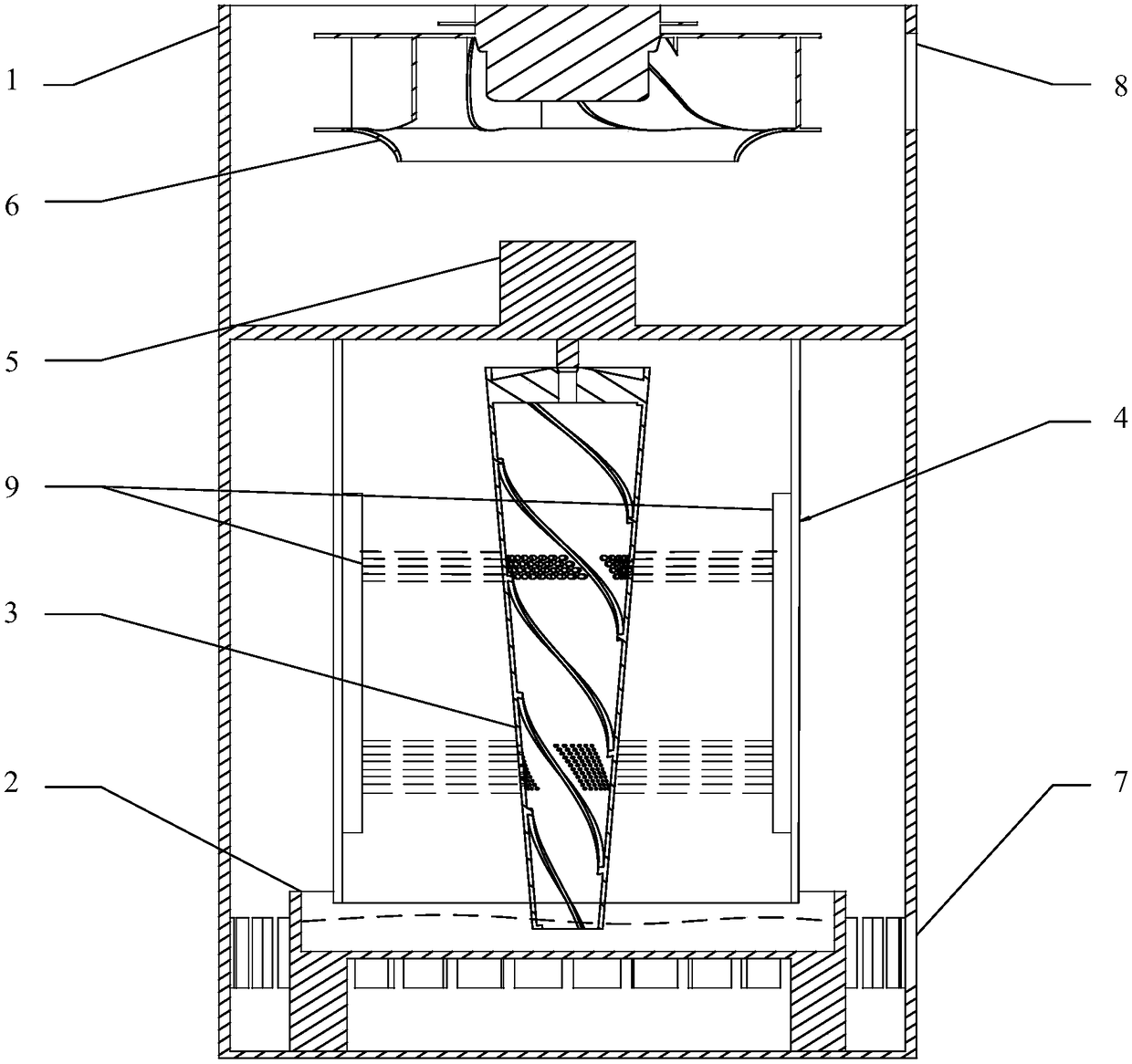

Dynamic wave and supergravity integrated dust removal purification device

InactiveCN104383775AIncrease the degree of atomizationImprove purification efficiencyCombination devicesImpellerSprayer

The invention relates to a dynamic wave and supergravity integrated dust removal purification device, belonging to the field of machinery. The dynamic wave and supergravity integrated dust removal purification device is internally provided with a reversely rotating filter drum, wherein the reversely rotating filter drum is connected with a self-suction impeller through a rotary shaft; a dynamic wave sprayer and a lower sprayer are arranged on the upper side and the lower side of the reversely rotating filter drum, respectively; a waste gas inlet is formed in the upper end of the dynamic wave sprayer while a sewage outlet is formed in the lower end of the lower sprayer; a demister is arranged at the upper end of the reversely rotating filter drum; an air outlet is formed in one side of the demister; an air flue is arranged at the joint between the reversely rotating filter drum and the self-suction impeller; a bearing bracket is arranged at one end, close to the self-suction impeller, of the rotary shaft; a transmission belt pulley is arranged on one side, close to the reversely rotating filter drum, of the rotary shaft. The dynamic wave and supergravity integrated dust removal purification device has the beneficial effects of being compact in size, good in dust removal effect, high in purifying efficiency, and small in water amount which is about one fifth of that of a traditional device, and the burden of follow-up sewage treatment is greatly reduced.

Owner:JINAN QIANKUN ENVIRONMENTAL PROTECTION EQUIP

Autonomous navigation pesticide spraying robot for orchard operation and working method of autonomous navigation pesticide spraying robot

InactiveCN109892311ARealize the spraying operationFunctionalInsect catchers and killersAgricultural scienceAgricultural engineering

The invention relates to an autonomous navigation pesticide spraying robot for orchard operation and a working method of the autonomous navigation pesticide spraying robot, and belongs to the field ofagricultural intelligent equipment. The robot comprises a robot body and accessory equipment, wherein the robot body comprises a movable chassis, a pneumatic conveying pesticide spraying device, an inertial navigation device, a satellite positioning device, a control system, a remote communication device and an energy power system, and the front and rear ends of the robot body are provided with radar obstacle avoidance devices respectively; the accessory equipment comprises a remote control and a communication base station; the pneumatic conveying pesticide spraying device, the inertial navigation device, the satellite positioning device, the energy power system and the radar obstacle avoidance devices are all connected with the control system; the control system is connected with the remote communication device, the remote communication device is connected with the Internet through the communication base station, and the remote communication device is also in wireless communication with the remote control. The autonomous navigation pesticide spraying robot for the orchard operation and the working method of the autonomous navigation pesticide spraying robot can significantly reduce the labor amount and labor intensity of orchard pesticide spraying operation, and are of great significance to the improvement of quality and synergy of the modern fruit industry and the conversionof new and old kinetic energy.

Owner:济南钰成霖信息科技有限公司

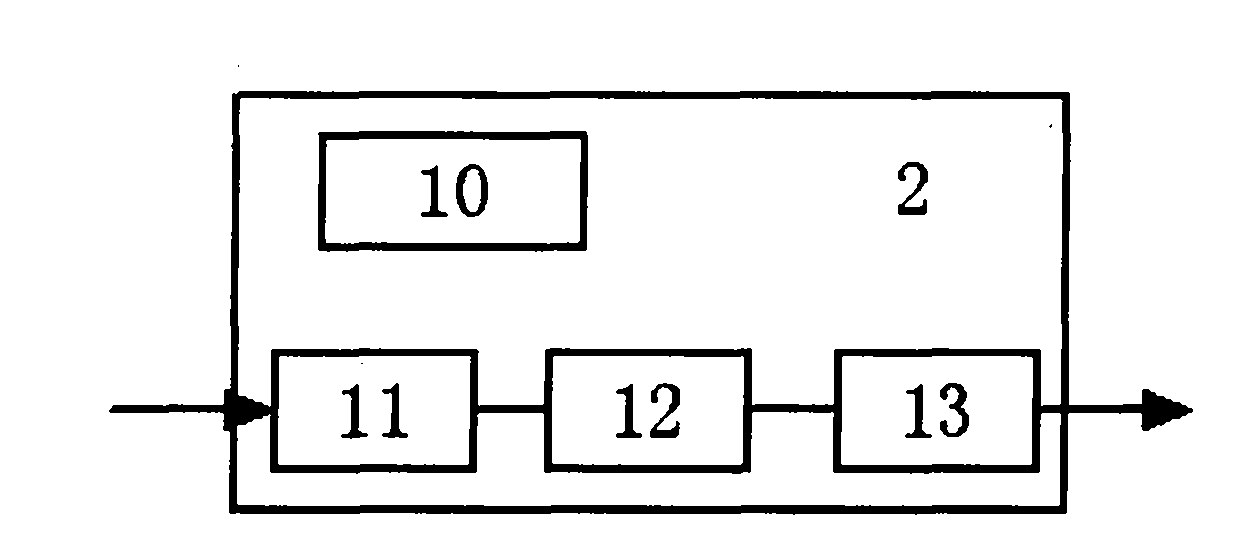

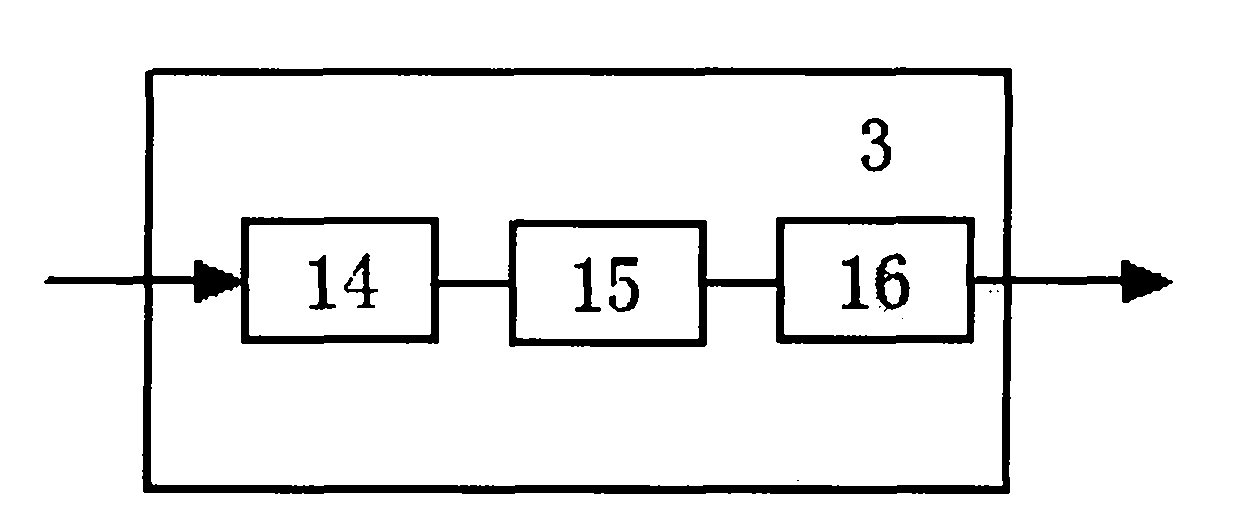

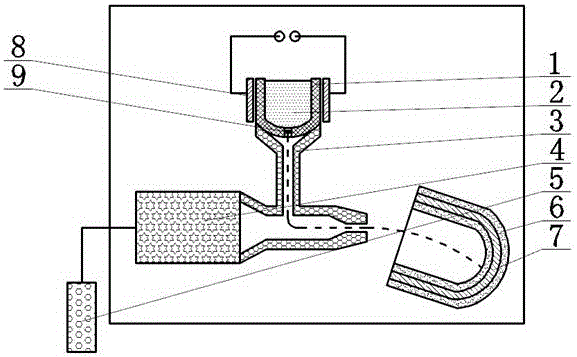

Method and device for cleaning up carbon deposited in automobile engine

InactiveCN102808693AImprove fuel atomizationFine atomizationMachines/enginesEngine componentsVIT signalsClean-up

The invention relates to the technical field of automobile electronics, specifically to a method and a device for cleaning up carbon deposited in an automobile engine, wherein the device comprises a sensor, a controller and a pulse generator, wherein the controller is composed of a power circuit, a signal input circuit, a processor and a signal output interface, wherein the signal input circuit, the processor and the signal output interface are orderly connected; the pulse generator is composed of a condition indicator, a pulse circuit and a signal output circuit, wherein the pulse circuit and the signal output circuit are connected with each other; the sensor is connected with the signal input circuit of the controller; and the pulse generator is connected with the signal output interface of the controller. The method and the device provided by the invention can transmit a pulse signal timely according to an operation condition of the engine so as to clean up original deposited carbon of the engine, prevent newly deposited carbon from being generated, ensure a combustion condition is optimal under various conditions, and improve overall performance of entire automobile.

Owner:威海中创国际贸易有限公司

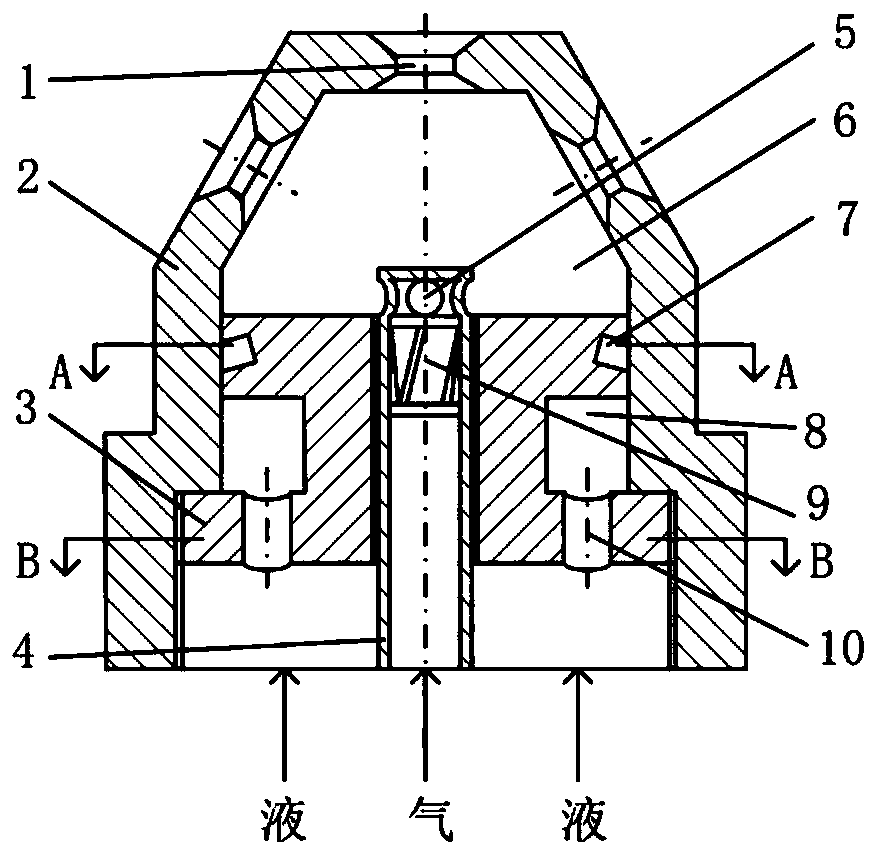

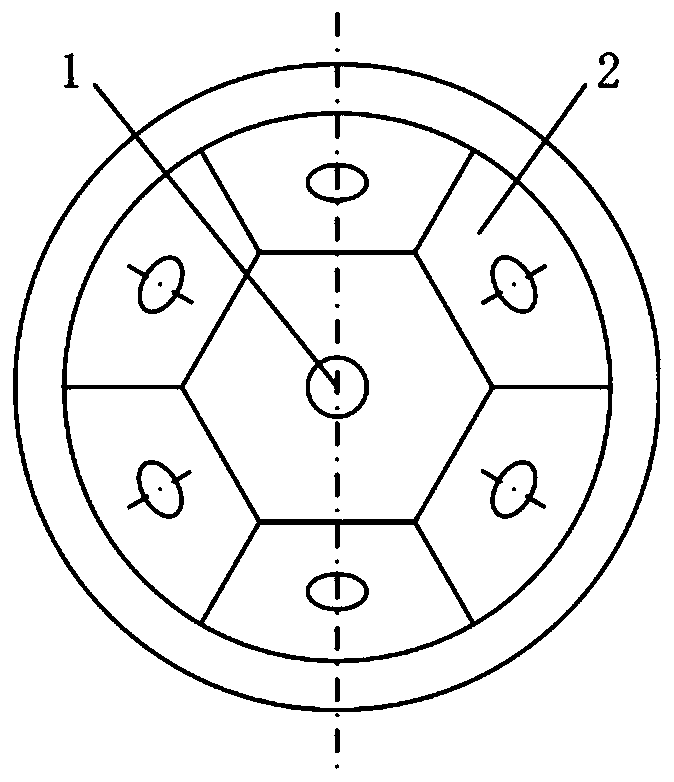

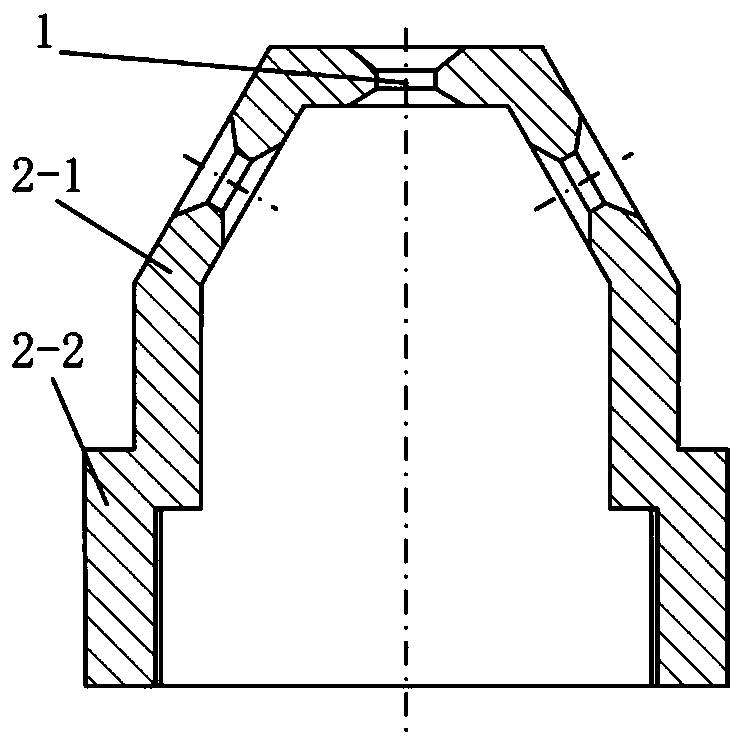

Multi-spray-hole gas-liquid two-phase atomization nozzle

ActiveCN111468319ABreak faster and more violentlyBroken violentlyLiquid spraying apparatusAqueous dropletEngineering

Disclosed is a multi-spray-hole gas-liquid two-phase atomization nozzle. The multi-spray-hole gas-liquid two-phase atomization nozzle comprises a nozzle cap, a nozzle body arranged in the nozzle cap in a nested manner, and a gas injection pipe body arranged in the nozzle body in a nested manner; the nozzle cap comprises an upper cap and a lower cap, and the upper cap is provided with a plurality of spray holes; the end, at the liquid inlet position, of the nozzle body is provided with a plurality of liquid inlet holes; and the inner wall surface of the upper cap and the upper wall surface of the nozzle body define a mixing cavity, the spray holes communicate with the liquid inlet holes after sequentially passing through the mixing cavity and a throat cavity defined by the inner wall surface of the nozzle cap and the outer wall surface of the nozzle body, and the gas injection pipe body communicates with the mixing cavity. Compared with the prior art, the multi-spray-hole gas-liquid two-phase atomization nozzle has the advantages that the single nozzle can realize multi-spray-hole spraying with a large coverage area, a short water droplet breaking distance and a high atomization degree, the complexity of a spray cooling system is reduced, the size and weight of the spray cooling system are reduced to a great extent, and the cost is saved; and besides, the multi-spray-hole gas-liquid two-phase atomization nozzle has a larger spraying range, water droplets break more rapidly and violently, and a better atomization effect can be obtained.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

Aluminum-manganese alloy and powder metallurgical molding method thereof

The invention discloses an aluminum-manganese alloy and a powder metallurgical molding method thereof. The aluminum-manganese alloy comprises, by weight percent, 70% to 75% of aluminum and 25% to 30% of manganese. The powder metallurgical molding method of the alloy comprises the steps of firstly, preparing of raw materials, auxiliary materials, tools and devices; secondly, vacuum induction smelting of the alloy; thirdly, preparing of mother alloy powder; and fourthly powder metallurgical molding. The aluminum-manganese alloy is low in impurity content, fine in grain, uniform in component and high in manganese content; the powder metallurgical molding method of the alloy is high in purification, free of pollutants, free of waste gas, easy to control, stable in quality and high in yield.

Owner:JIANGSU HUAQI ALUMINUM SCI & TECH

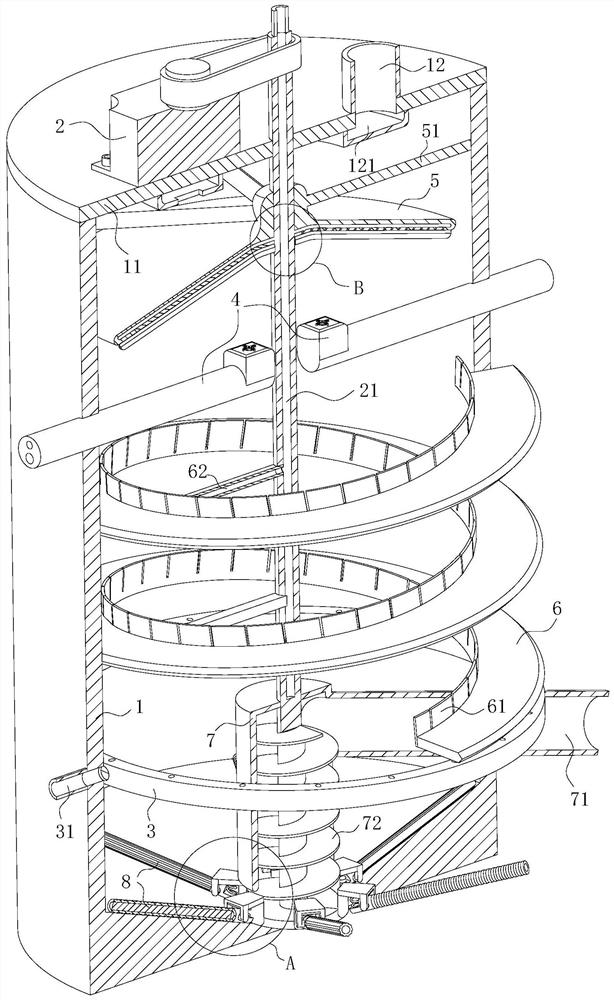

Degreased protein powder processing system for protein powder production

PendingCN112352903AImprove cleanlinessAvoid breedingDrying gas arrangementsFood preservationPROTEIN S HEERLENElectric machinery

The invention belongs to the technical field of food processing, and particularly relates to a degreased protein powder processing system for protein powder production. The degreased protein powder processing system comprises a drying device, which comprises a main body, wherein an upper cover is fixedly mounted above the main body, a motor and a rotating shaft connected with the motor are fixedlymounted on the upper surface of the upper cover, a waste gas outlet is formed in the upper cover, a collecting ring is mounted on the upper cover, an air outlet ring is fixedly mounted on the inner wall of the main body, a pipeline I is fixedly mounted on the side surface of the main body, a discharge pipe is mounted below the main body, a plurality of groups of spray heads are uniformly mountedin the main body, and a scraping plate II is mounted in the main body, is fixedly connected to the rotating shaft through a bracket, is clung to the inner wall of the main body and is spiral. According to the invention, the possibility of nozzle blockage can be reduced while protein powder cakes attached to the inner wall of the main body are scraped and crushed, so that the quality of finished products is improved, and the drying efficiency is guaranteed.

Owner:计香晴

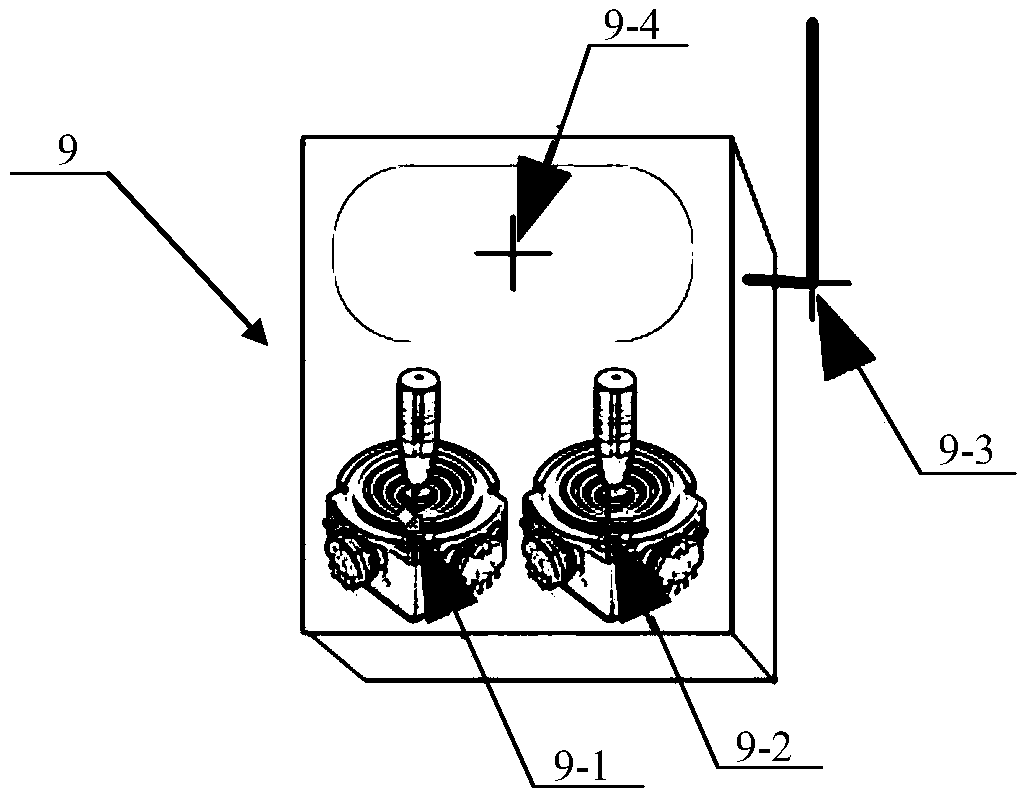

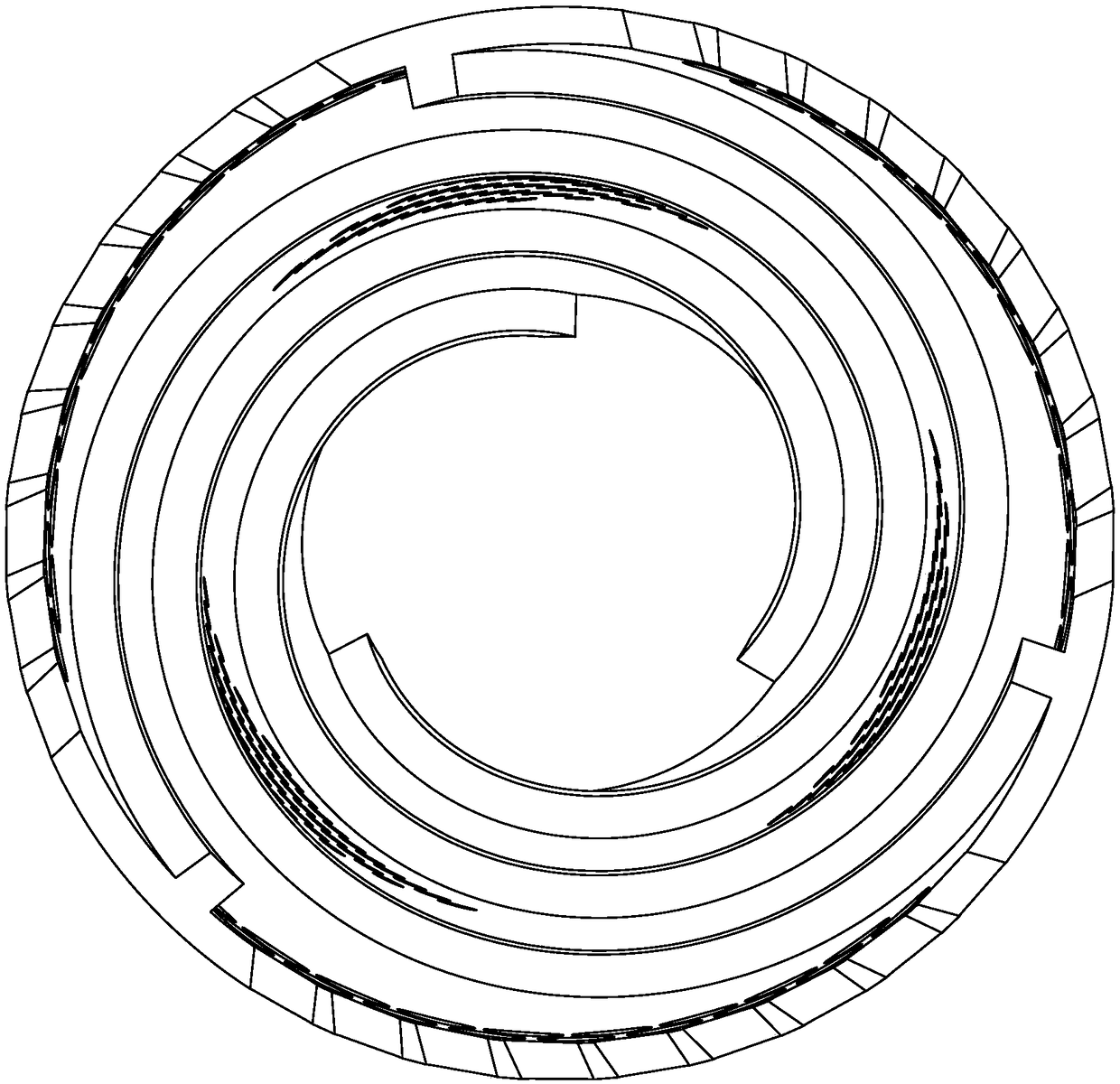

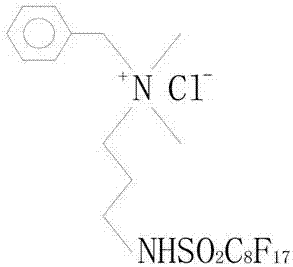

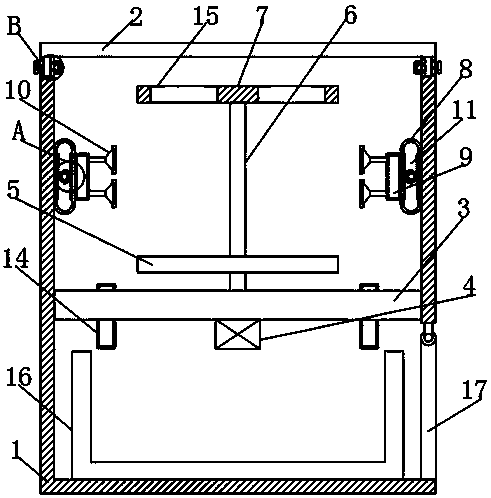

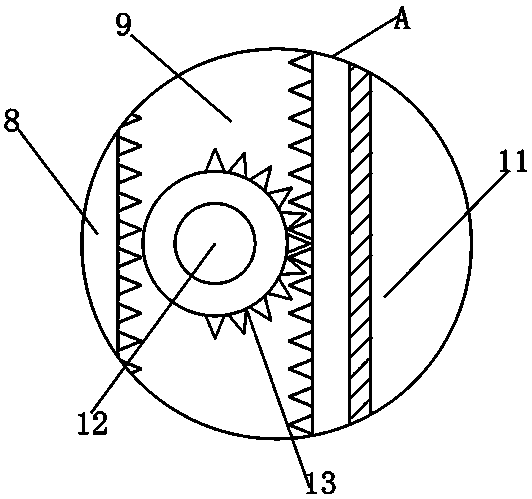

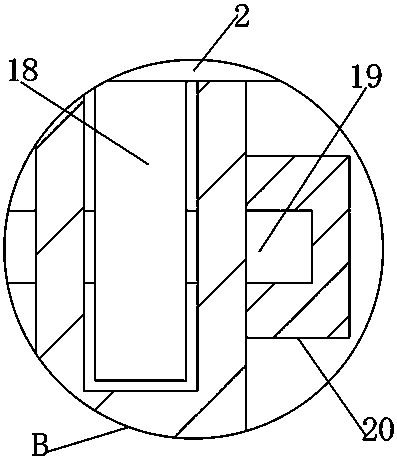

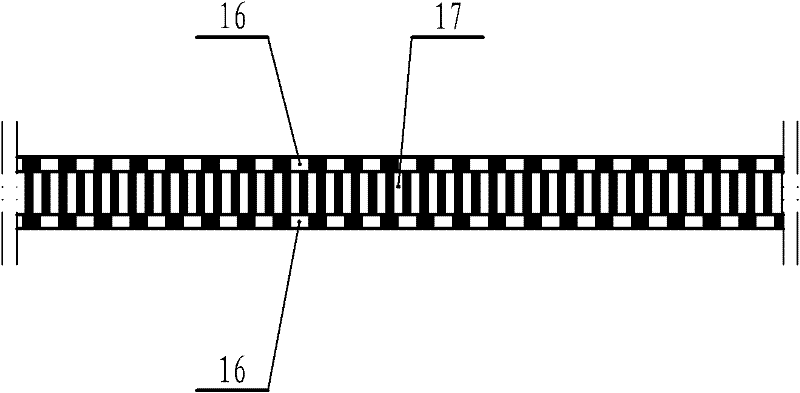

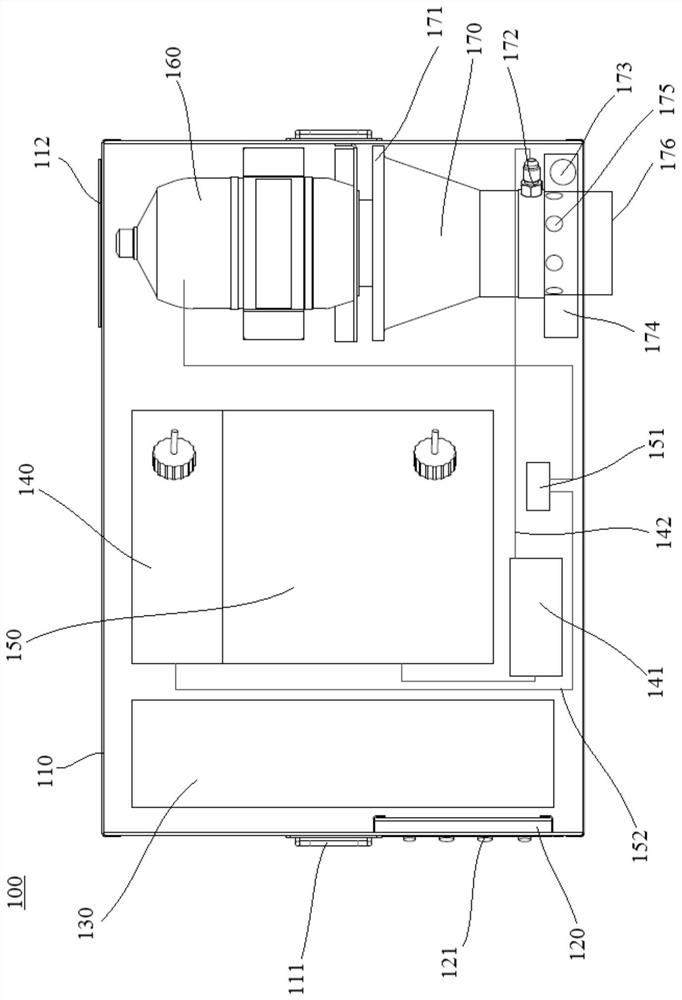

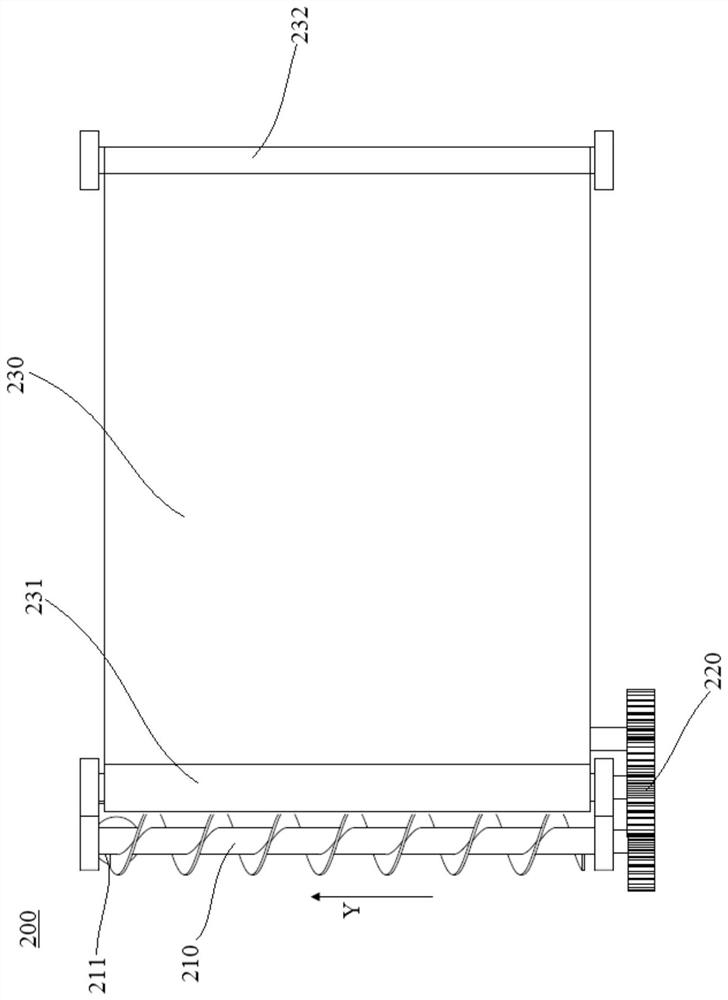

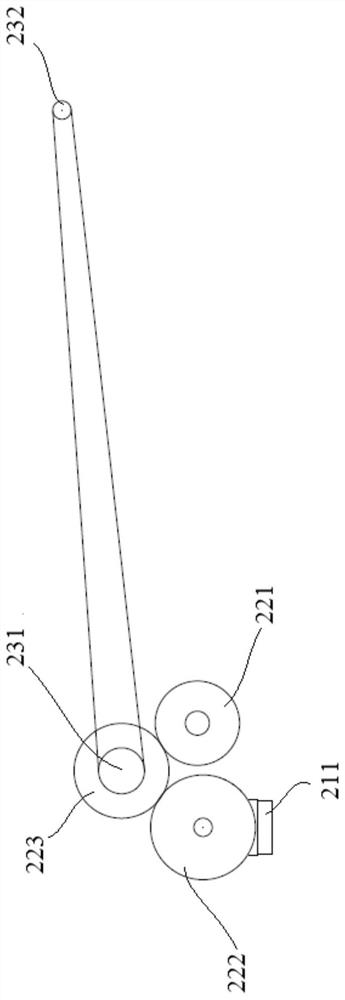

Seed coating machine and seed coating method

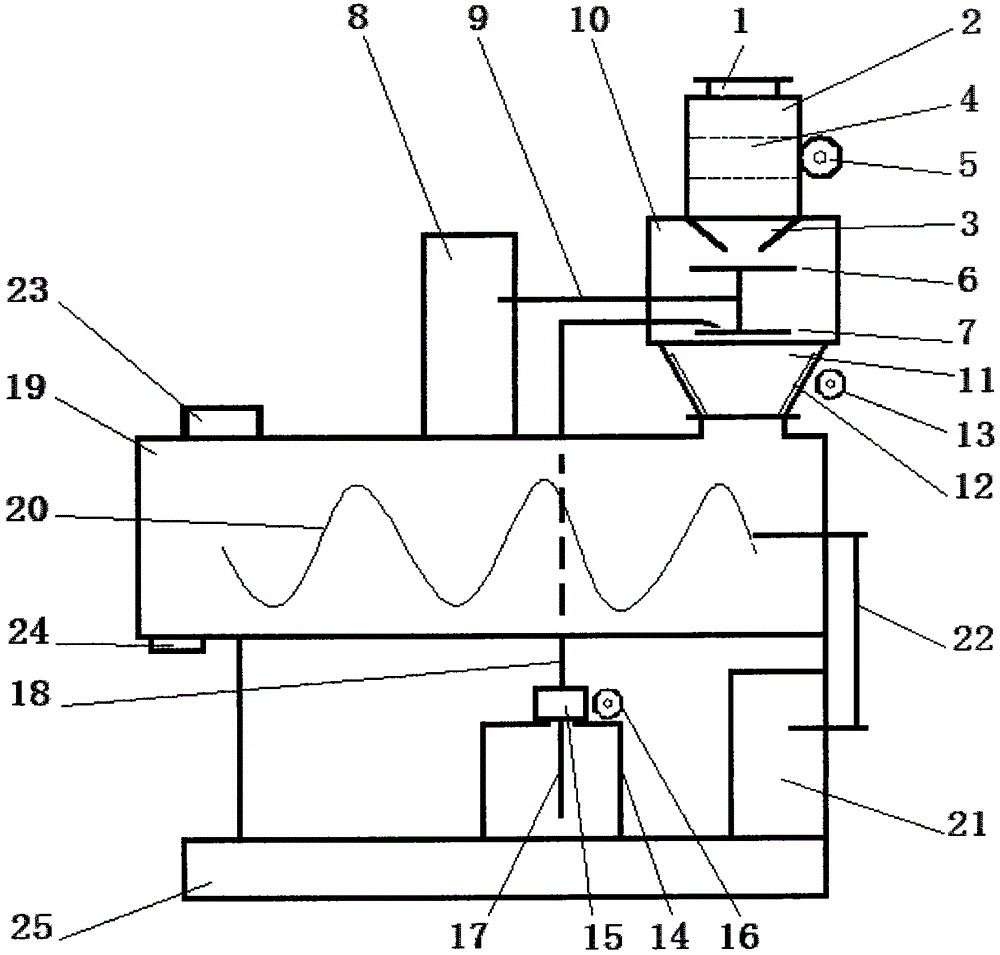

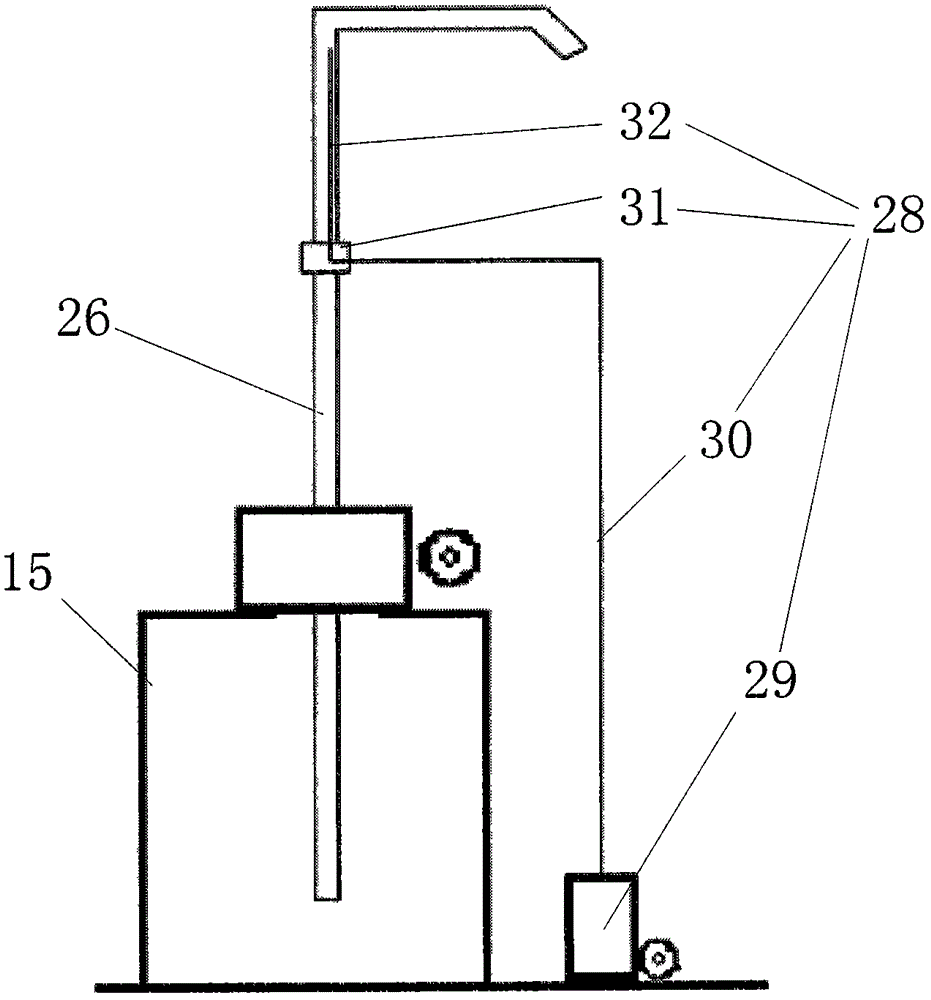

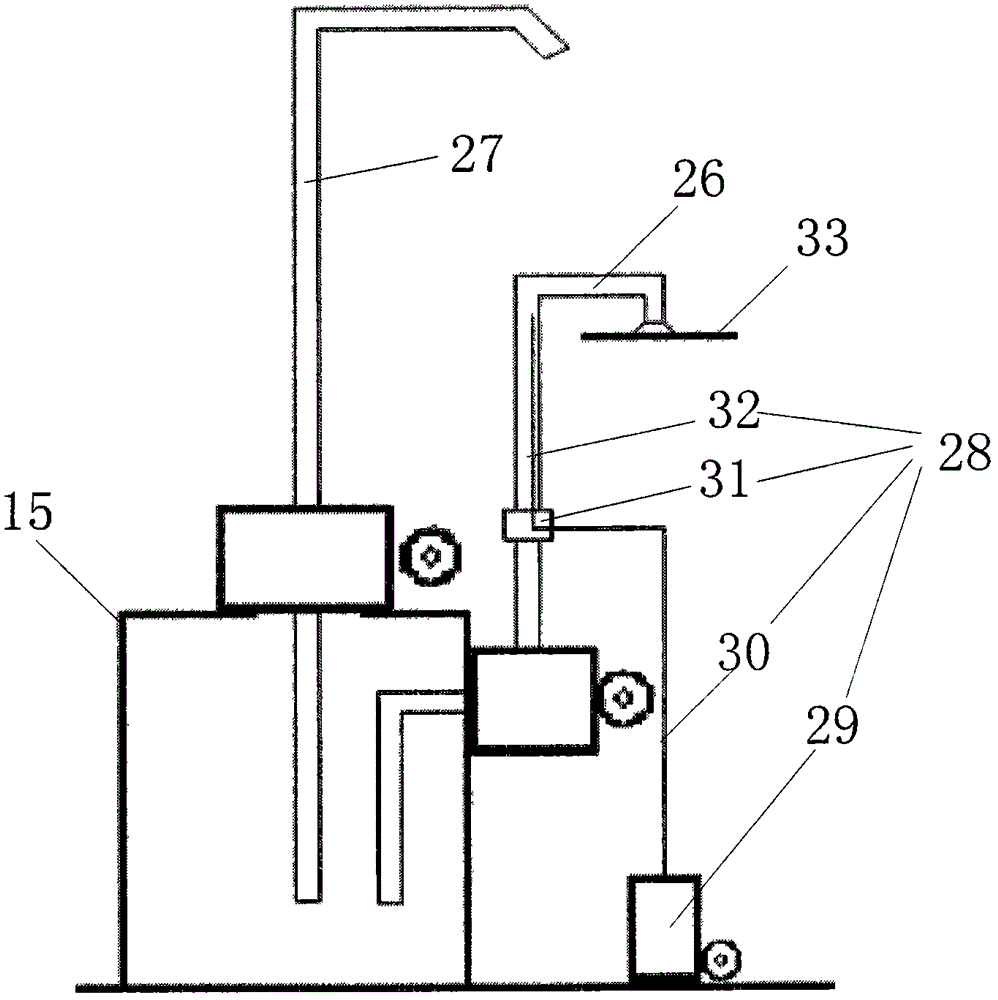

InactiveCN104396381AImprove the pass rate of coatingImprove pass rateSeed coating/dressingEngineeringReagent

The invention provides a seed coating machine which comprises a feeding device, an atomizing chamber, a stirring box, a reagent supply device and a rack, wherein the atomizing chamber is connected with the feeding device in a matching manner; the stirring box is connected with the atomizing chamber in a matching manner; the reagent supply device is used for supplying reagent liquids into the atomizing chamber; the reagent supply device comprises a seed coating agent box and a first reagent supply tube which is communicated with the seed coating agent box and the atomizing chamber; an electrostatic device is arranged on the first reagent supply tube. By adopting the seed coating machine, the atomization degree is further increased under the condition that the overall structure of the seed coating machine is not changed, concave parts of umbilical regions of seeds can be covered, and the purpose of increasing the pass percent of seed coating is achieved; the seed coating machine is also applicable to atomization on the seeds under the condition that the seeds are mingled with dust in the atomizing chamber, and the pass percent of seed coating is also increased.

Owner:孙永国

Ash removing device of tail flue of fluidized boiler

ActiveCN104613485AEfficient emissionsAchieve separationSolid removalAxial flow pumpsParticulatesFluidized bed

The invention relates to an ash removing device of the tail flue of a fluidized boiler. The ash removing device comprises a smoke inlet pipe, a cooling pipe, a separation pipe and a sedimentation pipe, wherein the axis of the columnar pipeline of the separation pipe is vertical to the ground, the open end of the columnar pipeline faces to the ground, and the smoke inlet pipe is arranged on the lateral wall of the columnar pipeline; one end of the smoke inlet pipe is communicated with the interior of the columnar pipeline, and the other end thereof is communicated with the tail flue of the fluidized boiler; the cooling pipe is mounted at the sealed end at the top of the separation pipe, the other end of the cooling pipe is communicated with the interior of the separation pipe, and a spraying component is mounted in the cooling pipe; a separator is disposed on the wall face of the separation pipe and comprises a plurality of filter plates, and the filter plates are arranged on the inner wall of the separation pipe in a zigzag and staggered manner; an exhaust pipe is arranged at the bottom of the separation pipe. The ash removing device has the advantages that smoke is absorbed through water, and separation of waste gas, particles and soluble impurities is achieved by the filtering separation mechanism.

Owner:BRIGHT THERMAL EQUIP CO LTD

Aluminium-zirconium alloy and powder metallurgic forming method thereof

The invention discloses an aluminium-zirconium alloy and a powder metallurgic forming method thereof. The aluminium-zirconium alloy comprises the following components in percent by weight: 70-75 percent of aluminium and 25-30 percent of zirconium. The powder metallurgic forming method comprises the four steps of (1) preparing raw materials, auxiliary materials, tools and devices; (2) conducting vacuum induction melting on the alloy; (3) preparing master alloy powder; and (4) conducting powder metallurgic forming. The aluminium-zirconium alloy is low in impurity content, fine in crystal particle, homogeneous in component, and high in zirconium content, and the powder metallurgic forming method is high in purity, free of pollutants and waste gas, easy to control, stable in quality, and high in finished product ratio.

Owner:JIANGSU HUAQI ALUMINUM SCI & TECH

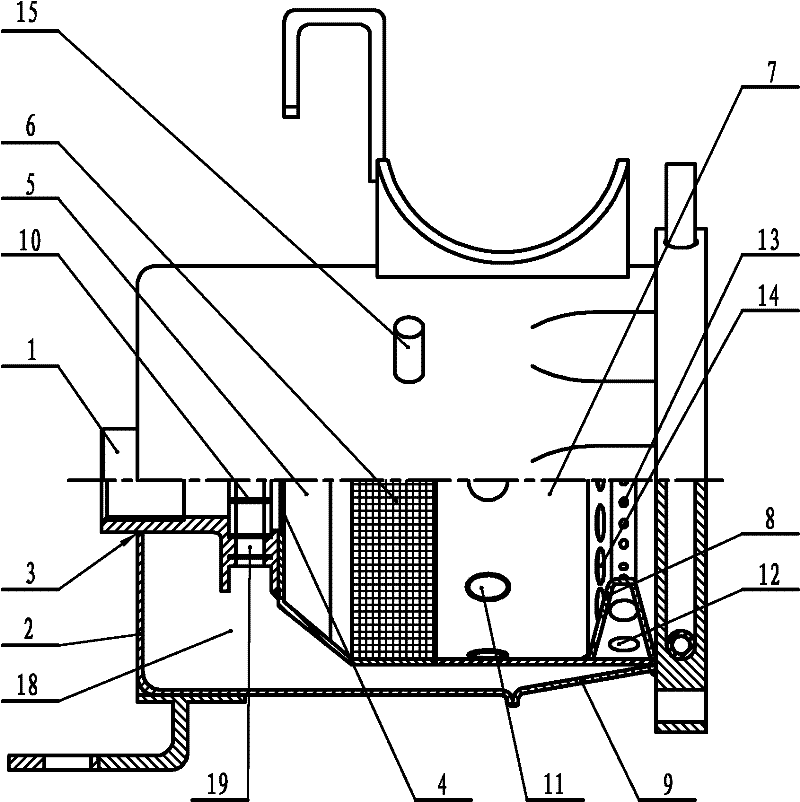

Anion constant-humidity water filtering device

InactiveCN108371863AIncrease the degree of atomizationImprove filtering effectCombination devicesUsing liquid separation agentElectricityWater filter

The invention discloses an anion constant-humidity water filtering device which comprises a shell, a water tank, a water curtain device, a cylinder type air duct, a motor, a fan, an anion module, an air inlet and an air outlet, wherein the air inlet is formed in the side wall of the lower part of the shell, the air outlet is formed in the side wall of the top or the upper part, a base is sealed; the anion module is arranged on the inner wall of the shell and at the inner side of the air inlet, an anion generator is arranged in the anion module, the anion generator is electrically connected with a carbon brush; the water tank is arranged at the lower part in the shell and is filled with water; the water curtain device is arranged in the middle in the shell and above the water tank, the lower end of the water curtain device extends into the water tank, the lower edge of the water curtain device is lower than the upper edge of water in the water tank; the water curtain device is a cone thick in upper part and thin in lower part, the water curtain device is hollow inside, and spiral and convex ribs are arranged on the inner wall; a plurality of through holes are formed in the wall of the water curtain device and between adjacent ribs, the through holes are divided into an upper layer and a lower layer, water mist holes are at the lower layer, and large water drop holes are at the upper layer; the cylinder type air duct is arranged in the middle in the shell and at the periphery of the water curtain device, and extends into the water tank, and the lower edge of the cylinder typeair duct is higher than the upper edge of water in the water tank.

Owner:徐信东 +1

Homogeneous and high-efficient water-based pesticide aerosol with low VOC (Volatile Organic Compounds) content

The invention provides homogeneous and high-efficient water-based pesticide aerosol with low VOC (Volatile Organic Compounds) content. The homogeneous and high-efficient water-based pesticide aerosol comprises the following components in parts by weight: 25-40 parts of dimethyl ether, 40-60 parts of de-ionized water, 10-20 parts of edible alcohol with mass-percentage concentration of 95 percent, 0.05-2 parts of dimefluthrin, 0.1-0.4 part of rich-d-transallethrin, 0.1-0.3 part of permethrin, 0.05-0.2 part of d-trans-cyphenothrin, 0.05-0.2 part of sodium benzoate, 0.05-0.2 part of sodium nitrite, 0.05-0.2 part of sodium dodecyl sulfate succinate, 0.05-0.2 part of triethanolamine, 0.1-1.0 part of synergist and 0.1-0.5 part of essence. According to the homogeneous and high-efficient water-based pesticide aerosol with low VOC content, disclosed by the invention, the advantages of good atomizing effect and insert-killing effect can be achieved without vibration and shaking before use.

Owner:山东美多包装有限公司

A kind of aluminum-manganese alloy and its powder metallurgy forming method

The invention discloses an aluminum-manganese alloy and a powder metallurgical molding method thereof. The aluminum-manganese alloy comprises, by weight percent, 70% to 75% of aluminum and 25% to 30% of manganese. The powder metallurgical molding method of the alloy comprises the steps of firstly, preparing of raw materials, auxiliary materials, tools and devices; secondly, vacuum induction smelting of the alloy; thirdly, preparing of mother alloy powder; and fourthly powder metallurgical molding. The aluminum-manganese alloy is low in impurity content, fine in grain, uniform in component and high in manganese content; the powder metallurgical molding method of the alloy is high in purification, free of pollutants, free of waste gas, easy to control, stable in quality and high in yield.

Owner:JIANGSU HUAQI ALUMINUM SCI & TECH

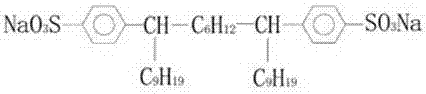

Fuel filter capable of improving energy consumption and discharging of engine

InactiveCN107142789AIncrease the degree of atomizationHigh combustion valueWater-repelling agents additionSurfactants additionFiberPorosity

The invention relates to the technical field of filters and particularly relates to a fuel filter capable of improving the energy consumption and discharging of an engine. A far infrared ceramic filter element and infrared filter paper are sequentially arranged in a filter body along the flow direction of engine oil, the porosity of the far infrared ceramic filter element is 80%-90%, the pore density of the far infrared ceramic filter element is 30ppi-50ppi, and the infrared filter paper is prepared from plant fiber slurry, infrared functional powder and the like. By virtue of an infrared ray activation effect of the far infrared ceramic filter element and the infrared filter paper, fuel is activated, generates resonance with fuel molecular groups and is micronized, so that the Van der Waals force among fuel molecules is reduced, the atomizing degree of the fuel is increased, the combustion is relatively adequate, the combustion value of the fuel is increased, and the energy consumption and discharging of the engine are reduced. The fuel filter can be mounted in an oil tank or oil pipe.

Owner:江力

Spraying salt-sunning method

InactiveCN1440929AIncrease productionIncrease the degree of atomizationAlkali metal chloridesEvaporation by sprayingSpray nozzleEngineering

The spraying salt-sunning method features that under 1.5-2.5 atm, brine is conveyed via stem pipe and branch pipes and sprayed to air via the nozzles to form fogy water drops, and the said process is repeated until required concentration is reached. In the production process, two kinds of different nozzles and multilayer spraying are used, and yield as high as 5 times that of available method may be obtained.

Owner:林雄

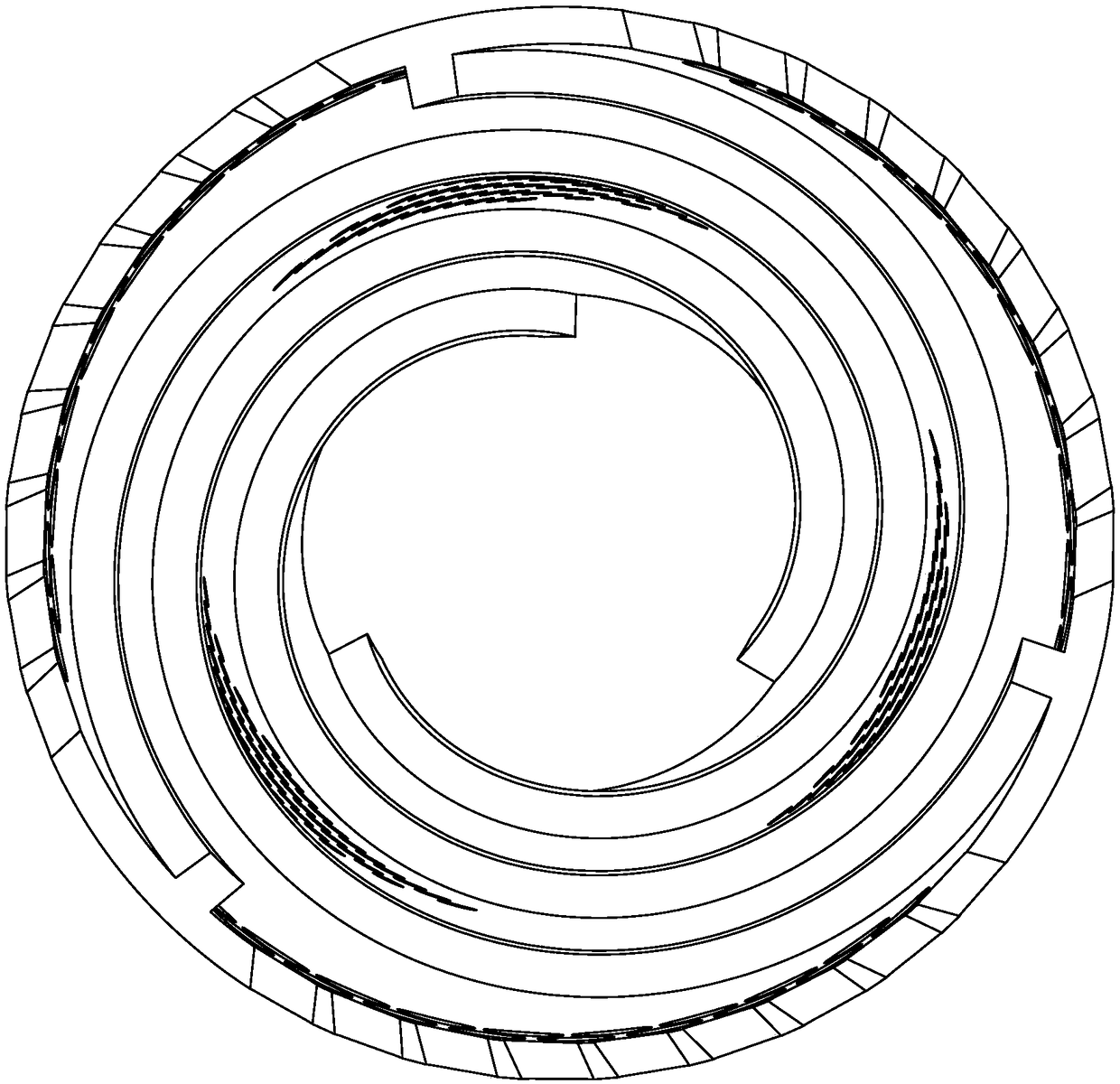

Constant-humidity water curtain filtering system

InactiveCN108261864AIncrease the degree of atomizationImprove filtering effectUsing liquid separation agentFilter systemEngineering

The invention discloses a constant-humidity water curtain filtering system, which comprises a case, a water tank, a water curtain device, a cylindrical type air duct, a motor, a fan, an air inlet andan air outlet, wherein the case is of a tube with the hollow inside; the air inlet is formed in the side wall of the lower part of the case; the air outlet is formed in the side wall of the upper partor the top; the base is sealed; the water tank is arranged at the lower part inside the case; water is contained in the box; the water curtain device is arranged in the middle inside the case and above the water tank; the lower end of the water curtain device extends into the water tank; the lower edge is lower than the upper edge of the water in the water tank; the water curtain device is a conebody with the thicker upper side and the finer lower side; the inside is hollow; a plurality of spiral projected ribs are arranged on the inner wall; a plurality of through holes are also formed in the wall of the water curtain device and between the adjacent ribs; the through holes are divided into upper layer through holes and lower layer through holes; the lower layer through holes are water mist holes; the upper layer through holes are big water drip holes; the cylindrical type air duct is arranged in the middle part inside the case and on the outer periphery of the water curtain device,and extends into the water tank; the lower edge is higher than the upper edge of the water in the water tank; the motor is electrically connected with the water curtain device; the motor drives the water curtain device to rotate; the fan exhausts air to the outside.

Owner:徐信东 +1

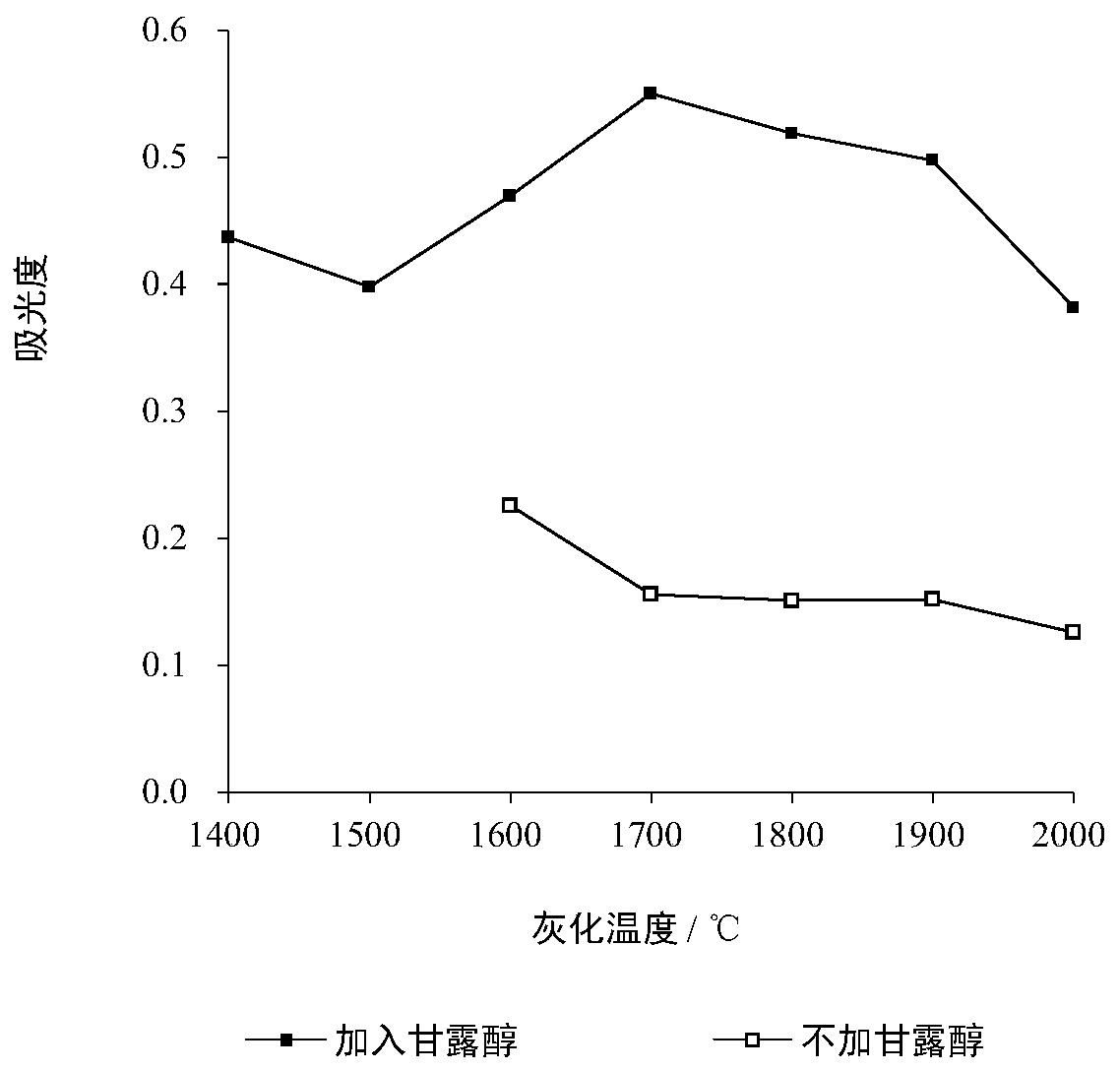

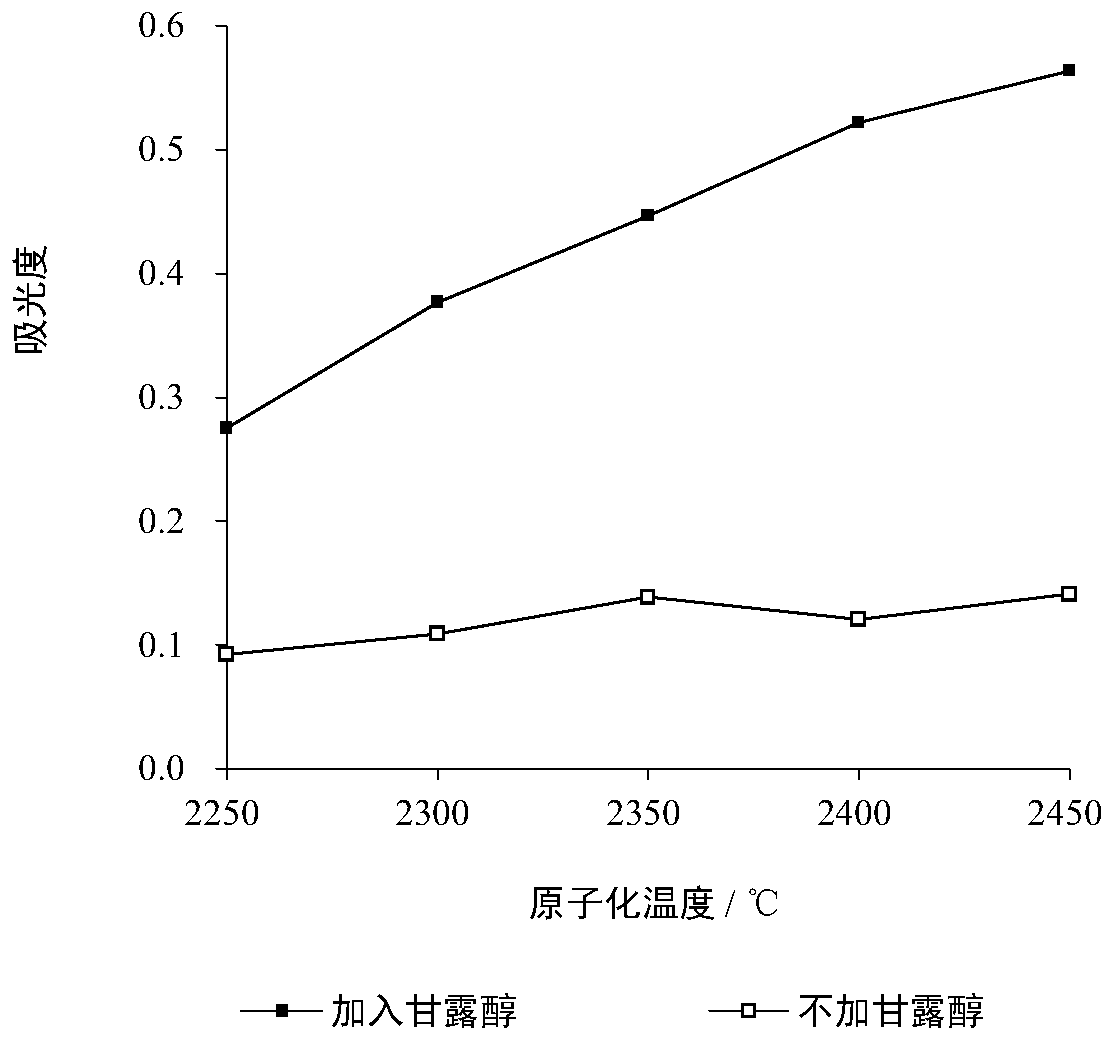

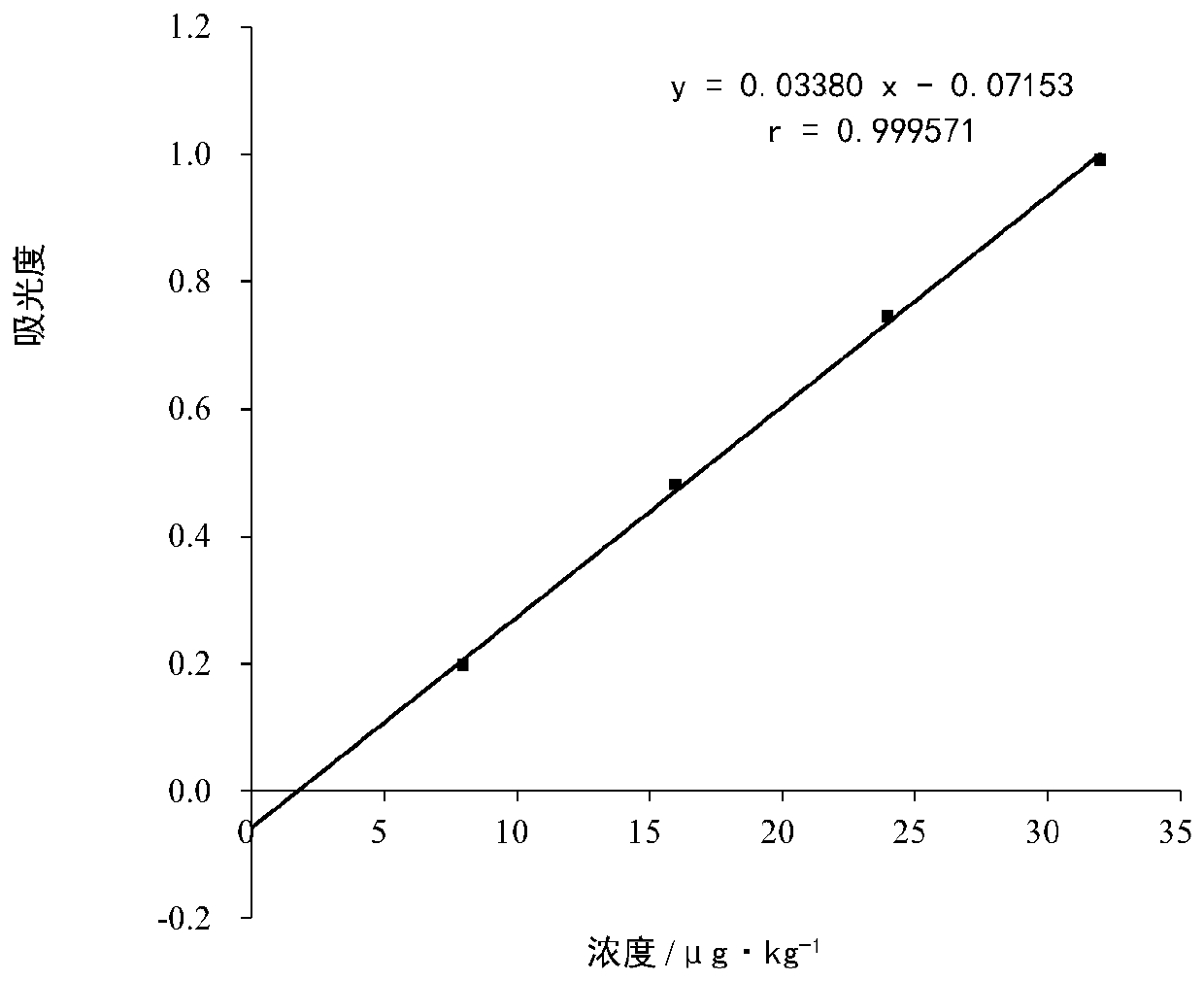

Matrix modifier and method for measuring calcium content by graphite furnace atomic absorption spectrometry

ActiveCN111077138AOptimized heating characteristicsReduce the degree of varianceNuclear energy generationAnalysis by thermal excitationAnalytePressurized water reactor

The invention discloses a matrix modifier for measuring calcium content by graphite furnace atomic absorption spectrometry. The matrix modifier is added into a diluent and a sample to be measured, thesample to be measured is a pressurized water reactor boric acid medium, and the matrix modifier comprises mannitol. By using the matrix modifier disclosed by the invention, the heating characteristicof a graphite furnace can be optimized, the difference degree of parallel measurement results is reduced, and the problem of serious trailing of an analyte spectral peak is solved, so that the analyte spectral peak is more symmetrical and smooth, and the integral calculation of the analyte spectral peak is more accurate. The complexing effect of a boric acid matrix and calcium is reduced, the atomization degree of calcium is improved, and then the sensitivity of calcium detection is improved. The defect of insufficient matching degree of a standard solution and a sample matrix is overcome, the influence of the matrix on an analysis result is reduced, manual dilution or boric acid addition operation adopted for matching the matrix is avoided, the risk of radioactive contamination to workers is reduced, and the irradiation dose of analysts is reduced.

Owner:GUANGXI FANGCHENGGANG NUCLEAR POWER +1

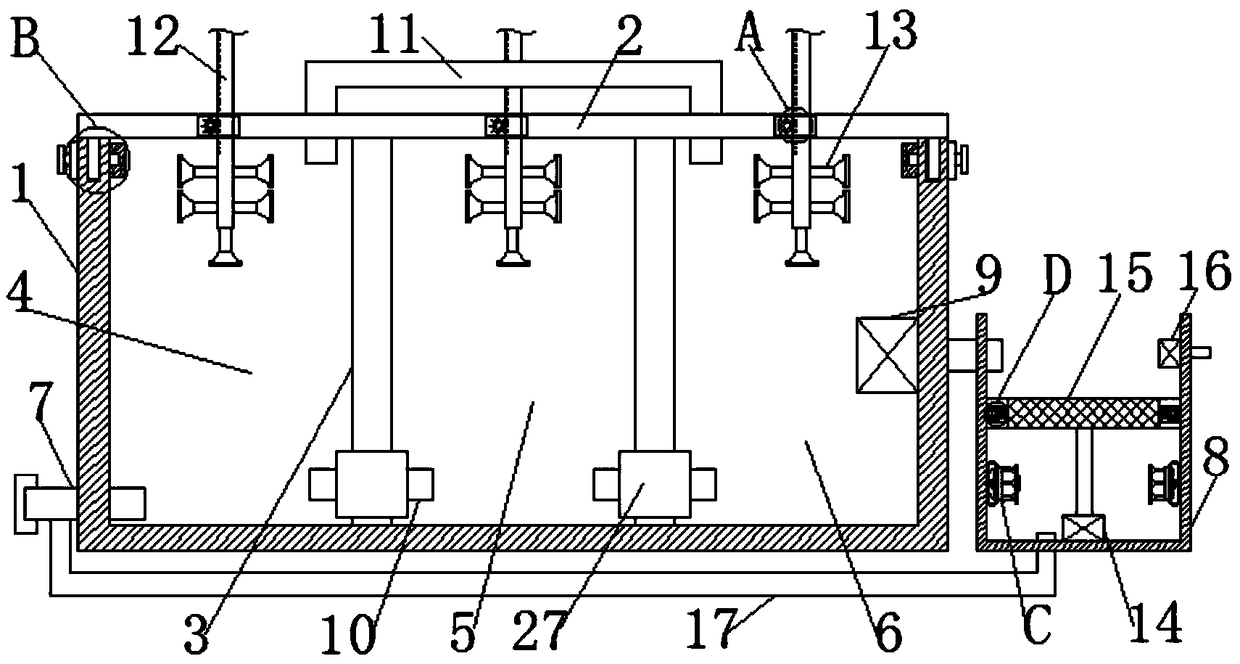

AAO reaction pool

InactiveCN108706729AFirmly connectedSports state is stableSpecific water treatment objectivesBiological treatment apparatusAnaerobic chamberSludge

The invention discloses an AAO reaction pool which comprises a sewage pool body and a pool cover. Two vertical partitions are arranged in the sewage pool body and divides the same into an anoxia chamber, an anaerobic chamber and an aerobic chamber, each of the partitions is provided with a communication pipe thereon, the two communication pipes are arranged in the manner of penetrating the partitions, a water inlet pipe is horizontally arranged in the anoxia chamber and penetrates one side wall of the anoxia chamber to be communicated externally, a sludge pool body is arranged on one side wallof the sewage pool body, a water outlet pump is arranged on one side wall of the aerobic chamber, the output end of the water outlet pump penetrates one side wall of the aerobic chamber to be communicated with the interior of the sewage pool body, a liquid return pipe is arranged on one side wall of the pool cover with two ends penetrating the pool cover, and two ends of the liquid return pipe are respectively communicated with the anoxia chamber and the aerobic chamber. By the arrangement, the sewage pool body and the sludge pool body are cleaned conveniently and uniformly, and cleaning costcan be lowered.

Owner:张建华

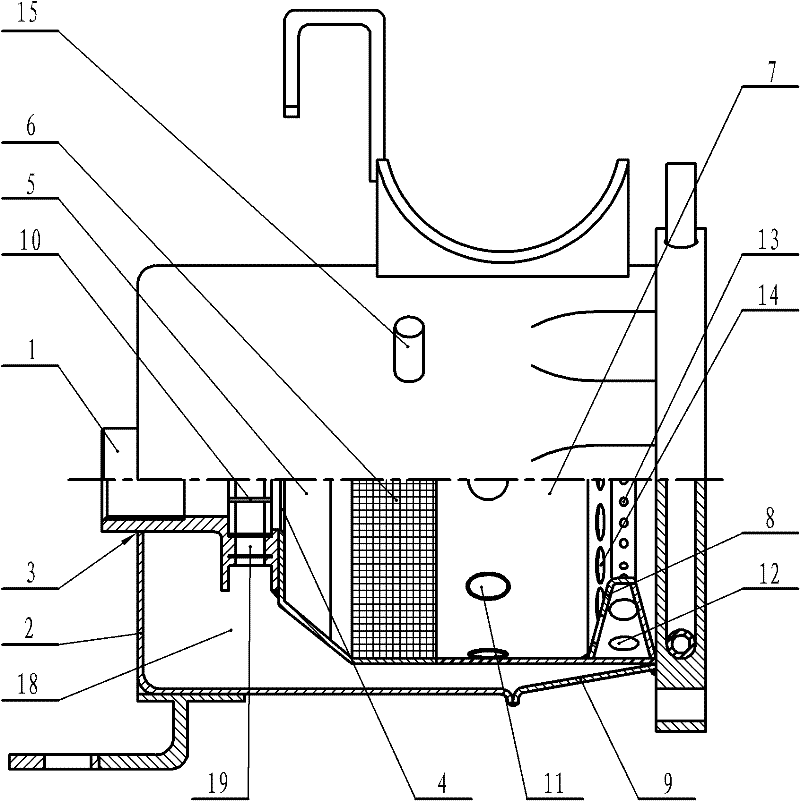

Spraying equipment for electric cabinet coating production

InactiveCN108838007AIncrease the degree of atomizationEasy to disassemble and overhaulSpray boothsBiochemical engineeringElectric machinery

The invention discloses spraying equipment for electric cabinet coating production. The spraying equipment comprises a box body, a first through hole communicating with the outside is formed in the upper end of the box body, and a box cover matched with the first through hole is arranged at the opening position of the first through hole; a horizontally-arranged fixing plate is arranged inside thebox body, moreover, the two ends of the fixing plate are fixedly connected with the inner walls of the two sides of the box body, a first driving motor is fixedly connected to the bottom wall of the fixing plate, and the output end of the first driving motor penetrates through the fixing plate and is fixedly connected with a horizontally arranged first supporting plate; and a supporting rod whichis vertically arranged is fixedly connected to the side wall of the upper side of the first supporting plate, moreover, one end, far away from the first supporting plate, of the supporting rod is fixedly connected with a second supporting plate which is horizontally arranged, two symmetrically-arranged clamping grooves are formed in the second supporting plate, and the clamping grooves are matchedwith the electric cabinet. According to the equipment, an electric cabinet body can be uniformly coated, and recycling of painting is convenient, the environment is prevented from being polluted, andresources are prevented from being wasted.

Owner:JIANGSU YAFENG TECH GRP CO LTD

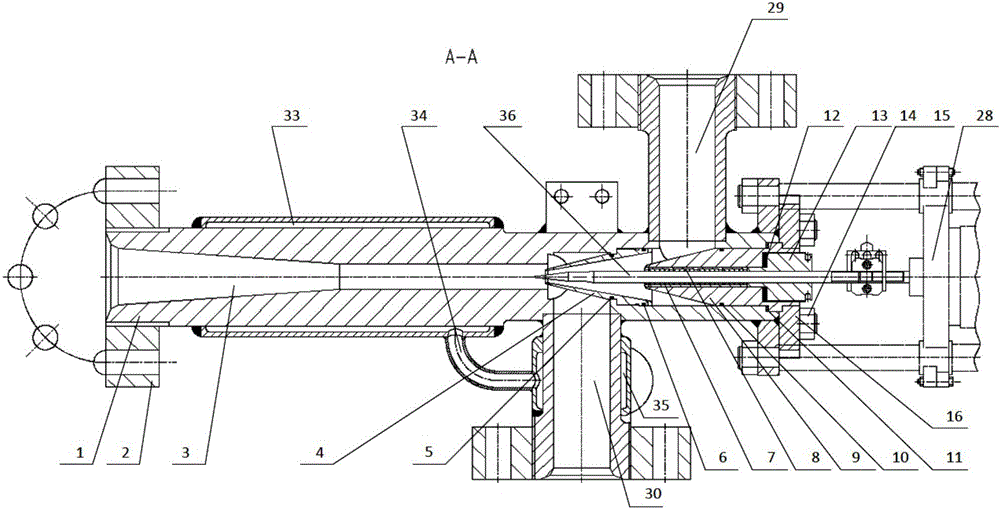

new combustion chamber

A novel combustion chamber comprises an oil jet nozzle seat, a combustion chamber housing, a front air barrel, a rear air barrel and a butterfly-like air plate, wherein an air channel is arranged between the combustion chamber housing and the front air barrel and the rear air barrel; the oil jet nozzle seat is fixedly connected to the combustion chamber housing and the front air barrel, respectively; an oil jet nozzle is provided with an air inlet on which a plurality of vortex plates are evenly distributed; the rear air barrel is provided with a plurality of rear air barrel front-section airinlets and a plurality of rear air barrel rear-section air inlets, respectively; a plurality of air curtain holes are formed on the bottom of the butterfly-like air plate; a plurality of reflecting holes are formed on a side wall, facing the direction of the front air barrel, of the butterfly-like air plate; and a heat-resistant alloy fibre evaporation mesh is jointed on the internal surface of the front air barrel. The novel combustion chamber of the invention allows the air to enter the combustion chamber via the reflecting holes in a direction opposite to the direction of a combustion gas flow in the combustion chamber, so that the turbulence condition of a fuel-oil mixed gas is evener and more rational. Moreover, the heat-resistant alloy fibre evaporation mesh improves the atomizationdegree of the fuel oil and promotes the secondary evaporation of the wall-attached fuel oil, so that the combustion efficiency can stably reach 95% or higher; therefore, the energy-saving effect is very obvious.

Owner:北京北机机电工业有限责任公司

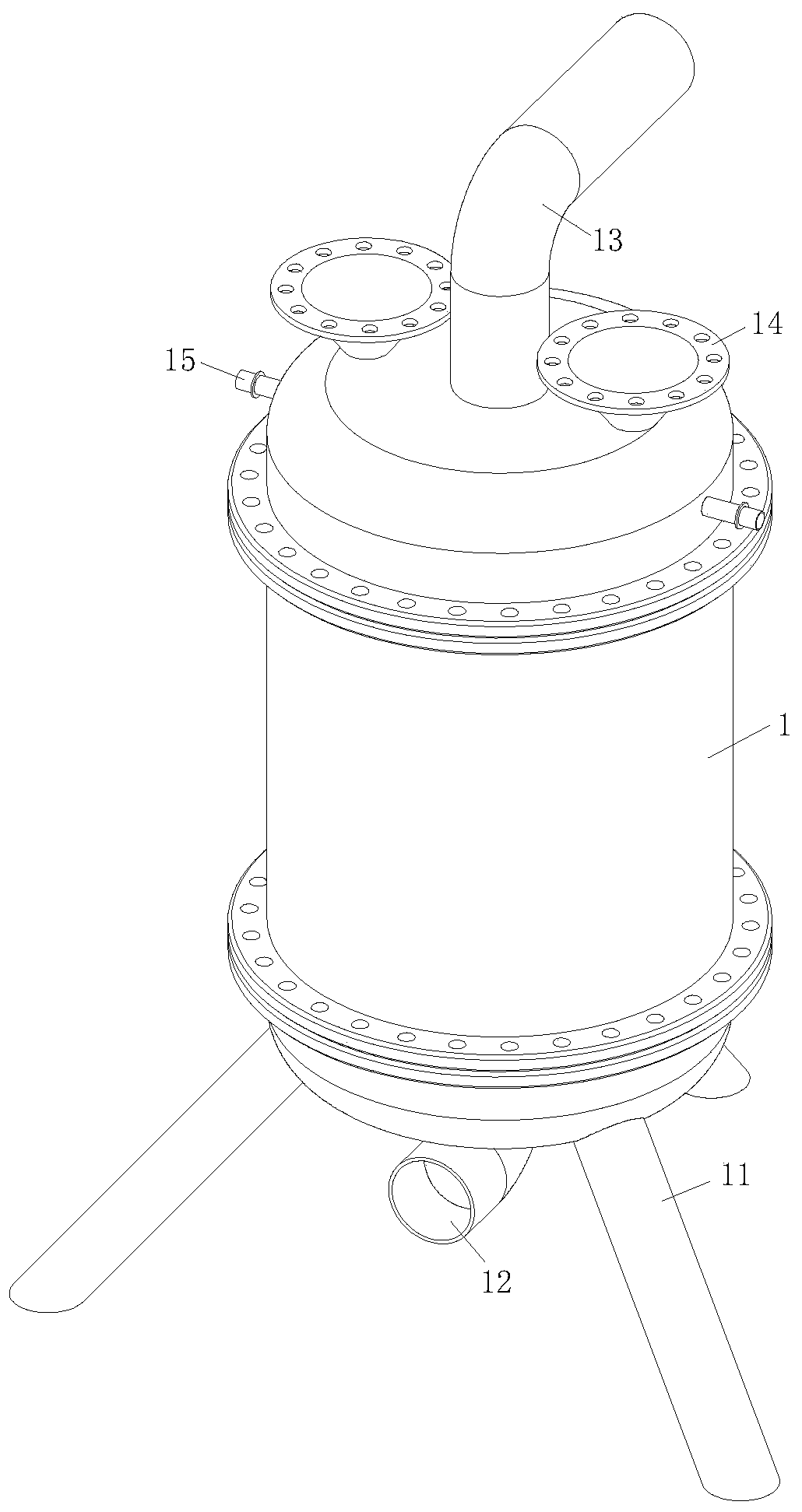

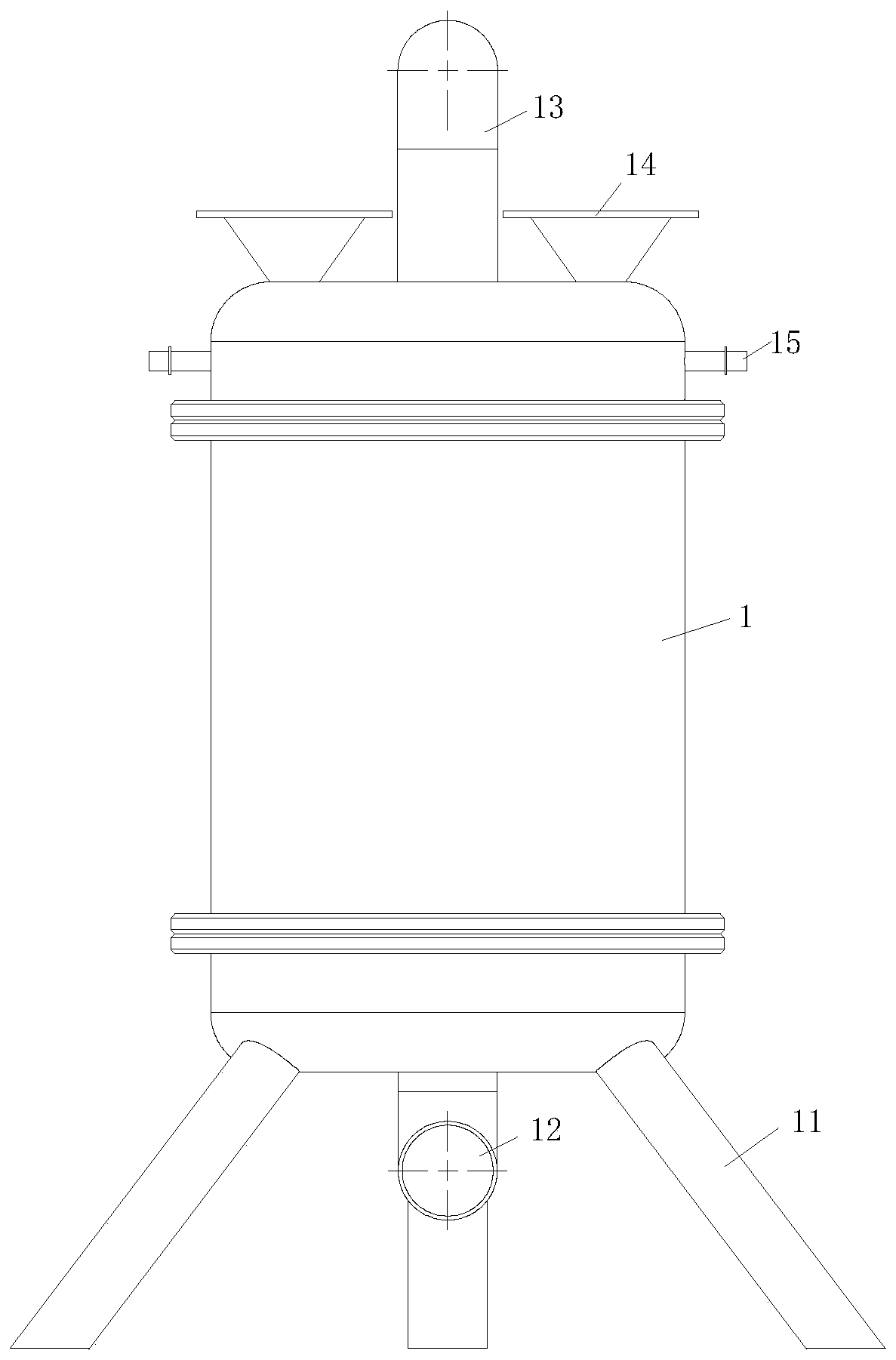

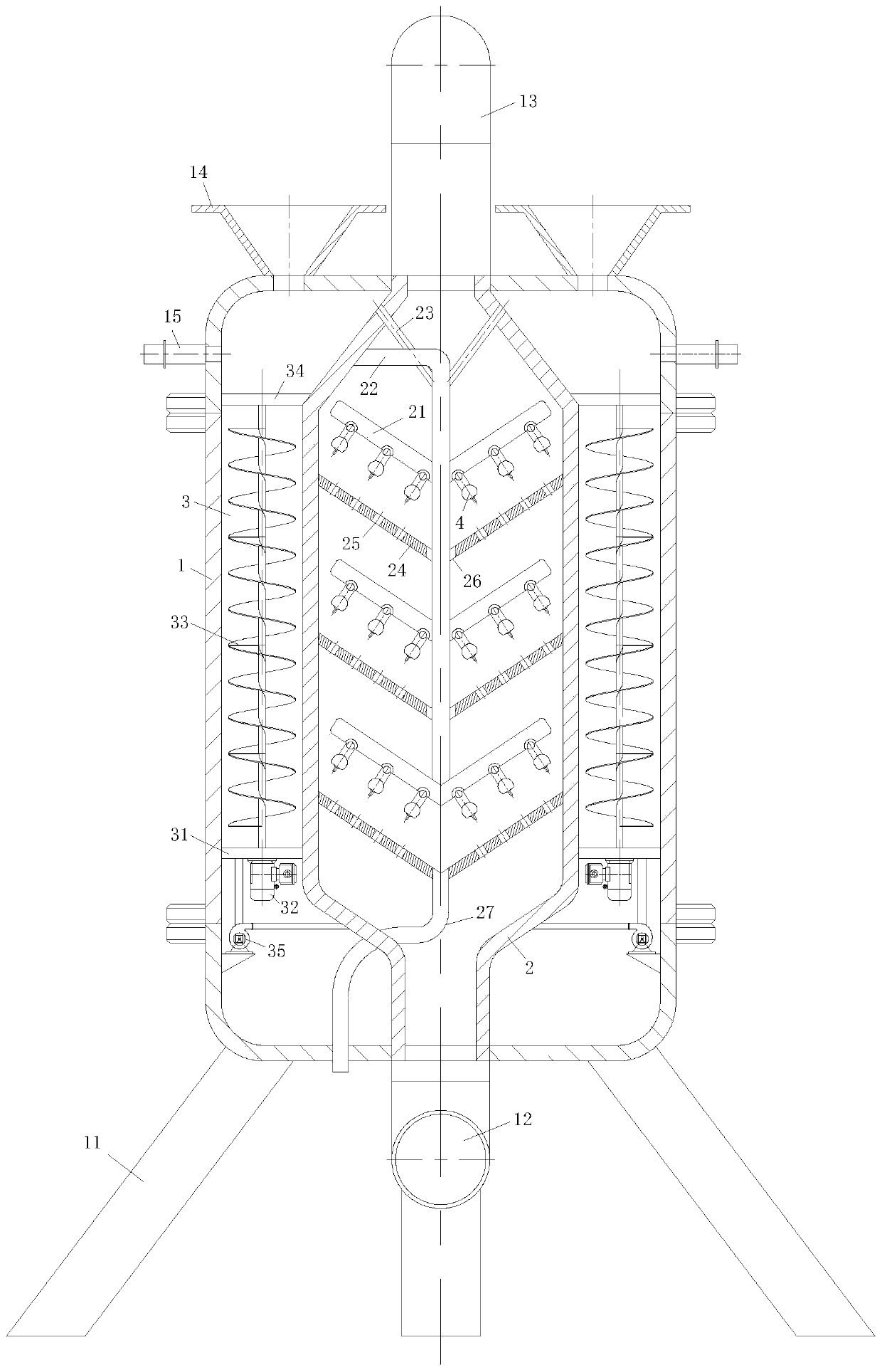

Energy-saving vulcanization tower for steelmaking plant

ActiveCN110327766AReduce pollutionIncrease the degree of atomizationDispersed particle separationSteelmakingVulcanization

The invention belongs to the technical field of flue gas treatment, in particular to an energy-saving vulcanization tower for a steelmaking plant. The energy-saving vulcanization tower for the steelmaking plant comprises a tower body, wherein a base and an air intake pipe are arranged at the bottom of the tower body, an exhaust pipe is arranged at the middle part of the top of the tower body, andtwo feed inlets are symmetrically distributed at the top of the tower body; a spindle-shaped inner tank is arranged in the tower body, and the upper end and lower end of the inner tank are respectively communicated with the exhaust pipe and the air intake pipe; the inner tank and the tower body form a digestive cavity through a sealing plate, and the digestive cavity is communicated with a water inlet pipe; a set of nozzles are fixedly connected in the inner tank uniformly, and a set of spray units are uniformly arranged on the nozzles; the spray units are communicated with the bottom of the digestive cavity through the nozzles, a conveying pipe and a water pump. According to the energy-saving vulcanization tower, quicklime in the digestive cavity is subjected to digestion reaction to generate a large amount of heat and desulfurized exhaust gas in the inner tank is heated and then exhausted through the exhaust pipe, and finally discharged into the upper atmosphere through a chimney, thereby reducing the pollution of the exhaust gas in the steelmaking plant to the lower atmosphere.

Owner:山西新唐工程设计股份有限公司

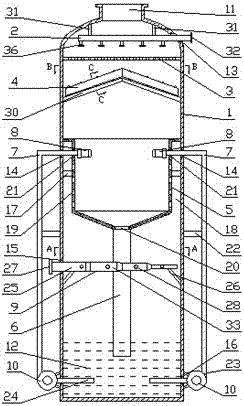

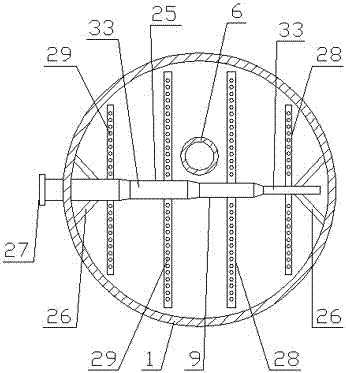

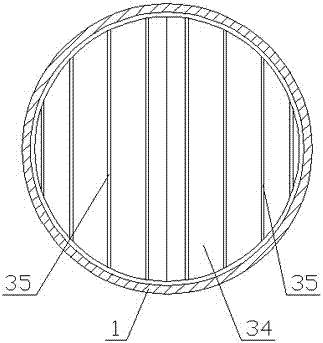

Device for treating refined cotton bleaching tail gas

InactiveCN107149860APromote absorptionIncrease the degree of atomizationGas treatmentDispersed particle separationProcess engineeringReaction zone

The invention discloses a device for treating refined cotton bleaching tail gas. The device is characterized in that a waste gas outlet is formed in the top of tower, the tower is loaded with an absorbing agent, a spraying port, paired accelerating tube inlets, a gas distributor inlet and paired water pump inlets are formed in the lateral wall of the tower, a flow guide cylinder is fixedly mounted inside the tower through a first support, an annular flow guide groove is formed between the outer lateral wall of the flow guide cylinder and the inner lateral wall of the tower, gas inlets are formed in the lateral wall of the flow guide cylinder, the bottom of the flow guide cylinder is conical, a liquid downflow port is formed in the conical bottom, the upper end of a downcomer is fixedly mounted at the bottom of the flow guide cylinder and communicated with the liquid downflow port, and the lower end of the downcomer is submerged into the absorbing agent. The device has the advantages that the absorbing effect of the device is 3-4 times of that of a common aqueous solution, and the waste gas absorbing effect is increased greatly; the atomizing degree of the absorbing agent is enhanced greatly to greatly increase the contact area between waste gas and the absorbing agent when the waste gas collides with a flow reaction area.

Owner:HUBEI JINHANJIANG REFINED COTTON

Environment optimization method

ActiveCN104033972AWon't clogReduce maintenance costsMechanical apparatusLighting and heating apparatusWater sourceSpray nozzle

The invention provides an environment optimization method which is more environment friendly and energy saving. The environment optimization method includes the steps of purifying water; monitoring environmental status before optimization and indicating operation mode of spraying equipment; spraying specialized water from a spray nozzle with precise micropores under the state of high pressure; spraying natural droplets into the external environment and the like. Water sources are subjected to purification before atomization, so that the spray nozzle used in atomization can be enabled not to be jammed due to aggregation of water impurities; meanwhile, microorganisms, heavy metals and inorganic impurities contained in the water can be removed without causing harm to the environment and human body, and environment friendliness is achieved; compared with the prior art, the environment optimization method adopting an impingement atomization mode is low in water consumption, uniform in atomization effect and large in atomization range.

Owner:福建省亿安环保服务有限公司

Smoke screen generation system

PendingCN113295050AIncrease flow rateWell mixedLavatory sanitoryFog generating apparatusElectric controlSmoke screen

The invention provides a smoke screen generation system. The smoke screen generation system comprises a smoke generator device; the smoke generator device comprises a smoke generator box body, a box body air inlet is formed in the smoke generator box body, a control panel is embedded in the smoke generator box body, and at least one button is arranged on the control panel; a power device, an injection device, a fuel system, a power source, an electric control module and other components are further contained in the smoke generator box body; and the smoke screen generation system can further comprise an atomized oil system and / or a material agent conveying device and the like so as to supply smoke agent materials to the injection device. The smoke screen generation system is compact in structure and allows portable use.

Owner:山东信悦机械有限公司

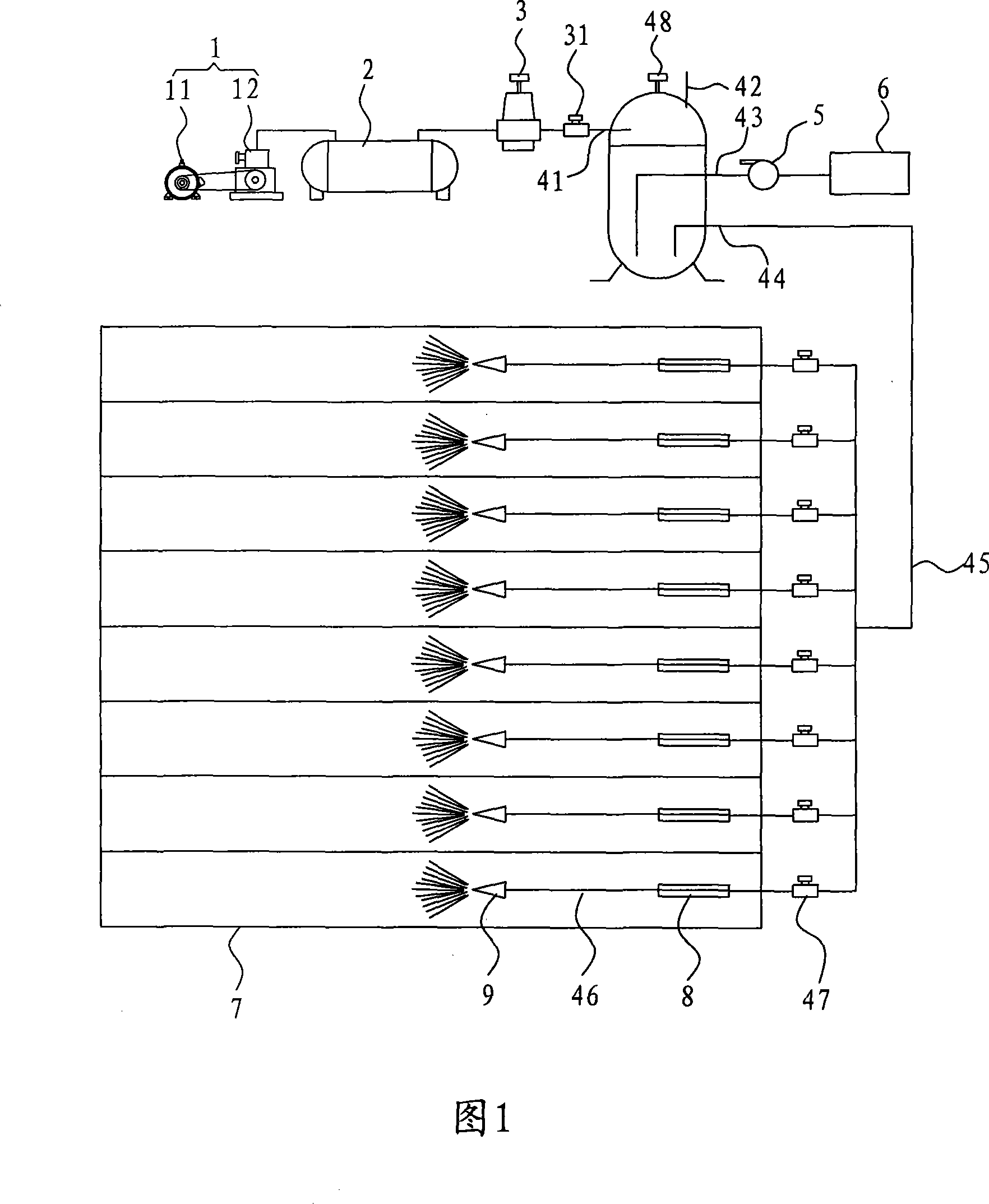

Energy-efficient building blocks curing device

InactiveCN101224598AIncrease water pressureIncrease humidityCeramic shaping apparatusArchitectural engineeringHigh pressure water

The invention discloses an energy-saving building block curing device which is low in operating cost and is safe in production; the device includes an air compressor, a plenum chamber, a water pump, a jet nozzle and a curing room used for placing the building blocks; the plenum chamber has an air intake, an air outlet, a water inlet and a water outlet; the air outlet of the air compressor is connected with the air inlet of the plenum chamber, the water inlet of the plenum chamber is connected with the water outlet of the water pump, the water outlet of the plenum chamber is connected with the building block curing room by a pipe, and the jet nozzle is arranged at the end of the pipe and is used for atomizing the high pressure water. The invention improves the water pressure in the plenum chamber by the high pressure air from the air compressor, the jet nozzle at the end of the water outlet of the plenum chamber atomizes the high pressure water instantly, thus improving the humidity of the curing room and realizing the purpose of curing the building block.

Owner:李仰水

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com