Prepreg fiber cloth and preparation method thereof

A technology of fiber cloth and glass fiber cloth, which is applied in the field of prepreg fiber cloth and its preparation, can solve problems such as insufficient interlayer bonding force, and achieve the effect of excellent interlayer bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

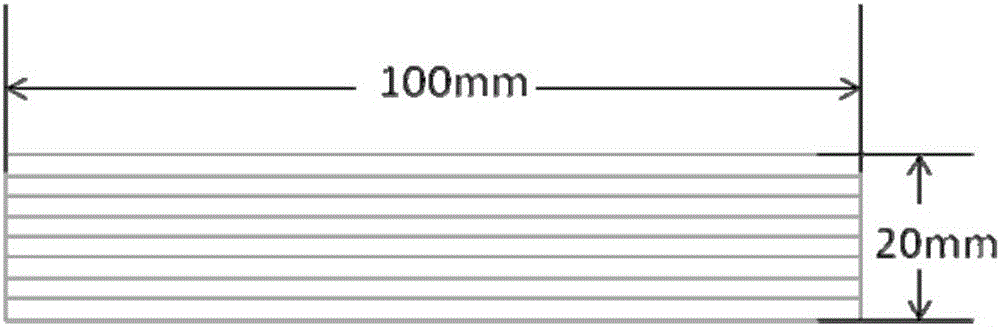

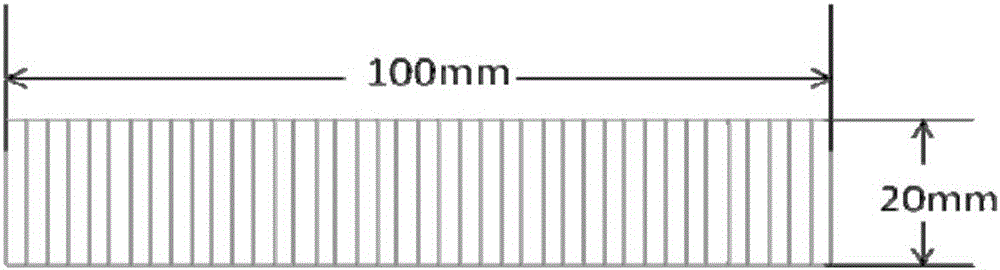

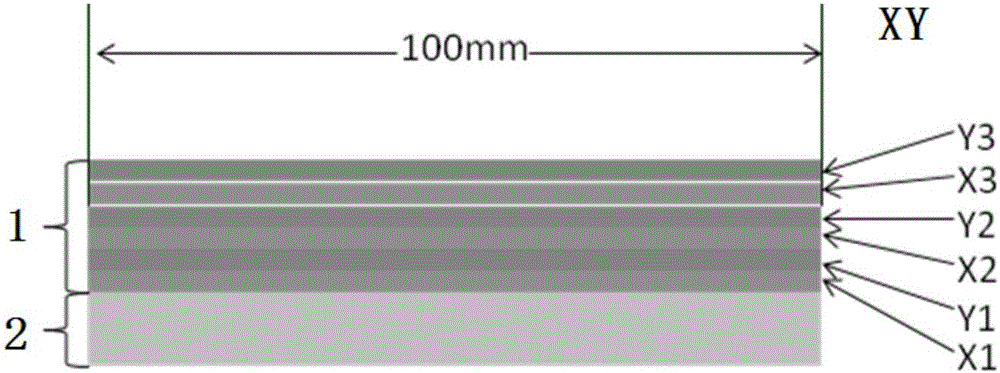

[0050] The present invention also provides a method for preparing prepreg fiber cloth, wherein the method is: in the presence of a magnetic field, impregnating a resin composition containing a thermosetting binder resin and magnetic chopped fibers into the fiber cloth , followed by heat curing.

[0051] In the preparation method of the prepreg fiber cloth of the present invention, since the impregnation of the resin composition is carried out in the presence of a magnetic field, the magnetic chopped fibers contained in the resin composition are all arranged in the same direction under the action of the magnetic field, In addition, since the cross-sectional diameter is small, it is easily inserted into the fiber cloth, so that in the obtained prepreg fiber cloth, the magnetic chopped fibers can have the first part inserted in the fiber cloth and fixed to the fiber cloth. The state of the second part exists in the resin bonding layer. In addition, the alignment direction of the...

Embodiment 1

[0083] 1) Prepare the pretreatment agent according to the ratio (mass ratio) of silane coupling agent: dispersant: ethanol = 1:3:100;

[0084] 2) Spray pretreatment agent on the surface of 4Kg magnetic chopped fiber (magnetic glass chopped fiber EMG-200, length is 200 μm, cross-sectional diameter is 10 μm), and dry to obtain pretreated fiber filament X;

[0085] 3) Weigh 48Kg of epoxy resin and 25Kg of reactive diluent, and disperse with a high-speed disperser (purchased from Shanghai Farfly Energy Co., Ltd., the same below) to obtain mixture A;

[0086] 4) Add the pretreated fiber filament X obtained in step 2) into mixture A, and disperse with a high-speed disperser to obtain mixture B;

[0087] 5) Weigh 15Kg of dicyandiamide (curing agent), 5Kg of 1-methylimidazole (curing accelerator), and 3Kg of defoamer, add them to mixture B, disperse with a high-speed disperser to obtain prepreg, and add fiber prepreg Dip tank;

[0088] 6) Place a magnet on the upper and lower ends o...

Embodiment 2

[0092] 1) Prepare the pretreatment agent according to the ratio (mass ratio) of silane coupling agent: dispersant: ethanol = 1:3:100;

[0093] 2) Spray a pretreatment agent on the surface of 8Kg magnetic chopped fibers (magnetic carbon chopped fibers DCMG-300, the length is 50 μm, and the cross-sectional diameter is 7 μm), and dry to obtain the pretreated fiber filament X;

[0094] 3) Take by weighing 75Kg of epoxy resin and 10Kg of reactive diluent, and disperse with a high-speed disperser to obtain mixture A;

[0095] 4) Add the pretreated fiber filament X obtained in step 2) into mixture A, and disperse with a high-speed disperser to obtain mixture B;

[0096] 5) Weigh 5Kg of dicyandiamide (curing agent), 0.7Kg of 1-methylimidazole (curing accelerator), and 1.3Kg of defoamer, add them to the mixture B, disperse with a high-speed disperser to obtain a prepreg, and add In the fiber prepreg tank;

[0097] 6) Place a magnet on the upper and lower ends of the fiber prepreg tan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com