Matrix modifier and method for measuring calcium content by graphite furnace atomic absorption spectrometry

A technology of matrix modifier and graphite furnace atom, which is applied in the direction of reducing greenhouse gases, material excitation analysis, climate sustainability, etc., can solve the problem of insufficient linear correlation of standard curve, insufficient atomization of calcium element, and numerical fluctuation of analysis results, etc. problems, to achieve the effect of reducing the risk of radioactive contamination, improving the degree of atomization, and rapid analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

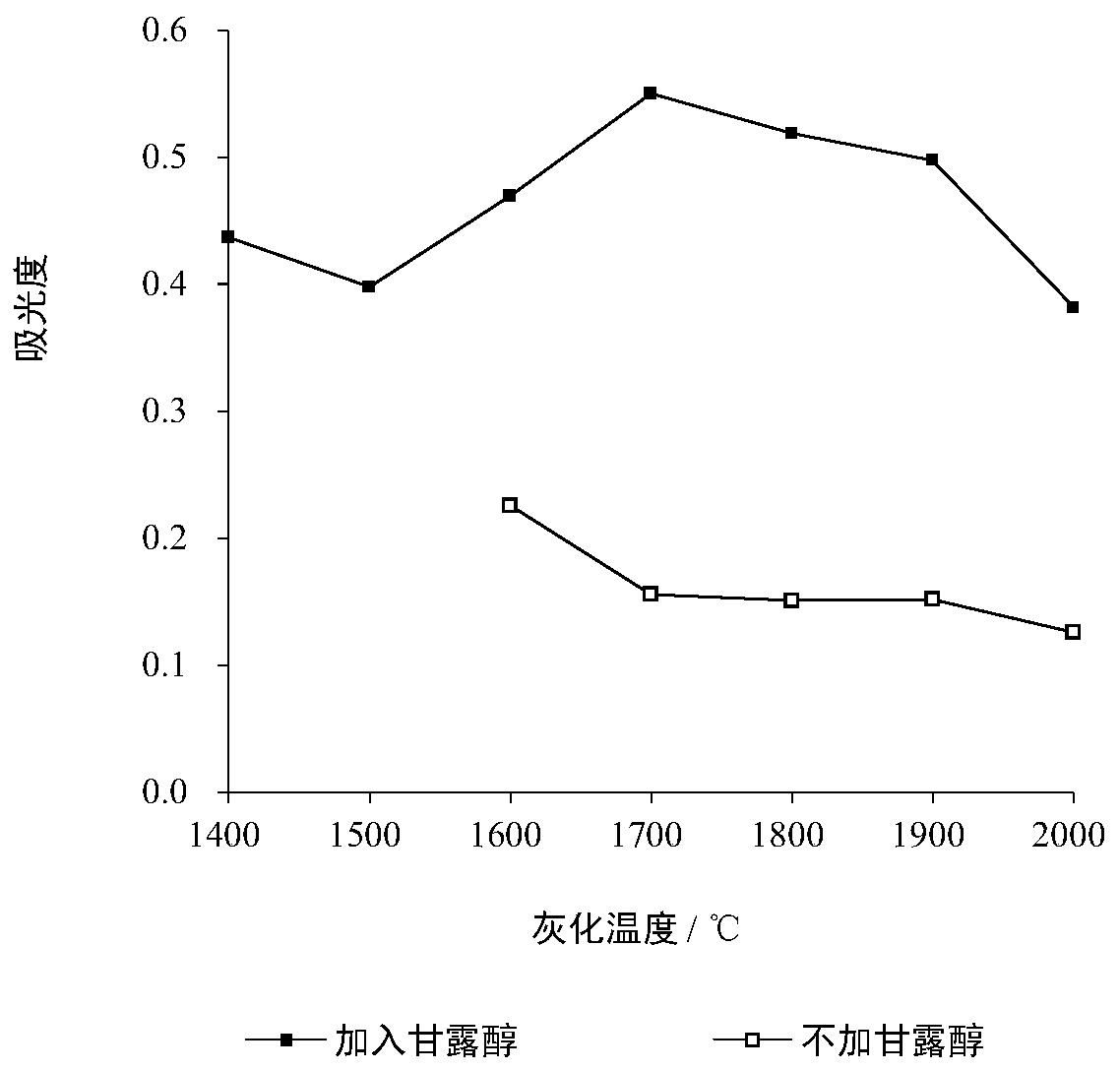

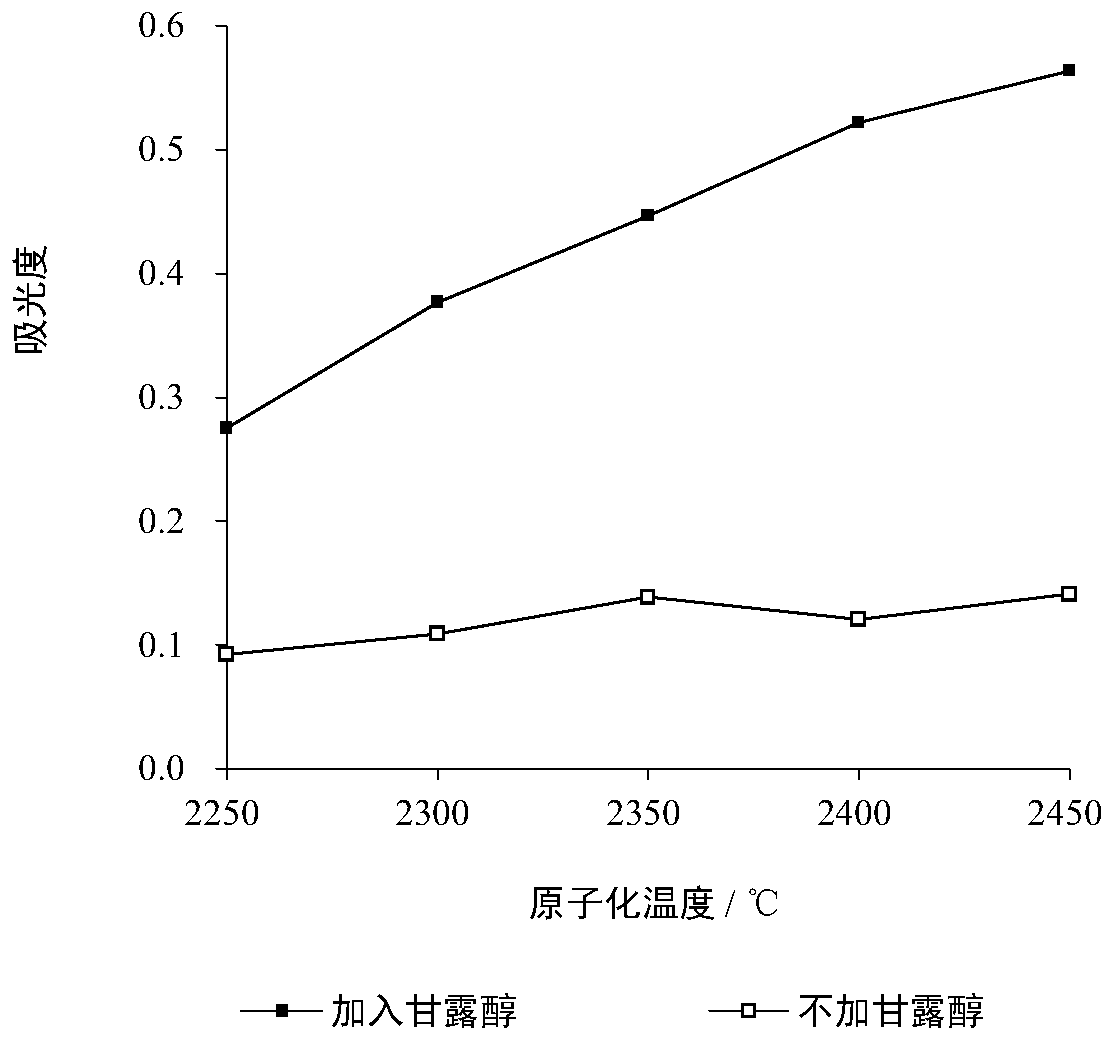

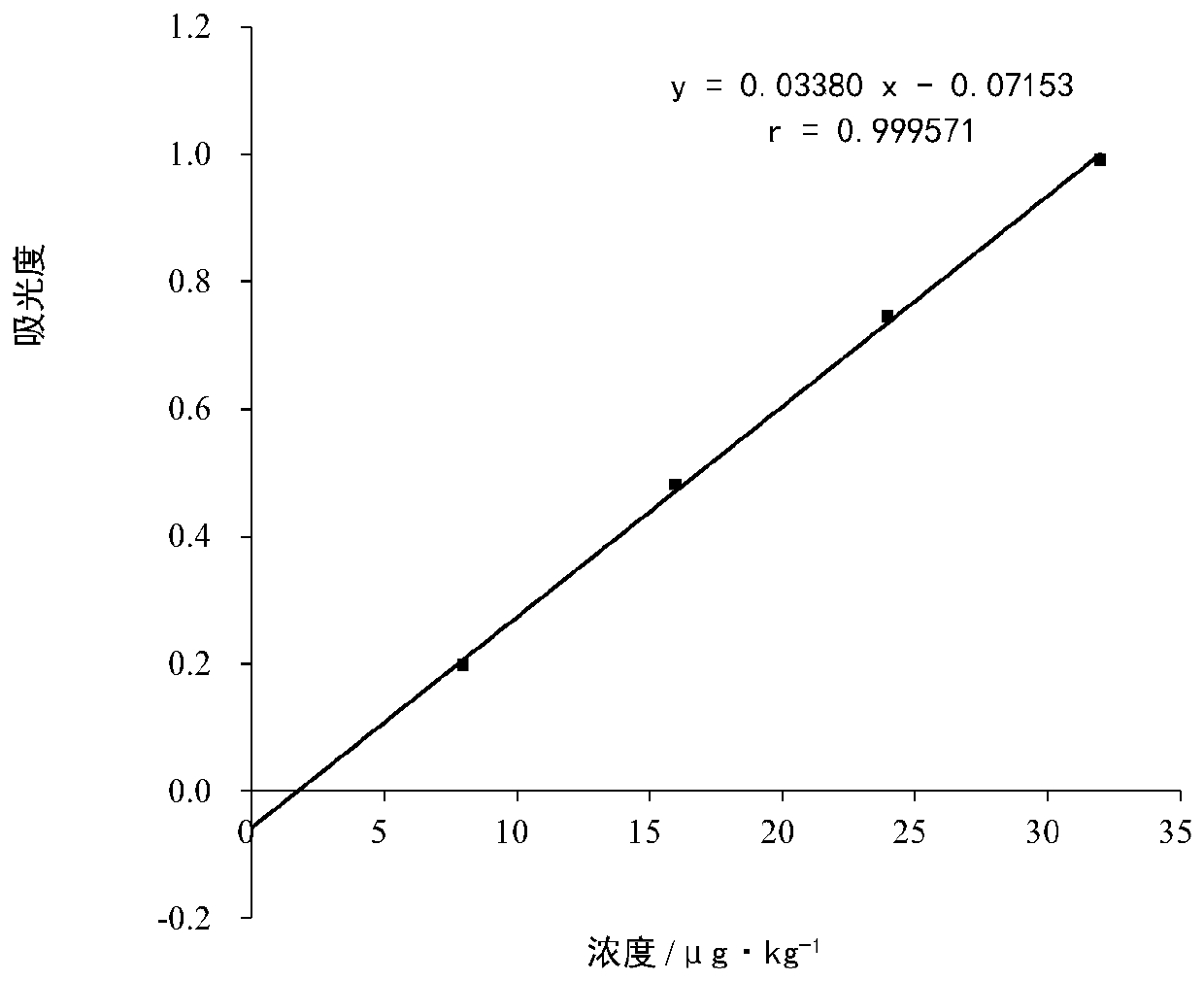

Method used

Image

Examples

experiment example

[0061] (1) Precision experiment

[0062] Use the above-mentioned standard reserve mother liquor, solid high-purity boric acid and ultrapure water to prepare simulated samples with different calcium concentrations and different B matrix mother liquor concentrations, and calculate the relative standard deviation and relative error of the measurement results to verify that different concentrations of B matrix are different The detection influence of concentration calcium-containing samples, precision analysis results are shown in Table 1 below. It can be seen from Table 1 that the relative standard deviation of the measurement results is not more than 7.5%, and the relative error is not more than 13.2%. When the B matrix concentration in the sample is 0-2500mg / kg, the B matrix will not cause too much influence on the detection results of high and low calcium concentrations.

[0063] Table 1

[0064]

[0065] (2) Standard recovery test

[0066] A certain amount of Ca standar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com