Energy-efficient building blocks curing device

A block and curing room technology, applied in the field of energy-saving block curing devices, can solve the problems of high maintenance equipment cost, inconvenient maintenance, hidden dangers in production safety, etc., and achieve the effects of shortening maintenance time, low operating cost, and convenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

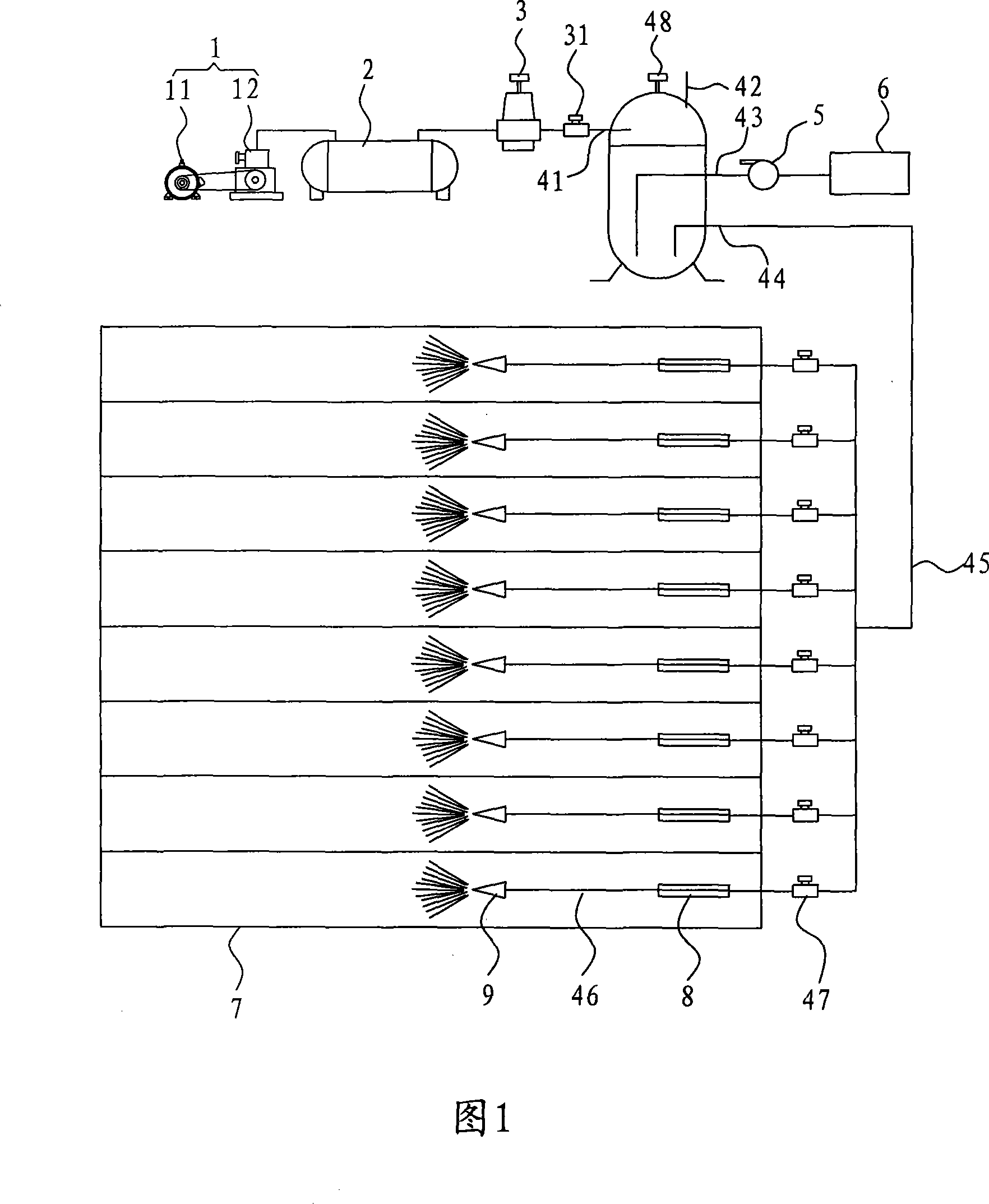

[0012] 1, the embodiment discloses an energy-saving block maintenance device, which includes an air compressor 1, a gas storage tank 2, a pressure limiting valve 3, a booster chamber 4, a water pump 5, a pool 6, a curing chamber 7, and a heater 8. , Nozzle 9 and other components, the air compressor 1 is a motor 11 drives the compressor 12 to compress the air to obtain high-pressure air, the air outlet of the air compressor 1 is connected to the air tank 2, so that the air compressor 1 compresses the air The high-pressure air is blown into the air storage tank 2. The pressurizing chamber 4 is provided with an air inlet 41, an exhaust port 42, a water inlet 43, a water outlet 44 and a safety valve 48. The air storage tank 2 passes through a pressure limiting valve 3 is connected to the air inlet 41, and the air outlet 42 is connected to the atmosphere. The air outlet 42 is provided with a solenoid valve for controlling the opening or closing of the air outlet 42. The water inlet of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com