A micro-nano temperature sensitive alarm

A micro-nano and alarm technology, applied in the micro-nano field, can solve the problems of difficult temperature changes of micro-nano components, and achieve the effects of enhanced designability, improved temperature sensitivity and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

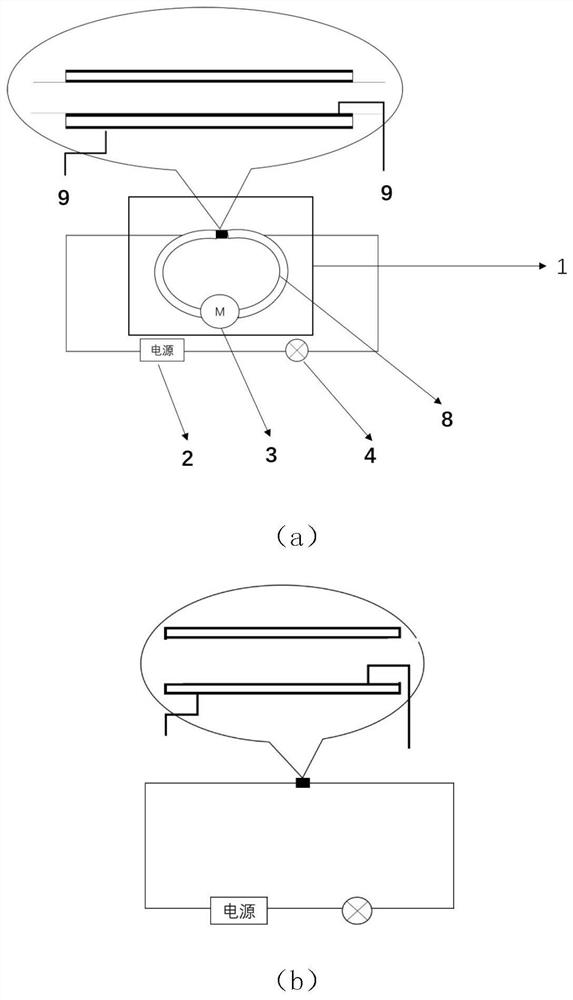

Method used

Image

Examples

example 1

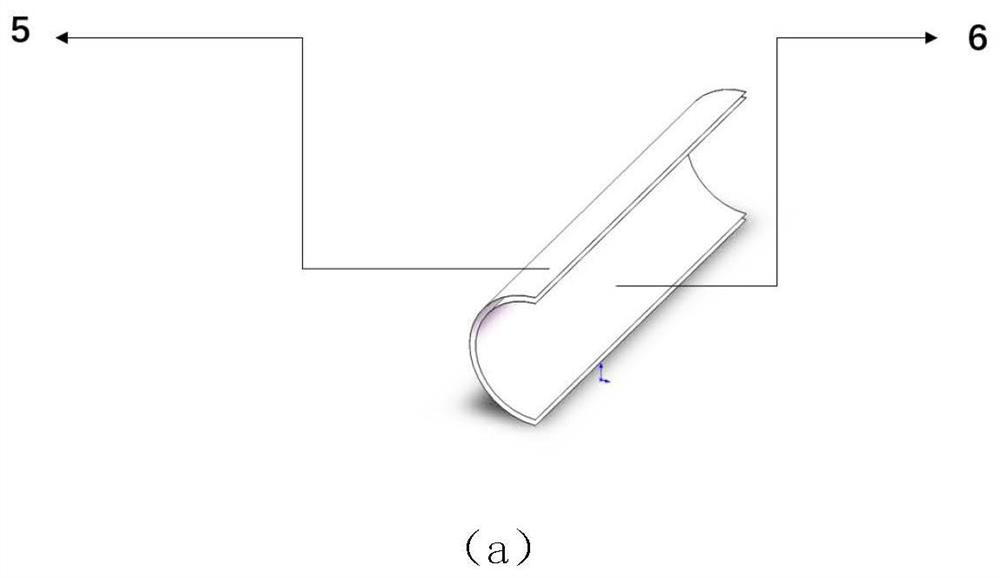

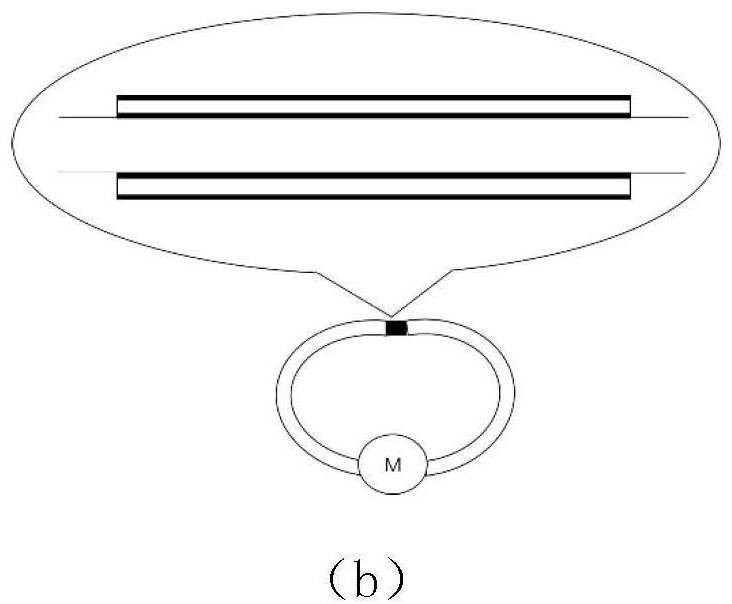

[0038] (1) Type 1: The inner pipe is not filled with liquid, and the system does not contain a fluid circulation device. The inner layer pipe adopts a pipe made of aluminum elements (because the thermal expansion coefficient of aluminum is relatively large, the pipe made of aluminum elements is more sensitive to temperature changes). It is also possible to use other inner layer pipes made of composite materials with larger thermal expansion coefficients and better electrical conductivity according to the specific working environment. The outer pipe is made of an alloy material composed of nickel (>8%), chromium (>18%), iron, carbon (0.1%) elements (both mass fractions) (small thermal expansion coefficient, moderate rigidity, and electrical conductivity) , the three add up to 100% quality. It is also possible to make exclusive external pipes of compatible materials according to different working environments. The ratio of length to diameter of the inner pipe is 50:1, and the ...

example 2

[0042] (1) Type 2: The inner nanotube is filled with liquid, and the system contains a fluid circulation device. The inner tube is made of aluminum elements and ceramics whose properties change along the radius. The outer material of the inner tube is aluminum and the inner material is ceramics (aluminum has a larger thermal expansion coefficient and is more sensitive to temperature changes, and the inner part is made of ceramics. To a certain heat insulation effect, so that the temperature of the fluid in the tube has the least influence on the temperature of the inner tube). It is also possible to use other inner layer pipes made of composite materials with larger thermal expansion coefficients and better electrical conductivity according to the specific working environment. The outer pipe is made of an alloy material composed of nickel (>8%), chromium (>18%), iron, carbon (0.1%) elements (both mass fractions) (small thermal expansion coefficient, moderate rigidity, and elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com