Fuel filter capable of improving energy consumption and discharging of engine

A fuel filter and engine technology, applied in the field of filters, can solve problems such as limited service life and filtration accuracy, easy covering of pores by coating layer, short distance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

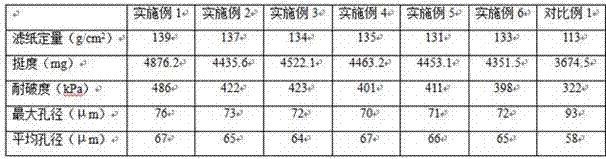

Embodiment 1

[0048] A fuel filter for improving engine energy consumption and emission, including a filter body, in which a far-infrared ceramic filter element and an infrared filter paper are arranged in sequence according to the fuel flow direction, and the porosity of the far-infrared ceramic filter element is is 85%, and the pore density is 40ppi, and described infrared filter paper is made up of the raw material of following weight part:

[0049] Plant fiber pulp 120-150 parts

[0050] Microcrystalline cellulose 10-16 parts

[0051] Infrared functional powder 20-40 parts

[0052] Diatomaceous earth 5-10 parts

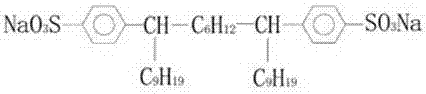

[0053] Dispersant 5-7 parts

[0054] 1-5 parts of coupling agent

[0055] Reinforced resin 10-20 parts

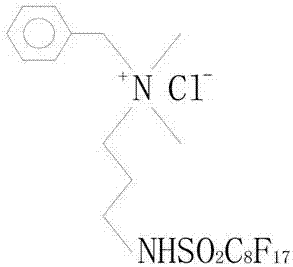

[0056] Surfactant 1-5 parts;

[0057] Wherein, the preparation method of the infrared functional powder comprises the following steps:

[0058] (1) Add nano-infrared ore into polymer spinning solution, and carry out ultrasonic dispersion to obtain spinning stock solut...

Embodiment 2

[0076] A fuel filter for improving engine energy consumption and emission, including a filter body, in which a far-infrared ceramic filter element and an infrared filter paper are arranged in sequence according to the fuel flow direction, and the porosity of the far-infrared ceramic filter element is is 90%, and the pore density is 50ppi, and described infrared filter paper is made up of the raw material of following weight portion:

[0077] 120 parts of vegetable fiber pulp

[0078] 10 parts microcrystalline cellulose

[0079] Infrared functional powder 20 parts

[0080] Diatomaceous earth 5 parts

[0081] Dispersant 5 parts

[0082] 1 part coupling agent

[0083] Reinforced resin 10 parts

[0084] 1 part of surfactant;

[0085] Wherein, the preparation method of the infrared functional powder comprises the following steps:

[0086] (1) Add nano-infrared ore into polymer spinning solution, and carry out ultrasonic dispersion to obtain spinning stock solution;

[0087]...

Embodiment 3

[0104] A fuel filter for improving engine energy consumption and emission, including a filter body, in which a far-infrared ceramic filter element and an infrared filter paper are arranged in sequence according to the fuel flow direction, and the porosity of the far-infrared ceramic filter element is is 80%, and the pore density is 30ppi, and described infrared filter paper is made up of the raw material of following weight part:

[0105] 150 parts of plant fiber pulp

[0106] 16 parts microcrystalline cellulose

[0107] Infrared functional powder 40 parts

[0108] Diatomaceous earth 10 parts

[0109] Dispersant 7 parts

[0110] 5 parts of coupling agent

[0111] Reinforcing resin 20 parts

[0112] 5 parts of surfactant;

[0113] Wherein, the preparation method of the infrared functional powder comprises the following steps:

[0114] (1) Add nano-infrared ore into polymer spinning solution, and carry out ultrasonic dispersion to obtain spinning stock solution;

[0115]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole density | aaaaa | aaaaa |

| Hole density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com