Calibration method of light source irradiation direction

A calibration method and irradiation direction technology, applied in the direction of using feedback control, etc., can solve the problems of solar cell module output power distortion and low calibration accuracy, and achieve the effects of improving calibration accuracy, improving economic benefits, and avoiding economic losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in a variety of different ways defined and covered by the claims.

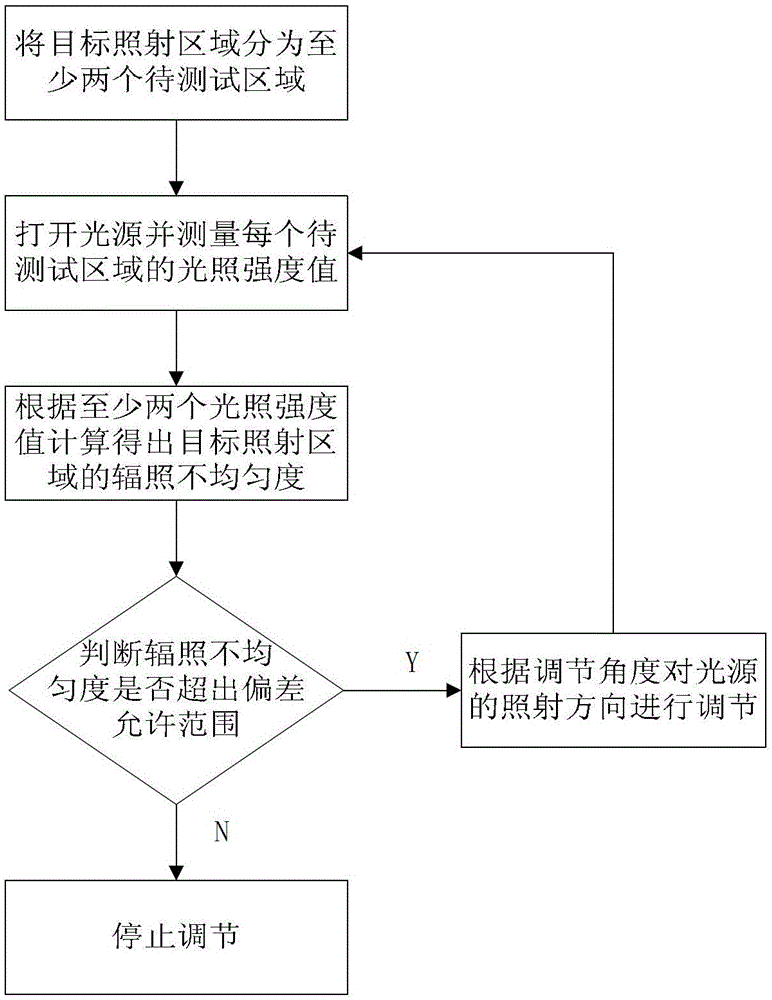

[0034] The invention provides a method for calibrating the illumination direction of a light source. Calibration methods include:

[0035] Step S1: divide the target irradiation area into at least two areas to be tested;

[0036] Step S2: Turn on the light source and measure the light intensity value of each area to be tested;

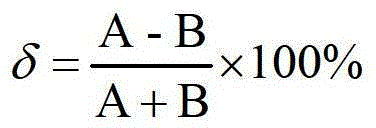

[0037] Step S3: Determine the adjustment angle of the light source according to the light intensity value;

[0038] Step S4: Adjust the illumination direction of the light source according to the adjustment angle.

[0039] Preferably, the area of each area to be tested is equal.

[0040] When using the calibration method of the present invention, the light source of the solar simulator should be placed in the dark box first, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com