AAO reaction pool

A technology for reaction pools and pool covers, which is applied to special treatment targets, water/sludge/sewage treatment, biological water/sewage treatment, etc. It can solve the problems of high cleaning costs, inconvenient cleaning of sewage pools and sludge pools, and uneven cleaning and other problems, to achieve the effect of convenient operation, conducive to cleaning and improving the degree of atomization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Various embodiments of the invention will be described in more detail below with reference to the accompanying drawings. In the various drawings, the same elements are denoted by the same or similar reference numerals. For the sake of clarity, various parts in the drawings have not been drawn to scale.

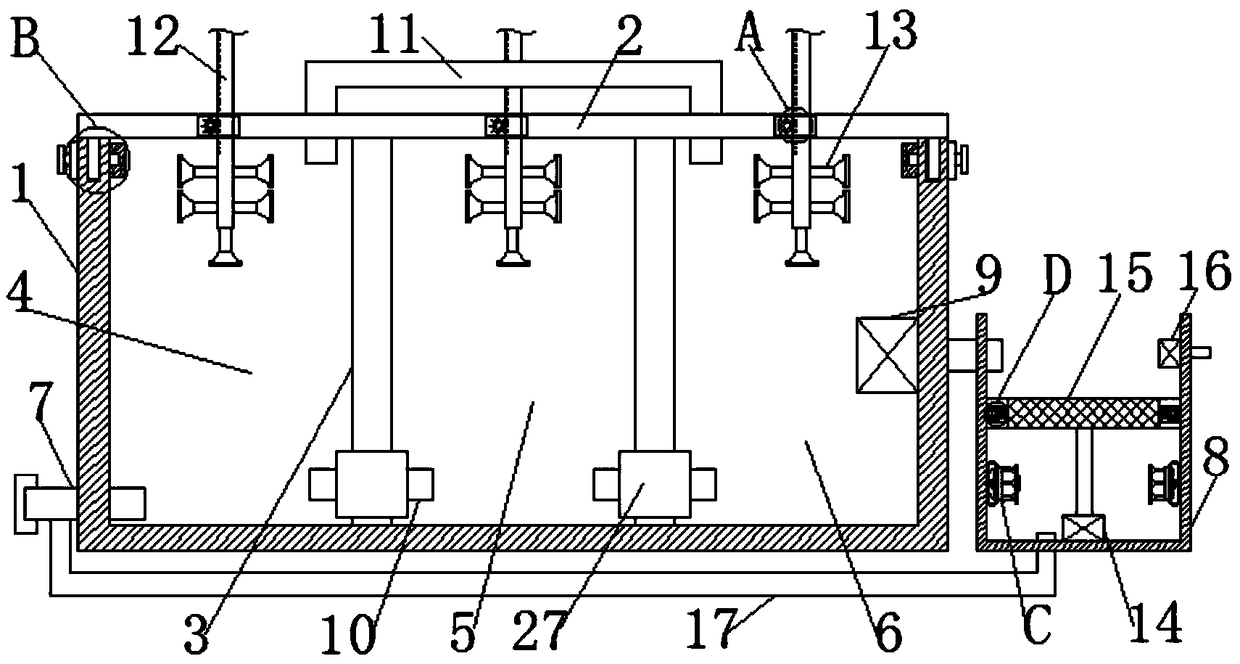

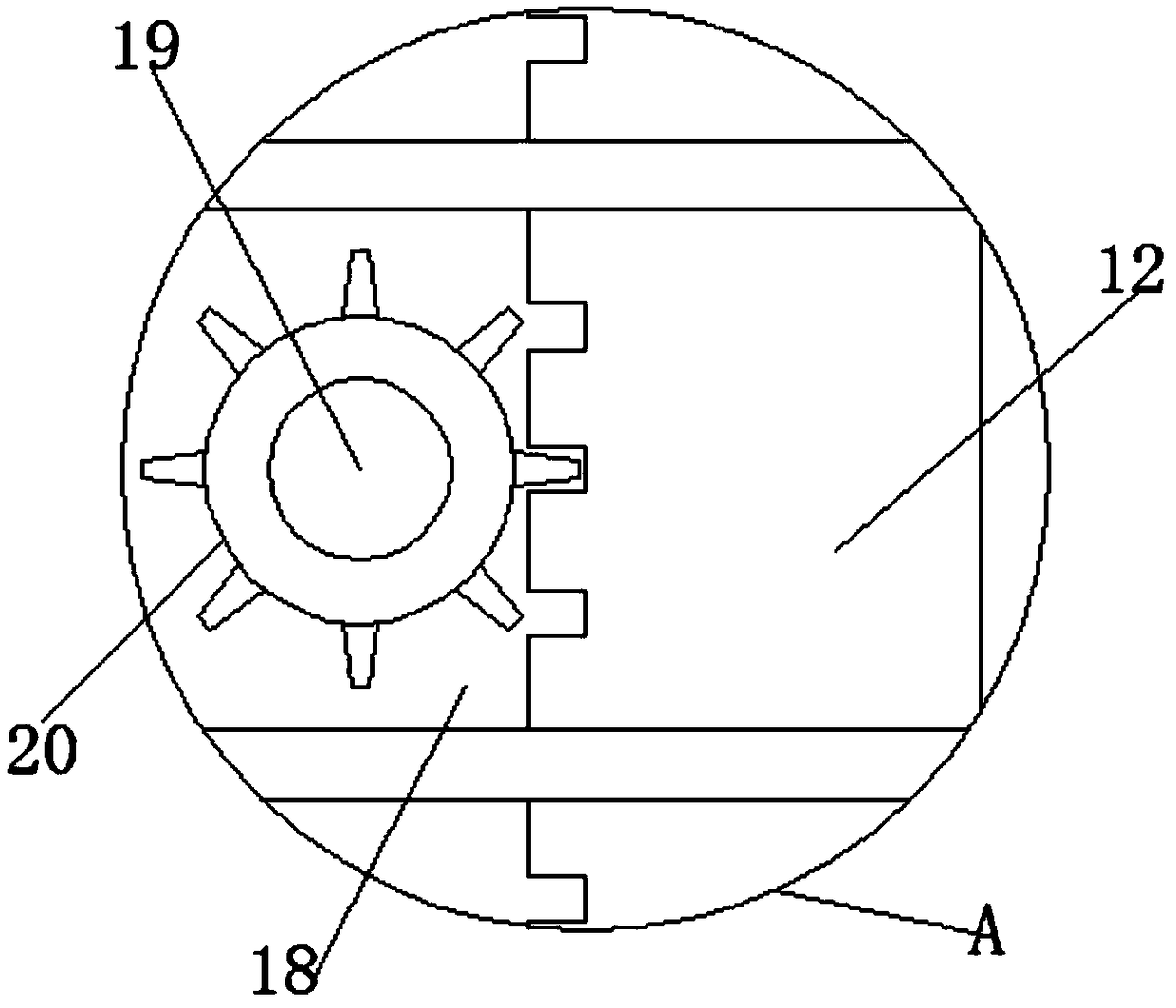

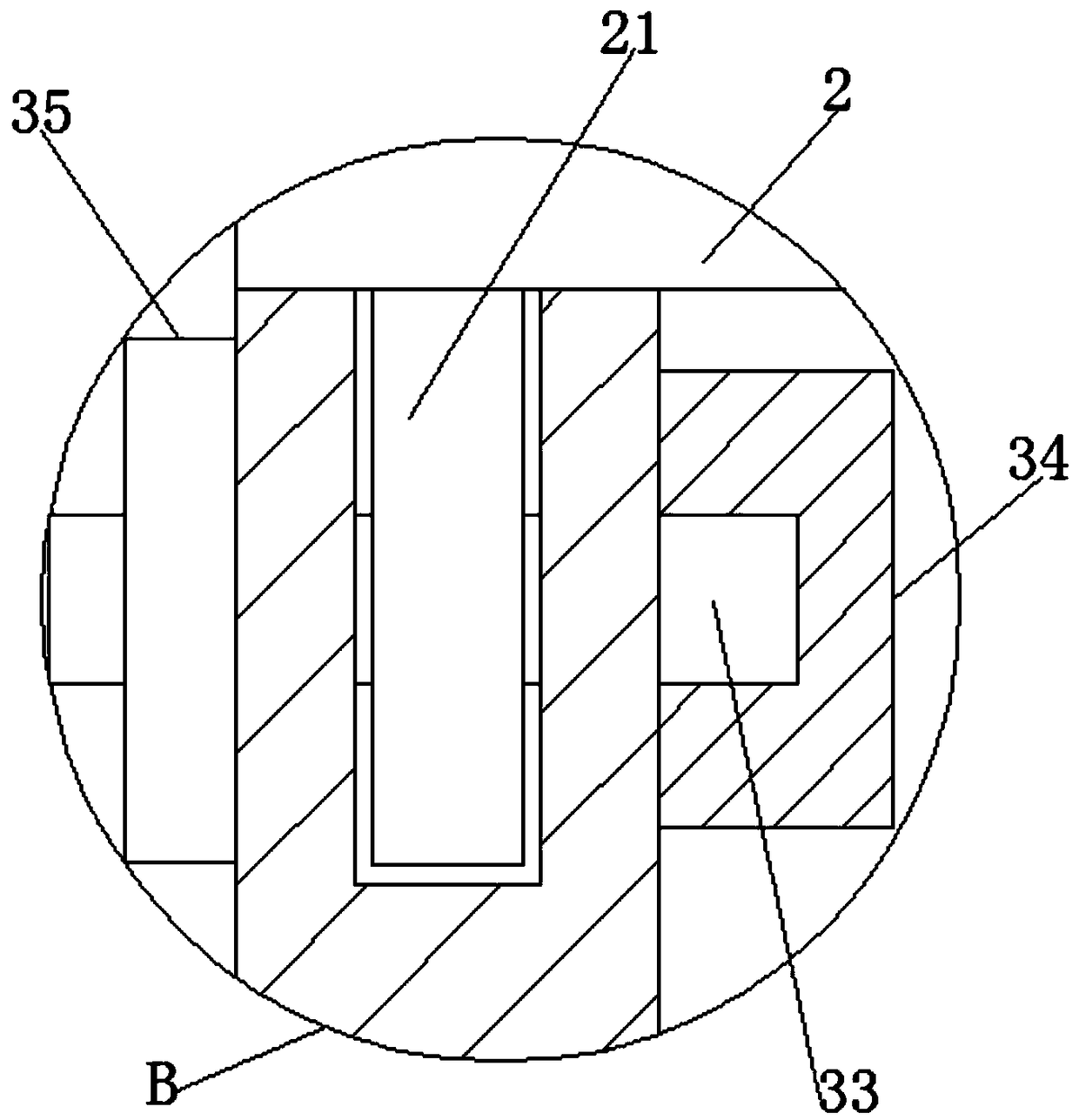

[0025] refer to Figure 1-5 , an AAO reaction pool, including a sewage pool 1 and a pool cover 2, the pool cover 2 is provided with a plurality of installation cavities 18 matched with the cleaning pipes 12, and each cleaning tube 12 is set through the installation cavities 18, each Rotating rods 19 are provided in the installation cavity 18, and one end of each rotating rod 19 is installed through one side wall of the pool cover 2 along the horizontal direction, and the other end of each rotating rod 19 is connected with a first gear 20, One side wall of each cleaning pipe 12 is provided with a first tooth groove meshed with the first gear 20, and the rotating rod 19...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com