A kind of nano-microporous thermal insulation material and preparation method thereof

A technology of thermal insulation and nano-micropores, which is applied in the field of thermal insulation materials, can solve problems such as low strength, easy to open and absorb water, and poor stability, and achieve improved thermal insulation capabilities, enhanced thermal insulation performance, and good thermal insulation performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

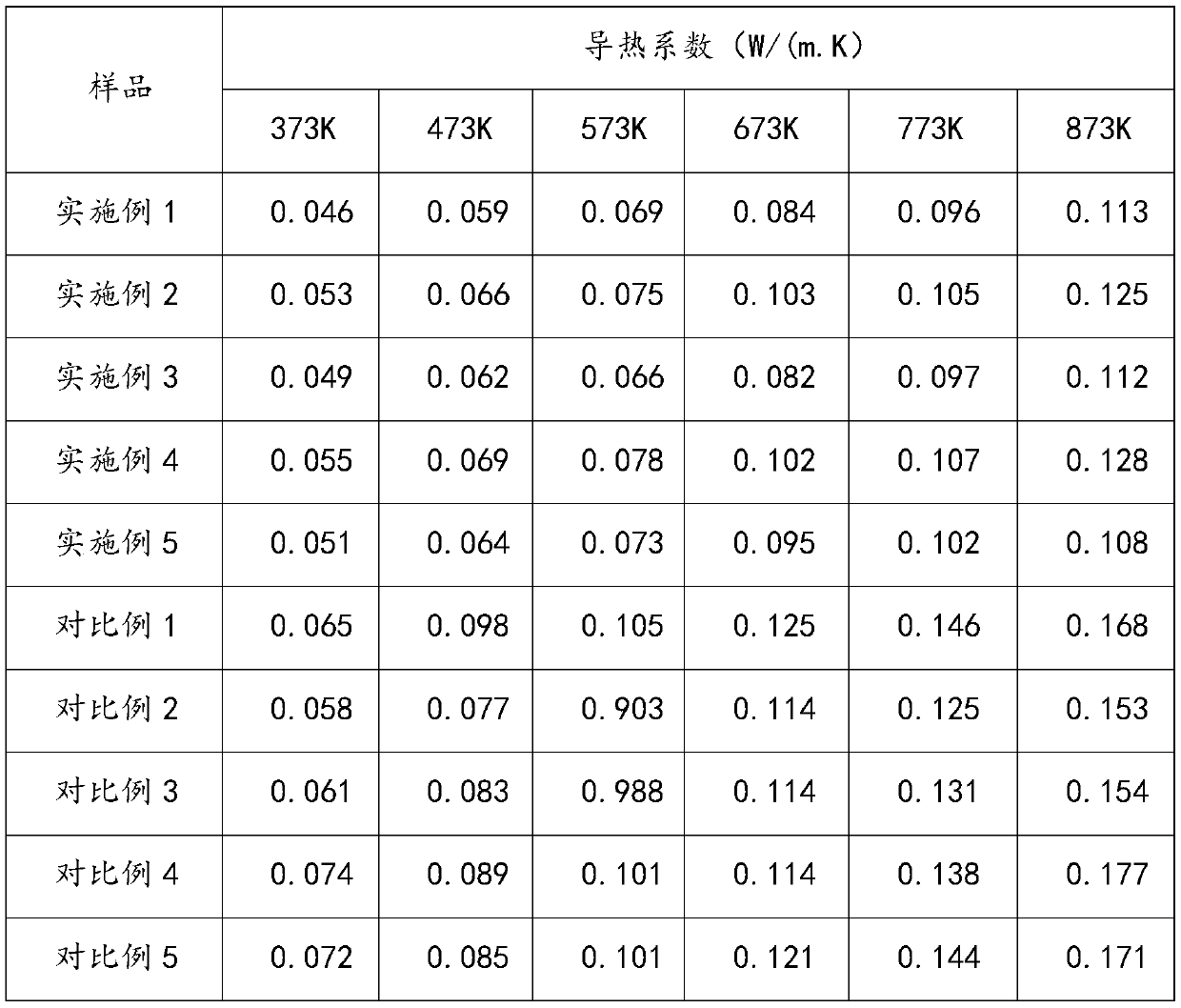

Examples

Embodiment 1

[0041] The nano-microporous thermal insulation material of the present embodiment includes a porous base layer and a thermal insulation layer attached to the surface of the base layer. The base layer is composed of the following raw materials in parts by weight: 28 parts of polymer hollow microspheres, paraffin wax / porous perlite- 1 part of urea-formaldehyde resin phase-change microcapsules, 11 parts of nano-alumina hollow spheres, 5 parts of nano-silica sol, and 3 parts of aluminum silicate fibers;

[0042] The heat insulating layer is composed of the following raw materials in parts by weight: 44 parts of silica airgel, 14 parts of modified starch, 4 parts of hollow microspheres, 10 parts of nano-titanium oxide, 3 parts of mullite whiskers, foaming 2 doses.

[0043] Wherein, the polymer hollow microspheres are polystyrene hollow microspheres with a particle diameter of 0.2-0.6 μm.

[0044] Wherein, the phase change material in the paraffin wax / porous perlite-urea formaldehy...

Embodiment 2

[0060] The nano-microporous thermal insulation material of the present embodiment includes a porous base layer and a thermal insulation layer attached to the surface of the base layer. The base layer is composed of the following raw materials in parts by weight: 36 parts of polymer hollow microspheres, paraffin wax / porous perlite- 5 parts of urea-formaldehyde resin phase-change microcapsules, 19 parts of nano-alumina hollow spheres, 12 parts of nano-silica sol, and 7 parts of aluminum silicate fibers;

[0061] The heat insulating layer is composed of the following raw materials in parts by weight: 54 parts of silica airgel, 18 parts of modified starch, 8 parts of hollow microspheres, 16 parts of nano-titanium oxide, 5 parts of mullite whiskers, foaming 4 doses.

[0062] Wherein, the polymer hollow microspheres are polystyrene hollow microspheres with a particle diameter of 0.2-0.6 μm.

[0063] Wherein, the phase change material in the paraffin wax / porous perlite-urea formalde...

Embodiment 3

[0079] The nano-microporous thermal insulation material of the present embodiment includes a porous base layer and a thermal insulation layer attached to the surface of the base layer. The base layer is composed of the following raw materials in parts by weight: 32 parts of polymer hollow microspheres, paraffin wax / porous perlite- 3 parts of urea-formaldehyde resin phase-change microcapsules, 15 parts of nano-alumina hollow spheres, 8.5 parts of nano-silica sol, and 5 parts of aluminum silicate fibers;

[0080] The heat insulating layer is composed of the following raw materials in parts by weight: 49 parts of silica airgel, 16 parts of modified starch, 6 parts of hollow microspheres, 13 parts of nano-titanium oxide, 4 parts of mullite whiskers, foam 3 doses.

[0081] Wherein, the polymer hollow microspheres are polystyrene hollow microspheres with a particle diameter of 0.2-0.6 μm.

[0082] Wherein, the phase change material in the paraffin wax / porous perlite-urea formaldehy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com