Patents

Literature

41results about How to "Realize thermal insulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

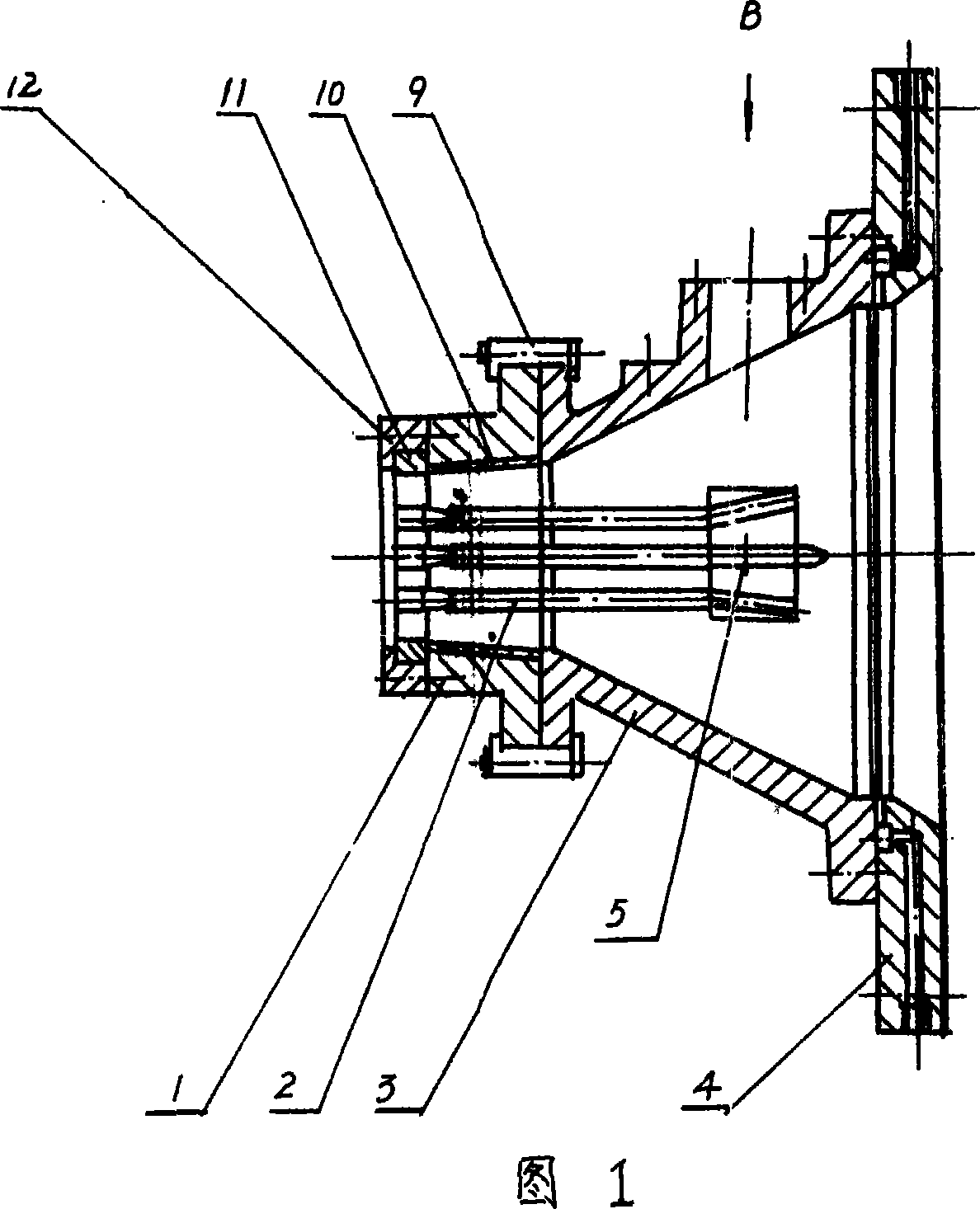

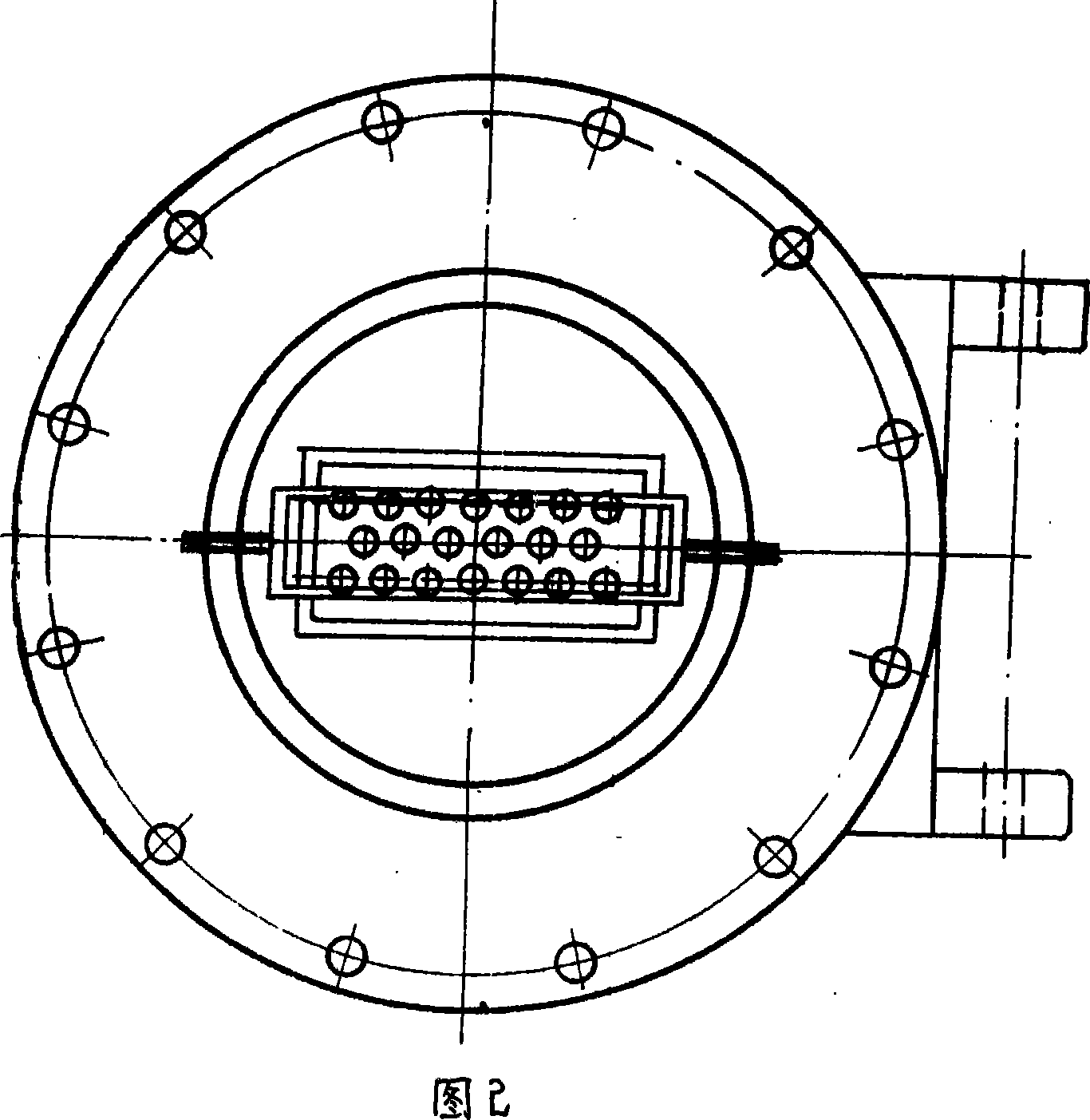

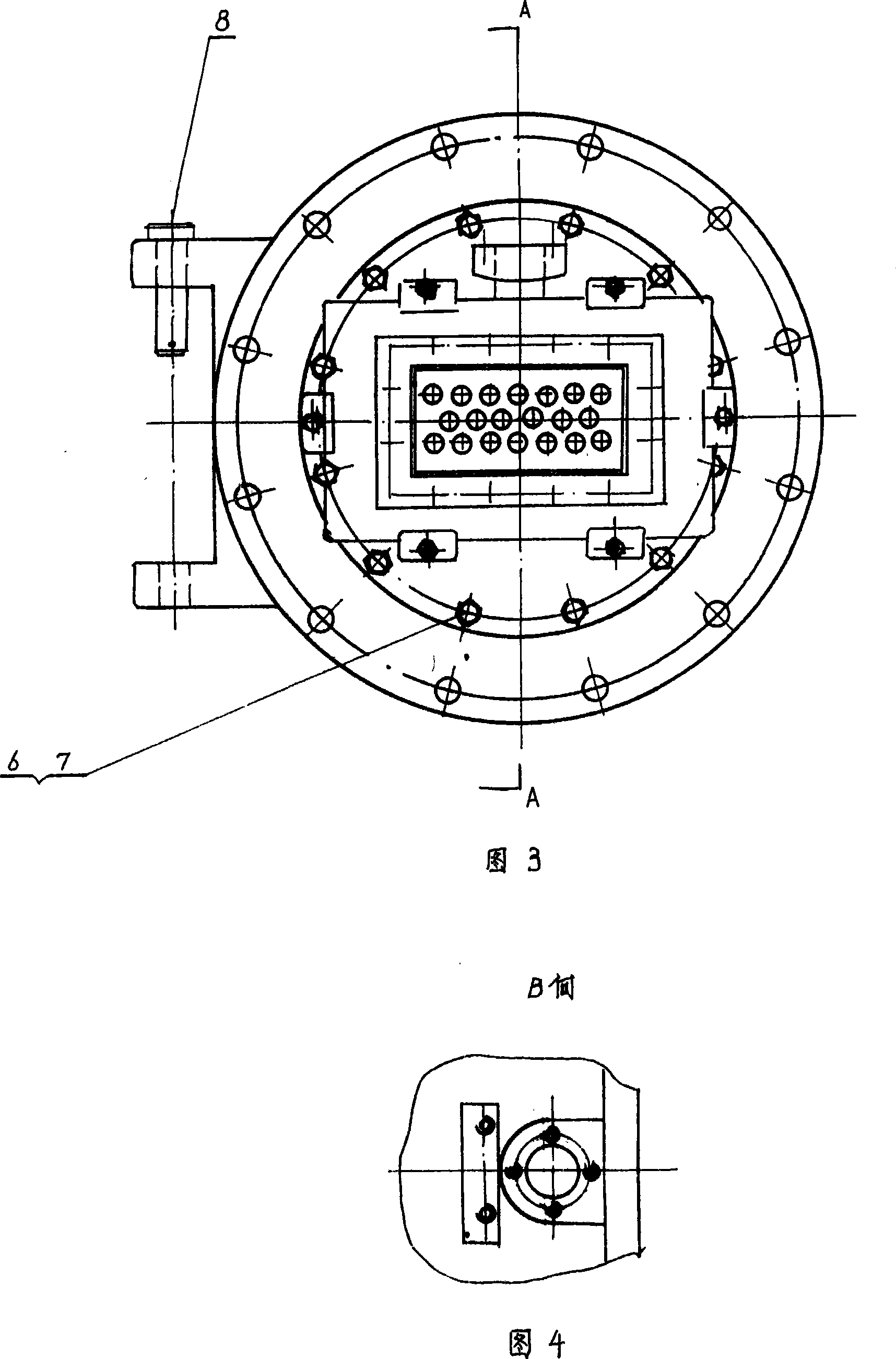

Sintered horizontal hole building block forming mould

InactiveCN101104291AGood effectPromote healthy developmentMouldsCeramic extrusion diesBrickButt joint

Disclosed is a sintered horizontal-hole concrete block die, which belongs to the technical field of building material machinery. The invention comprises a machine mouth component, a core rack component, a machine head and an oil distributing disk, wherein the machine mouth is connected with a butt-joint flange of the machine head by a fixing block; the machine head is connected with the oil distributing disk by bolts to integrate the machine mouth component, the machine head and the oil distributing disk; the core rack component, which is nested in the cavity of the machine head, is axially fixed with the inner concave shoulder platform arranged at two sides of the inner wall of the machine head and the bolts adjust horizontally to ensure the concentricity and fixation. The technical characteristics of the invention are that, first of all , the invention is applicable to the Chinese condition, which means that firstly, the invention is applicable to the condition of current technology of the sintered brick vacuum extruder so that the combination of technology and the conversion of product can be achieved directly; secondly, the invention is applicable to the properties of various non-clay materials in our country so that the work process of soil-saving and waste-utilizing can be accelerated.

Owner:程玉全

Thermal coating special for building exterior wall and preparing method of coating

The invention discloses a thermal coating special for a building exterior wall. The thermal coating is prepared from, by weight, 20-30 parts of acrylic emulsion, 15-25 parts of novolac epoxy, 12-18 parts of modified talc powder, 4-9 parts of attapulgite, 5-11 parts of titanium dioxide, 3-7 parts of hollow glass beads, 6-10 parts of silicon dioxide gel, 2-4 parts of nano titanium dioxide, 1-3 partsof lignocellulose, 2-3 parts of dispersing agent, 1-4 parts of coalescing agent and 30-40 parts of deionized water. The thermal coating is excellent in performance, saves energy and protects the environment, can form effective protection on the surface of a coated base material, and is high in decoration property, low in energy consumption, resistant to fire and combustion, capable of insulatingand preserving heat and long in service life.

Owner:合肥天沃能源科技有限公司

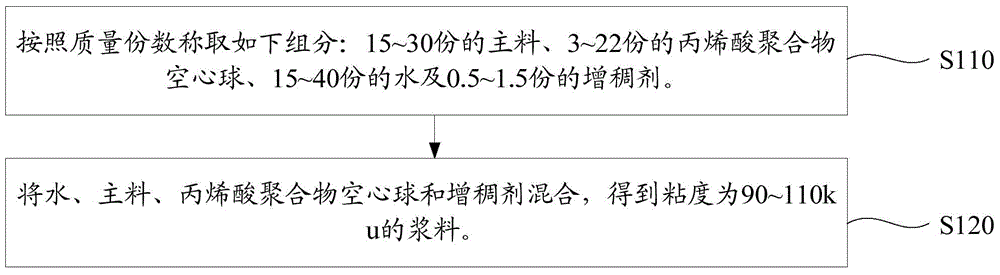

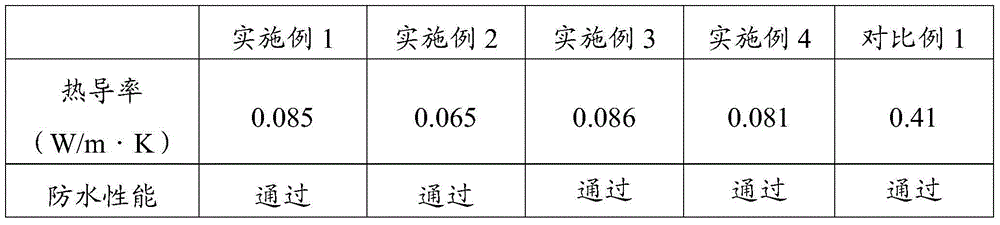

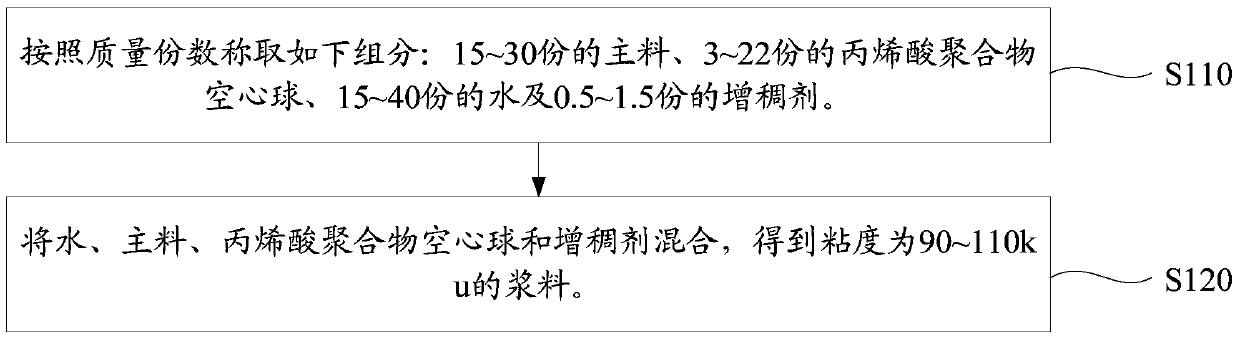

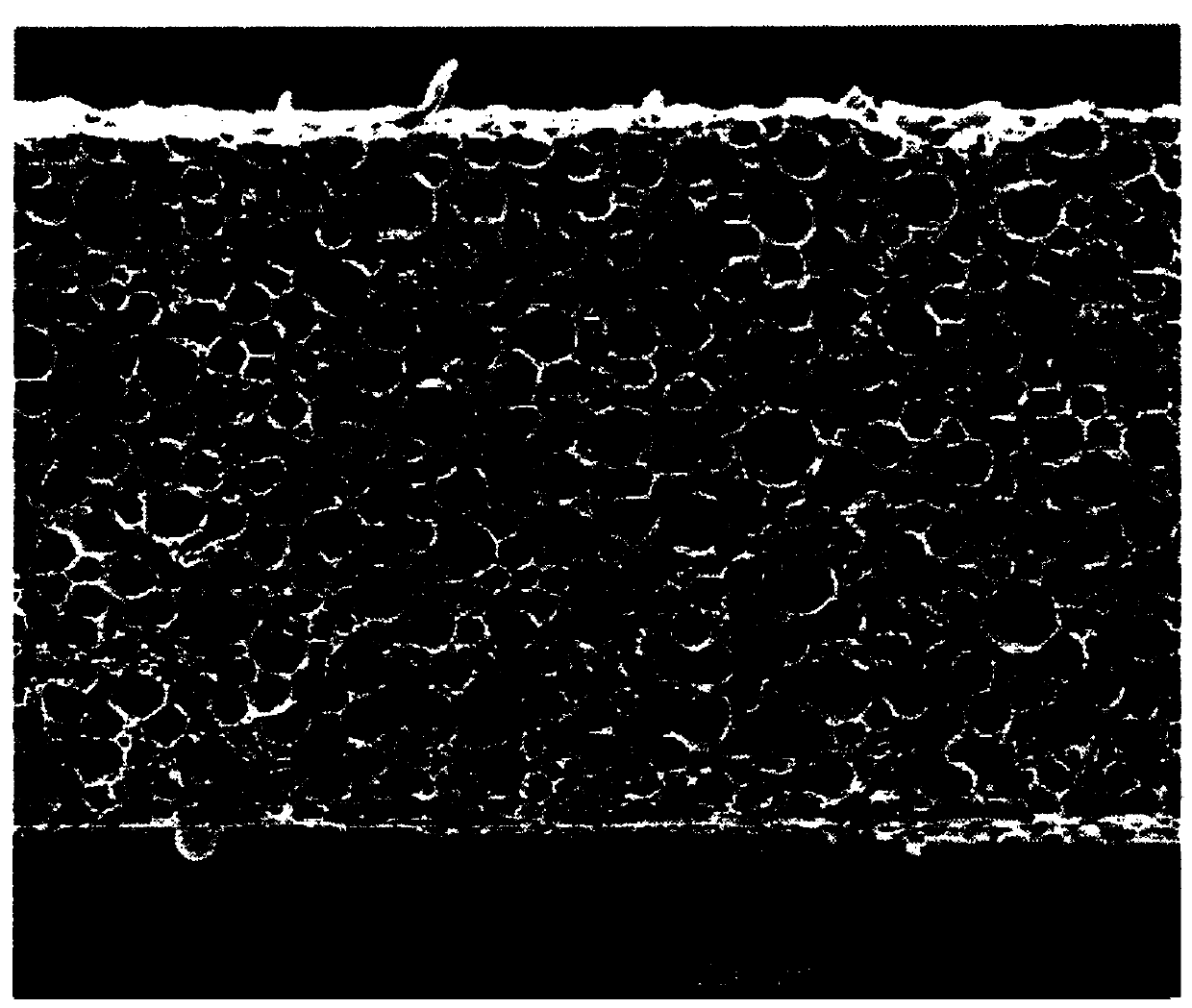

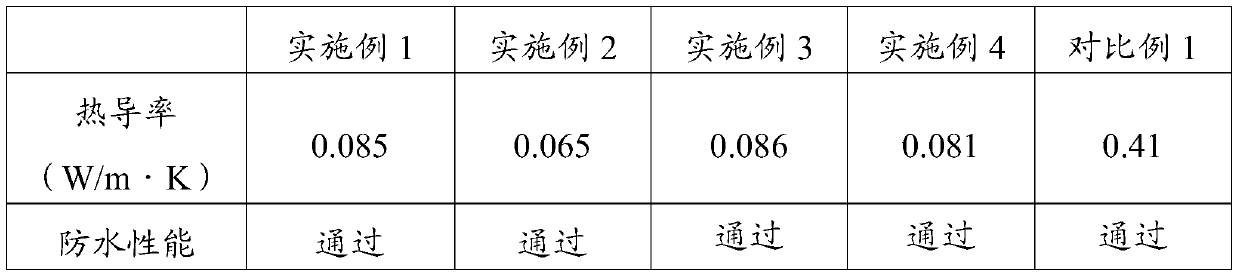

Thermal insulation paint and preparation method thereof and thermal insulation coating

ActiveCN106147442ARealize thermal insulationImprove waterproof performancePolyurea/polyurethane coatingsVitrificationPolymer science

The invention relates to thermal insulation paint and a preparation method thereof and a thermal insulation coating. The thermal insulation paint is prepared from, by mass, 15-30 parts of main ingredient, 3-22 parts of acrylic polymer hollow spheres, 15-40 parts of water and 0.5-1.5 parts of thickener, wherein the main ingredient is polymer resin of which the elastic elongation ratio is 800% or above, and the glass transition temperature is below -10 DEG C. The thermal insulation paint is good in thermal insulation effect.

Owner:和平县长丰环保新材料有限公司

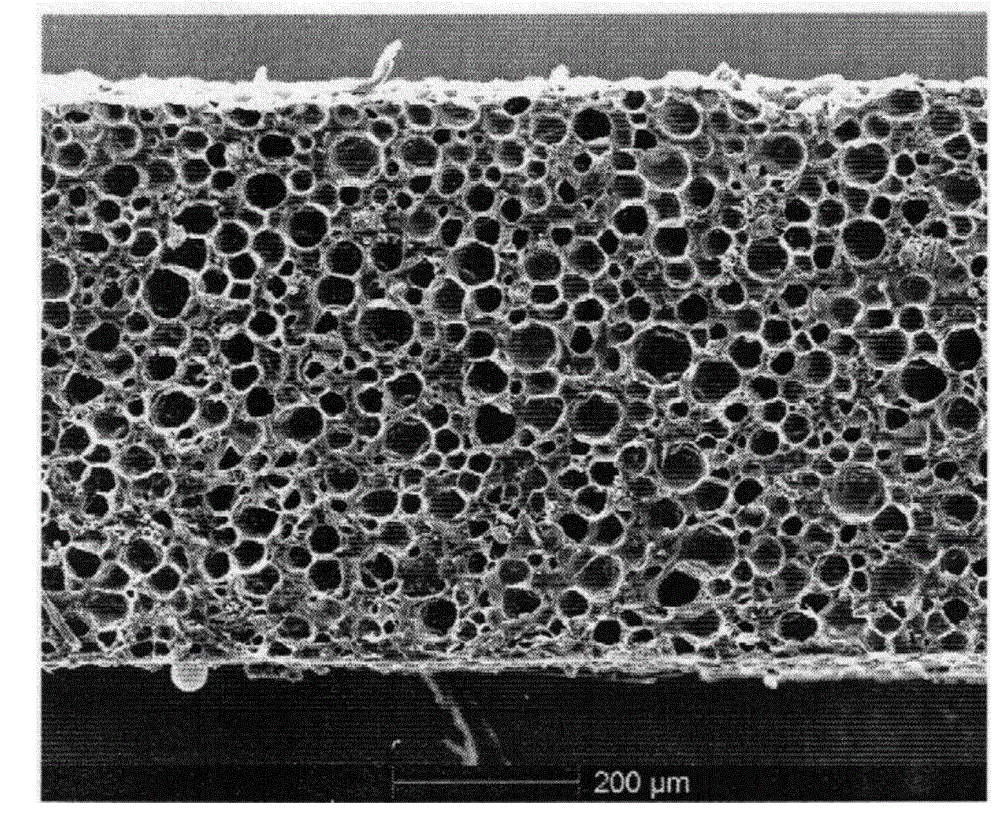

Nano-microporous thermal insulation material and preparation method thereof

The invention relates to a nano-microporous thermal insulation material, which includes a porous base layer and a heat insulation layer attached to the surface of the base layer. The base layer consists of the following raw materials by weight: 28-36 parts of polymer hollow microspheres, 1-5 parts of paraffin / porous perlite-urea-formaldehyde resin phase change microcapsules, 11-19 parts of nano-alumina hollow spheres, 5-12 parts of nano-silica sol, and 3-7 parts of alumina silicate fiber. The heat insulation layer is composed of the following raw materials by weight: 44-54 parts of silica aerogel, 14-18 parts of modified starch, 4-8 parts of hollow microspheres, 10-16 parts of nano-titanium oxide, 3-5 parts of mullite whisker, and 2-4 parts of a foaming agent. The nano-microporous thermalinsulation material provided by the invention has good heat insulation performance and high strength, does not shrink easily, and can meet the heat insulation requirements of building walls.

Owner:龙元明筑科技有限责任公司

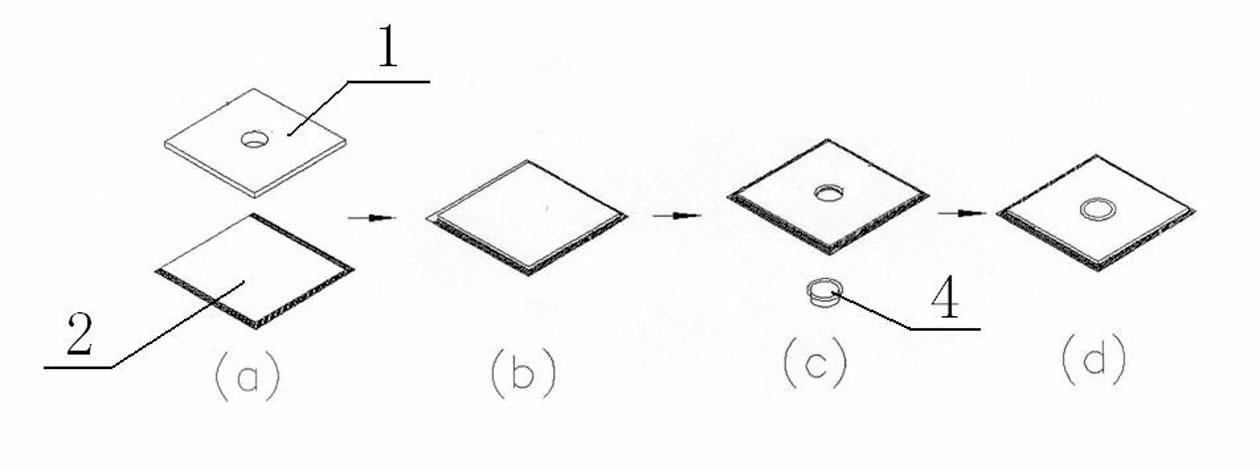

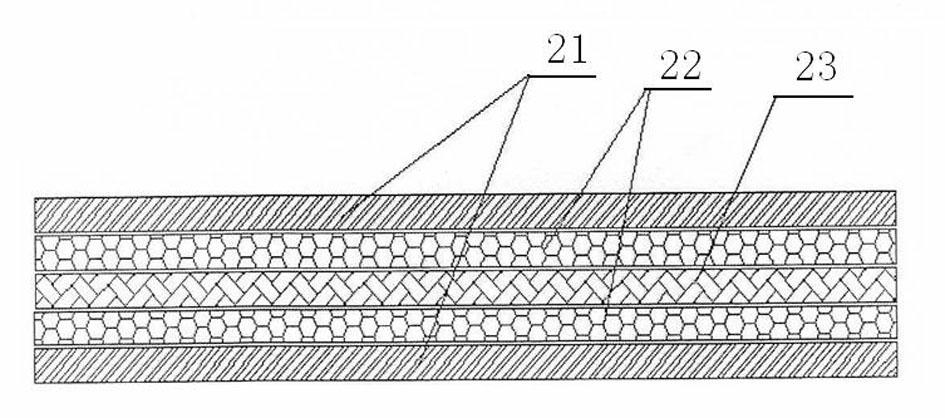

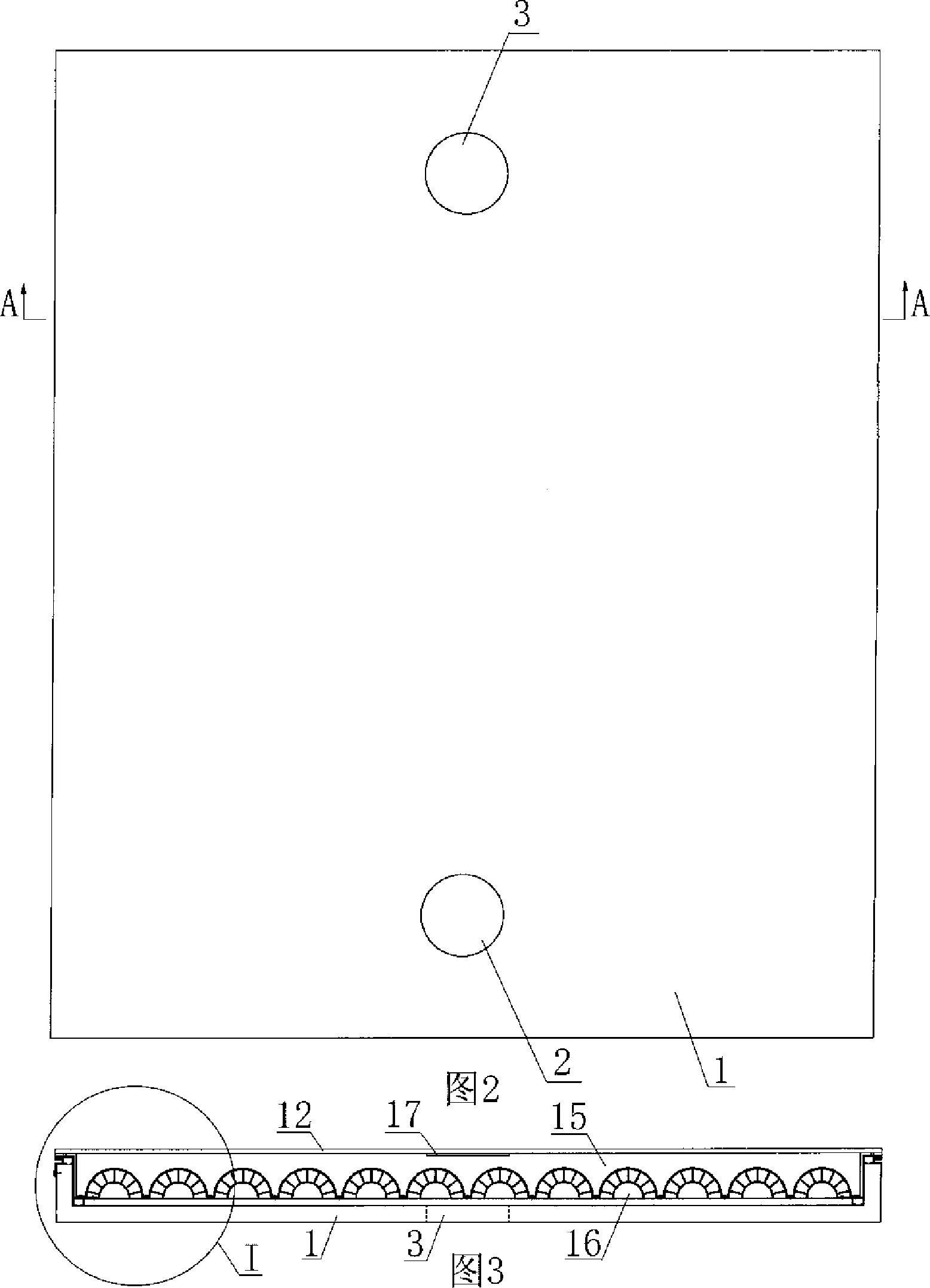

Glass fiber vacuum insulating plate with holes and manufacturing method thereof

InactiveCN102095048ASolve the problem that high insulation materials cannot be usedRealize thermal insulationThermal insulationPipesGlass fiberMoisture barrier

The invention discloses a glass fiber vacuum insulating plate with holes. The vacuum insulating plate disclosed by the invention comprises a core material with holes and moisture barriers, wherein the moisture barriers are covered on the upper and lower surfaces of the core material; the circumference and perforation position of the core material are provided with sealing sides formed by the moisture barriers; and a clamp slot for protecting the sealing sides is sheathed outside the sealing sides in the perforation position of the core material. The vacuum insulating plate disclosed by the invention can be used in places with holes where pipelines or other devices need to be installed, and wires or pipelines pass through the holes reserved on the vacuum insulating plate, thereby expanding the service range of the vacuum insulating plate, and solving the problem that a wall surface can not be made from high thermal insulating materials because of the holes.

Owner:SUZHOU V I P NEW MATERIAL

Solar energy air heat-collecting heat-preserving decorative wall plate

InactiveCN101109193ABreak through the blind area of integrated developmentConducive to industrial mass productionRoof covering using slabs/sheetsRoof covering using tiles/slatesFlat glassBuilding integration

A decorative heat-preserved wall board with solar and air heat collection is provided, which comprises a back board, a panel, a rim and an inner cavity. The back board is a shallow box-like heat-preservation sandwich board, an air inlet is provided at the lower part of the box bottom, an air outlet is provided at the upper part of the box bottom, at the air outlet, a solar fan is installed. The power supply of the fan is a solar photovoltaic power generating board at inner side at front of the panel. The panel is a flat glass. Between the panel and the back board, the rim is connected. On the rim, some concave ports for connecting are provided. In the inner cavity enclosed by the panel, back board and the rim, a corrugated heat-absorbing board is fixedly connected on the inner bottom side of the shallow box-like heat-preservation sandwich board. The outer surface of the corrugated heat-absorbing board is provided with a heat-absorbing coating. The inner wall of the corrugated heat-absorbing board is connected with heat-exchanging fins. The inside of the corrugated heat-absorbing board forms a heat-exchanging cavity, which is communicated with the air inlet and the air outlet. The invention greatly reduces the cost of the wall board integrating solar with a building, is easy to maintain, improves the service life and is easy to spread and apply in large area.

Owner:杜德利

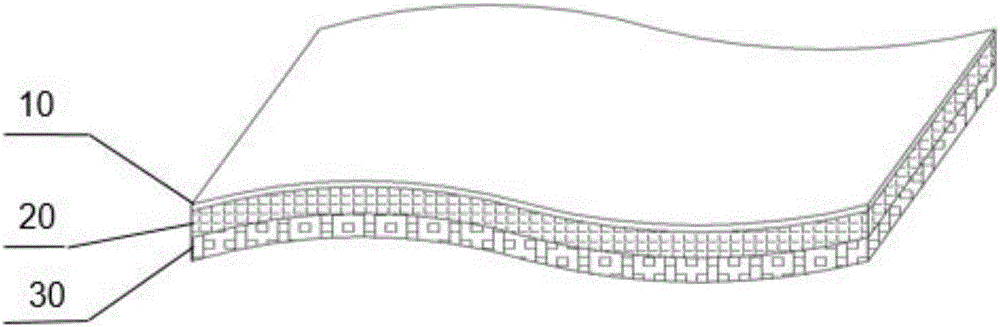

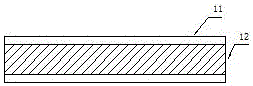

Flexible heat preservation and heat insulation film and preparation method thereof

InactiveCN106042550ARealize thermal insulationAvoid heat conductionSynthetic resin layered productsCoatingsThermal insulationReflective layer

The invention discloses a flexible heat preservation and heat insulation film. The flexible heat preservation and heat insulation film is characterized in that a PE protective film, a PET plastic thin film and an aerogel coating are included; the outer surface of the PE protective film is provided with an aluminum film reflecting layer; the PET plastic thin film is arranged between the PE protective film and the aerogel coating. According to the flexible heat preservation and heat insulation film, the aerogel coating serves as a main function achieving layer for heat preservation and heat insulation, a nano porous structure can effectively inhibit gas heat conduction and solid heat conduction, and therefore the heat insulation performance is efficient; the aluminum reflecting layer can overcome the defect that aerogel cannot inhibit radiation heat conduction, so that the material achieves heat preservation and heat insulation comprehensively; the thickness of the flexible heat preservation and heat insulation film is only a few millimeters, and therefore the flexible heat preservation and heat insulation film can adapt to multiple complex geometrical shapes and mechanical and thermal property requirements; interlayer bonding is firm, and the service life is long.

Owner:SUZHOU JUNYUE NEW MATERIAL TECH

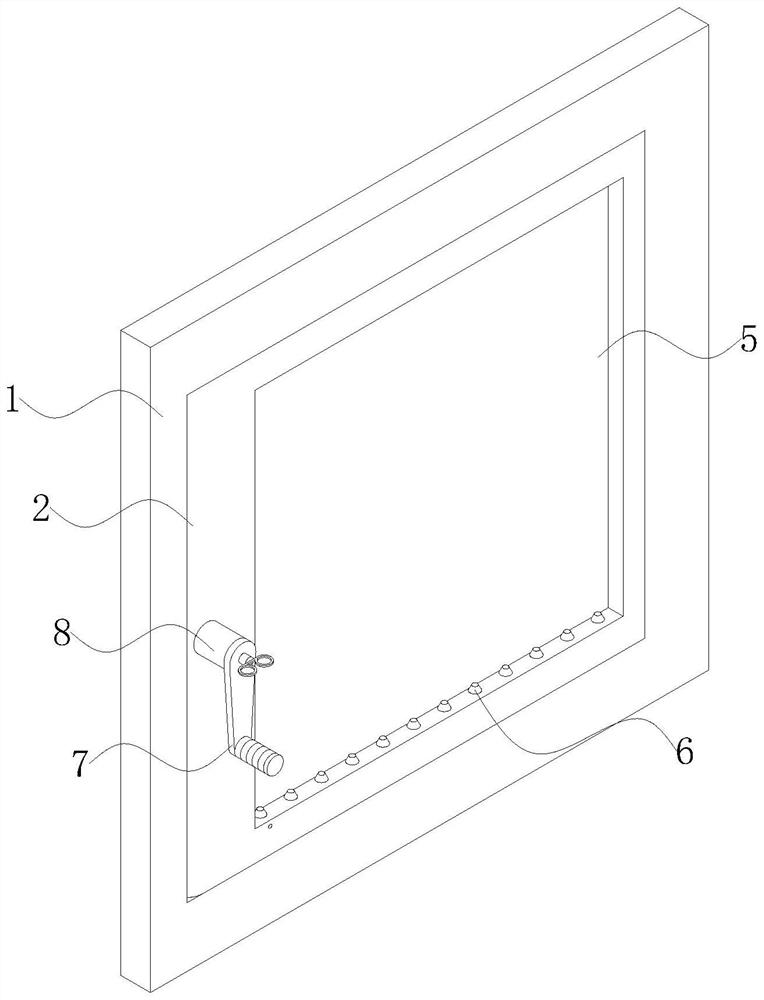

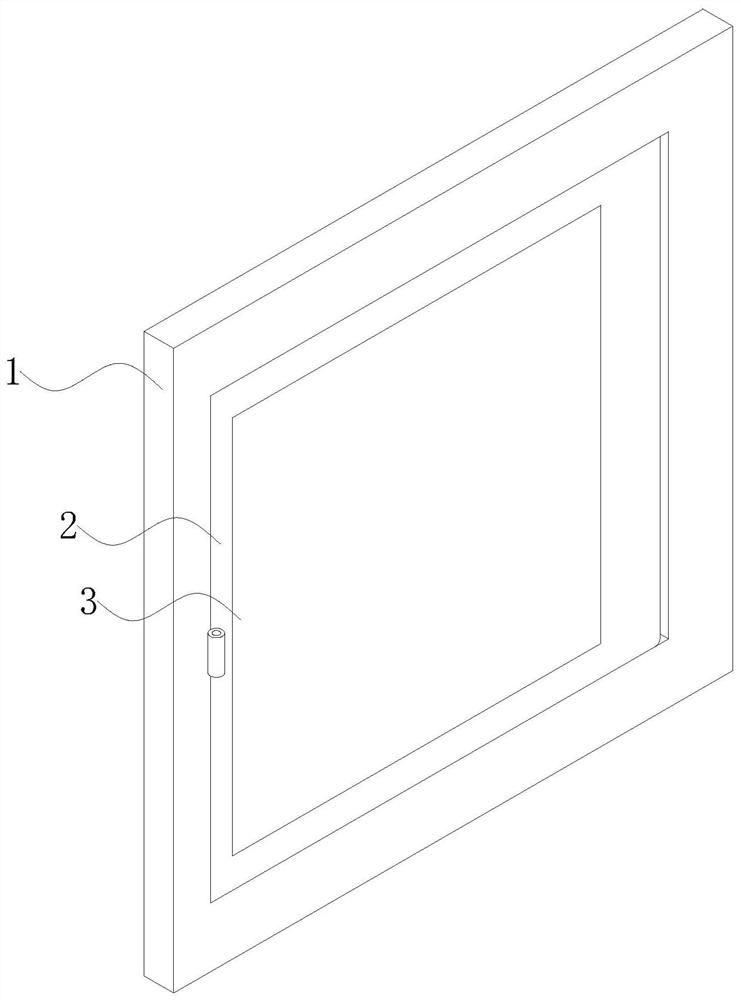

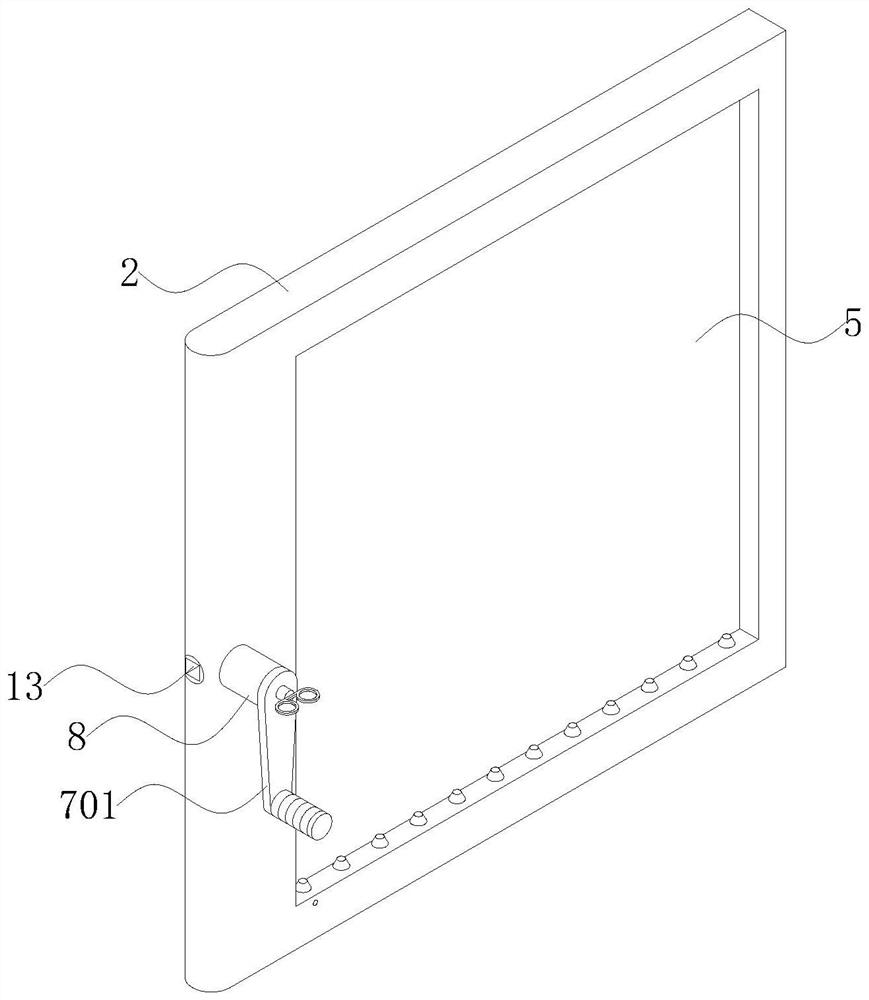

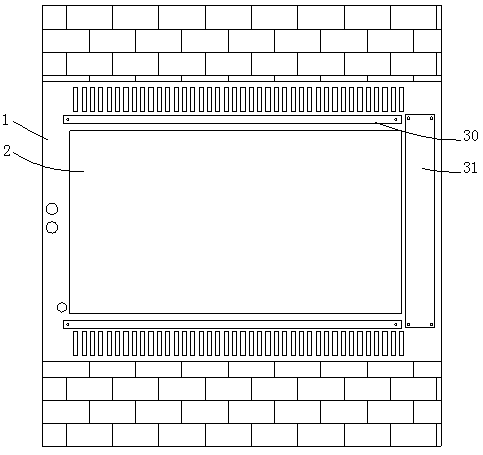

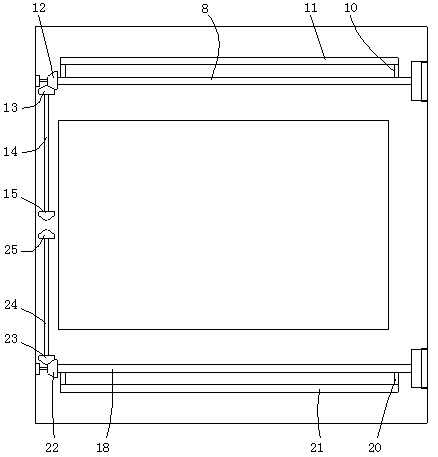

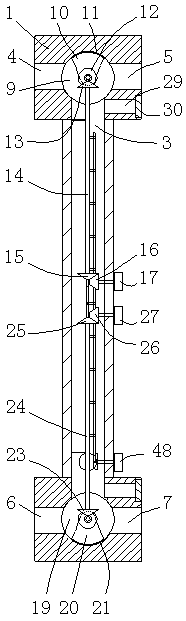

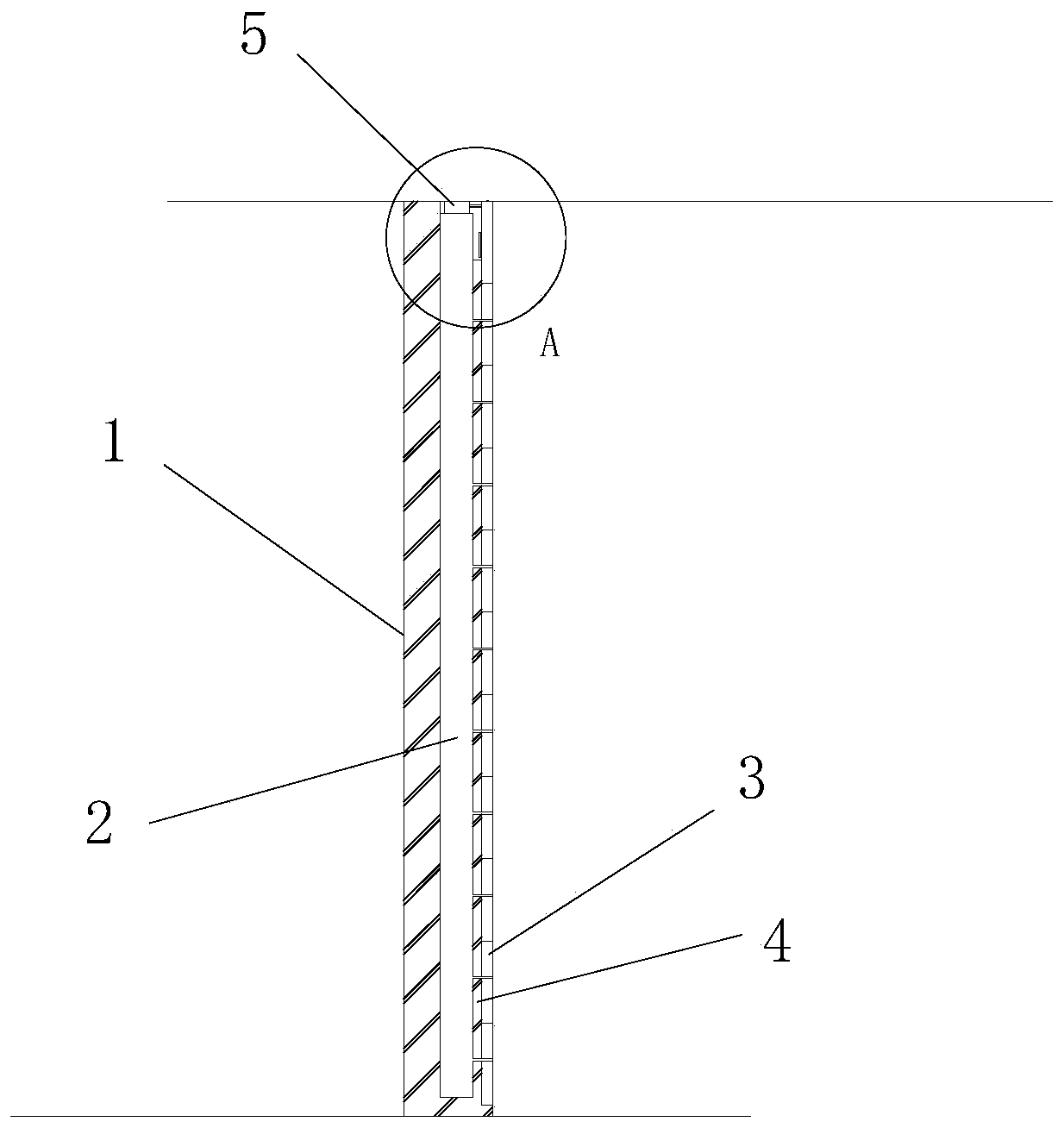

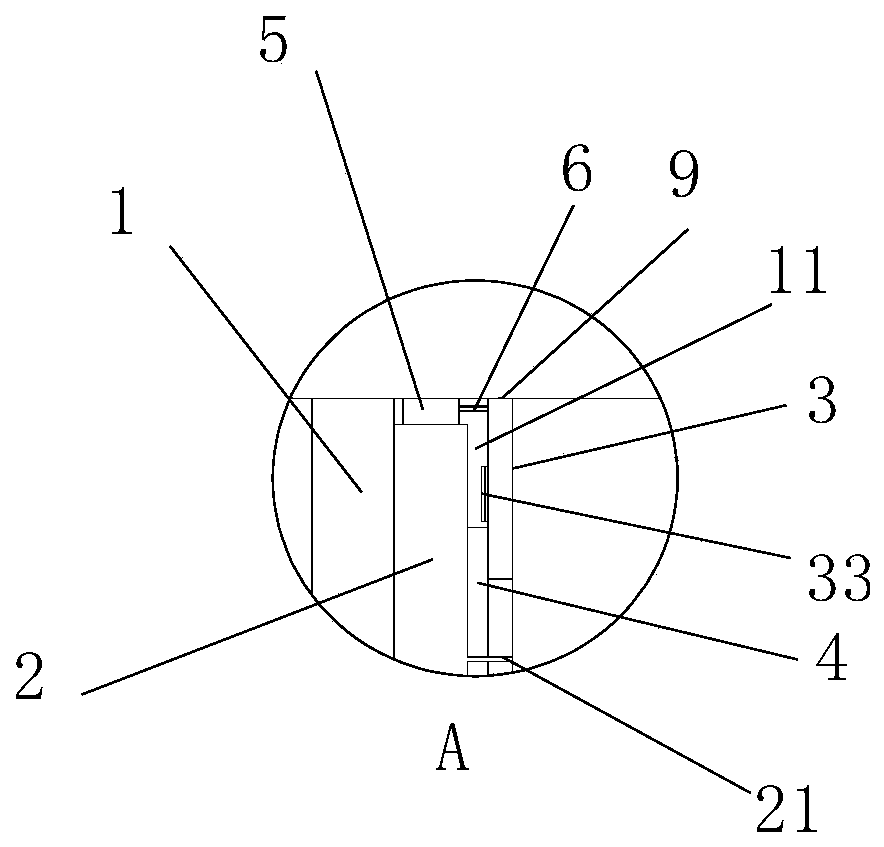

Heat preservation and insulation aluminum alloy door and window

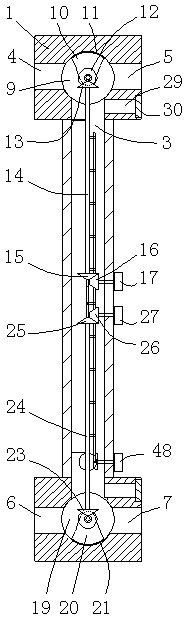

InactiveCN112761494ARealize thermal insulationAvoid heat exchangeFireproof doorsClimate change adaptationDrive shaftEngineering

The invention provides a heat preservation and insulation aluminum alloy door and window. The heat preservation and insulation aluminum alloy door and window comprises a door frame, wherein a window body is arranged in the door frame, the middle of one side of the back face of the window body is hinged to the door frame through a hinge, a first open groove is formed in the front face of the window body and is close to the hinge, a second open groove is formed in the back face of the window body, one side of the second open groove communicates with the first open groove, and a transparent plate is fixedly arranged on the other side of the first open groove. According to the heat preservation and insulation aluminum alloy door and window, a handle is arranged and can drive a transmission shaft to rotate, and then a driving mechanism can operate; under the effect of the driving mechanism, a piston can be extruded to move in a limiting groove, a first gas one-way valve is matched, along with downward moving of the extruded piston, gas in an interlayer can be sucked into the limiting groove, and therefore the interlayer is in a vacuum state; and through the vacuum state of the interlayer, indoor and outdoor heat exchange can be stopped, and heat preservation and insulation of the aluminum alloy door and window are achieved.

Owner:成都广艺云智能装备科技有限公司

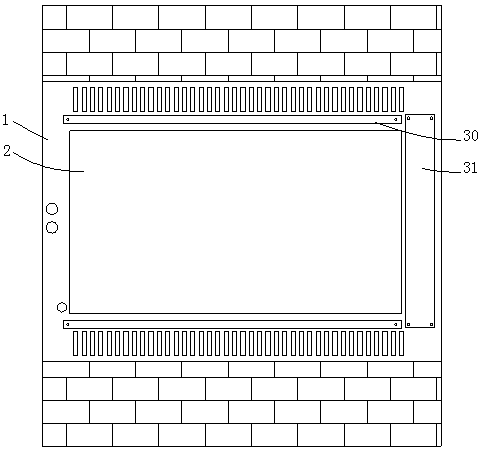

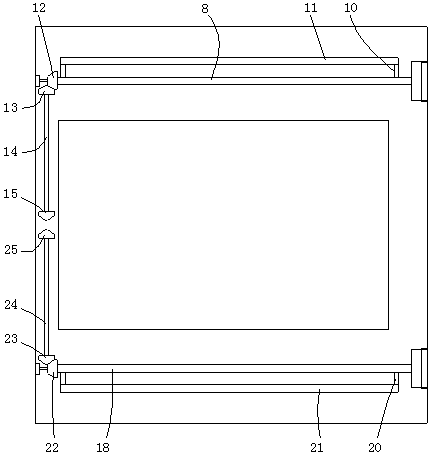

Air conditioner room ventilation control method based on blower and ventilation window

ActiveCN111021913AAvoid taking awayReduce indoor heat loadVentilation arrangementLight protection screensFresh airHeat conservation

The invention discloses an air conditioner room ventilation control method based on a blower and a ventilation window. The glass window is provided with double layers of glass, and a ventilation cavity is formed between the two layers of glass; a shutter device is arranged in the ventilation cavity to divide the ventilation cavity into an inner side ventilation cavity and an outer side ventilationcavity; and room ventilation is realized through control according to a summer indoor cooling ventilation mode and a winter indoor heating ventilation mode. By adopting the air conditioner room ventilation control method, the double layers of glass can serve as a ventilation passage, so that requirements on the amount of indoor fresh air can be met; reflection heat radiation can be also adjusted,so that indoor heat preservation and insulation can be better realized; indoor air conditioner energy consumption is better lowered; and the conditioner room ventilation control method further has the advantage that cleaning of the inner parts of the double layers of glass can be conveniently realized.

Owner:CHONGQING UNIV

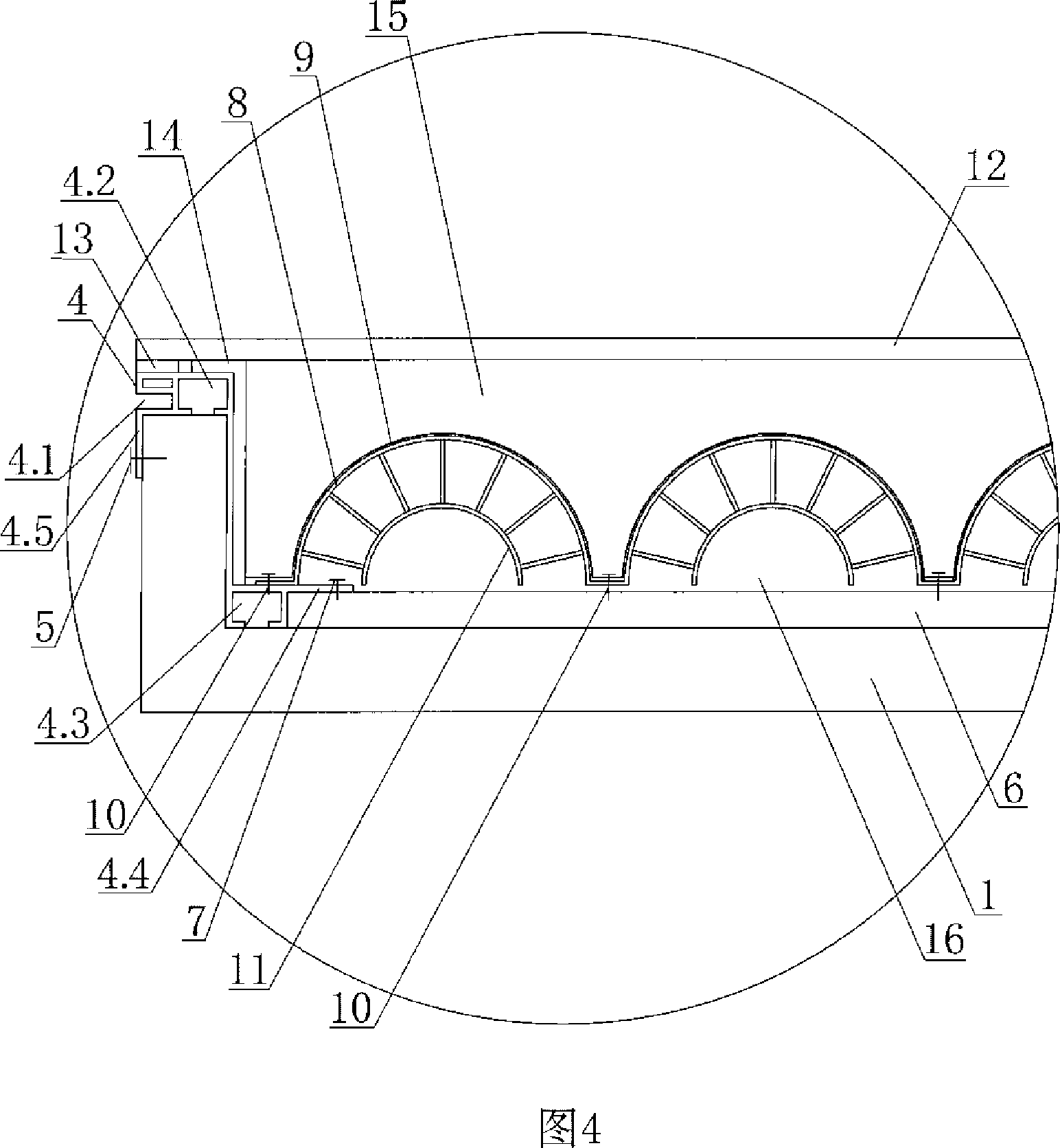

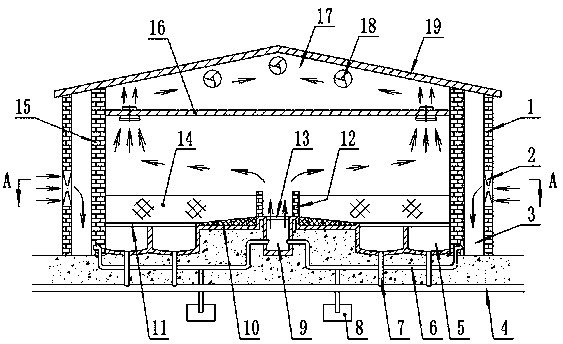

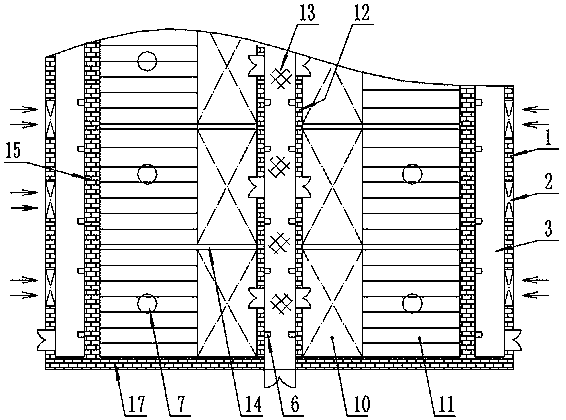

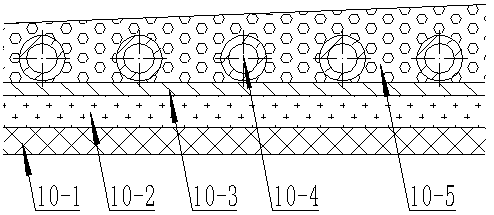

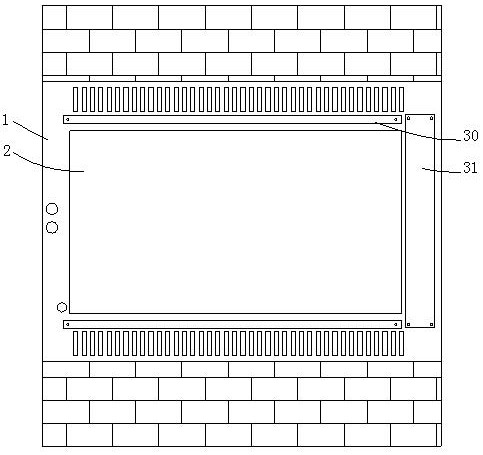

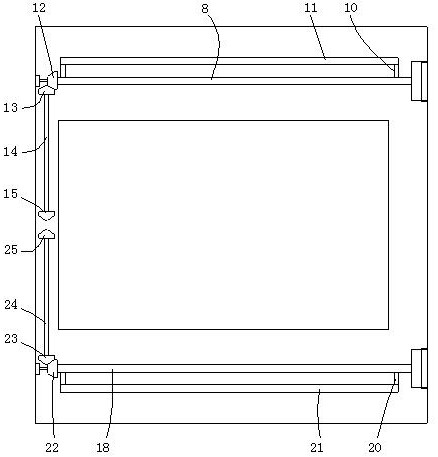

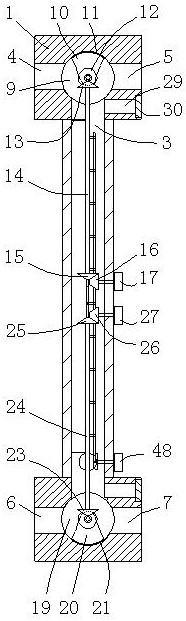

Closed ventilating and insulating pig breeding workshop

PendingCN110946076AAvoid volatilityRealize thermal insulationAnimal housingAnimal sciencePig breeding

The invention discloses a closed ventilating and insulating pig breeding workshop and belongs to pig breeding plants. The closed ventilating and insulating pig breeding workshop comprises pig houses in a plant; the wall body of two sides of the plant has an interlayer structure formed by an inner wall (15) and an outer wall (1), and a wet curtain device (2) is arranged in each window opening; a ventilating duct (9) covered with a grid plate (13) is formed in the floor of the plant, a buried air hose (6) is used for communicating between the ventilating duct and an interlayer channel (3); suction fans (18) are fixed on a ceiling (16) and a gable (17); each pig house positioned on two sides of the ventilating duct (9) is divided into a rest region (10) and an active region (11); the floor ofeach rest region (10) is compound floor, and each active region (11) is formed by slatted floor covering the surface of a manure ditch (5); and the bottom of the manure ditch (5) communicates with amanure delivery pipe (4) through a drainage pipe (7). The closed ventilating and insulating pig breeding workshop is energy-saving and environment-friendly, is warm in winter and cool in summer, and is a plant for pig breeding.

Owner:申学林

Externally-hung light stone molded by desulfurized gypsum industrial waste residues and method thereof

The invention relates to an externally-hung light stone material by desulfurized gypsum industrial waste residues, which comprises the following components by weight percentage: 40.0%-50.0% of desulfurized gypsum; 29.85%-40.25% of magnesium oxide, 10.0%-15.0% of magnesium sulfate, 0.15%-0.25% of citric acid, 0.10%-0.25% of a water reducing agent, 0.50%-0.80% of polymer powder, 2.50%-3.20% of fibers and 0.5%-1.0% of pigment. The magnesium oxide is selected from white powder with the calcination temperature of 400 DEG C, and the mesh number of 400 and the industrial grade purity of 90% or above.The water resistance of the magnesium oxysulfate cement and the toughness and strength of the artificial stone are improved, the density of the artificial stone is greatly reduced due to a large number of micropores contained in the magnesium oxysulfate cement, and multiple functions of heat preservation, heat insulation, humidity adjustment, sound insulation and the like of the artificial stoneare achieved. The industrial waste residue desulfurized gypsum is safely and reliably treated, and the utilization rate is as high as 40% or above.

Owner:上海鼎中新材料有限公司

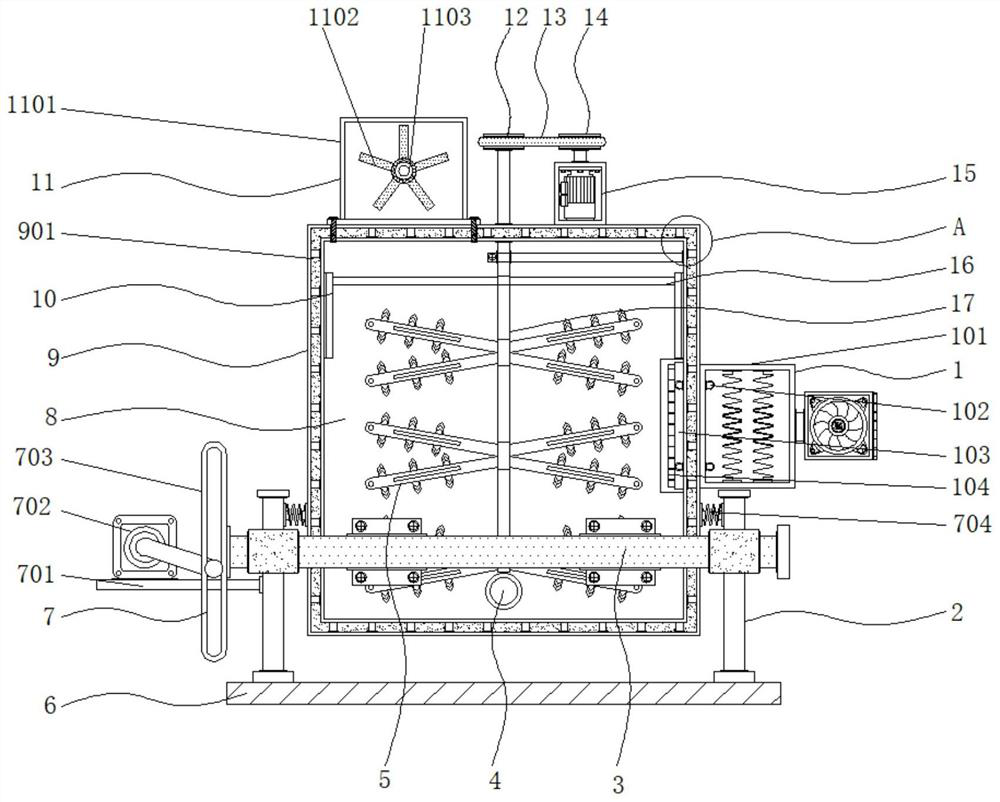

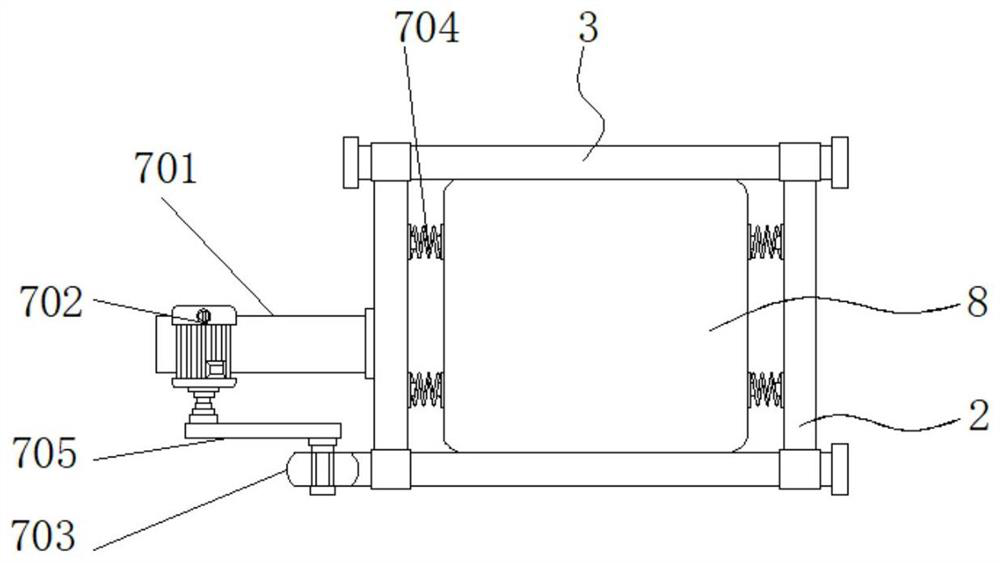

Plastic film raw material mixing device

InactiveCN113211668AImprove the mixing effectWell mixedHollow article cleaningVibration suppression adjustmentsElectric machineEngineering

The invention discloses a plastic film raw material mixing device, and particularly relates to the technical field of plastic film processing. The plastic film raw material mixing device comprises a device body, wherein the two ends of the bottom of the device body are fixedly connected with a fixed bracket; the two sides of the fixed bracket are fixedly connected with supporting plates through connecting sleeve blocks; the bottom ends of the supporting plates are fixedly connected with a bottom plate; and one side of the fixed bracket is equipped with a vibrating mixing mechanism. According to the plastic film raw material mixing device disclosed by the invention, a charge base, a connecting plate, a connecting rotary shaft and a drive motor are arranged, so that raw materials are poured in through an opening in the top of the charge base in use; the drive motor is started, and drives the connecting rotary shaft to rotate through a coupler, so that the connecting rotary shaft drives the connecting plate to rotate while rotating; and the connecting plate consists of five groups of rectangular plates to form a windmill shape, so that the raw materials are uniformly charged, and therefore, blockage caused by excessive raw materials poured in once is prevented, working efficiency of the device is improved, a raw material blockage condition is reduced, and raw material processing efficiency is guaranteed.

Owner:刘和斌

Building decorating plate

ActiveCN111472467AAvoid contactSlow spreadCovering/liningsFire proofingMechanical engineeringOpen cavity

The invention discloses a building decorating plate. The building decorating plate comprises decorating plates which are arranged on a concrete wall body, wherein a hollow cavity is formed in the sideface, close to the interior, of a concrete wall; a mounting wall is formed on the concrete wall body through the hollow cavity; the decorating plates are arranged on a mounting wall surface in an upward-downward sliding way; an open cavity is formed in the top of the mounting wall; the decorating plates enter the hollow cavity by passing through the open cavity; the hollow cavity is filled with an air bag barrier layer; the air bag barrier layer extends to the top of the concrete wall body; a counterweight is placed on a topmost portion of the air bag barrier layer; the decorating plates areoverlapped one above the other, and connected through elastic belts; and the elastic belt of the decorating plate on the topmost portion is connected with the counterweight. The building decorating plate disclosed by the invention not only greatly improves the heat-insulating performance, but also can well improve the fireproof security of the decorating plates, and is higher in fireproof performance after being mounted in the room.

Owner:义乌市铂川建筑工程有限公司

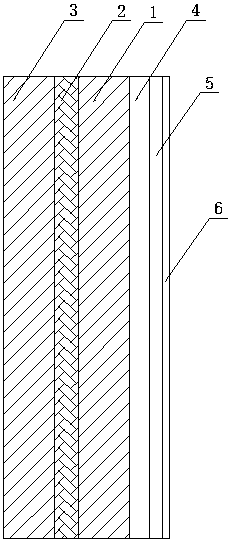

Novel wall composite material and production method

InactiveCN106088462AEasy constructionWaterproof and moisture-proof realizationBuilding componentsWater-setting substance layered productFoam concreteMethods of production

The invention discloses a novel wall composite material. The novel wall composite material is of a sandwich structure, the outer layers of the composite material are glass thin films, and the middle of the composite material is foamed concrete. The production method of the novel wall composite material comprises the steps that the glass thin films are unreeled, flattened; one layer of glass thin film is coated with the foamed concrete; another layer of glass thin film is arranged on the foamed concrete in a covering mode; the glass thin films are rolled and pressed, and the thickness of the foamed concrete is adjusted; and the foamed concrete is cured and forms a glass concrete composite material board, and the composite material board is cut into wall boards.

Owner:周虎

Ventilation control method for room with air conditioner based on exhaust fan and ventilation window

ActiveCN111219822AReduce energy consumptionMeet indoor fresh air volume requirementsMechanical apparatusLighting and heating apparatusThermal insulationFresh air

The invention discloses a ventilation control method for a room with an air conditioner based on an exhaust fan and a ventilation window. Double-layer glass is arranged on glass window; a ventilationinner cavity is formed between the double-layer glass; a shutter device is arranged in the ventilation inner cavity to isolate the ventilation inner cavity into two cavity channels including an insideventilation cavity and an outside ventilation cavity; and the ventilation of the room is realized through control in two manners including a summer indoor refrigeration ventilation mode and a winterindoor heating ventilation mode. According to the ventilation control method disclosed by the invention, the double-layer glass can be used as the ventilation channel to better meet the requirements for the indoor fresh air rate, and the reflection heat radiation can also be adjusted to better realize indoor thermal insulation, the indoor air conditioner energy consumption is higher reduced, and the ventilation control method also has the advantages of being convenient for internal cleaning of the double-layer glass and the like.

Owner:CHONGQING UNIV

Novel tempered glass

InactiveCN107901526AAvoid condensationRealize thermal insulationLayered productsOptoelectronicsToughened glass

The invention discloses novel tempered glass which comprises a first tempered glass layer and a second tempered glass layer. An expanded perlite layer is arranged between the first tempered glass layer and the second tempered glass layer, an electroconductive vacuum coated layer is arranged on the side face, away from the first tempered glass layer, of the second tempered glass layer, a silicone colloid layer is arranged on the side face of the electroconductive vacuum coated layer, and a self-restoring layer is arranged on the side face of the silicone colloid layer. The novel tempered glassis conducive to popularization and application.

Owner:四川鑫利民钢化玻璃有限公司

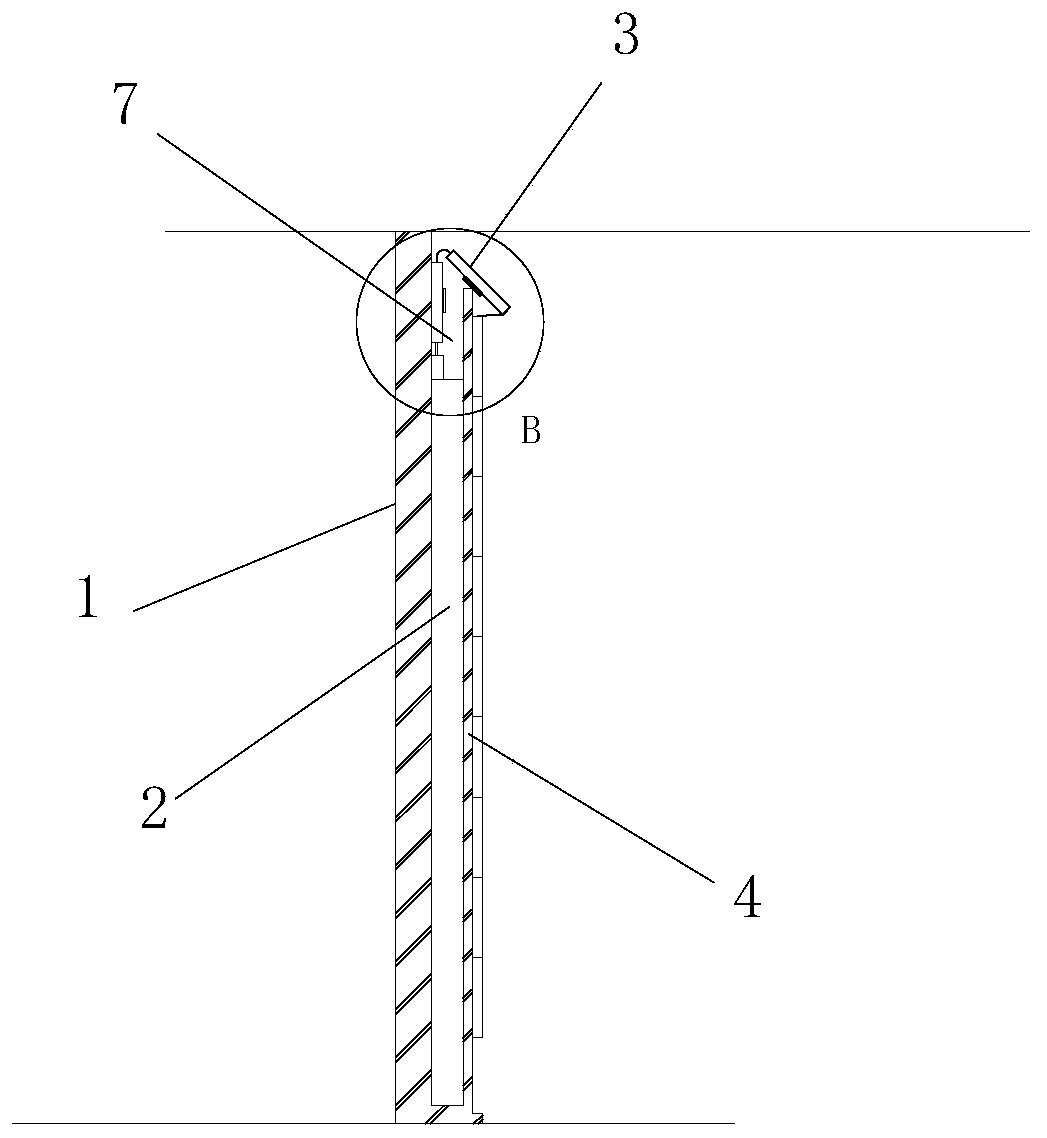

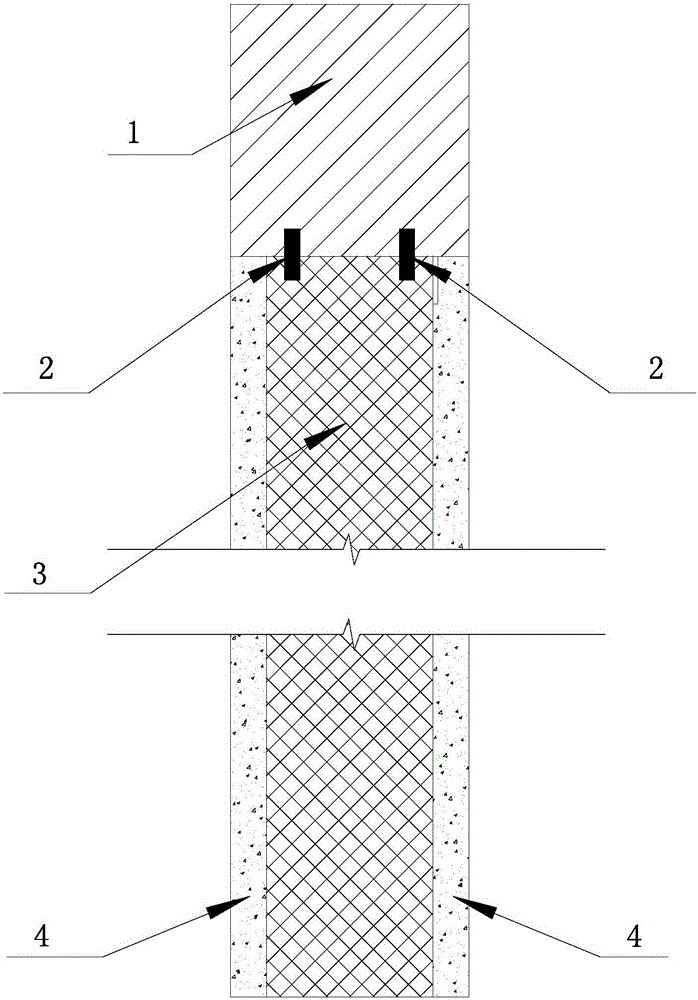

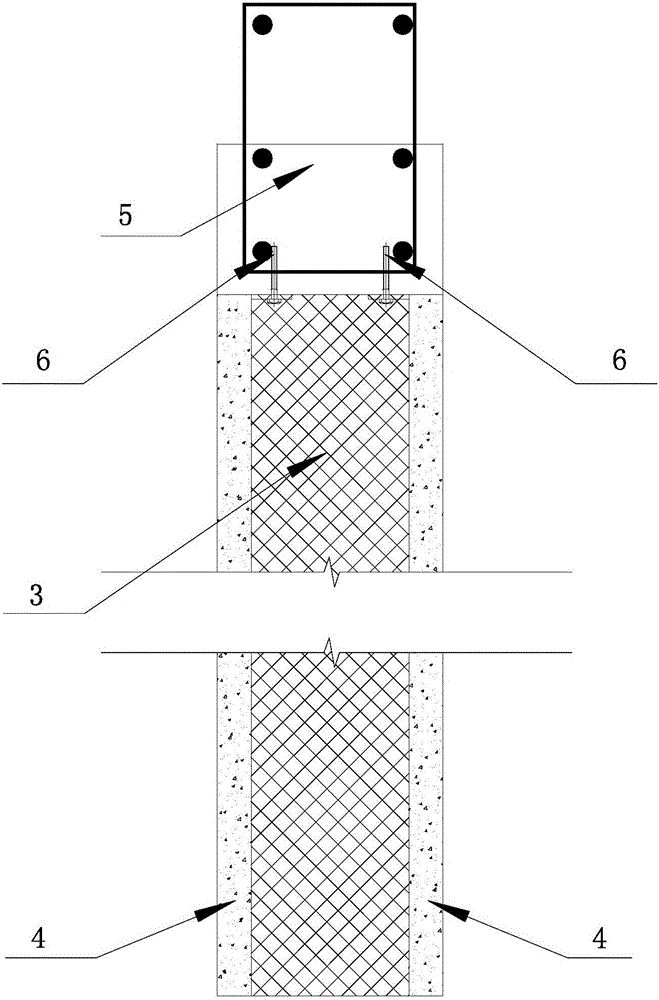

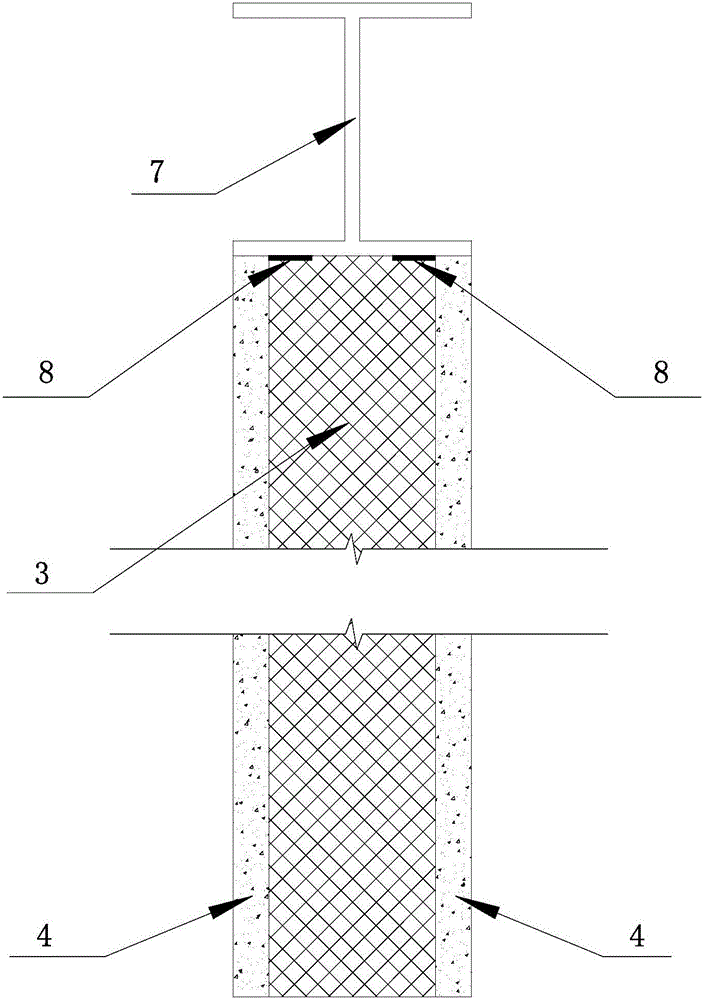

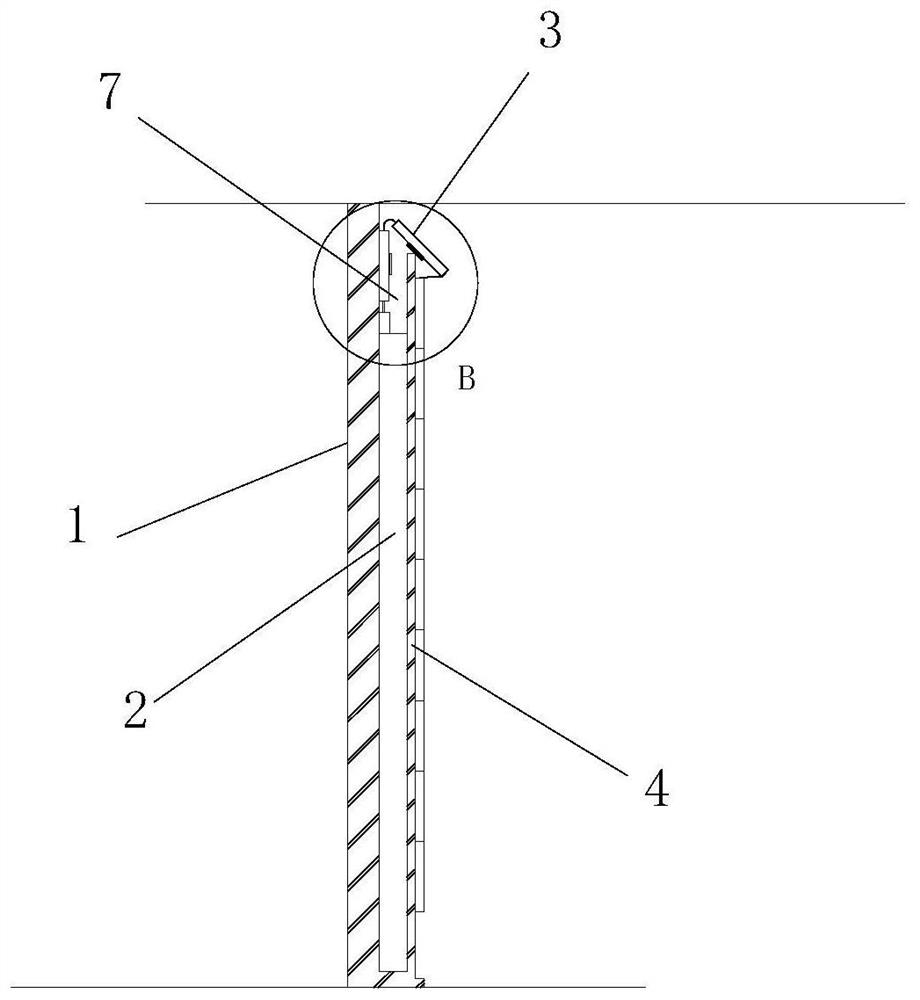

Precast fabricated type beam wall combination member

InactiveCN105908863AOvercome the disadvantage of too much splicingMeet the needs of construction industrializationWallsFilling materialsConcrete beams

The invention provides a precast fabricated type beam wall combination member, and relates to the technical field of a fabricated type beam wall combination member. The precast fabricated type beam wall combination member integrally consists of three parts of a precast fabricated type beam, a light-steel light-concrete wall body and connecting pieces between the precast fabricated type beam and the light-steel light-concrete wall body, wherein the precast fabricated type beam can be a precast fabricated type member in any other form, such as a precast fabricated type steel beam, a concrete superposed beam, or a concrete flat beam and the like; the light-steel light-concrete wall body is a light-steel light-concrete composite wall body which is integrally formed by light steel, light concrete and other components, wherein the light steel is used as a framework of the wall body; the light concrete is used as a filling material of the wall body; the connecting pieces between the precast fabricated type beam and the light-steel light-concrete wall body are connecting members between the precast fabricated type beam and the light-steel light-concrete wall body, and comprise a rear anchor fastener required by the connection between a light-steel framework and a precast fabricated type concrete beam, and a welding member between the light-steel light-concrete composite wall body and a precast steel beam. The precast fabricated type beam wall combination member disclosed by the invention is light in dead weight and low in rigidity, has favorable mechanical performance, and meets the requirements of buildings for filling wall bodies.

Owner:北京研创绿建科技有限公司

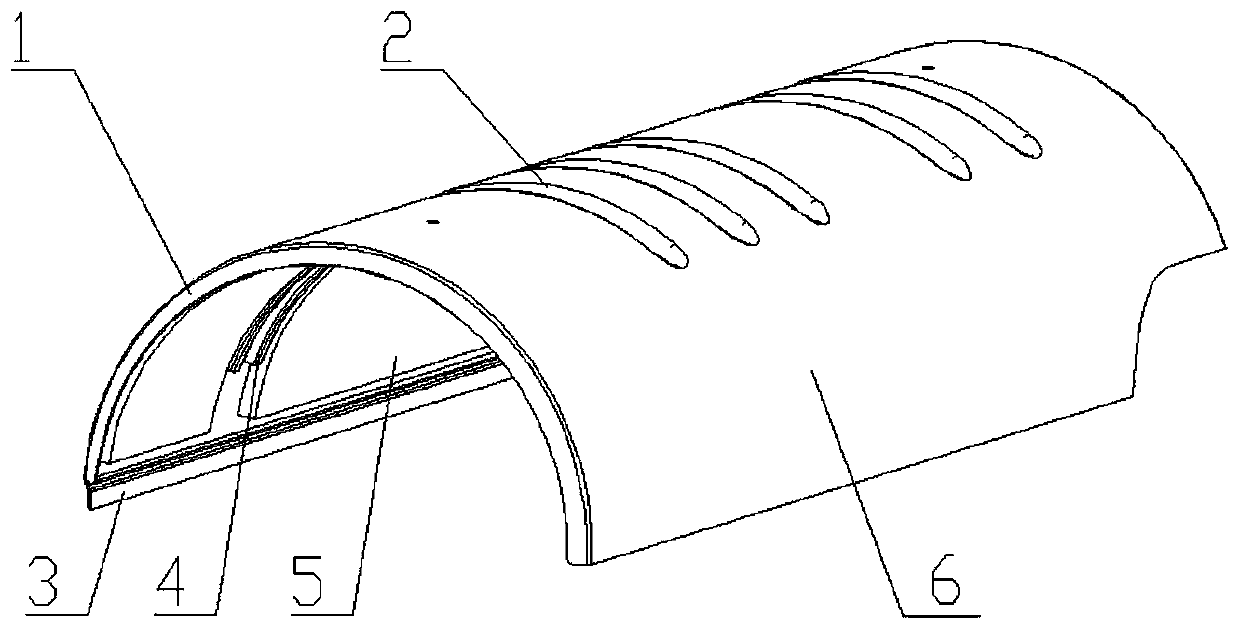

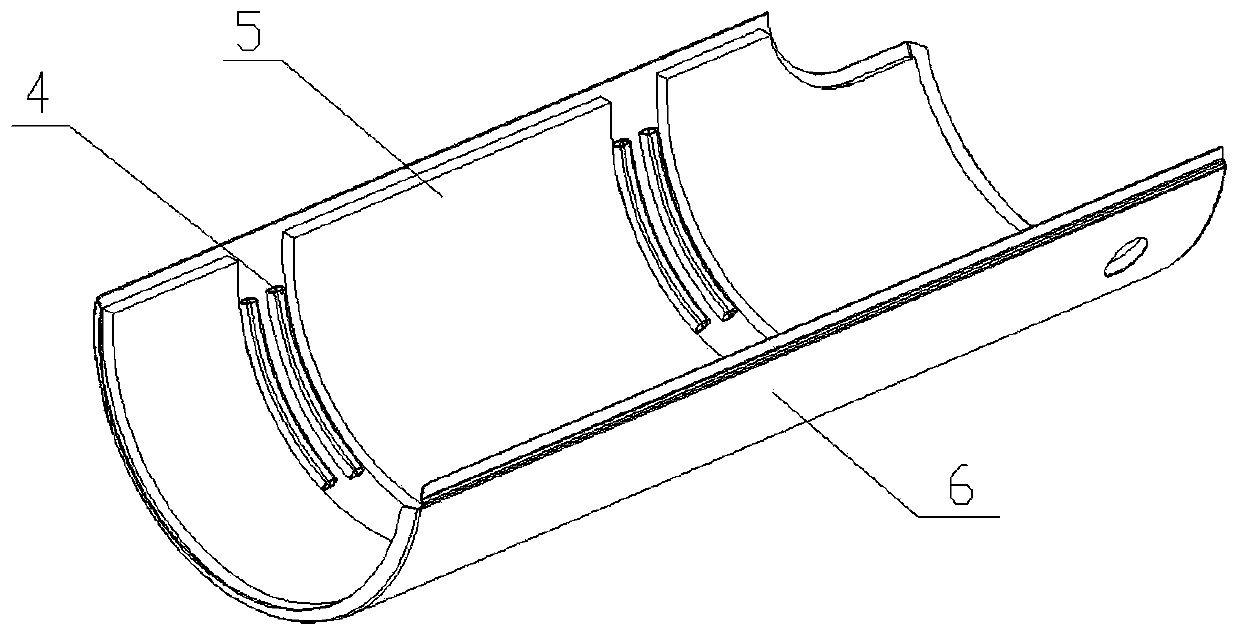

General exhaust aftertreatment heat shield

PendingCN111425290ALow costSatisfy the tight strength requirementsExhaust apparatusSilencing apparatusEngineeringHeat conservation

The invention belongs to the technical field of automobile exhaust aftertreatment package structures, and discloses a general exhaust aftertreatment heat shield. The general exhaust aftertreatment heat shield comprises heat insulating sheets with the semi-circular section, landing edges are arranged on one sides of the heat insulating sheets, and the two heat insulating sheets are buckled throughthe landing edges to form the cylindrical heat shield; and inclined corners are arranged at one ends of the heat insulating sheets, reinforcing bars are arranged on the outer surfaces of the heat insulating sheets, heat insulating cotton and reinforcing supports are arranged on the inner surfaces of the heat insulating sheets at intervals, and the reinforcing supports are arranged in the circumferential direction of the heat insulating sheets. The cost of an aftertreatment mold is greatly lowered; the process requirements of aftertreatment assembly production are met, welding is easy, and theproduction efficiency is improved; the loading reliability requirements when a hoop is fixed to the heat shield are met; and the overall heat preservation effect of aftertreatment is achieved, and theheat-insulating protection effect is achieved on parts surrounding aftertreatment.

Owner:WUXI WEIFU LIDA CATALYTIC CONVERTER

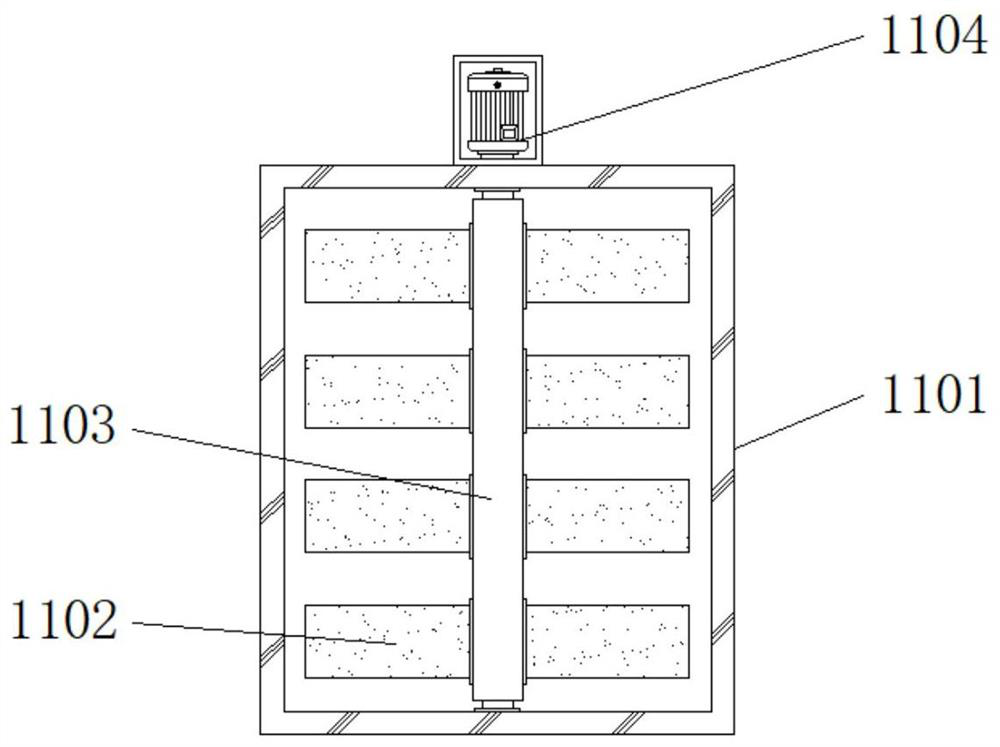

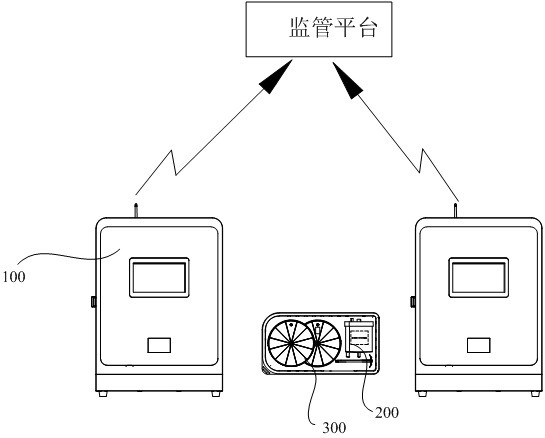

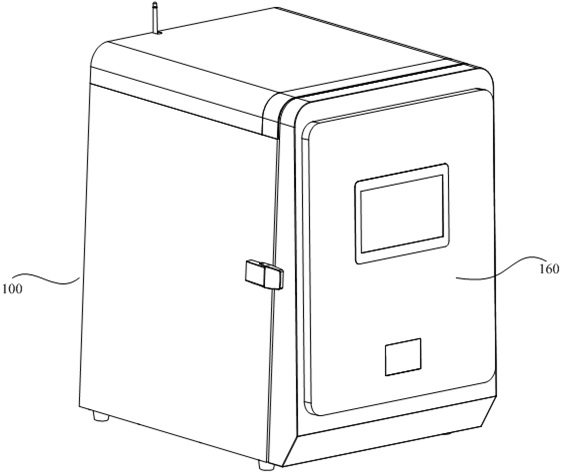

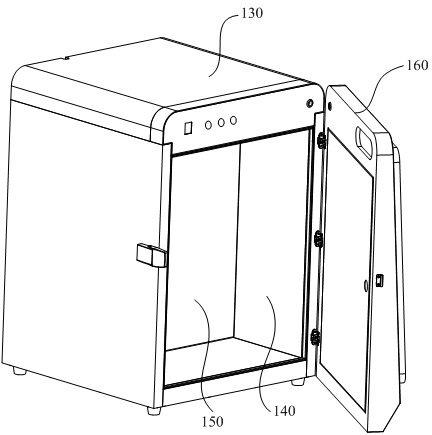

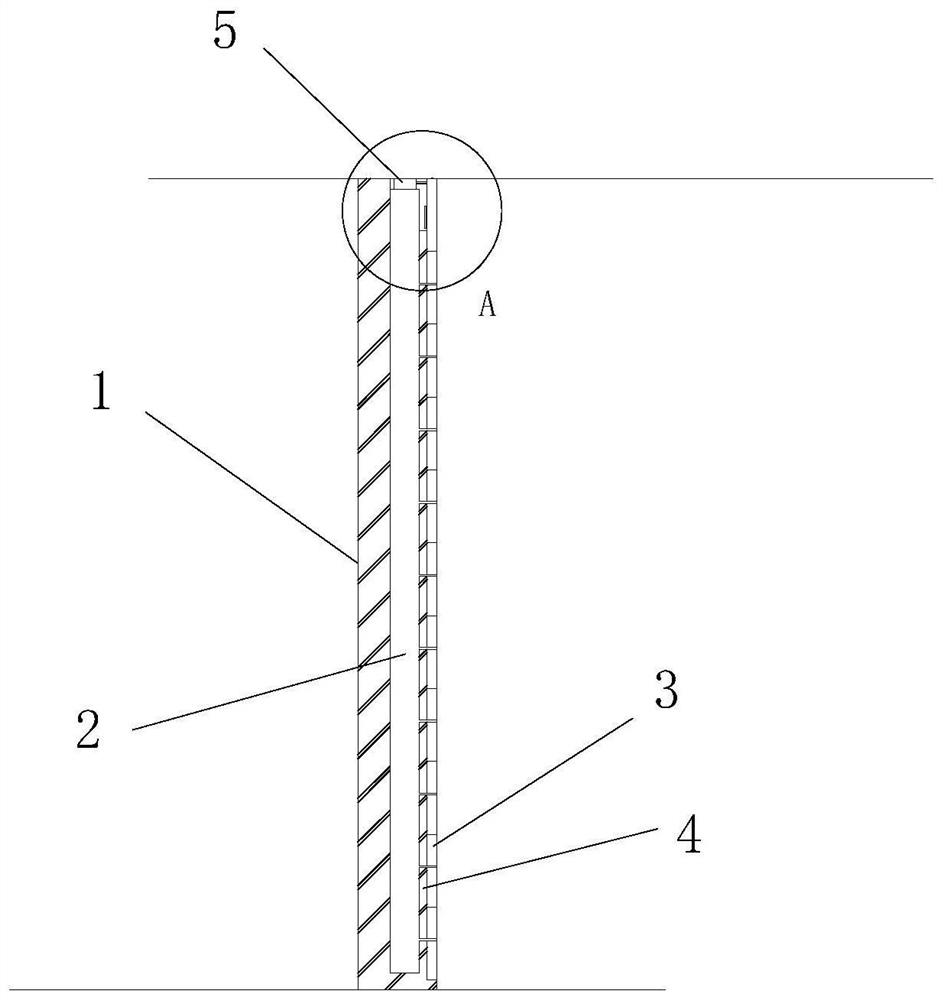

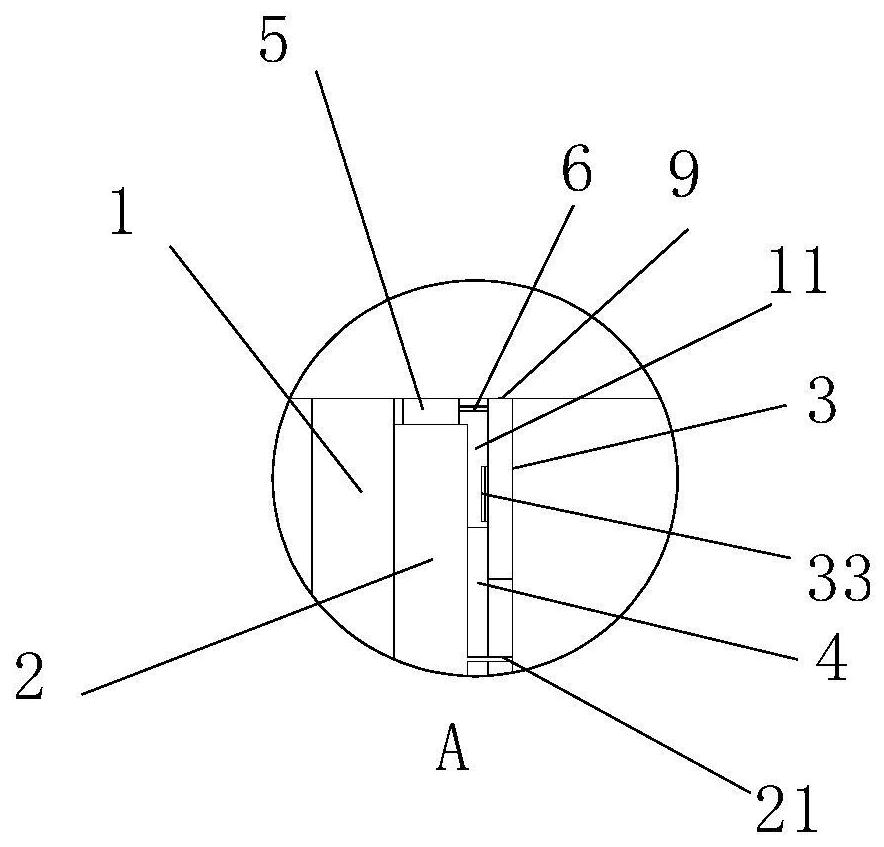

Intestinal content extraction supervision device

PendingCN114836316ARealize automatic extractionAchieve standardizationBioreactor/fermenter combinationsBiological substance pretreatmentsTemperature controlTerminal server

The invention discloses an intestinal content extraction supervision device, which comprises: a box body, in which a heat insulation cavity is formed; the stirring module is arranged in the heat insulation cavity; the filtering and separating module is arranged in the heat insulation cavity and is connected with the stirring module; the filtering driving module is used for driving the solution in the filtering and separating module to circularly flow so as to automatically filter and separate; the temperature control module is arranged on the heat insulation cavity and used for adjusting and controlling the temperature in the heat insulation cavity; the low-oxygen module is communicated with the heat insulation cavity and is used for detecting and controlling the oxygen partial pressure value in the heat insulation cavity; an auxiliary module; the control module is in communication connection with the stirring module, the filtering driving module, the temperature control module, the low-oxygen module and the auxiliary module; and the terminal server is in communication connection with the control module. According to the intestinal content extraction supervision device, automatic extraction of intestinal contents can be realized, the measurement accuracy is ensured, the low-oxygen and constant-temperature requirements of a coprophilous fungi collection environment are ensured, communication with the control module can be realized in real time, and supervision is realized.

Owner:QIHUI BIOTECHNOLOGY YANGZHOU CO LTD

building decorative panels

ActiveCN111472467BAvoid contactSlow spreadCovering/liningsFire proofingThermal insulationArchitectural engineering

The invention discloses a building decoration board, comprising a decoration board installed on a concrete wall, a hollow cavity is provided on the side of the concrete wall close to the room, an installation wall is formed on the concrete wall through the hollow cavity, and the decoration board slides up and down Installed on the installation wall, an opening is formed on the top of the installation wall, the decorative plate passes through the opening and enters the hollow cavity, the hollow cavity is filled with an airbag compartment, and the airbag compartment extends toward the top of the concrete wall A counterweight is placed on the top of the airbag compartment, and each decorative plate is stacked up and down, and is connected by an elastic band, and the elastic band of the top decorative plate is connected with the counterweight. The decorative board of the present invention not only greatly increases the heat insulation capacity, but also can well increase the fireproof safety of each decorative board, so that it has higher fireproof performance after being installed indoors.

Owner:义乌市铂川建筑工程有限公司

Ultra-wide-amplitude infrared thermal insulation coating

ActiveCN112961532ARealize thermal insulationCrystal structure intactPassive housesReflecting/signal paintsInfraredAmorphous selenium

The invention provides a technology-based ultra-wide-amplitude infrared thermal insulation coating. The technology-based ultra-wide-amplitude infrared thermal insulation coating comprises the following components: acrylic resin, polycopper carbosilane, an infrared reflecting agent, a curing agent, an auxiliary agent, a curing accelerator and a solvent. The polycopper carbosilane has a relatively complete crystal structure, so that the polycopper carbosilane has relatively strong infrared reflection capability; the infrared reflecting agent is prepared from a mixture of amorphous selenium powder, hematite powder and light red silver ore powder with high refractive index and certain particle size, and the component integrates the sum of infrared reflection bands of the amorphous selenium powder, the hematite powder and the light red silver ore powder and has ultra-wide-amplitude infrared reflection performance, so that the coating can achieve excellent effects of heat preservation and heat insulation.

Owner:米格(浙江)创新科技有限公司

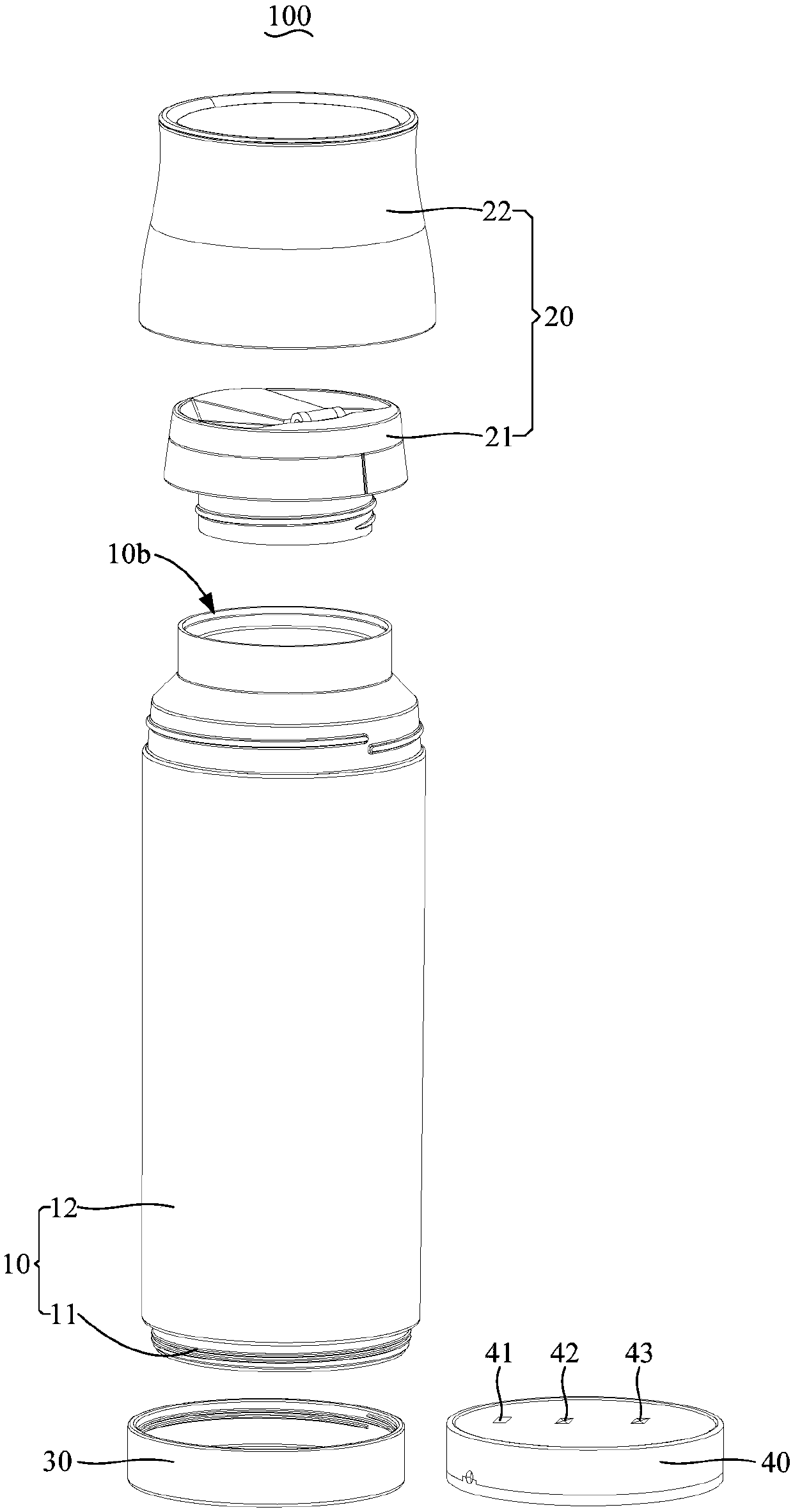

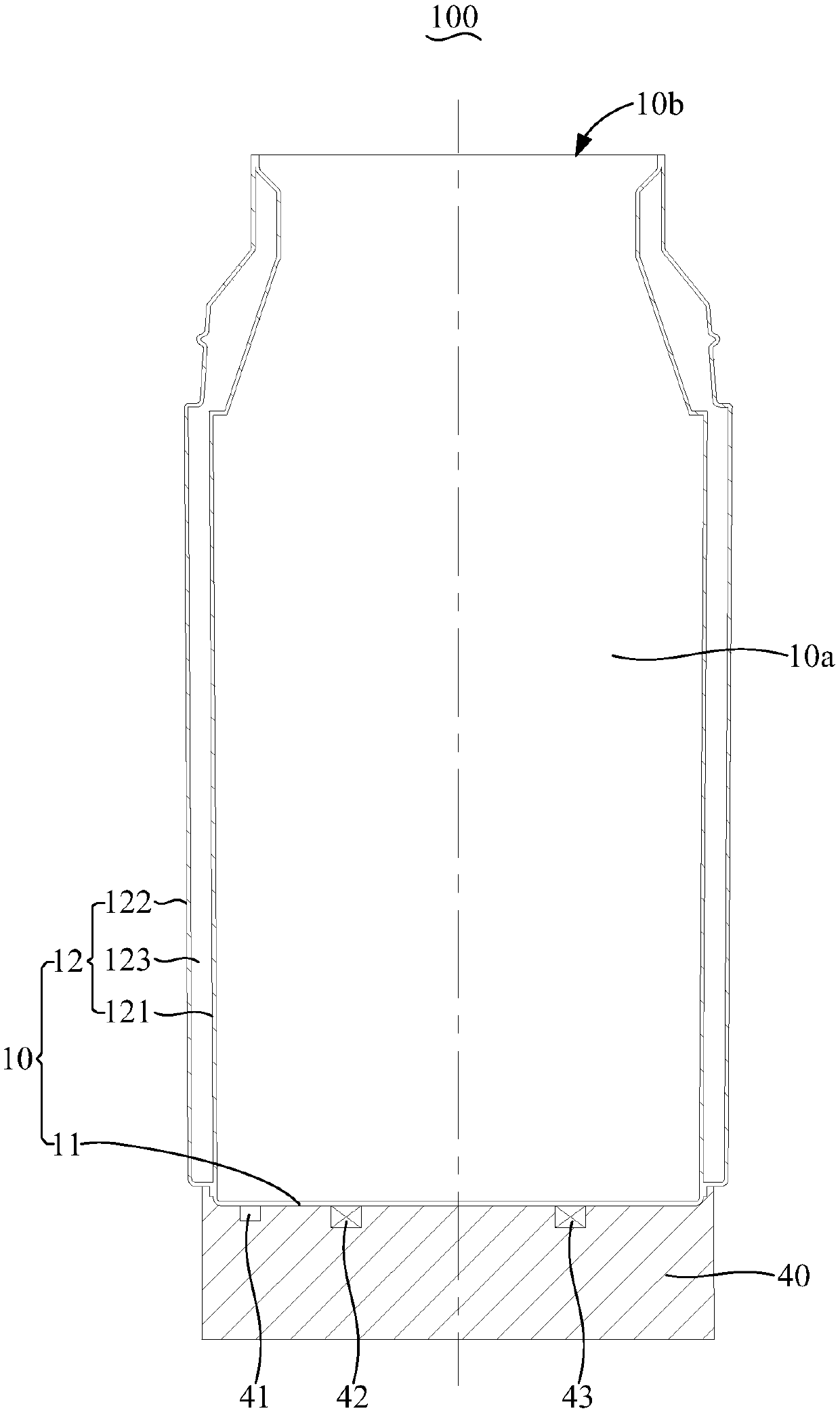

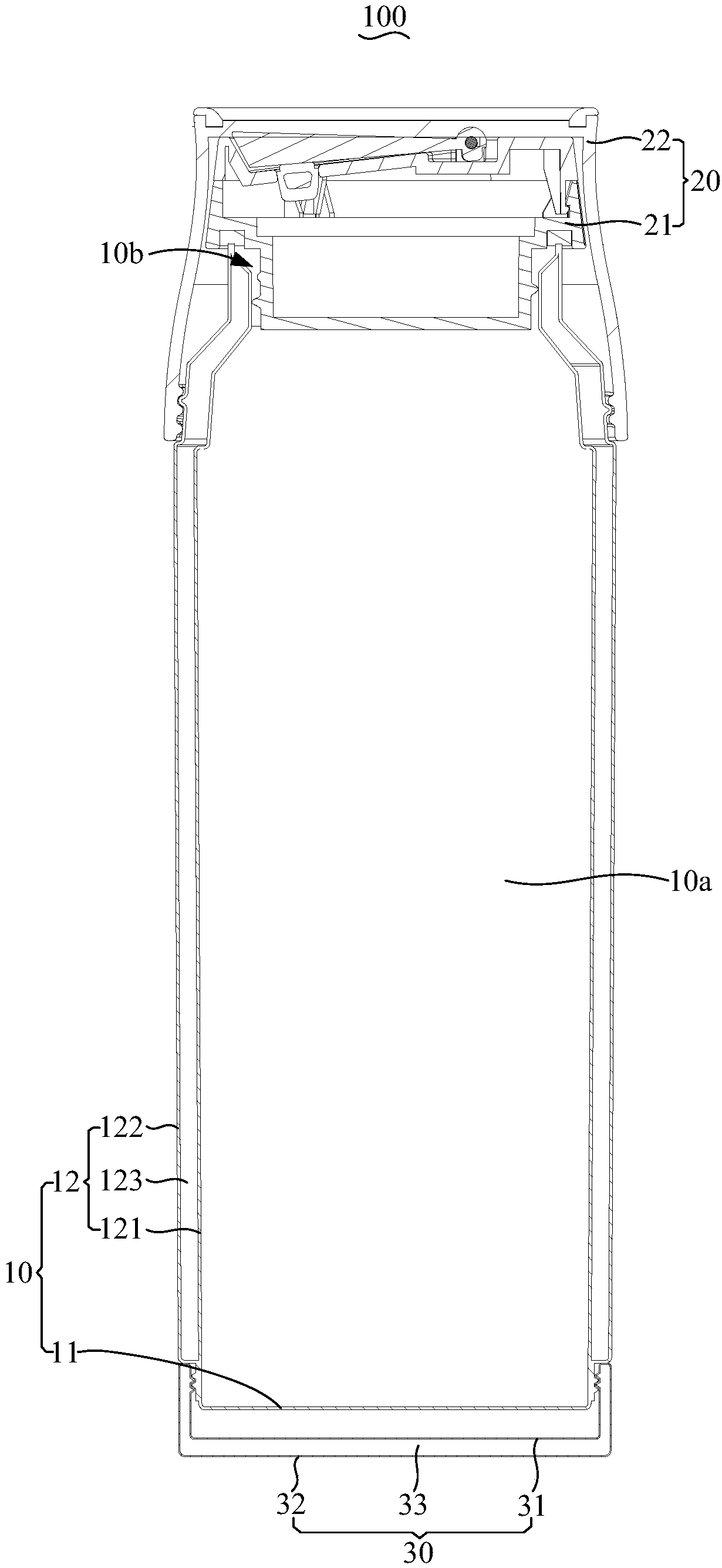

Electric heating cup

PendingCN111110052AWith heating functionWith carrying functionWarming devicesDrinking vesselsEngineeringHeat conservation

The invention discloses an electric heating water cup which comprises a cup body, a cup lid, a cup lid, a cup lid, a cup lid, a cup lid, a cup lid, a cup lid and an electric heating device. The cup cover covers the opening of the cup body; the bottom cover is detachably connected to the bottom of the cup body, and the bottom cover is provided with a heat insulation structure; the heating base is detachably connected to the bottom of the cup body so as to heat the cup body; the electric heating water cup has a heating state that the cup body is connected with the heating base and a using statethat the cup body is connected with the bottom cover. The invention aims to provide the electric heating water cup which not only can heat water, but also is convenient to carry and preserves heat.

Owner:GUANGDONG MIDEA CONSUMER ELECTRICS MFG CO LTD

Ventilation control method for air-conditioned room based on blower and ventilation window

ActiveCN111021913BReduce energy consumptionMeet indoor fresh air volume requirementsVentilation arrangementLight protection screensFresh airEngineering

The invention discloses a ventilation control method for an air-conditioned room based on a blower fan and a ventilation window. The glass window has double-layer glass and a ventilation inner cavity is formed between the double-layer glass, and a louver device is arranged in the ventilation inner cavity to isolate the ventilation inner cavity as an inner ventilation cavity. There are two chambers, one cavity and the outer ventilation cavity; and the ventilation of the room is controlled in two ways: indoor cooling and ventilation mode in summer and indoor heating and ventilation mode in winter. The invention not only can use the double-layer glass as a ventilation channel to better meet the requirements of indoor fresh air volume, but also can adjust the reflected heat radiation to better realize indoor heat insulation and reduce energy consumption of indoor air conditioners. The advantage of cleaning inside the laminated glass.

Owner:CHONGQING UNIV

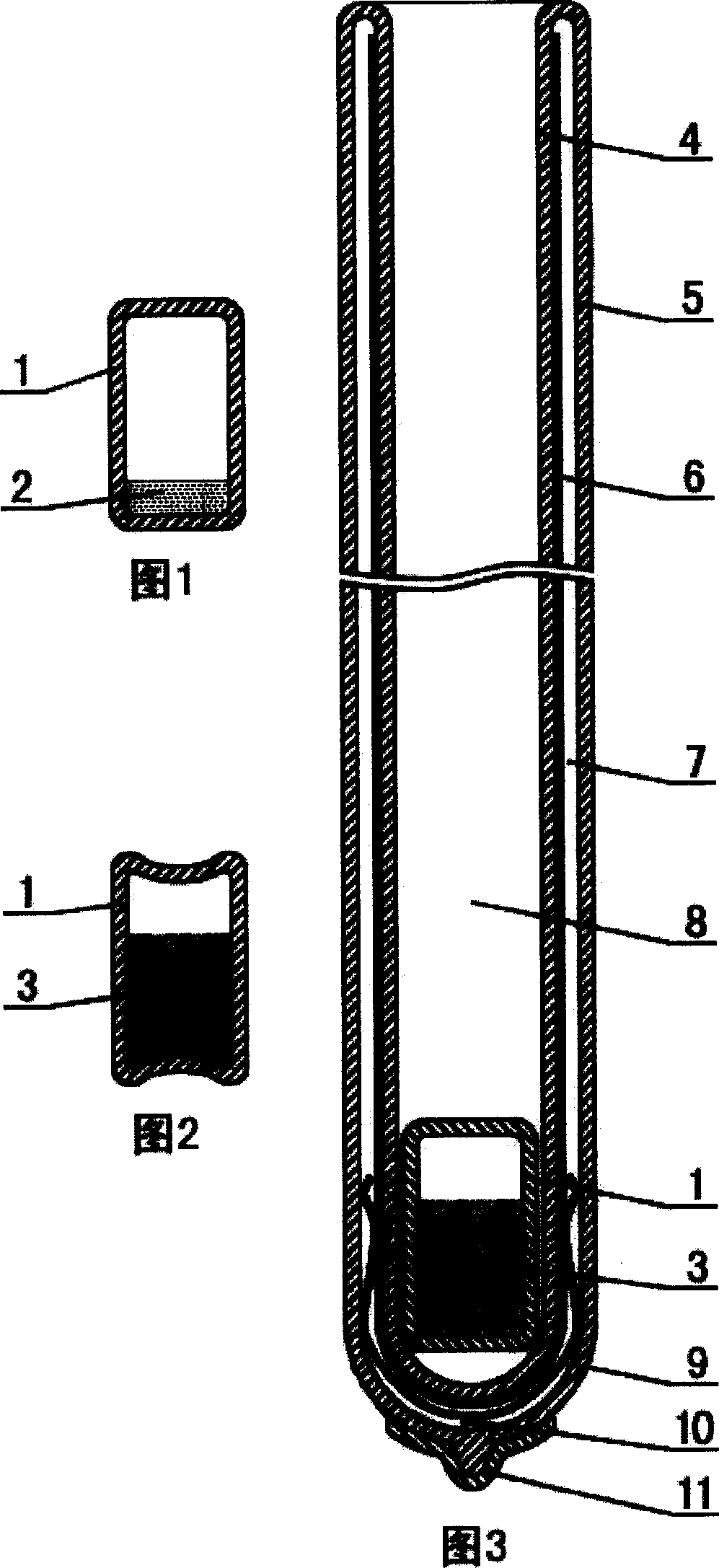

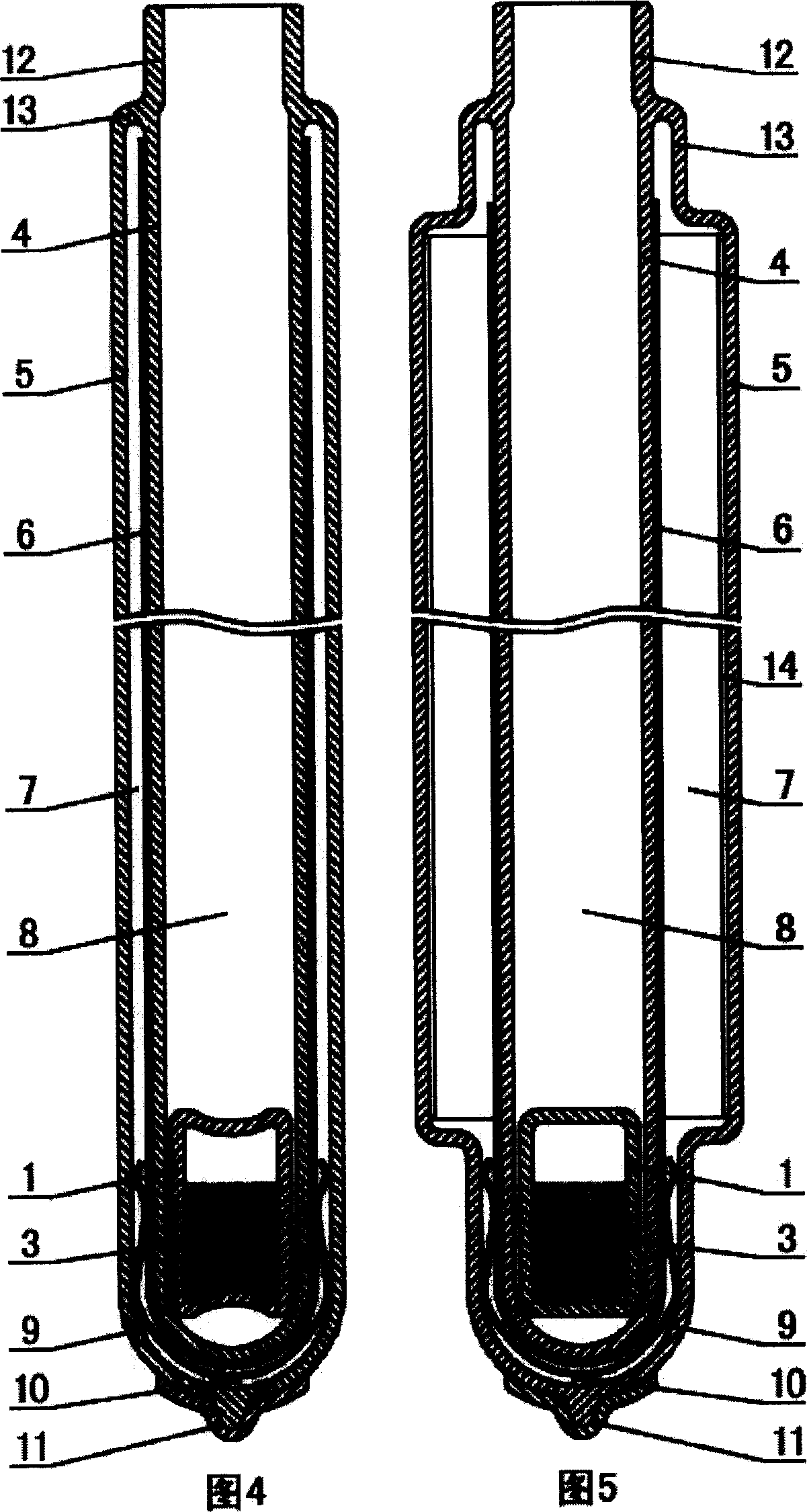

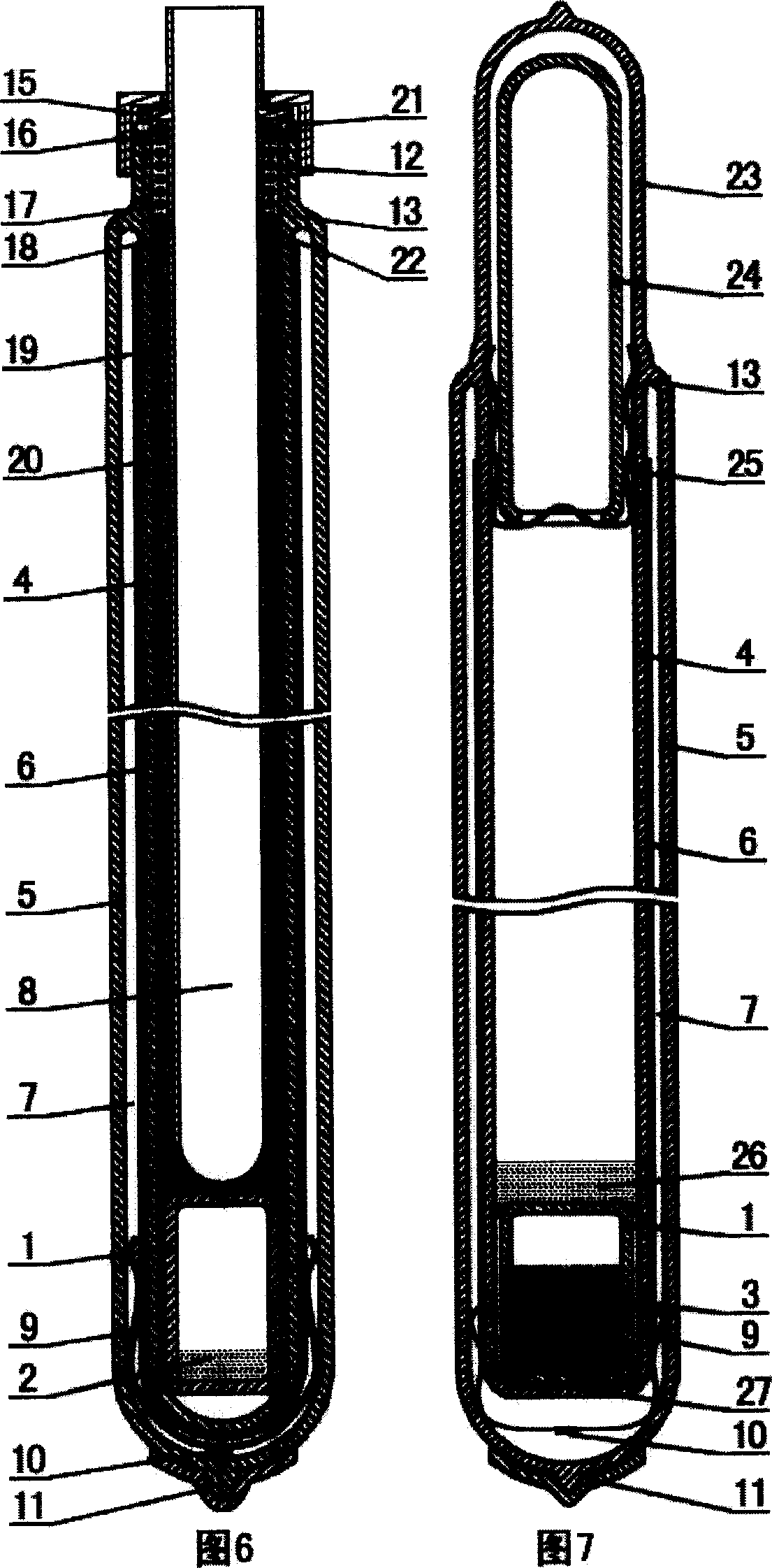

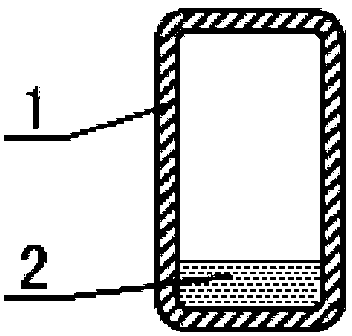

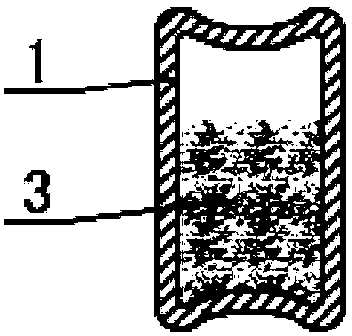

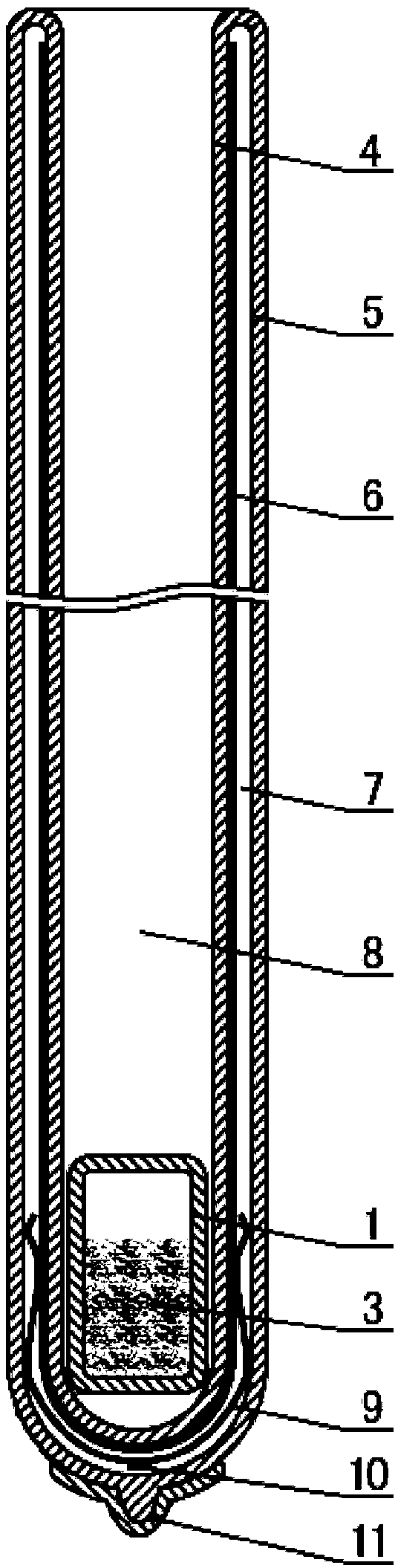

Heat conduction and thermal insulation device of vacuum collector tube

InactiveCN101008530AImprove one-way thermal conductivityRealize thermal insulationSolar heating energySolar heat devicesPhase shiftedThermal insulation

A vacuum heat tube conductive thermal insulator is a sealed tube chamber, filled with phase-shift medium, or filled with weight material. The sealed tube chamber filled with weight material is heavier than the water in same volume. The diameter of sealed tube chamber is smaller than the inner diameter of vacuum heat collecting tube chamber. The specific weight of weight material is higher than water. The sealed tube chamber is filled with water. Or the weight material contains some water. The invention is mounted at the bottom of glass vacuum heat collecting tube chamber, relative to the elastic metal support clamper. In sunlight, the energy adsorbed by the adsorption film is conducted to the invention to heat the medium. In night, the invention utilizes the reduced temperature and one-way conductivity of heat tube to condense the steam in the element to obtain vacuum.

Owner:ZIBO ENVIRONMENTAL PROTECTION TECH CO LTD +1

Thermal insulation coating, preparation method thereof and thermal insulation coating

ActiveCN106147442BRealize thermal insulationImprove waterproof performancePolyurea/polyurethane coatingsVitrificationPolymer science

The invention relates to thermal insulation paint and a preparation method thereof and a thermal insulation coating. The thermal insulation paint is prepared from, by mass, 15-30 parts of main ingredient, 3-22 parts of acrylic polymer hollow spheres, 15-40 parts of water and 0.5-1.5 parts of thickener, wherein the main ingredient is polymer resin of which the elastic elongation ratio is 800% or above, and the glass transition temperature is below -10 DEG C. The thermal insulation paint is good in thermal insulation effect.

Owner:和平县长丰环保新材料有限公司

Heat conduction and thermal insulation device of vacuum collector tube

InactiveCN101008530BImprove one-way thermal conductivityRealize thermal insulationSolar heating energySolar heat devicesPhase shiftedThermal insulation

A vacuum heat tube conductive thermal insulator is a sealed tube chamber, filled with phase-shift medium, or filled with weight material. The sealed tube chamber filled with weight material is heavier than the water in same volume. The diameter of sealed tube chamber is smaller than the inner diameter of vacuum heat collecting tube chamber. The specific weight of weight material is higher than water. The sealed tube chamber is filled with water. Or the weight material contains some water. The invention is mounted at the bottom of glass vacuum heat collecting tube chamber, relative to the elastic metal support clamper. In sunlight, the energy adsorbed by the adsorption film is conducted to the invention to heat the medium. In night, the invention utilizes the reduced temperature and one-way conductivity of heat tube to condense the steam in the element to obtain vacuum.

Owner:ZIBO ENVIRONMENTAL PROTECTION TECH CO LTD +1

Desulfurization gypsum industrial waste slag molded external light stone and method

Owner:上海鼎中新材料有限公司

A kind of nano-microporous thermal insulation material and preparation method thereof

The invention relates to a nano-microporous thermal insulation material, which includes a porous base layer and a heat insulation layer attached to the surface of the base layer. The base layer consists of the following raw materials by weight: 28-36 parts of polymer hollow microspheres, 1-5 parts of paraffin / porous perlite-urea-formaldehyde resin phase change microcapsules, 11-19 parts of nano-alumina hollow spheres, 5-12 parts of nano-silica sol, and 3-7 parts of alumina silicate fiber. The heat insulation layer is composed of the following raw materials by weight: 44-54 parts of silica aerogel, 14-18 parts of modified starch, 4-8 parts of hollow microspheres, 10-16 parts of nano-titanium oxide, 3-5 parts of mullite whisker, and 2-4 parts of a foaming agent. The nano-microporous thermalinsulation material provided by the invention has good heat insulation performance and high strength, does not shrink easily, and can meet the heat insulation requirements of building walls.

Owner:龙元明筑科技有限责任公司

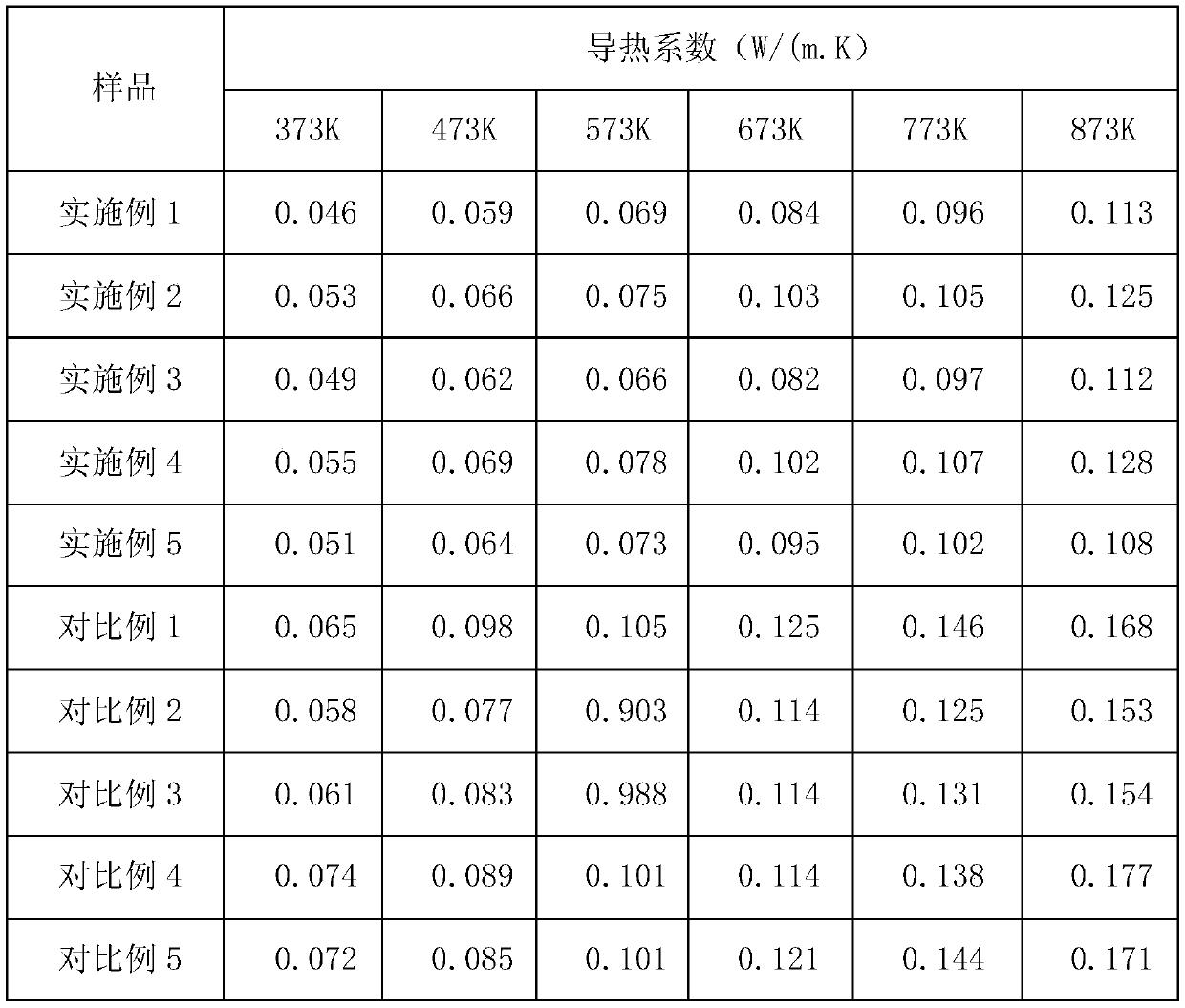

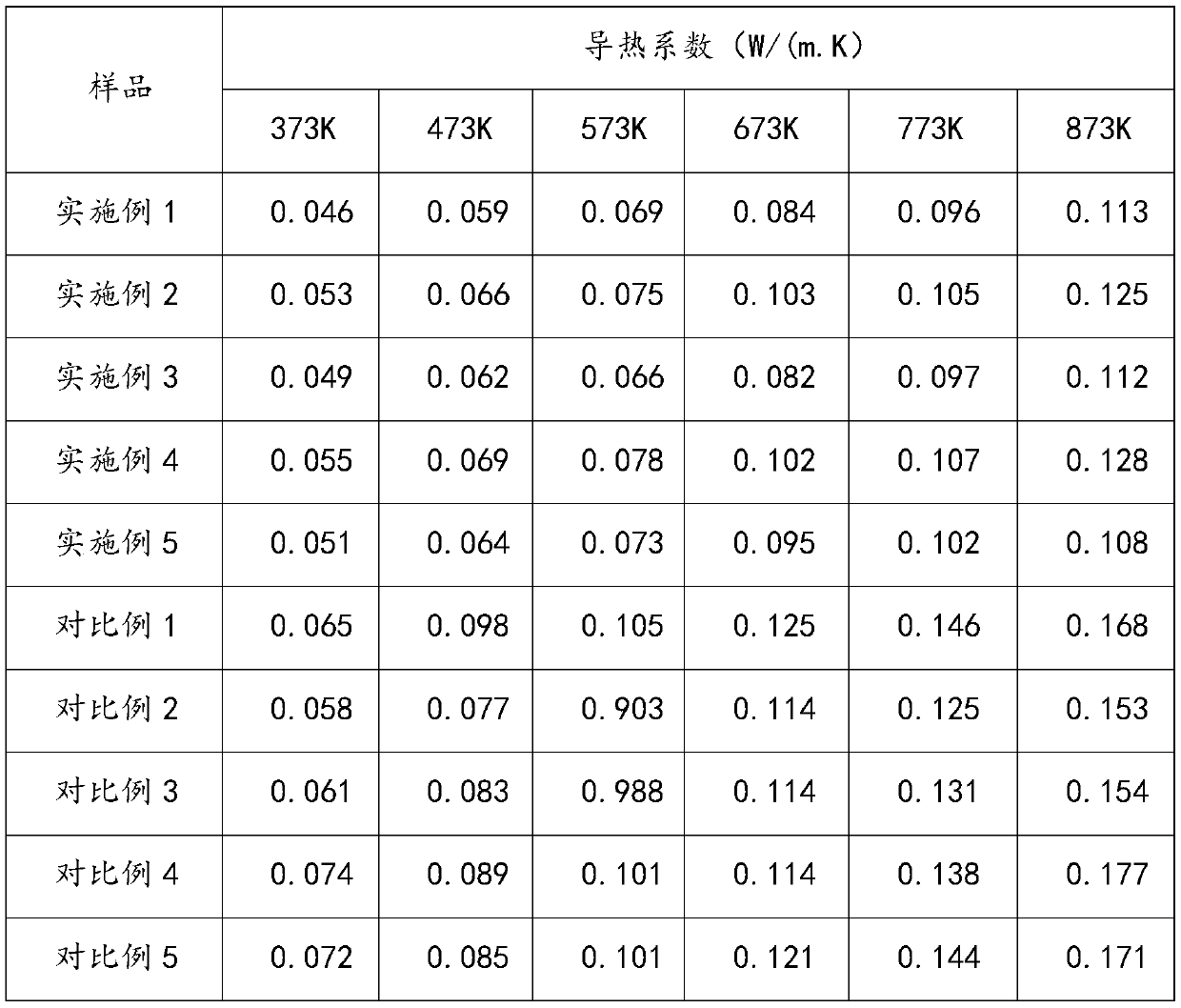

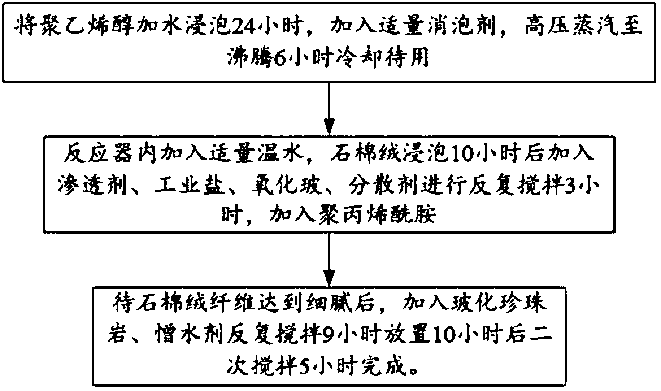

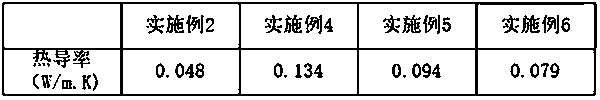

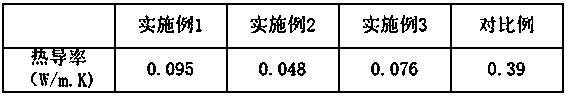

Heat insulation paint, preparation method of heat insulation paint and heat insulation coating thereof

InactiveCN109810586ARealize thermal insulationReduce churnCoatingsThermal isolationPolyvinyl alcohol

The invention relates to heat insulation paint, a preparation method of the heat insulation paint and a heat insulation coating thereof. The heat insulation paint is prepared from the following ingredients in parts by mass: 30 to 80 parts of asbestos wool, 80 to 120 parts of vitrified perlite, 0.8 to 1.2 parts of foaming agents, 0.5 to 1 part of dispersing agents, 0.3 to 0.8 part of antifoaming agents, 30 to 40 parts of zirconia, 20 to 30 parts of polyvinyl alcohol, 3 to 4 parts of moisture repellents, 2 to 3 parts of salt, 0.3 to 0.8 part of pigment, 3 to 4 parts of brightening agents, 0.3 to0.8 part of Polyacrylamide and 250 to 350 parts of water, wherein through the vitrified perlite, the heat insulation coating obtained by the heat insulation paint is of a porous structure, so that space steric hindrance is formed in the heat insulation coating; the heat conduction can be blocked through the space steric hindrance, so that the heat loss is reduced; therefore the heat insulation and thermal isolation of the heat insulation coating can be realized.

Owner:刘慧生

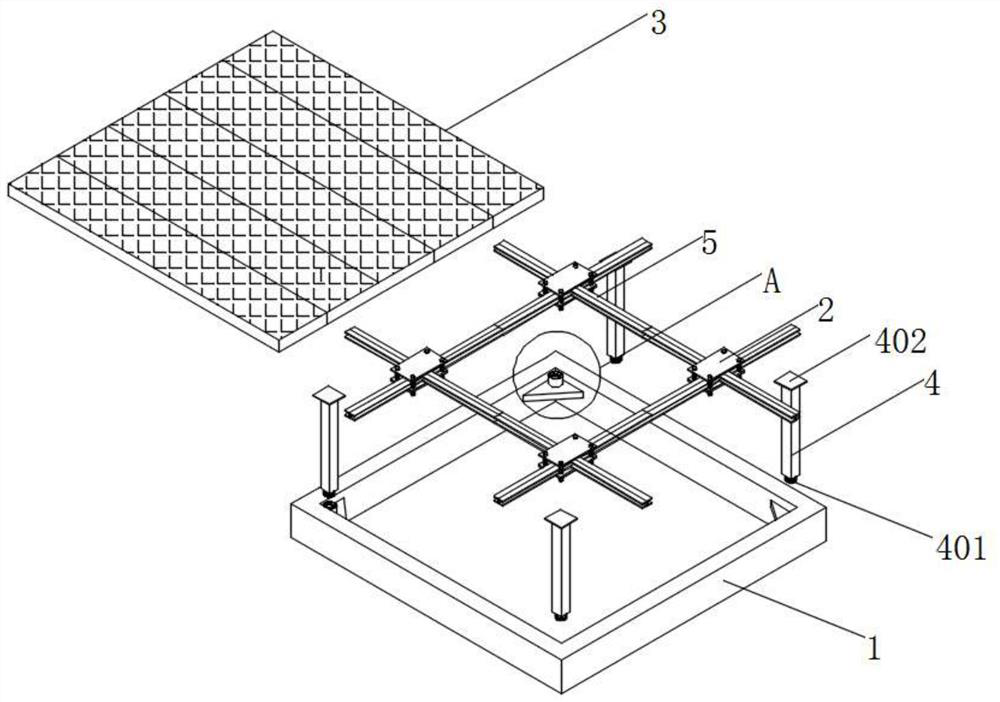

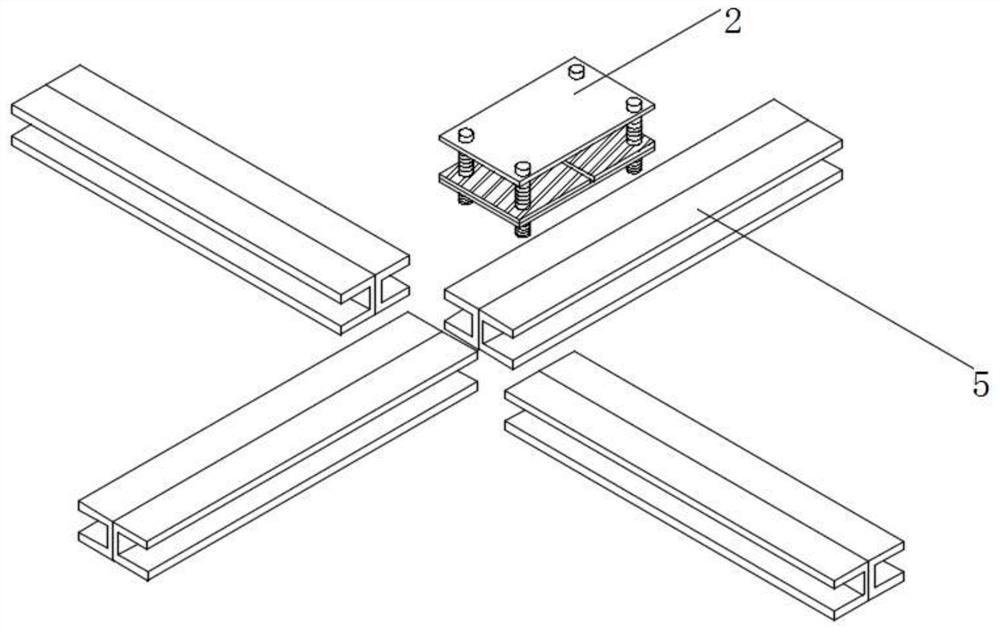

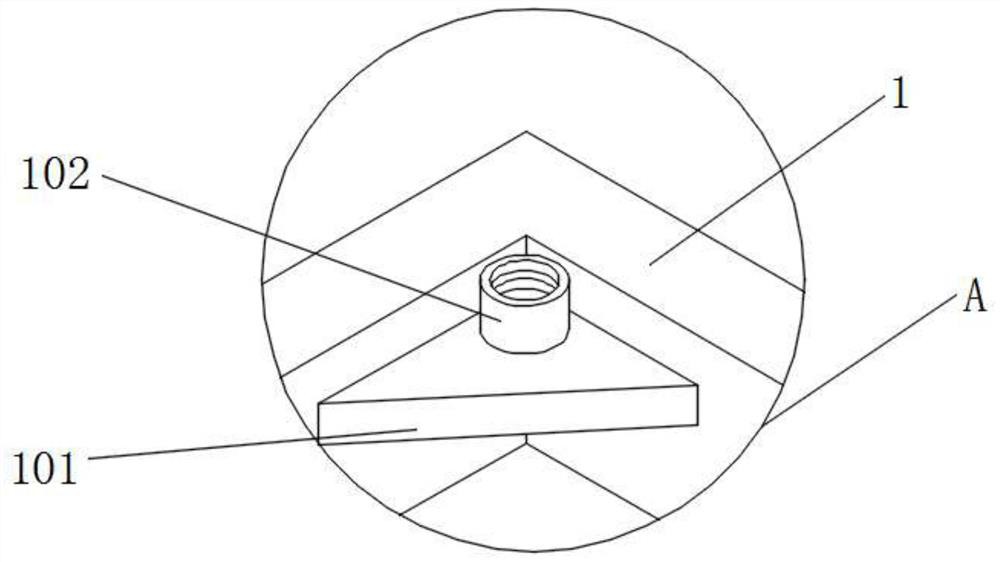

Detachable and movable heat preservation and insulation unit block roof

PendingCN113530058AHigh strengthReduce direct sunlightPhotovoltaic supportsBuilding roofsThreaded rodScrew thread

The invention discloses a detachable and movable heat preservation and insulation unit block roof. The roof comprises a box body; triangular plates are welded to the inner walls of the four corners of the box body; nut holes are welded to the tops of the triangular plates; threaded rods are in threaded connection with the interiors of the nut holes; sleeves are installed outside the threaded rods; rectangular supporting plates are installed at the tops of the sleeves; purlines are installed at the tops of the supporting plates; connecting structures are installed at the connecting positions of the purlines; the space between the purlines is filled with polyphenyl granule concrete; and a photovoltaic panel body is installed at the tops of the purlines. The purlines, expansion nets and the polyphenyl particle concrete are spliced to form heat preservation roof small panel blocks, then the heat preservation roof small panel blocks are connected through the connecting structures on the construction site to form the unit block roof, and then screws, the sleeves and the supporting plates are in threaded connection with the nut holes of the box body, so that industrialized production can be achieved and the purpose of fabricated construction engineering of fabricated construction is achieved.

Owner:湖南鸿云杭萧绿建科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com