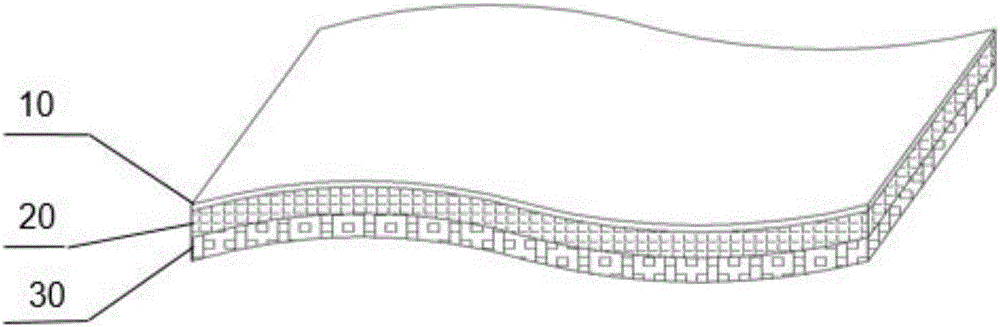

Flexible heat preservation and heat insulation film and preparation method thereof

A thermal insulation and flexible technology, applied in the field of thermal insulation materials, can solve the problems of protection plate protection and thermal insulation deterioration, low density of the protective plate, small thermal conductivity, etc., to achieve the suppression of solid heat conduction, firm interlayer bonding, and thermal insulation performance Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1, 1. Using hydrochloric acid as a catalyst, monomethyltriethoxysilane (MTES) and dimethyldiethoxysilane (DDS) as organic phase precursors, orthoethyl silicate (TEOS) as inorganic Phase precursor, prepare SiO2 / organic silicon coating material according to the process of sol-gel-aging-drying in Sol-Gel method.

[0031] 2. Shred the SiO2 / organic silicon coating material, screen out particles with a diameter less than 4mm, and mix it with the organic silicon resin at a volume ratio of 1:0.5, and use ultrasonic vibration to make it completely mixed to make a uniform dispersion coating material.

[0032] 3. Immerse the 1mm PET plastic film in a degreasing solution prepared with a certain concentration of sodium carbonate, sodium bicarbonate and disodium hydrogen phosphate for 15 minutes to remove oil, then rinse it with distilled water, and then put a certain concentration of sodium hydroxide Roughen in the roughening solution prepared with glycerol for 55 minutes, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com