Ultraviolet cross-linked polyphosphazene, preparation method, composite coating low-temperature temperature measurement optical fiber and preparation method

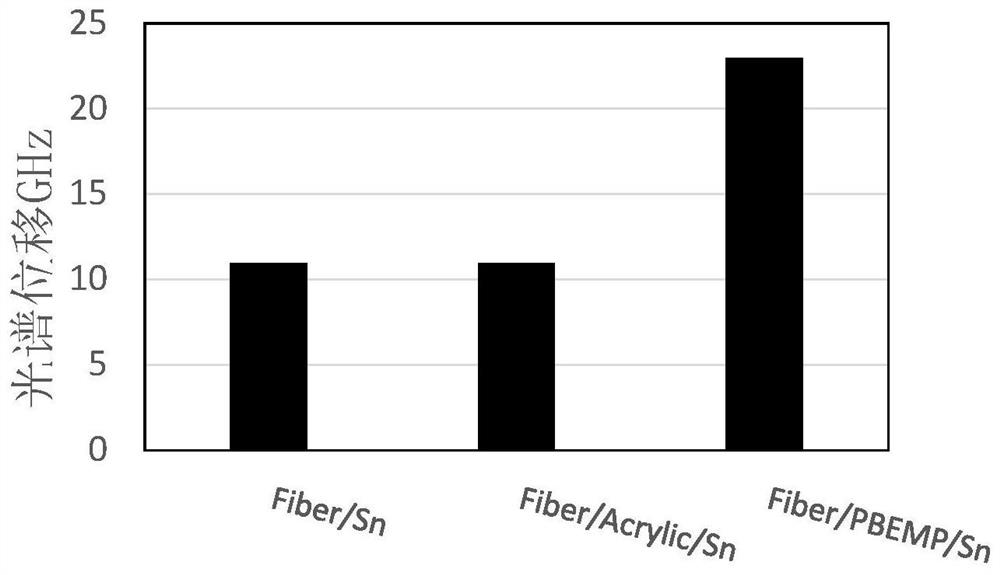

A temperature-measuring optical fiber and composite coating technology, which is applied in clad optical fiber, multi-layer core/clad optical fiber, coating, etc., can solve the problem of difficult to meet the temperature measurement requirements of high-temperature superconducting equipment and the interference of electrical signal sensors , optical fiber low-temperature sensitivity degradation and other issues, to avoid cracking and interface bonding force deterioration, no side reactions, good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment first prepares PBEMP, comprises the following process:

[0041] First, 0.05 mole of sodium butoxyalkoxide, 0.10 mole of sodium glycidoxyl alkoxide and 0.05 mole of sodium hydroxyethyl methacrylate were dissolved in 1000 ml of dry tetrahydrofuran solvent to prepare a nucleophilic substitution salt solution;

[0042] Subsequently, the above-mentioned salt solution was slowly added dropwise to 500 ml of dry tetrahydrofuran solution containing 0.1 mole of polydichlorophosphazene under ice-water bath conditions, and the reactants were stirred and reacted for 24 hours at room temperature and under nitrogen protection conditions; after the reaction, The reaction product is extracted and dried to obtain [N=P] n (OC 4 h 9 ) 0.25 (OCH 2 CHOCH 2 ) 0.50 (OCH 2 CH 2 OOCC (CH 3 )=CH 2 ) 0.25 , number average molecular weight M n >10000.

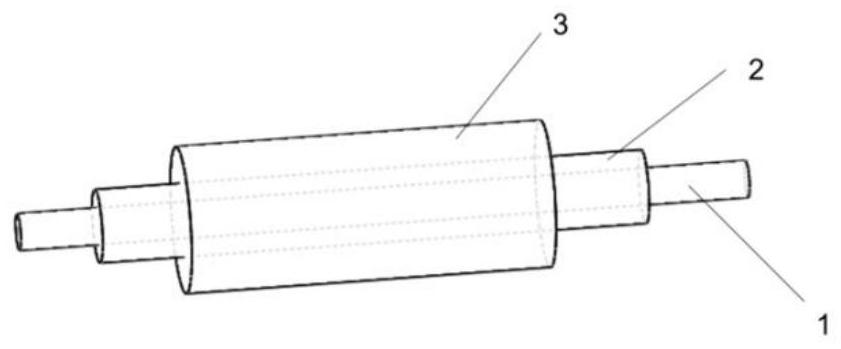

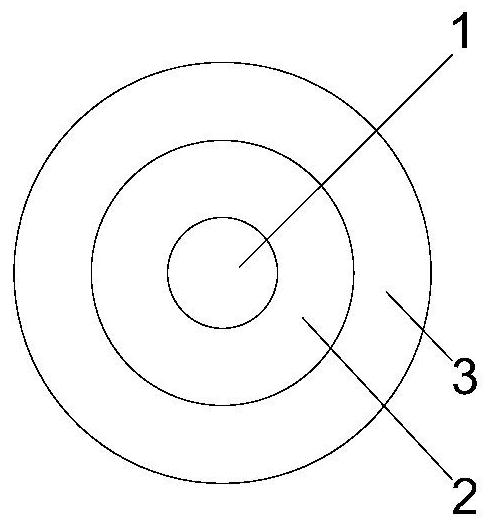

[0043] Next, PBEMP is used to make a composite coated cryogenic temperature measurement optical fiber, including the f...

Embodiment 2

[0049] This embodiment first prepares PBEMP, comprises the following process:

[0050] First, 0.10 mole of sodium butoxyalkoxide, 0.05 mole of sodium glycidoxyl alkoxide and 0.05 mole of sodium hydroxyethyl methacrylate were dissolved in 1000 ml of dry tetrahydrofuran solvent to prepare a nucleophilic substitution salt solution;

[0051] Subsequently, the above-mentioned salt solution was slowly added dropwise to 500 ml of dry tetrahydrofuran solution containing 0.1 mole of polydichlorophosphazene under ice-water bath conditions, and the reactants were stirred and reacted for 24 hours at room temperature and under nitrogen protection conditions; after the reaction, The reaction product is extracted and dried to obtain [N=P] n (OC 4 h 9 ) 0.50 (OCH 2 CHOCH 2 ) 0.25 (OCH 2 CH 2 OOCC (CH 3 )=CH 2 ) 0.25 , number average molecular weight M n >10000.

[0052] Next, PBEMP is used to make a composite coated cryogenic temperature measurement optical fiber, including the f...

Embodiment 3

[0057] This embodiment first prepares PBEMP, comprises the following process:

[0058] First, 0.09 mole of sodium butoxyalkoxide, 0.09 mole of sodium glycidoxyl alkoxide and 0.02 mole of sodium hydroxyethyl methacrylate were dissolved in 1000 ml of dry tetrahydrofuran solvent to prepare a nucleophilic substitution salt solution;

[0059] Subsequently, the above-mentioned salt solution was slowly added dropwise to 500 ml of dry tetrahydrofuran solution containing 0.1 mole of polydichlorophosphazene under ice-water bath conditions, and the reactants were stirred and reacted for 24 hours at room temperature and under nitrogen protection conditions; after the reaction, The reaction product is extracted and dried to obtain [N=P] n (OC 4 h 9 ) 0.45 (OCH 2 CHOCH 2 ) 0.45 (OCH 2 CH 2 OOCC (CH 3 )=CH 2 ) 0.10 , number average molecular weight M n >10000.

[0060] Next, PBEMP is used to make a composite coated cryogenic temperature measurement optical fiber, including the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com