Degreased protein powder processing system for protein powder production

A processing system and protein powder technology, applied in the field of food processing, can solve the problems of poor atomization effect of the nozzle on the solution, easy to bond protein powder, and large particle size of the product, so as to avoid incomplete drying and prolong exercise time. , Improve the drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

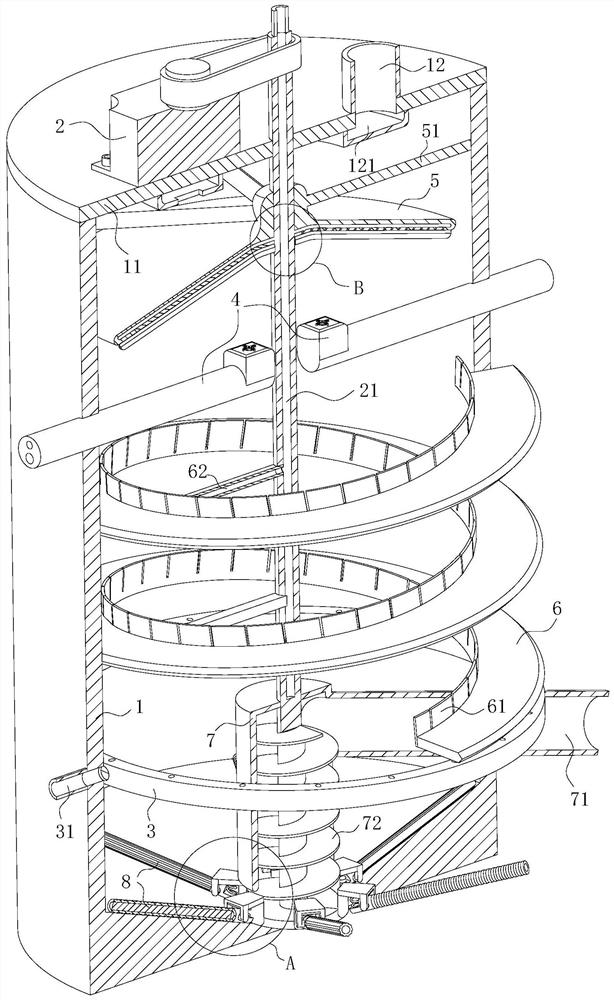

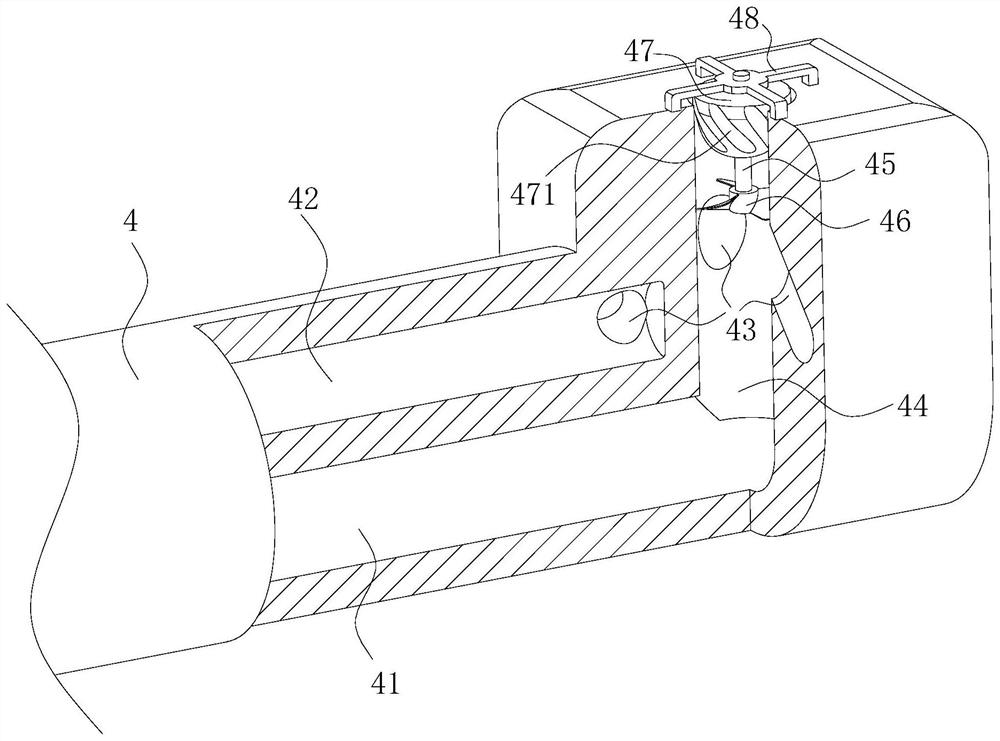

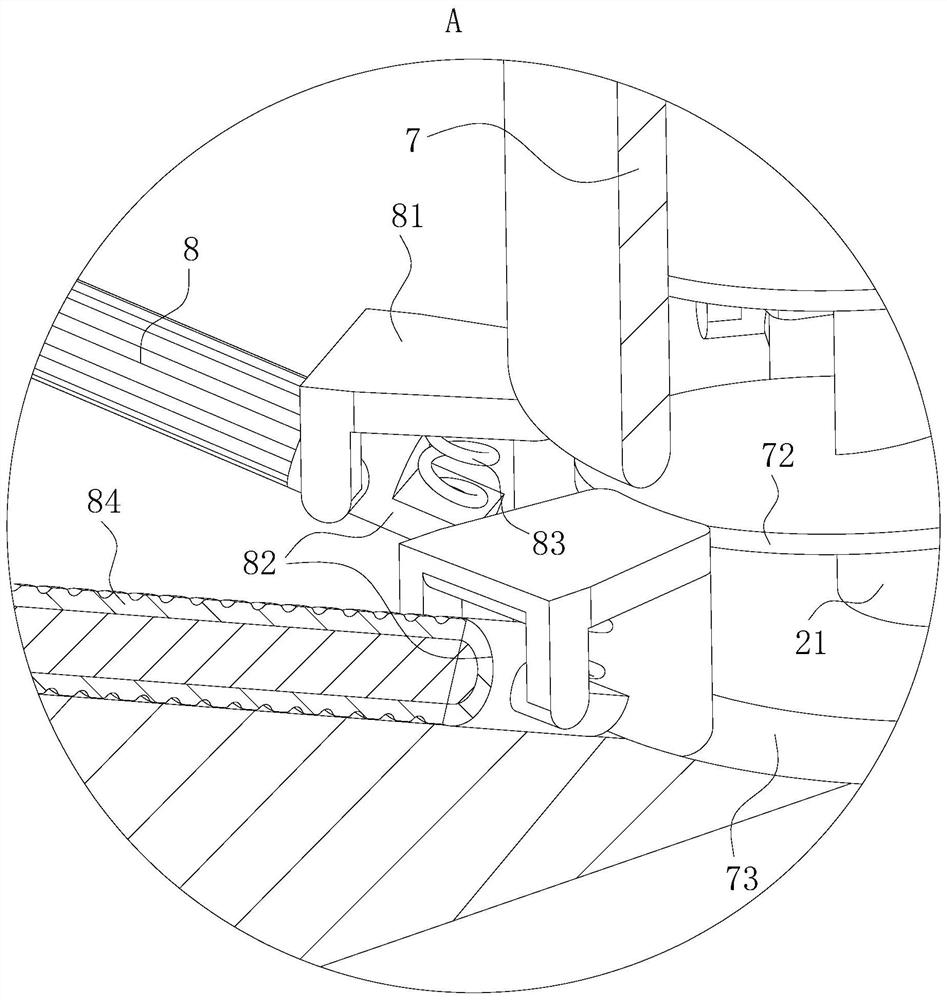

[0040] As an embodiment of the present invention, an umbrella-shaped board 5 is installed inside the main body 1; The center line of the umbrella plate 5 coincides with the center line of the rotating shaft 21; the rotating shaft 21 runs through the umbrella plate 5, and the rotating shaft 21 and the umbrella plate 5 can rotate relatively; the umbrella plate 5 is located at the nozzle 4, and the opening of the umbrella plate 5 is opposite to the ejection direction of the nozzle 4;

[0041] When working, since the ejection direction of the nozzle 4 is upward, after the atomized protein powder solution is sprayed from the nozzle 4, the protein powder solution has a certain upward movement trend, prolonging the movement time of the protein powder solution in the main body 1, and improving the protein powder. The drying effect of the protein powder is to avoid incomplete drying of the protein powder, which leads to the large particle size of the prepared powdery protein powder and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com