TEMPO oxidized nanocellulose-based composite hydrogel and preparation method thereof

A technology of nanocellulose and composite hydrogel, which is applied in the field of polymer materials, can solve problems such as poor mechanical properties and usability, hinder development, and single function, and achieve improved mechanical properties and usability, improved mechanical strength, and good adhesion. Adjunctive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

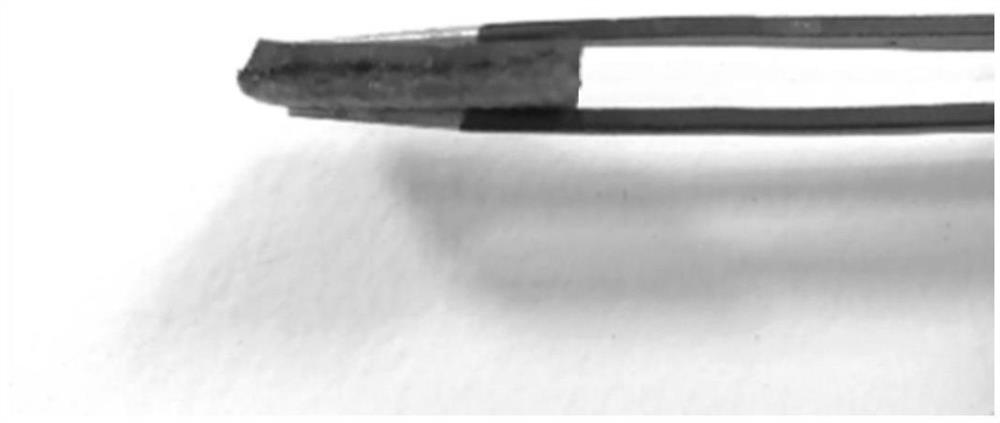

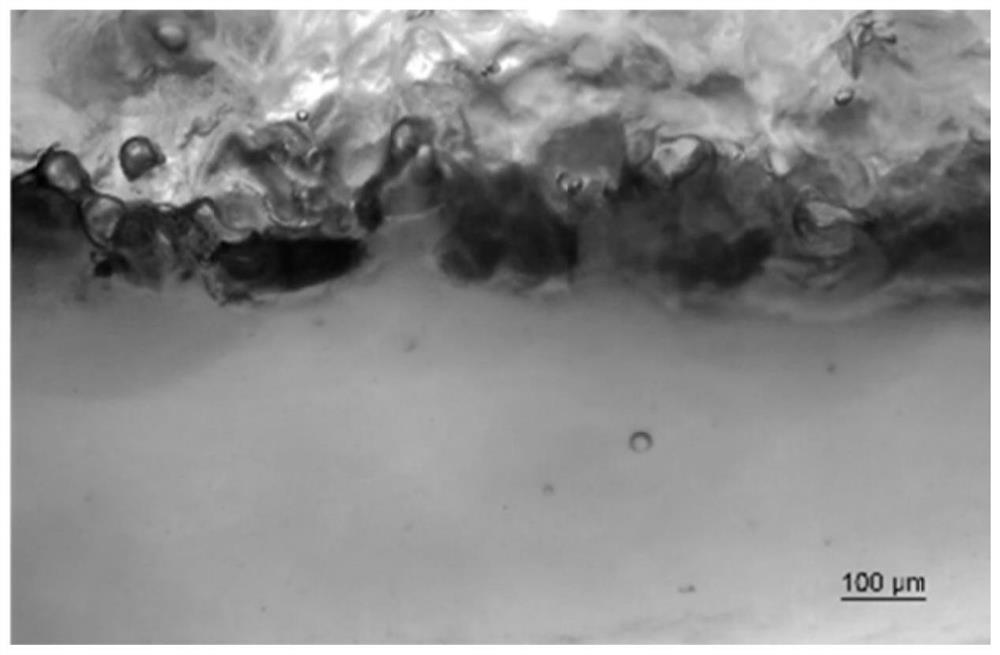

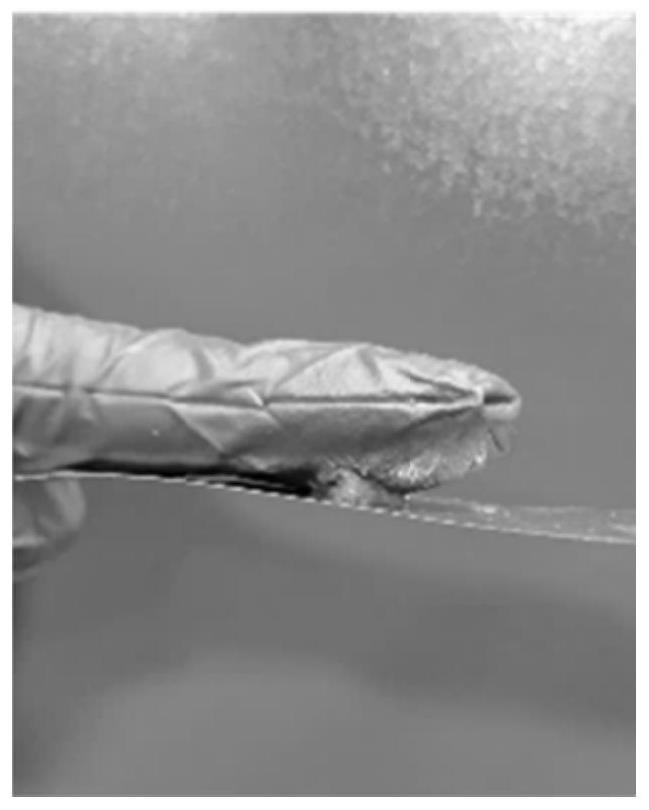

Image

Examples

preparation example Construction

[0036] The present invention is a preparation method of polyvinyl alcohol / chitosan / TEMPO oxidized nanocellulose-polyvinyl alcohol composite hydrogel with a double-layer structure, and its main raw material is the nanocellulose in TEMPO oxidized nanocellulose as a reserve on the earth The most abundant natural polymer cellulose derivative, with the advantages of renewable, wide source, good biocompatibility and degradability, is considered to be the most attractive sustainable green material in the 21st century; it consists of deacetylation unit (D-glucosamine) and chitosan composed of acetylated units (N-acetyl-D-glucosamine), a large number of hydrophilic groups such as amino and hydroxyl groups on the main chain can be used as cross-linking sites. An ideal hydrogel raw material; polyvinyl alcohol, abbreviated as PVA, is a water-soluble polymer material, and the abundant hydroxyl groups on the main chain make it have a large number of hydrogen bond interactions in the molecule...

Embodiment 1

[0046]Step 1, join 0.2g chitosan and 0.8g polyvinyl alcohol in the 1% (v / v) acetic acid solution of 7g, make the mass fraction of chitosan be 2.5%, the mass fraction of polyvinyl alcohol be 10 %, stirred at 85°C for 4h to dissolve completely, and cooled to room temperature to prepare polyvinyl alcohol / chitosan mixed solution;

[0047] Step 2, adding 7g of TEMPO oxidized nanocellulose solution with a mass fraction of 5wt% to the mixed solution prepared in step 1, stirring at room temperature for 1h, to obtain polyvinyl alcohol / chitosan / TEMPO oxidized nanocellulose with a single network structure Cellulose hybrid hydrogel;

[0048] Step 3, the mixed hydrogel obtained in step 2 was placed at -20°C, frozen for 1 hour, poured 5 g of polyvinyl alcohol solution with a mass fraction of 10 wt % on its surface, and placed at -20°C to continue freezing for 12 hours. After 12 hours, it was placed at room temperature to thaw naturally, and a polyvinyl alcohol / chitosan / TEMPO oxidized nanoc...

Embodiment 2

[0050] Step 1, join 0.03g chitosan and 0.48g polyvinyl alcohol in the 0.1% (v / v) acetic acid solution of 5.49g, make the massfraction of chitosan be 0.5%, the massfraction of polyvinyl alcohol is 8%, stirred at 85°C for 5h to dissolve completely, cooled to room temperature to prepare polyvinyl alcohol / chitosan mixed solution;

[0051] Step 2, adding 9g of TEMPO oxidized nanocellulose solution with a mass fraction of 4.5wt% to the mixed solution prepared in step 1, stirring at room temperature for 0.5h, to obtain polyvinyl alcohol / chitosan / TEMPO with a single network structure Oxidized nanocellulose hybrid hydrogel;

[0052] Step 3, the mixed hydrogel obtained in step 2 was placed at -25°C, frozen for 1.5h, poured 6g of polyvinyl alcohol solution with a mass fraction of 10wt% on its surface, and placed at -25°C to continue freezing for 14h. After 14 hours, it was placed at room temperature to thaw naturally, and a polyvinyl alcohol / chitosan / TEMPO oxidized nanocellulose-polyvin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com