Device for treating refined cotton bleaching tail gas

A tail gas treatment and cotton refining technology, applied in gas treatment, separation methods, dispersed particle separation, etc., can solve problems such as air pollution, poor tail gas absorption effect, chlorine dioxide overflow, etc., to improve absorption effect and occupy an area Small area, enhanced gas-liquid contact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

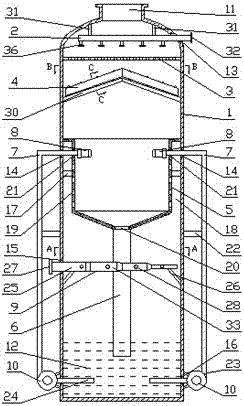

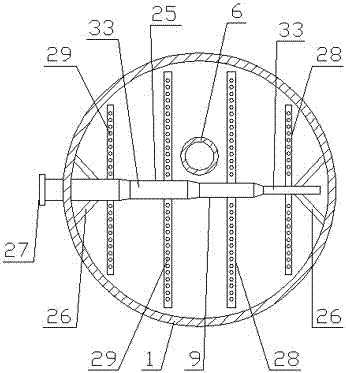

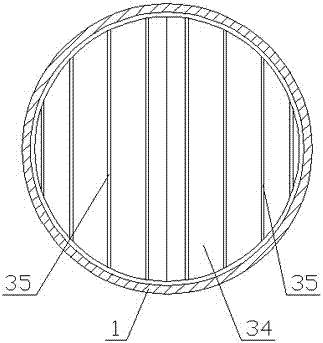

[0021] Depend on figure 1 As shown, the refined cotton bleaching tail gas treatment device includes a tower body 1 with a hollow cylindrical structure, a spray pipe 2, a screen plate 3, a demister 4, a guide tube 5, a downcomer 6, and a pair of Acceleration tube 7, paired pressure atomizing nozzle 8, gas distributor 9 and paired water pump 10, the top of the tower body 1 is provided with a waste gas outlet 11, and an absorbent 12 is contained in the tower body 1, the The absorbent 12 is a mixed solution of sodium percarbonate and sodium perborate. The side walls of the tower body 1 are respectively provided with a spray port 13, a pair of accelerator tube inlets 14, a gas distributor inlet 15 and a pair of water pump inlets 16, and the guide tube 5 is fixed by a first bracket 17 Installed inside the tower body 1, the guide tube 5 is made of glass fiber reinforced plastics, and an annular guide groove 18 is formed between the outer wall of the guide tube 5 and the inner side w...

Embodiment 2

[0026] Depend on figure 1 As shown, the refined cotton bleaching tail gas treatment device includes a tower body 1 with a hollow cylindrical structure, a spray pipe 2, a screen plate 3, a demister 4, a guide tube 5, a downcomer 6, and a pair of Acceleration tube 7, paired pressure atomizing nozzle 8, gas distributor 9 and paired water pump 10, the top of the tower body 1 is provided with a waste gas outlet 11, and an absorbent 12 is contained in the tower body 1, the The absorbent 12 is a mixed solution of sodium percarbonate, sodium perborate and EDTA. The side walls of the tower body 1 are respectively provided with a spray port 13, a pair of accelerator tube inlets 14, a gas distributor inlet 15 and a pair of water pump inlets 16, and the guide tube 5 is fixed by a first bracket 17 Installed inside the tower body 1, the guide tube 5 is made of glass fiber reinforced plastics, and an annular guide groove 18 is formed between the outer wall of the guide tube 5 and the inner si...

Embodiment 3

[0031] Depend on figure 1 As shown, the refined cotton bleaching tail gas treatment device includes a tower body 1 with a hollow cylindrical structure, and it also includes a spray pipe 2, a mesh plate 3, a demister 4, a guide tube 5, and a downcomer 6 , paired acceleration tubes 7, paired pressure atomizing nozzles 8, gas distributor 9 and paired water pumps 10, the top of the tower body 1 is provided with a waste gas outlet 11, and the tower body 1 is filled with absorption Agent 12, the absorbent 12 is a mixed solution of sodium percarbonate and EDTA. The side walls of the tower body 1 are respectively provided with a spray port 13, a pair of accelerator tube inlets 14, a gas distributor inlet 15 and a pair of water pump inlets 16, and the guide tube 5 is fixed by a first bracket 17 Installed inside the tower body 1, the guide tube 5 is made of glass fiber reinforced plastics, and an annular guide groove 18 is formed between the outer wall of the guide tube 5 and the inner...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com