Steel-titanium composite plate and preparation method thereof

A composite plate and titanium plate technology, applied in metal rolling, temperature control, etc., can solve the problems of high price, difficult manufacturing, high cost, etc., and achieve low manufacturing cost, high thickness control precision, and strong interlayer bonding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

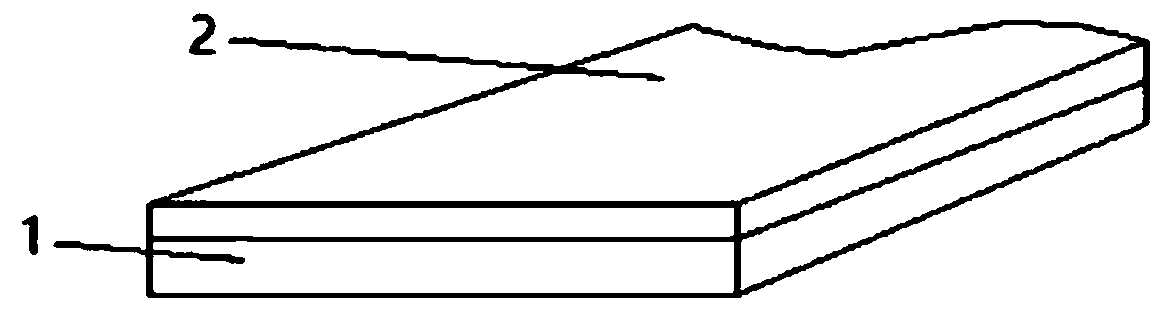

[0023] refer to figure 1 , a steel-titanium composite plate, comprising a steel plate base 1, at least one of the upper and lower surfaces of the steel plate base 1 is compounded with a titanium plate 2, the steel plate base 1 is specifically a carbon steel coil, and the carbon steel The thickness of the strip is 1.0-6.0mm, and the width is 300-1250mm. The carbon steel strip is hot-rolled or cold-rolled carbon steel strip, using high-quality carbon structural steel substrate strip and low-alloy high-strength structural steel strip One of them, carbon steel coils can also be used but not limited to the grades listed in the Chinese National Standard GB / T3274-2017 and the Chinese National Standard GB / T711-2008.

[0024] The thickness of the titanium plate layer 2 is 0.2-2.0 mm, and the width is 300-1250 mm. The preparation process of the titanium plate layer 2:

[0025] A. Select titanium block, zinc block, magnesium block, molybdenum block and copper block, and the weight ratio...

Embodiment 2

[0034] refer to figure 1 , a steel-titanium composite plate, comprising a steel plate base 1, at least one of the upper and lower surfaces of the steel plate base 1 is compounded with a titanium plate 2, the steel plate base 1 is specifically a carbon steel coil, and the carbon steel The thickness of the strip is 1.0-6.0mm, and the width is 300-1250mm. The carbon steel strip is hot-rolled or cold-rolled carbon steel strip, using high-quality carbon structural steel substrate strip and low-alloy high-strength structural steel strip One of them, carbon steel coils can also be used but not limited to the grades listed in the Chinese National Standard GB / T3274-2017 and the Chinese National Standard GB / T711-2008.

[0035] The thickness of the titanium plate layer 2 is 0.2-2.0 mm, and the width is 300-1250 mm. The preparation process of the titanium plate layer 2:

[0036] A. Select titanium block, zinc block, magnesium block, molybdenum block and copper block, and the weight ratio...

Embodiment 3

[0045] refer to figure 1 , a steel-titanium composite plate, comprising a steel plate base 1, at least one of the upper and lower surfaces of the steel plate base 1 is compounded with a titanium plate 2, the steel plate base 1 is specifically a carbon steel coil, and the carbon steel The thickness of the strip is 1.0-6.0mm, and the width is 300-1250mm. The carbon steel strip is hot-rolled or cold-rolled carbon steel strip, using high-quality carbon structural steel substrate strip and low-alloy high-strength structural steel strip One of them, carbon steel coils can also be used but not limited to the grades listed in the Chinese National Standard GB / T3274-2017 and the Chinese National Standard GB / T711-2008.

[0046] The thickness of the titanium plate layer 2 is 0.2-2.0 mm, and the width is 300-1250 mm. The preparation process of the titanium plate layer 2:

[0047] A. Select titanium block, zinc block, magnesium block, molybdenum block and copper block, and the weight ratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com