Spraying salt-sunning method

A spray system and spray head technology, applied in the direction of spray evaporation, alkali metal chloride, etc., can solve the problem of limited synergy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

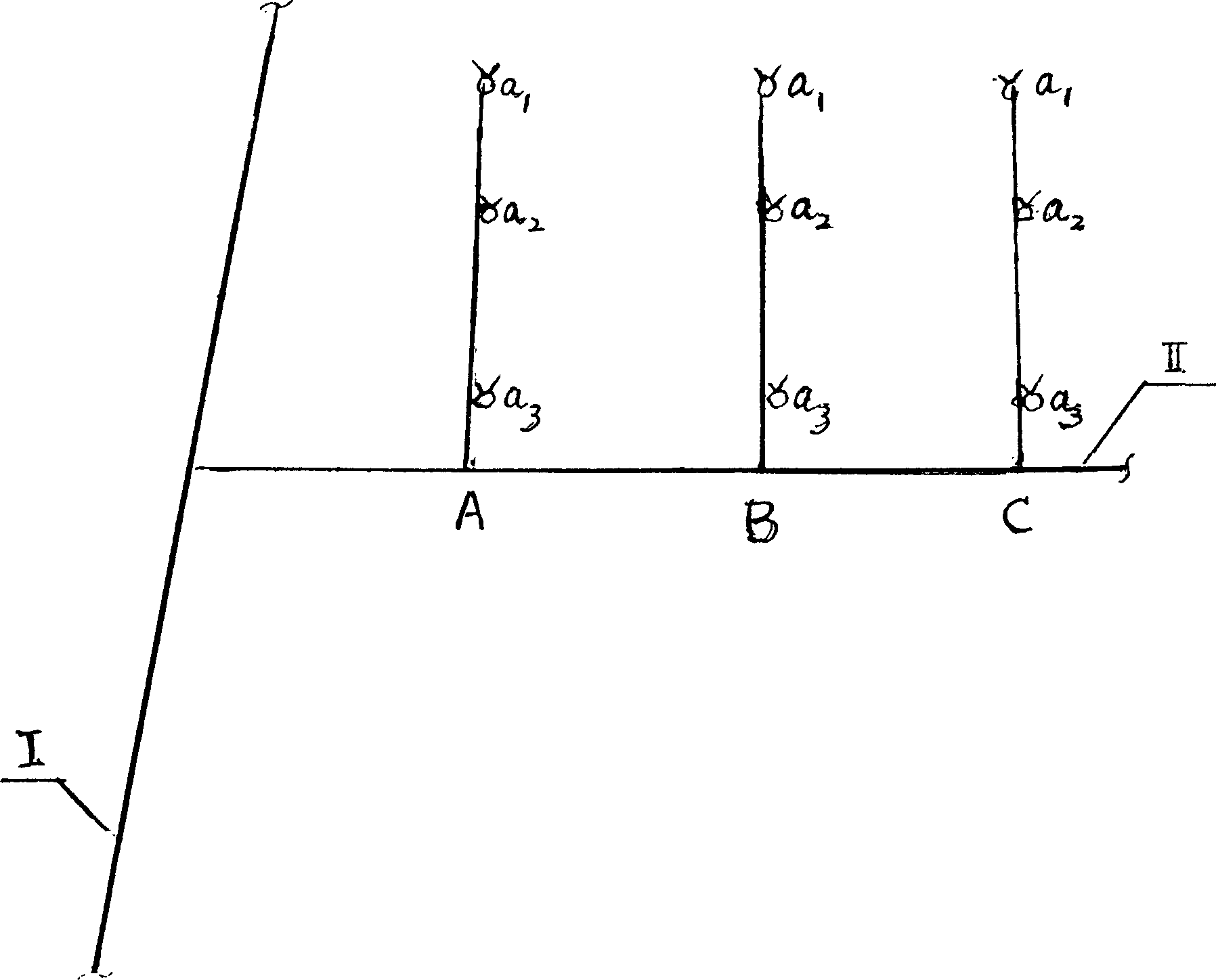

[0022] This example is spray sun salt experiment.

[0023] Experimental conditions: air temperature 22°C, relative humidity 70%, wind force level 4, spraying is carried out at the leeward side of the house facing the sun. Before spraying, the specific gravity of the salt water is 10° (1.10), the diameter of the nozzle is 1.5 mm, the height of the nozzle is 0.5 m, the nozzle is facing upwards, and the spray pressure is 2 standard atmospheres, and it is operated with an agricultural sprayer.

[0024] Experimental process: When the agricultural sprayer sprays salt water to a height of 0.5 meters or more, small mist-like water droplets fall on the ground in 5 areas with an area of 116cm 2 In the plastic box, accept the salt water 240 milliliters / hour box after the spray of specific gravity is 11 °; It is 46 milliliters that 10 ° of salt water is sun-dried and made specific gravity is the salt water of 11 °, in other words, every box (area 116cm 2 ) can only be dried to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com