Precast fabricated type beam wall combination member

A technology of prefabricated assembly and combined components, applied to building components, walls, building structures, etc., can solve the problems of high rigidity, high cost, self-heavy, etc., and achieve the effects of small rigidity, reduced workload, and light self-weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

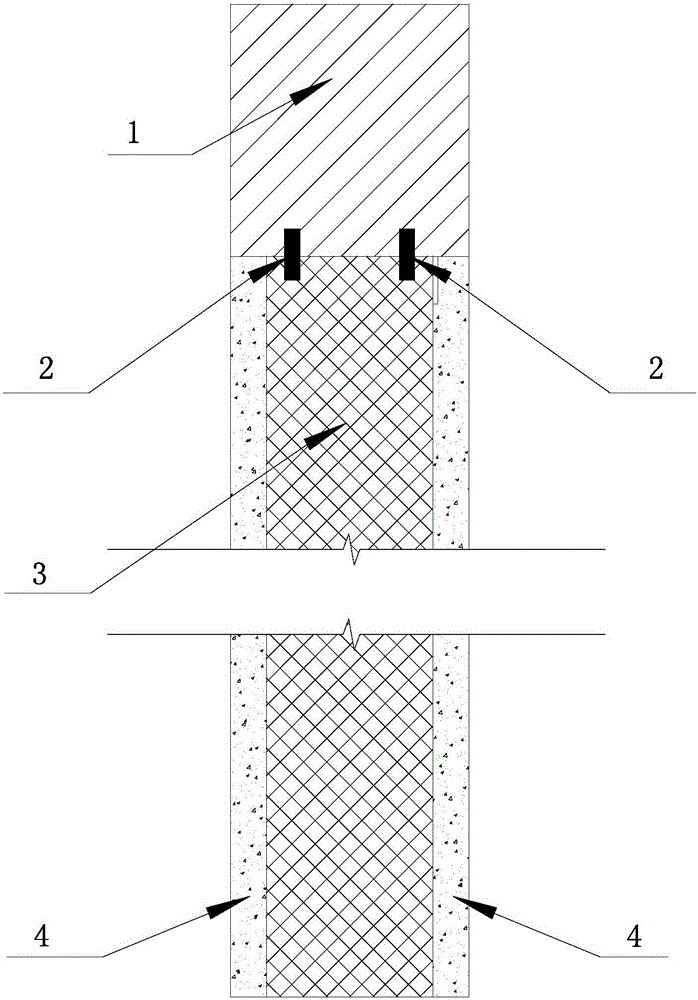

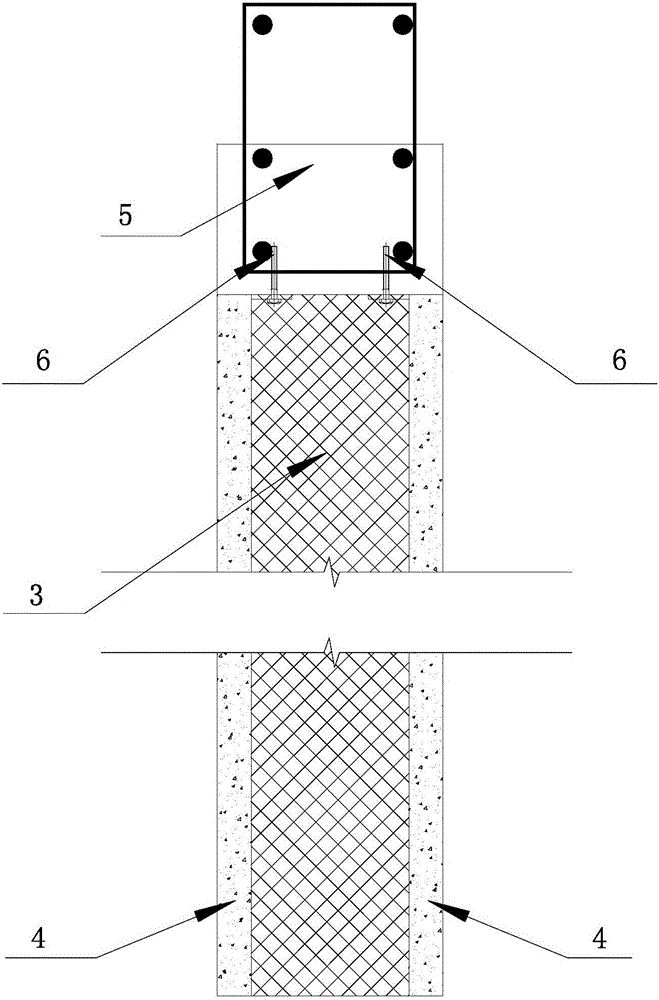

Embodiment 1

[0027] Such as figure 2 , Figure 4 and Figure 5 As shown, the prefabricated assembled beam 1 is specifically a prefabricated assembled concrete composite beam 5, and the prefabricated assembled concrete composite beam 5 and the light steel and light concrete composite wall core 3 are connected to each other by a connecting piece 6.

[0028] The longitudinal light steel 11 and the horizontal light steel 12 are connected to form a light steel skeleton 9; the inner cavity of the light steel skeleton 9 is filled with lightweight concrete 10, and the light steel and light concrete composite wall core 3 is formed together with the light steel skeleton 9; The outer side of the steel light concrete wall core 3 is provided with a wall surface layer 4 to form a light steel light concrete wall; the light steel light concrete composite wall is connected with the prefabricated assembly type through the connector 6 between the light steel light concrete composite wall and the composite ...

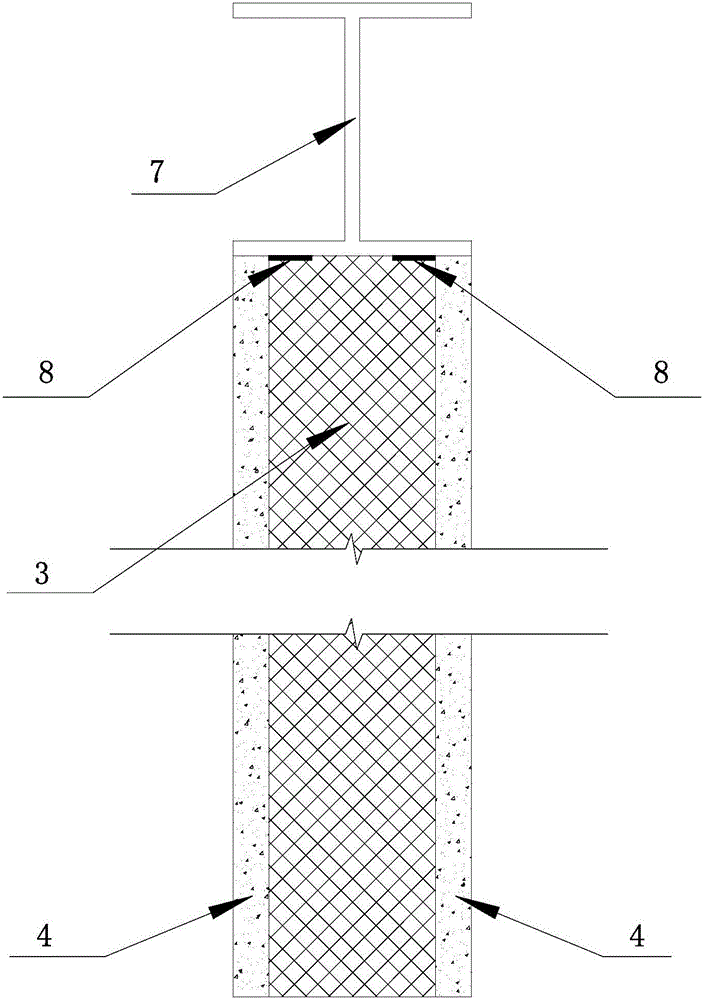

Embodiment 2

[0032] Such as image 3 , Figure 4 and Figure 6 As shown, the prefabricated assembled beam 1 is specifically a prefabricated assembled steel beam 7, and the prefabricated assembled steel beam 7 and the light steel light concrete composite wall wall core 3 are composed of a light steel light concrete composite wall and a prefabricated steel beam. The welded joints 8 are connected to each other.

[0033] The longitudinal C-shaped light steel 13 and the transverse C-shaped light steel 14 are connected to form a light steel skeleton 9; the inner cavity of the light steel skeleton 9 is filled with lightweight concrete 10, and the light steel and light concrete composite wall is formed together with the light steel skeleton 9 Core 3; light steel and light concrete wall core 3 is provided with a wall surface layer 4 to form a light steel and light concrete wall; the light steel and light concrete composite wall passes through the welded connection between the light steel and ligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com