Dynamic wave and supergravity integrated dust removal purification device

A purification device and dynamic wave technology, applied in the field of machinery, can solve the problems of large filtering area requirements, bulky equipment, insufficient contact, etc., and achieve the effects of compact size, high degree of atomization, and reduced burden.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

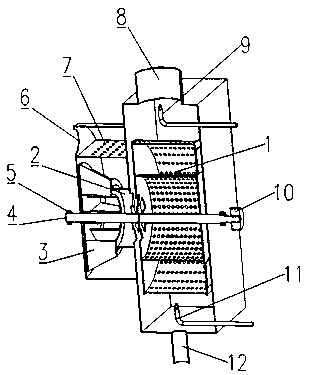

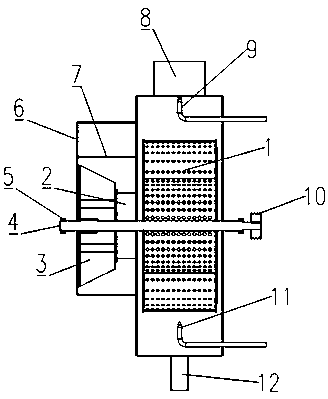

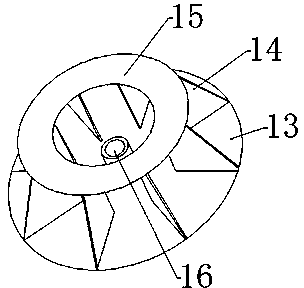

[0013] attached Figure 1-3 It is a specific embodiment of the present invention. The invention is a power wave cooperative supergravity dust removal and purification device. The device is equipped with a reverse rotation filter cartridge 1. The reverse rotation filter cartridge 1 is connected with the self-priming impeller 3 through the rotation shaft 4. The upper and lower sides of the reverse rotation filter cartridge 1 are respectively installed. There is a power wave nozzle 9 and a lower nozzle 11, the upper end of the power wave nozzle 9 is provided with an exhaust gas inlet 8, the lower end of the lower nozzle 11 is provided with a sewage outlet 12, and the upper end of the reverse rotation filter cartridge 1 is provided with a demister 7, a demister 7 There is an air outlet 6 on one side, and an air duct 2 is opened at the connection between the reverse rotation filter cartridge 1 and the self-priming impeller 3, and the end of the rotating shaft 4 near the self-primin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com