Energy-saving vulcanization tower for steelmaking plant

A technology for sulfidation towers and steelmaking plants, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of obvious flue gas cooling, secondary pollution, unfavorable chimney exhaust diffusion, etc., to increase contact area, reduce pollution, and increase the effect of removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

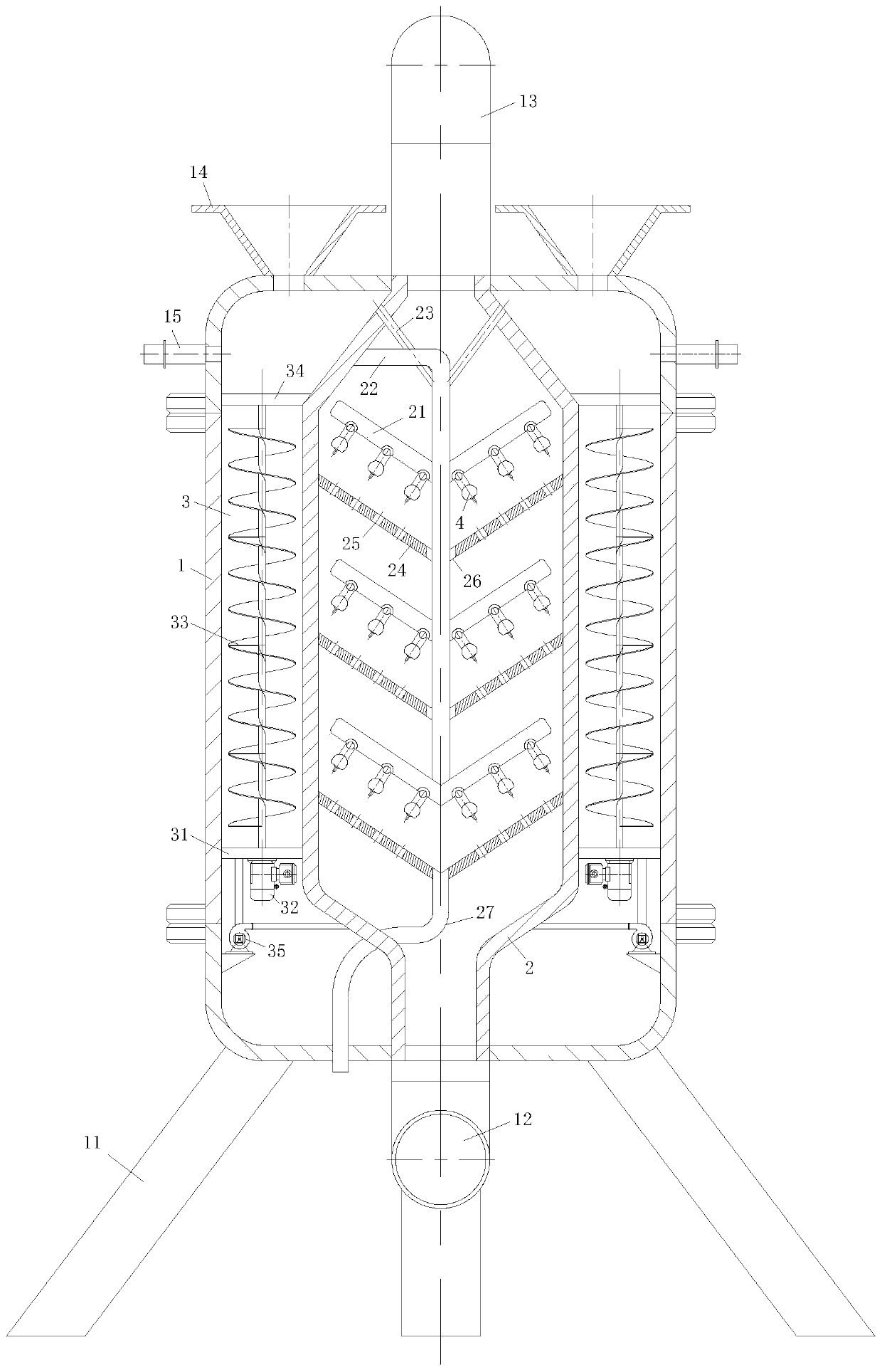

[0028] As an embodiment of the present invention, one end of the T-shaped air passage 411 close to the cylinder 49 is divided into a herringbone branch pipe 413, wherein one branch pipe 413 communicates with the rod chamber of the cylinder 49, and the other branch pipe 413 communicates with the cylinder 49. The rodless cavity is connected; the intersection of the branch pipe 413 is provided with a splitter plate 414 hinged with the ball head 42, and when the splitter plate 414 swings to one side, the airflow flows to the branch pipe 413 on the side away from the splitter plate 414; The arc-shaped slideway 415 between the branch pipes 413 is slidably connected with a slide block 416 matched therewith; the diameter of the slideway 415 is greater than the diameter of the branch pipe 413; the slide block 416 is fixedly connected with the splitter plate 414; when lime When the larger particles in the milk still cannot be quickly discharged from the spout 45 by opening the semicircul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com