Decomposition resistant ps conductive masterbatch

A masterbatch and raw material technology, applied in the field of decomposition-resistant PS conductive masterbatch, can solve the problems of product production and product quality defects, product stress cracking, inability to use antistatic products, etc., to broaden the application field, excellent high temperature resistance and Physical and mechanical properties, the effect of effective ESD protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

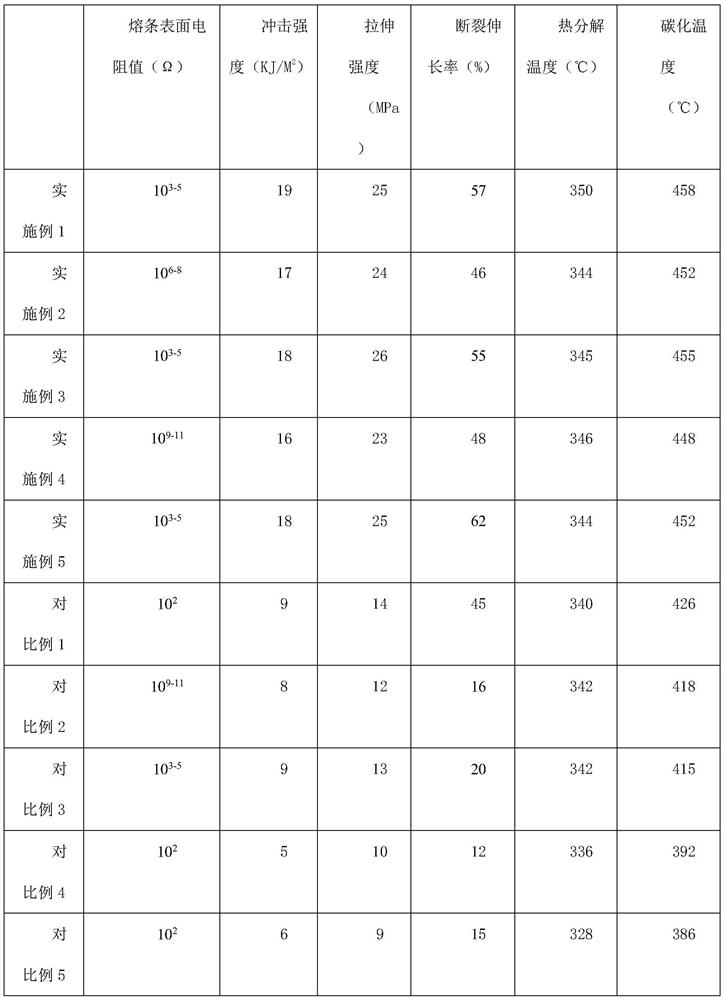

Examples

Embodiment 1

[0027] A decomposition-resistant PS conductive masterbatch, comprising the following raw materials in parts by weight: 10 parts of superconducting carbon black, 46 parts of high-impact polystyrene PS, a toughening agent (consisting of 10 parts of ethylene butyl acrylate and 15 parts of drawing grade polystyrene) ethylene compound) 25 parts, reinforcing agent (by CaCO 3 and SiO 2 According to the weight ratio of 1:1, 8 parts, 0.8 parts of vinyltriethoxysilane, 1.2 parts of antioxidants, 1 part of EBS, and 8 parts of EMA; the preparation method of the decomposition-resistant PS conductive masterbatch comprises the following steps :

[0028] S1, take by weighing each raw material according to the above-mentioned weight portion ratio;

[0029] S2, adding high-impact polystyrene PS, superconducting carbon black, reinforcing agent, coupling agent, antioxidant, EBS, EMA into the mixing equipment in turn and mixing at 50° C. for 20 minutes to obtain Mixture A;

[0030] S3, set the ...

Embodiment 2

[0033] A decomposition-resistant PS conductive masterbatch, comprising the following raw materials in parts by weight: 7 parts of superconducting carbon black, 52 parts of high-impact polystyrene PS, a toughening agent (consisting of 10 parts of ethylene butyl acrylate and 15 parts of drawing grade polystyrene) ethylene compound) 25 parts, reinforcing agent (by CaCO 3 and SiO 2 According to the weight ratio of 3:1, 7 parts, 0.4 part of coupling agent, 0.8 part of antioxidant, 0.8 part of EBS, 3 parts of EMA;

[0034] The preparation method of the decomposition-resistant PS conductive masterbatch comprises the following steps:

[0035] S1, take by weighing each raw material according to the above-mentioned weight portion ratio;

[0036]S2, adding high-impact polystyrene PS, superconducting carbon black, reinforcing agent, coupling agent, antioxidant, EBS, and EMA into the mixing equipment in turn and mixing at 55° C. for 30 minutes to obtain Mixture A;

[0037] S3, set the t...

Embodiment 3

[0040] A decomposition-resistant PS conductive masterbatch, comprising the following raw materials in parts by weight: 10 parts of superconducting carbon black, 53 parts of high-impact polystyrene PS, a toughening agent (made of 8 parts of ethylene butyl acrylate and 17 parts of drawing grade polystyrene) ethylene compound) 25 parts, reinforcing agent (by CaCO 3 and SiO 2 According to the weight ratio of 4:1, 6 parts, 0.3 part of coupling agent, 1 part of antioxidant, 0.7 part of EBS, 4 parts of EMA;

[0041] The preparation method of the decomposition-resistant PS conductive masterbatch comprises the following steps:

[0042] S1, take by weighing each raw material according to the above-mentioned weight portion ratio;

[0043] S2. Add high-impact polystyrene PS, superconducting carbon black, reinforcing agent, coupling agent, antioxidant, EBS, and EMA to the mixing equipment in turn and mix at 60° C. for 15 minutes to obtain Mixture A;

[0044] S3, set the temperature of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com