Seed coating machine and seed coating method

A coating machine and seed technology, applied in the direction of seed coating/seed dressing, etc., can solve the problems such as difficulty in further improving the degree of atomization, difficulty in improving the qualification rate and effect of seed coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

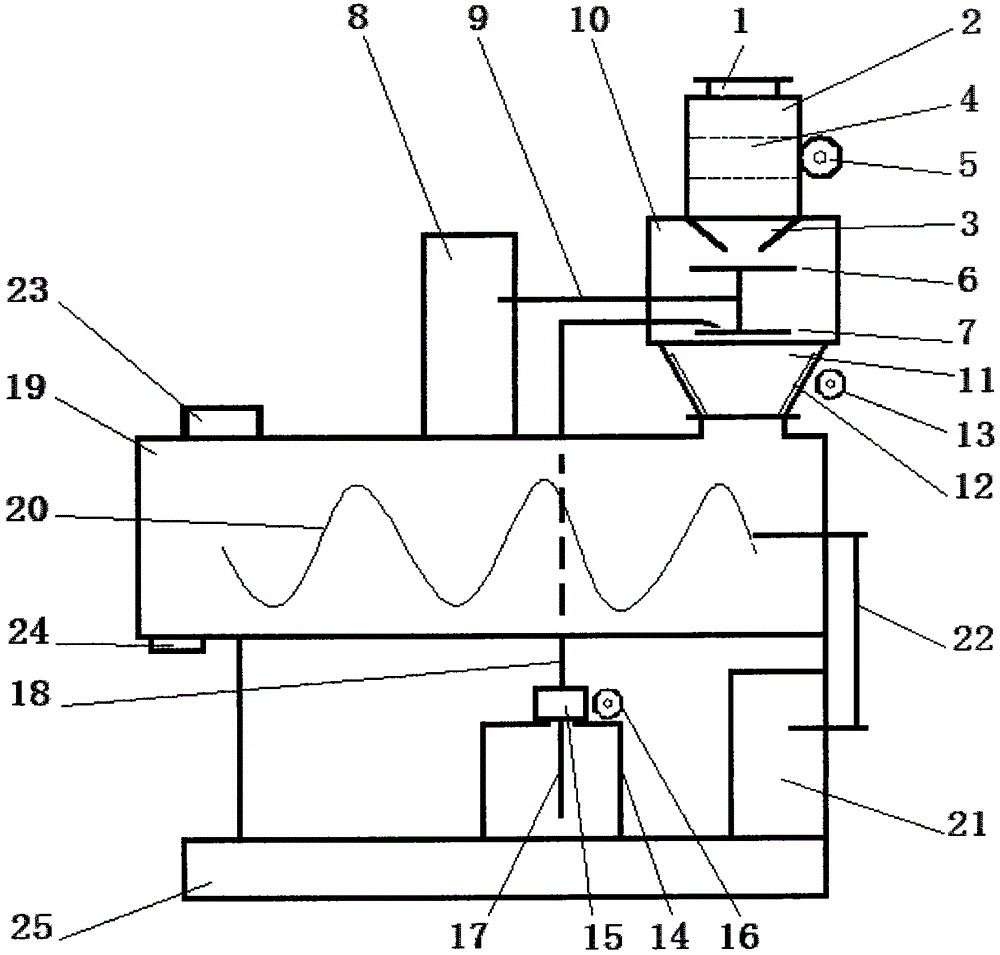

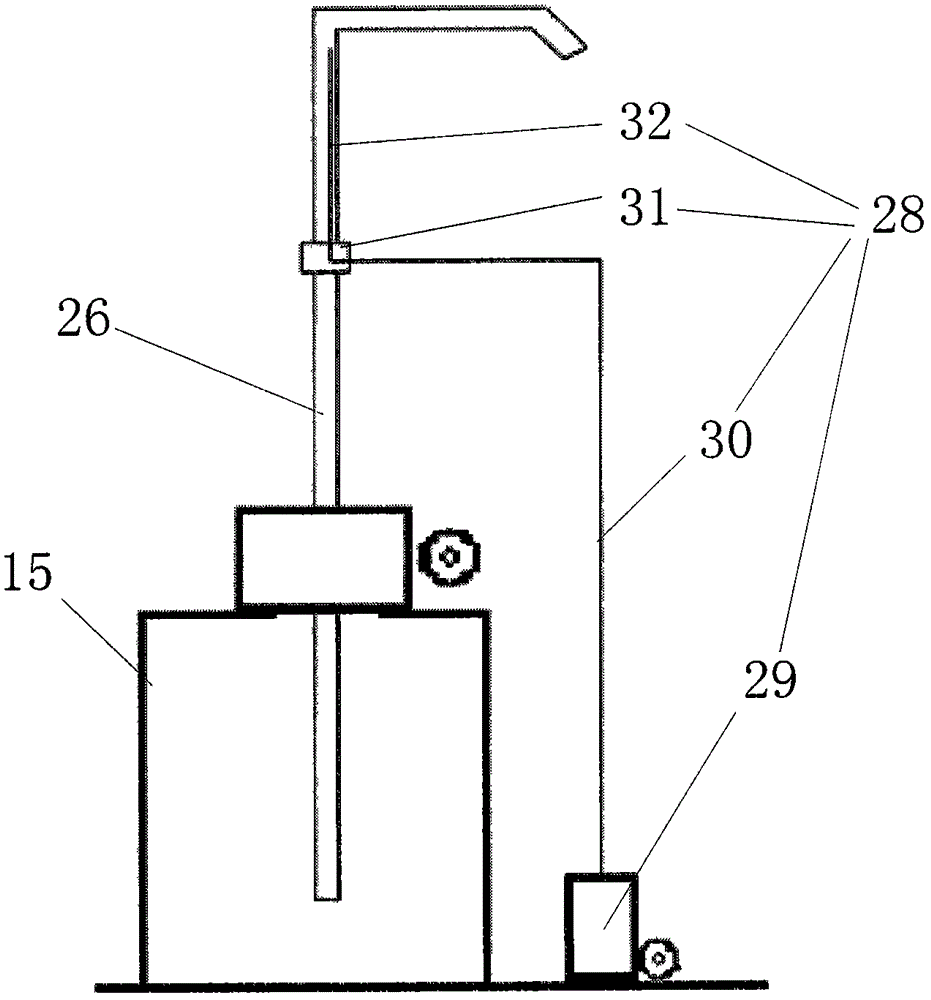

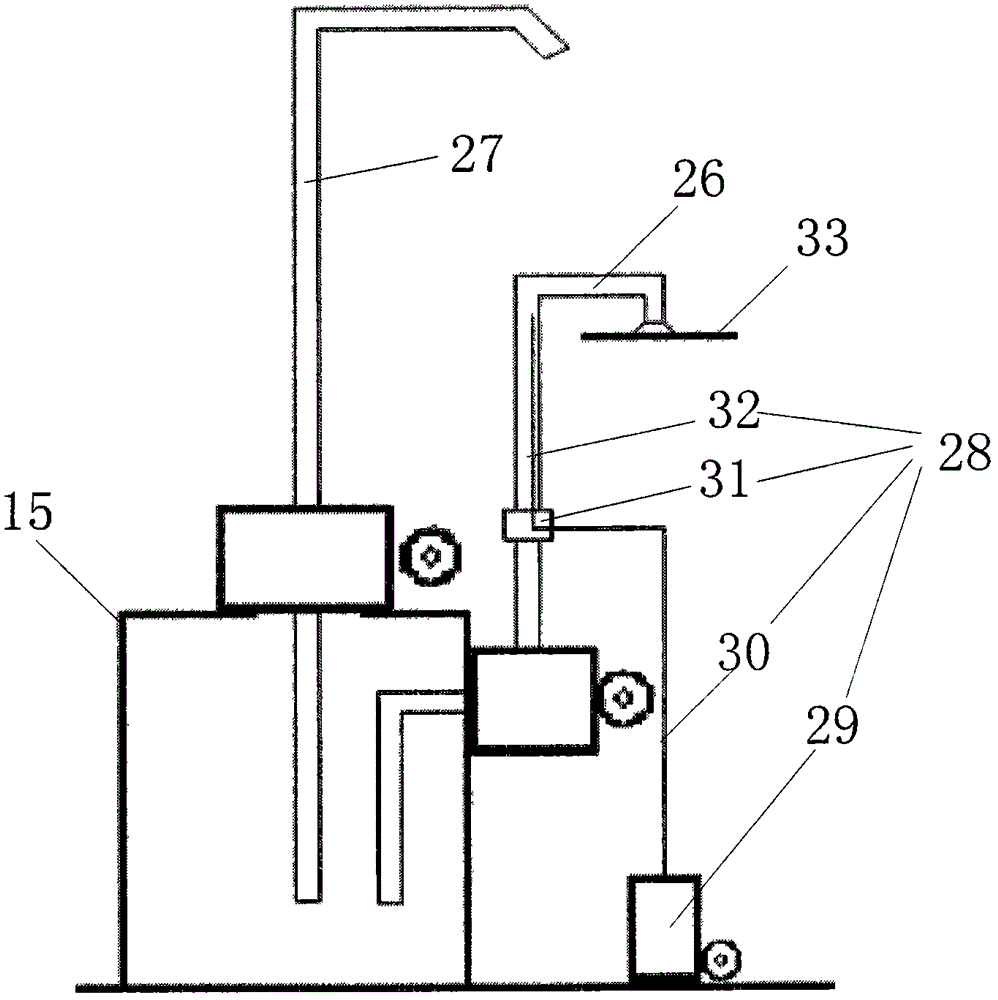

[0029] Combine below figure 1 with figure 2 Describe in detail the first embodiment of the present invention: a seed coating machine, including: a feeding device, an atomization chamber connected with the feeding device, a stirring box connected with the atomization chamber, and Said atomization chamber provides the supply device and frame of agent liquid; said supply device comprises seed coating agent box 15 and the first supply pipe 26 communicating said seed coating agent box 15 and said atomization chamber; The first dosing device 26 is provided with an electrostatic device 28; The joint 31 and the electrostatic discharge lead 32 arranged in the first supply tube 26 ; the electrostatic lead 30 passes through the mixing joint 31 and the electrostatic discharge lead 32 .

[0030] In the first embodiment, a rubber isolation curtain (not shown in the figure) is provided at the entrance of the stirring tank; the discharge port 24 of the stirring tank is grounded; plastic s...

Embodiment approach

[0038] The present invention also provides an embodiment: a seed coating method, comprising:

[0039] Step 100: the step of feeding and bulking the seeds to be coated;

[0040] Step 200: A step of atomizing the loaded and bulked seeds with a charged agent solution under centrifugal action;

[0041] Step 300: a step of stirring and drying the atomized seeds, and cutting the dried seeds.

[0042] Figure 5 Shown is a flow chart of the second embodiment of a seed coating method of the present invention.

[0043] The present invention also provides a second embodiment, a seed coating method, comprising:

[0044] Step 100: the step of feeding and bulking the seeds to be coated;

[0045] Step 210: A step of atomizing the seeds that have been fed and bulked;

[0046] Step 220: a step of secondary atomization treatment of spraying the seeds with an agent solution with high voltage static electricity;

[0047] Step 300: a step of stirring and drying the atomized seeds, and cuttin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com