Patents

Literature

35results about How to "Large block" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

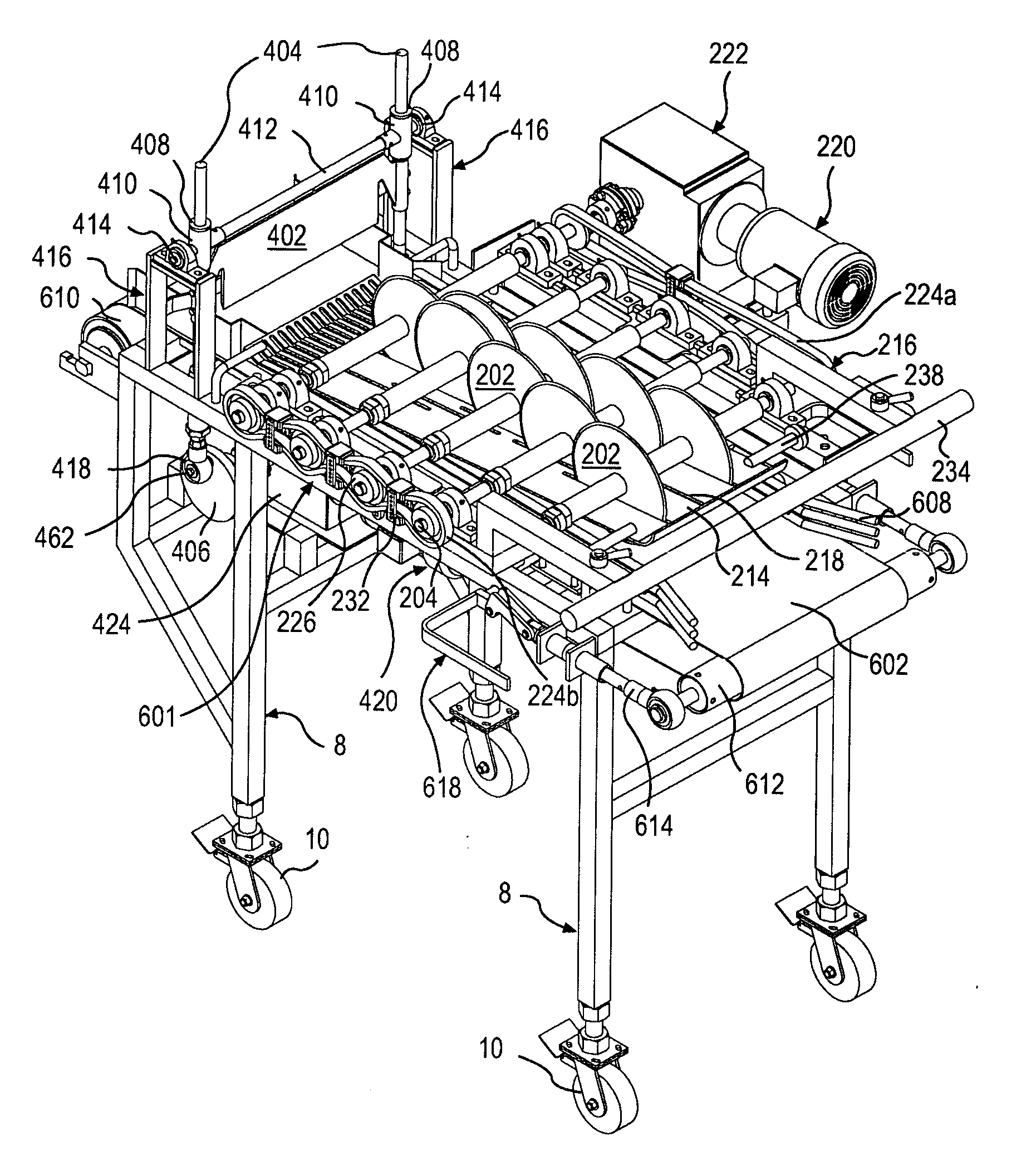

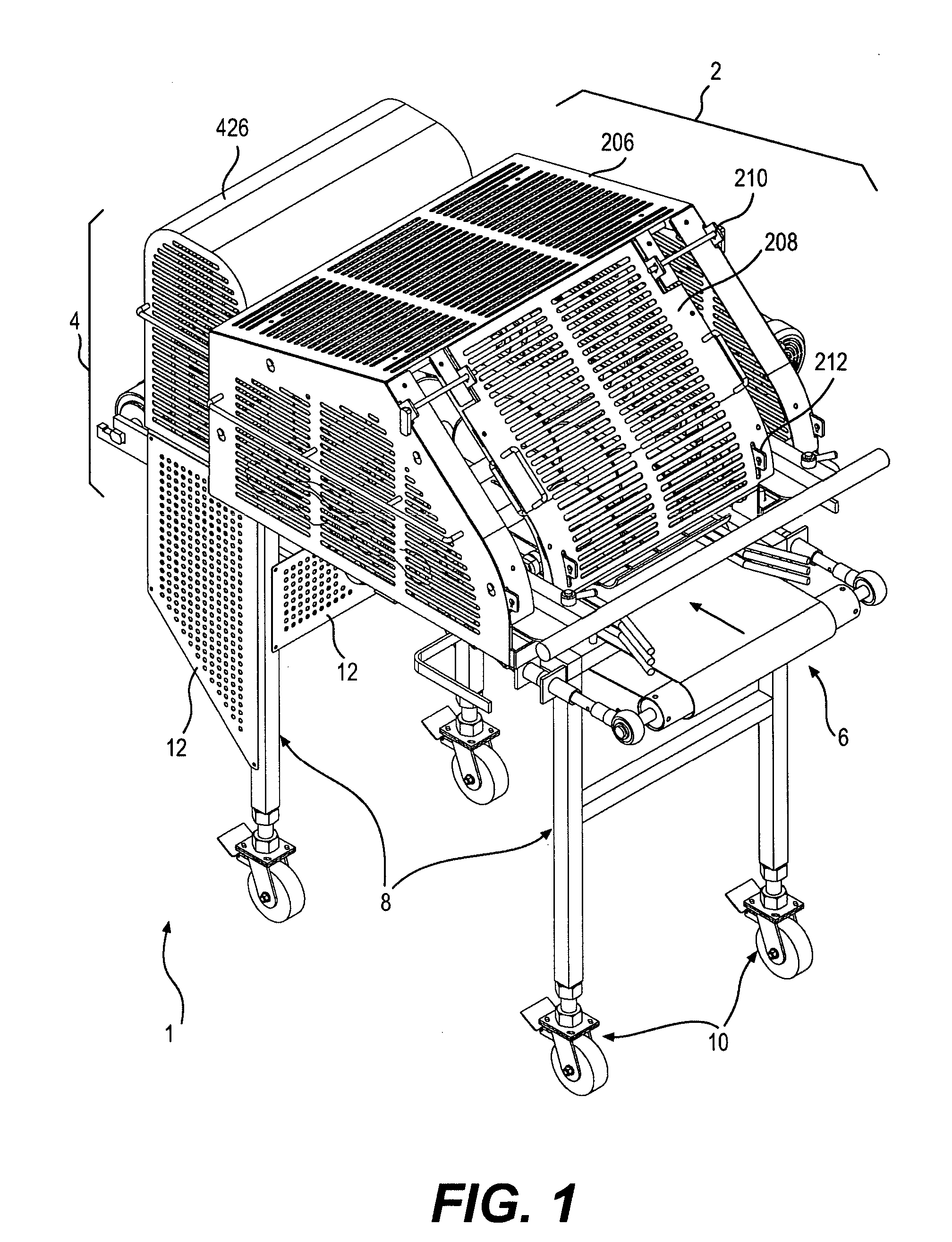

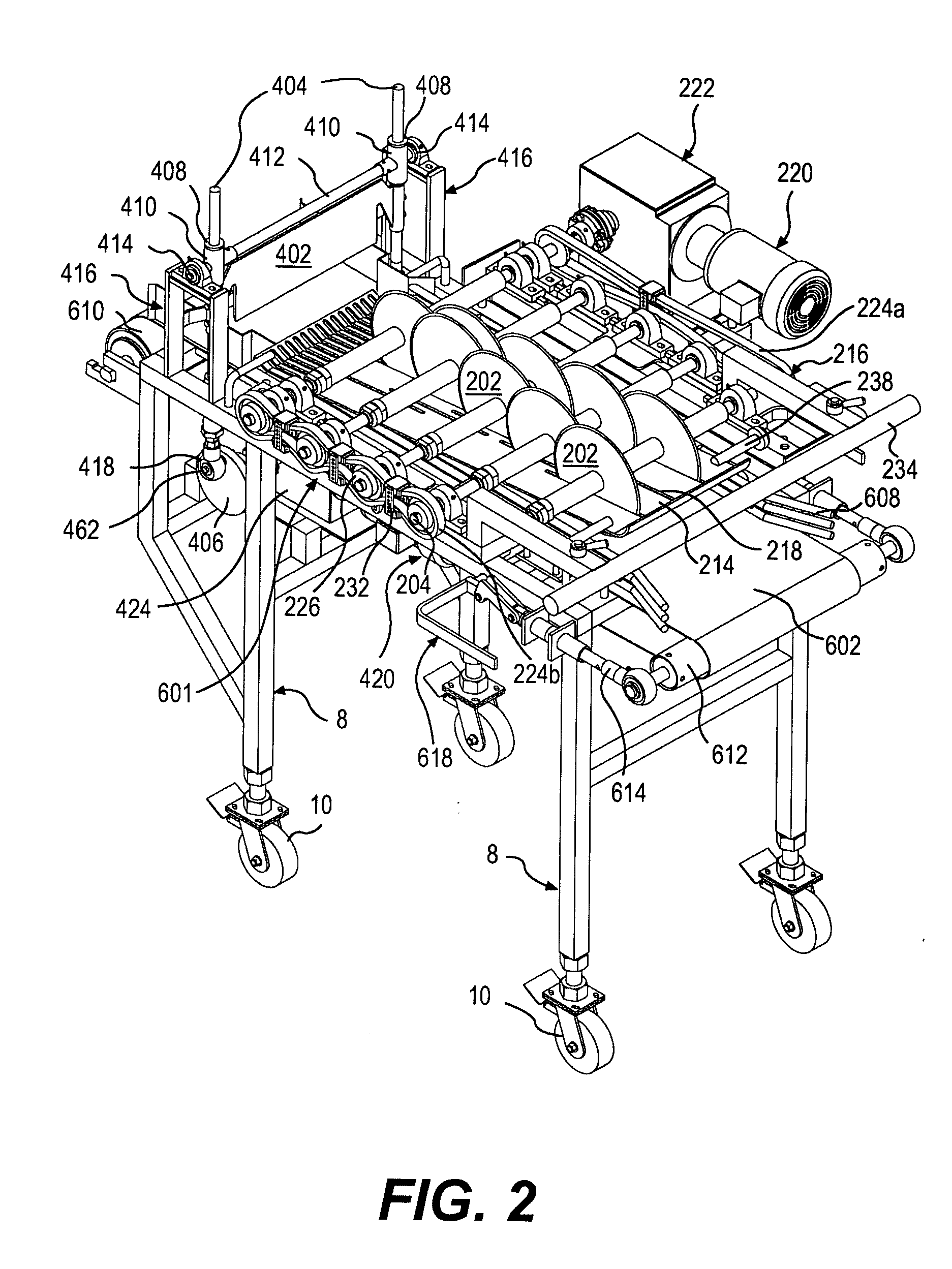

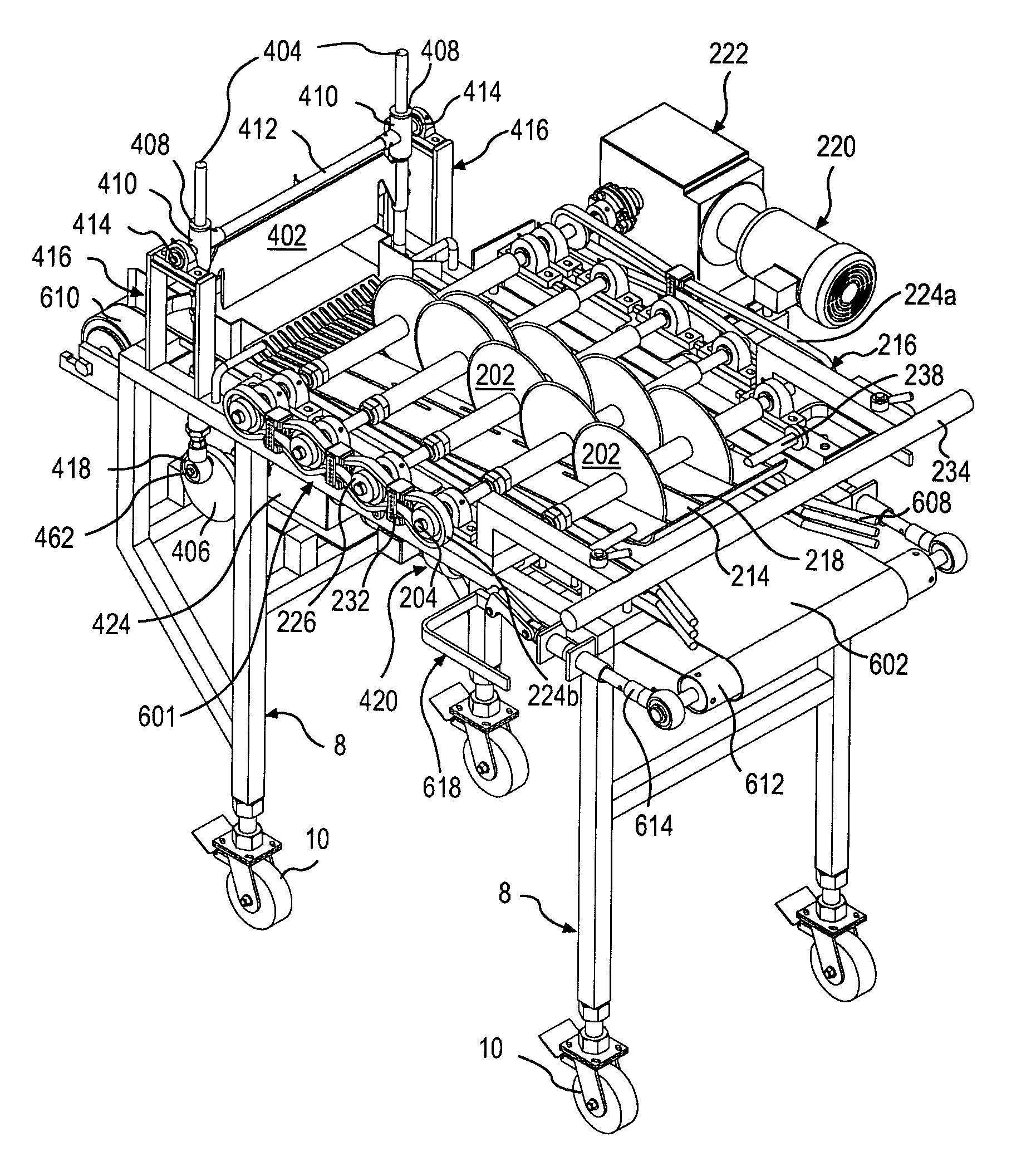

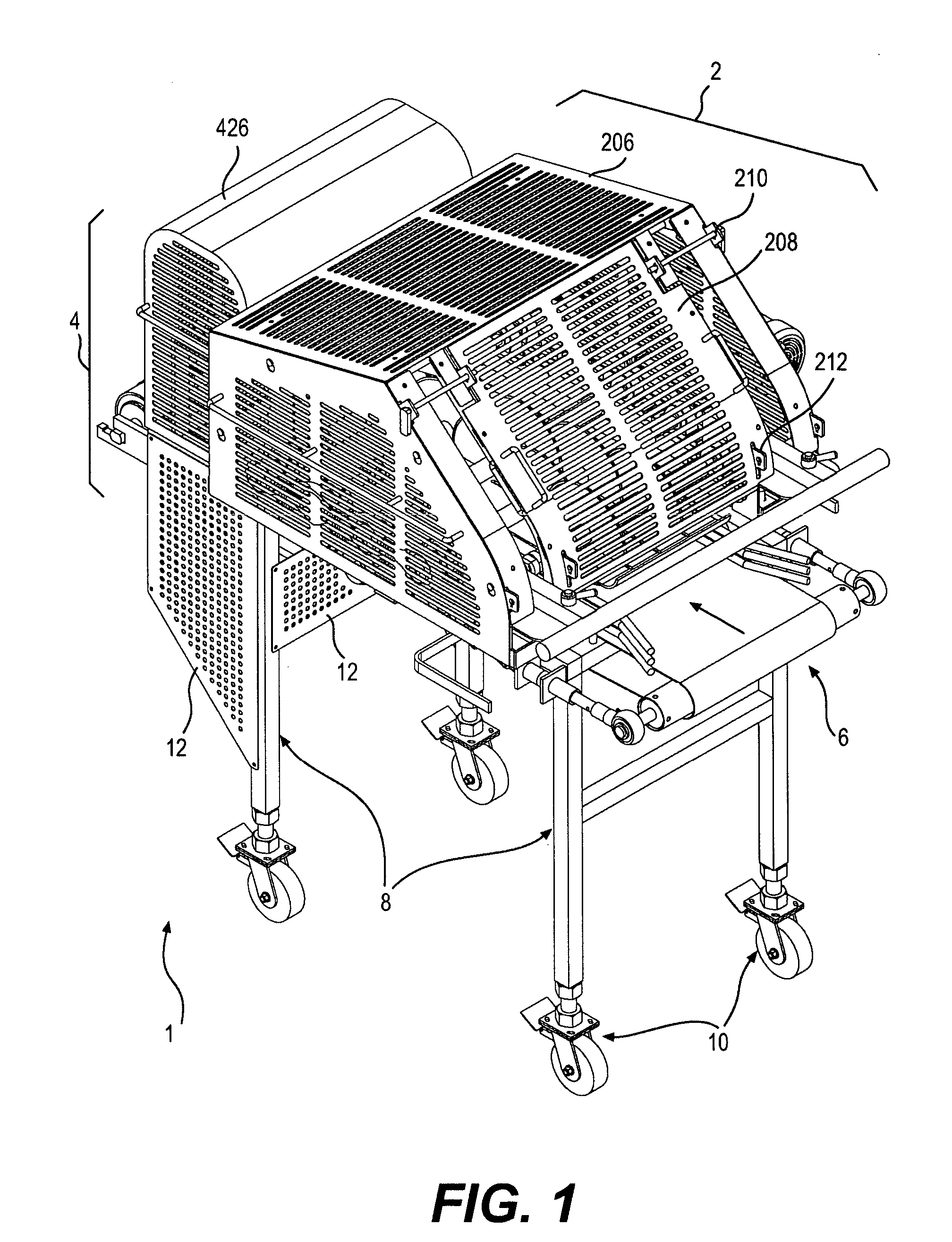

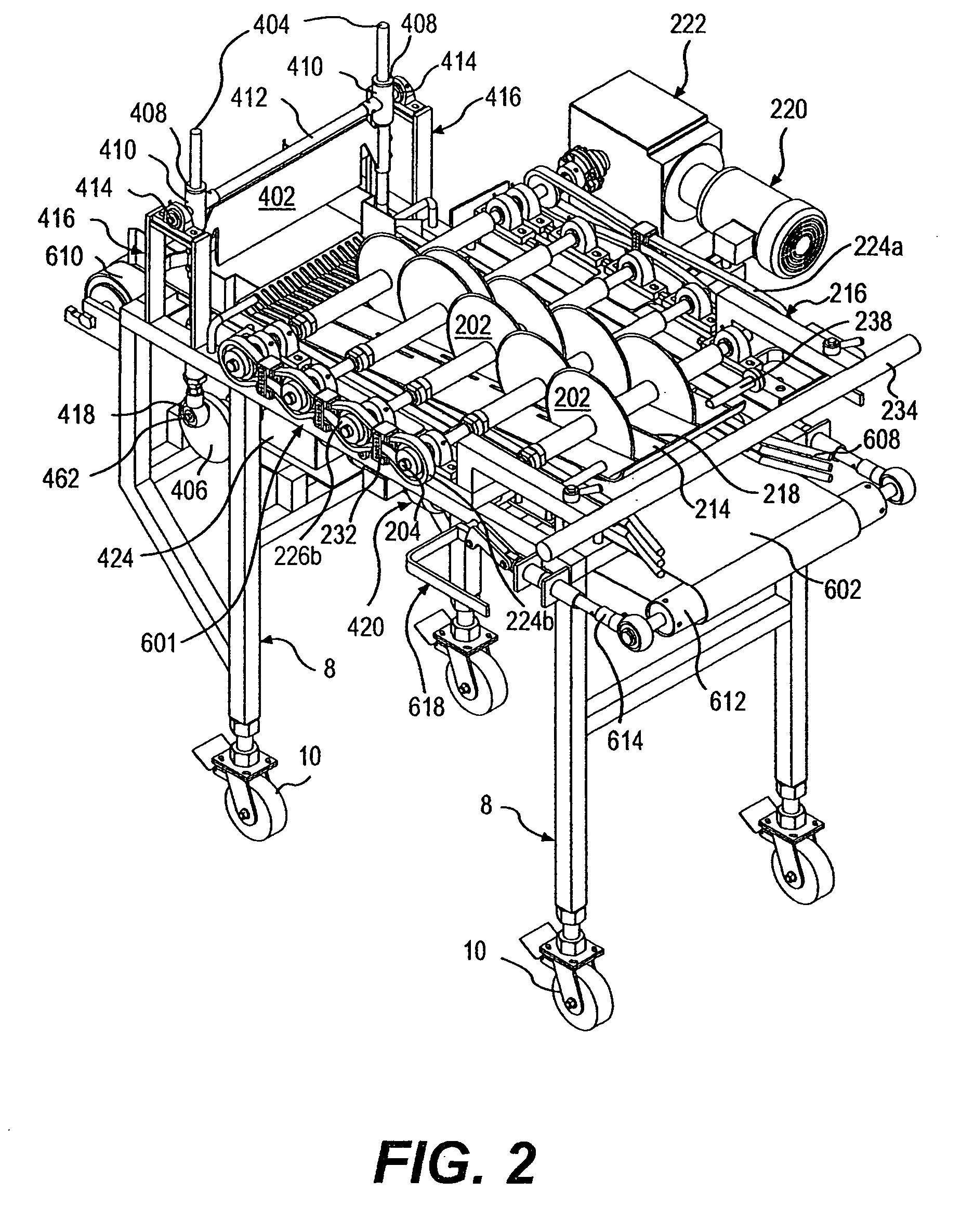

Apparatus and process for dicing a deformable product

ActiveUS20050005745A1Reduce in quantityMore productiveGuide fencesFeeding devicesEngineeringMovement pattern

An apparatus for cutting a product includes a conveyor assembly and a slitter assembly. The conveyor assembly conveys the product in a feed direction and defines a conveyance surface, on which the product is conveyed. The slitter assembly slits the product into strips as the product is conveyed in the feed direction. The slitter assembly comprises a plurality of cutting elements arranged in a V shape and overlapping one another in the feed direction, as viewed in a direction substantially normal to the conveyance surface. A chopping assembly is positioned downstream of the slitter assembly. The chopping assembly comprises an elongated blade, which moves in an elliptical cutting motion, such that it has a component in the downward direction to sever the strips of product, and a component in the feed direction to toss the severed pieces of product in the feed direction.

Owner:LEPRINO FOODS

Apparatus for dicing a deformable product

ActiveUS7100486B2Reduce in quantityMore productiveGuide fencesFeeding devicesMovement patternSheet material

An apparatus for cutting a product includes a conveyor assembly and a slitter assembly. The conveyor assembly conveys the product in a feed direction and defines a conveyance surface, on which the product is conveyed. The slitter assembly slits the product into strips as the product is conveyed in the feed direction. The slitter assembly comprises a plurality of cutting elements arranged in a V shape and overlapping one another in the feed direction, as viewed in a direction substantially normal to the conveyance surface. A chopping assembly is positioned downstream of the slitter assembly. The chopping assembly comprises an elongated blade, which moves in an elliptical cutting motion, such that it has a component in the downward direction to sever the strips of product, and a component in the feed direction to toss the severed pieces of product in the feed direction.

Owner:LEPRINO FOODS

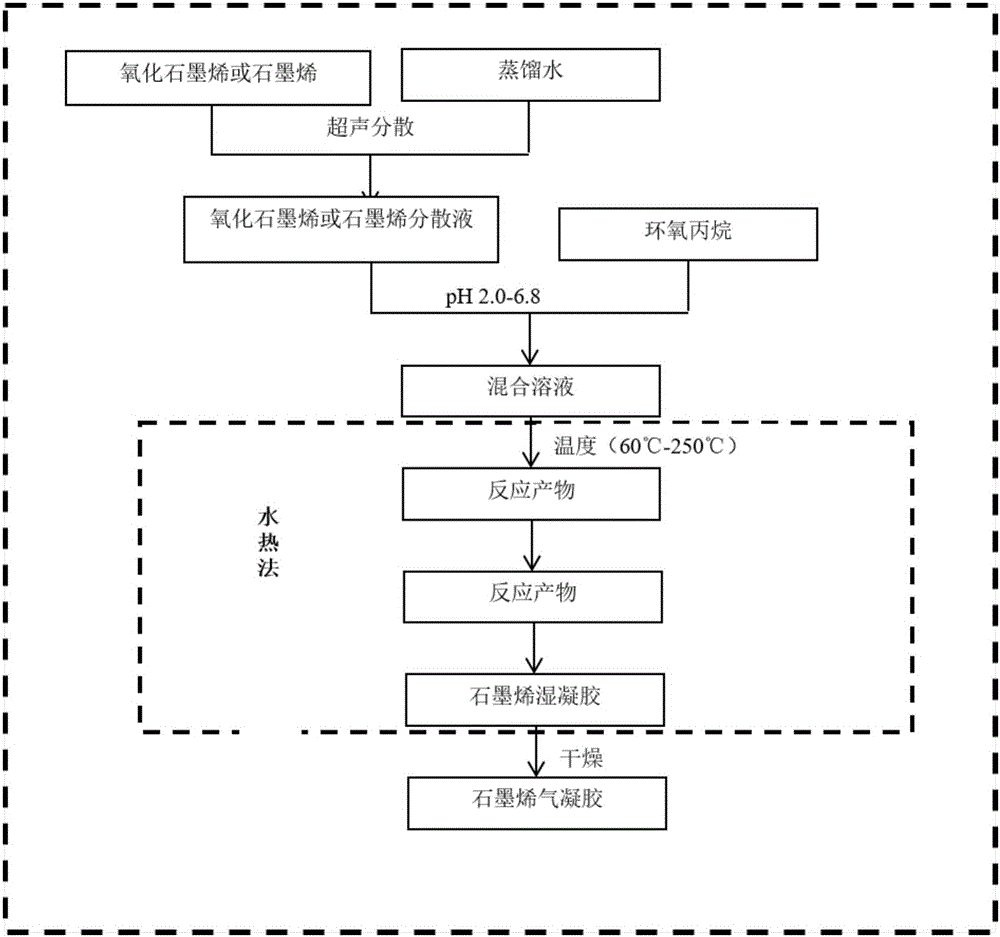

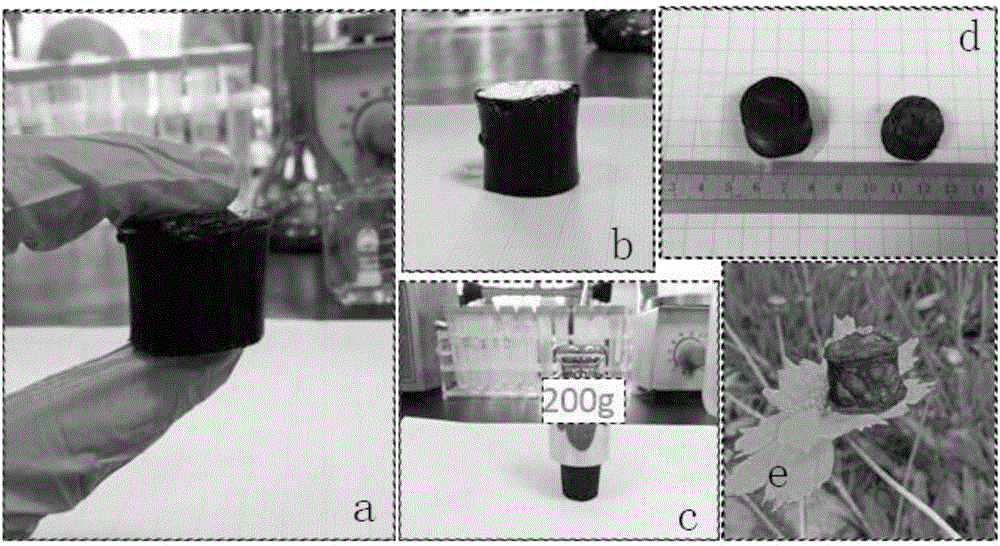

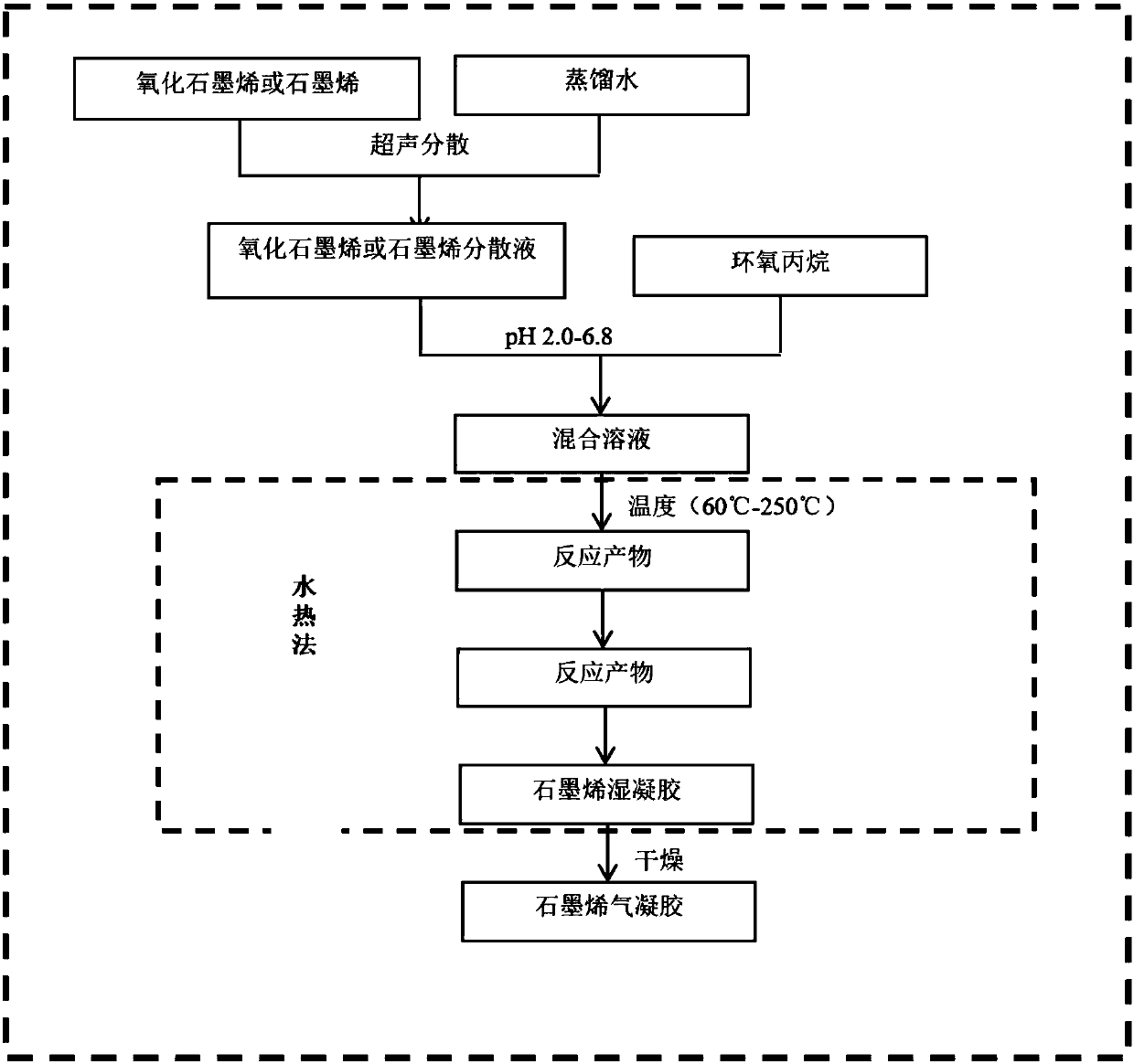

Method for preparing block graphene aerogel

The invention discloses a method for preparing block graphene aerogel. The method includes the specific steps that cheap small molecule epoxy propane serves as a cross-linking agent and is mixed with oxidized graphene or graphene dispersion liquid, a hydrothermal method is utilized to obtain graphene wet gel, drying is further conducted, and the graphene aerogel is obtained. The method is simple in operation step, good in repeatability, mild in reaction condition and suitable for industrialized production, the price of the cross-linking agent is low, and the finally obtained graphene aerogel is complete in block degree, low in density, good in elasticity and high in mechanical strength.

Owner:SOUTHEAST UNIV

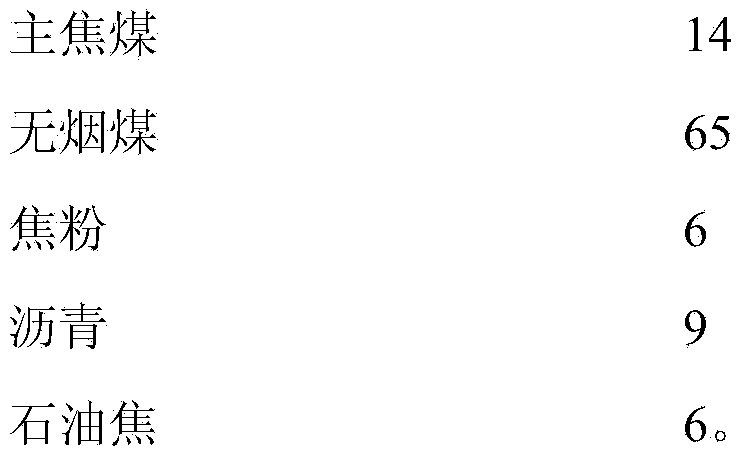

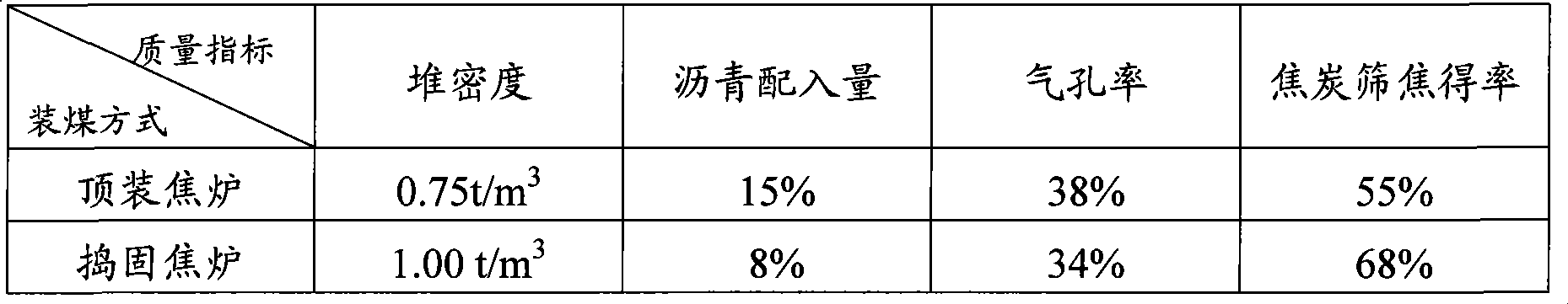

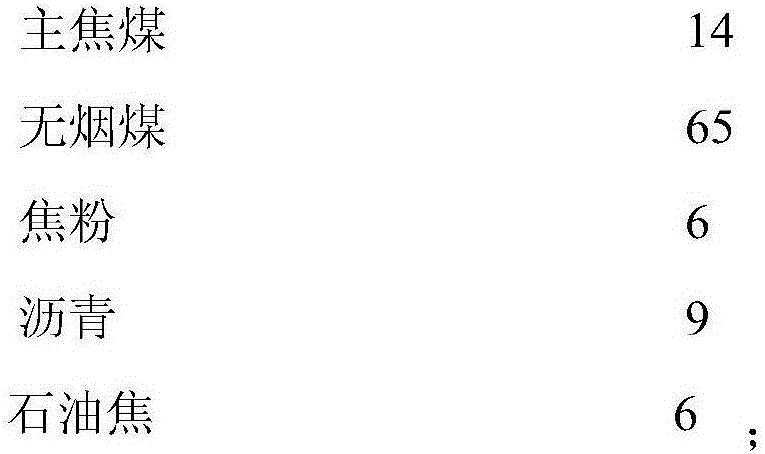

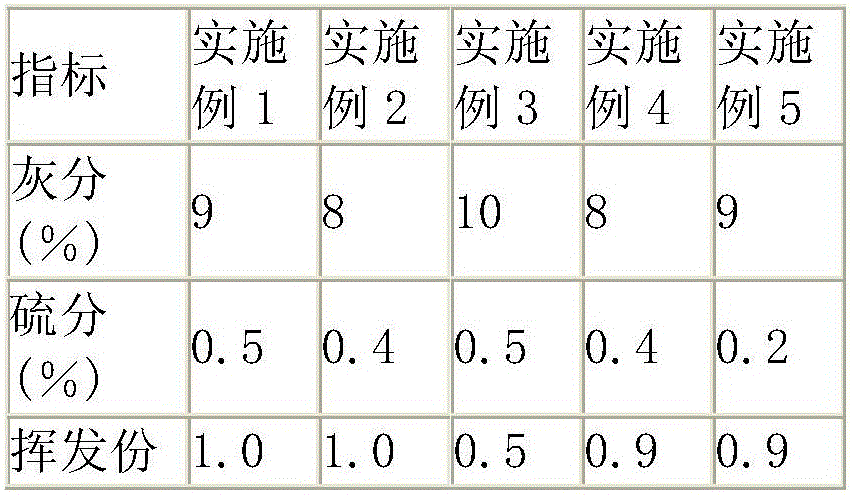

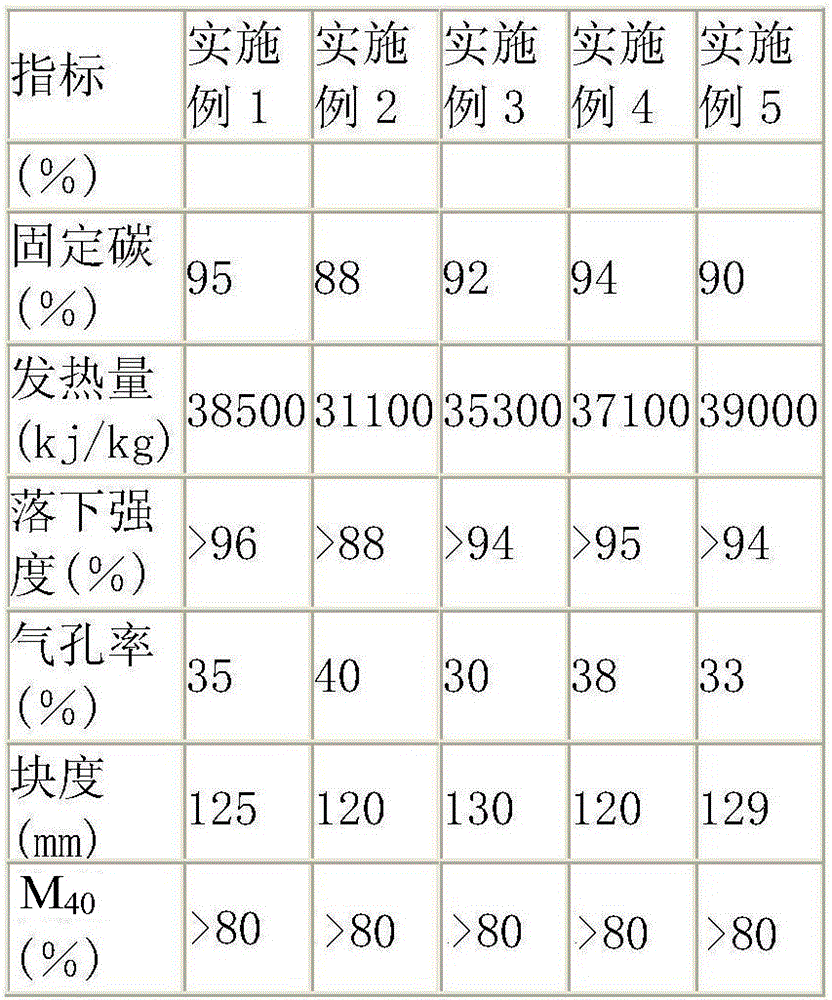

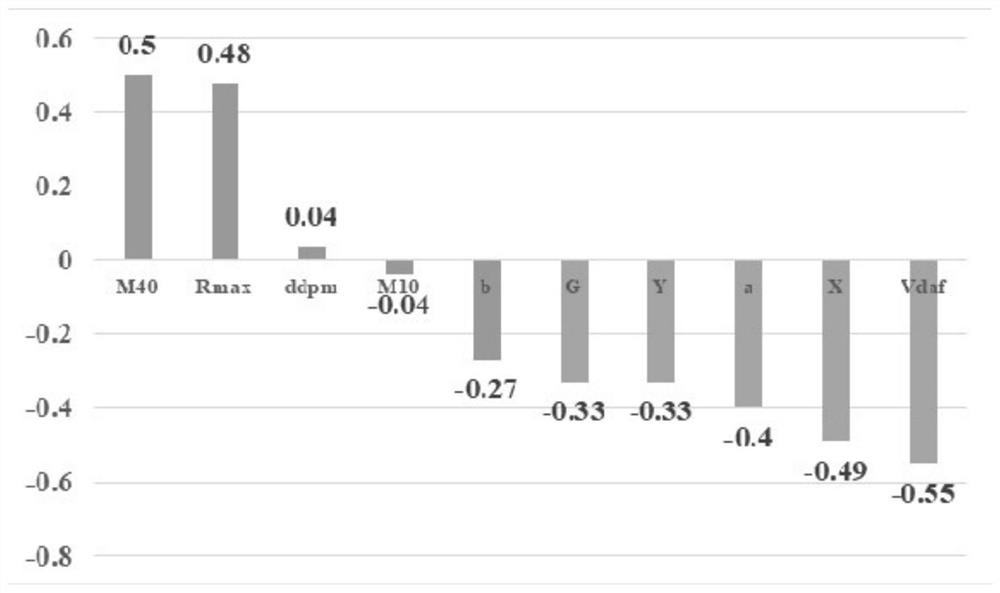

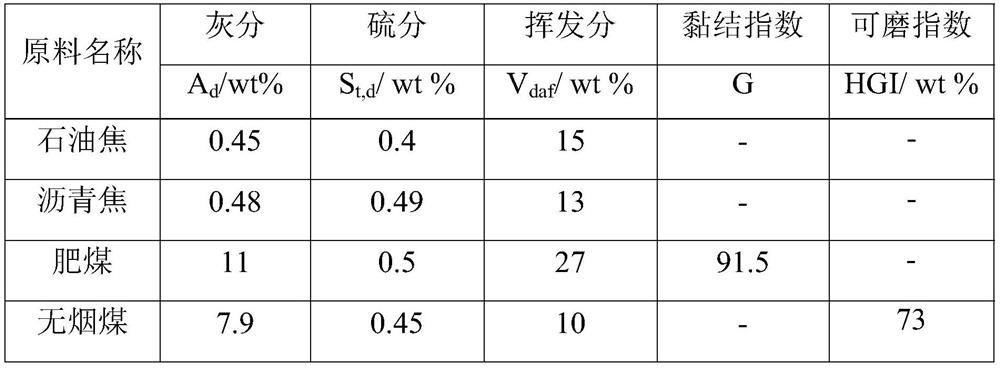

Method for preparing coke

ActiveCN104194813AQuality improvementHigh strengthSpecial form destructive distillationPorosityCoke oven

The invention provides a method for preparing coke. The invention provides a preparation method of formed coke in a vertical coke oven. The method comprises the step of carrying out dry distillation on the raw materials including coking coal, anthracite, coke powder, asphalt and petroleum coke. The formed coke is prepared by stirring blending coal at high temperature and high pressure according to a certain proportion and carrying out forming, charging and carbonizing processes. The method has the beneficial effects that a formula effectively solves the problem of impacts of plastic mass change under the conditions of high temperature and rapid heating; the coke quality reaches the A-level rate, which is above 95%, in the national standard; the coke has the characteristics of uniform product specification, high lumpiness, high strength, lower porosity and reactivity and low ash content and sulfur content.

Owner:SHANDONG JUMING ENERGY

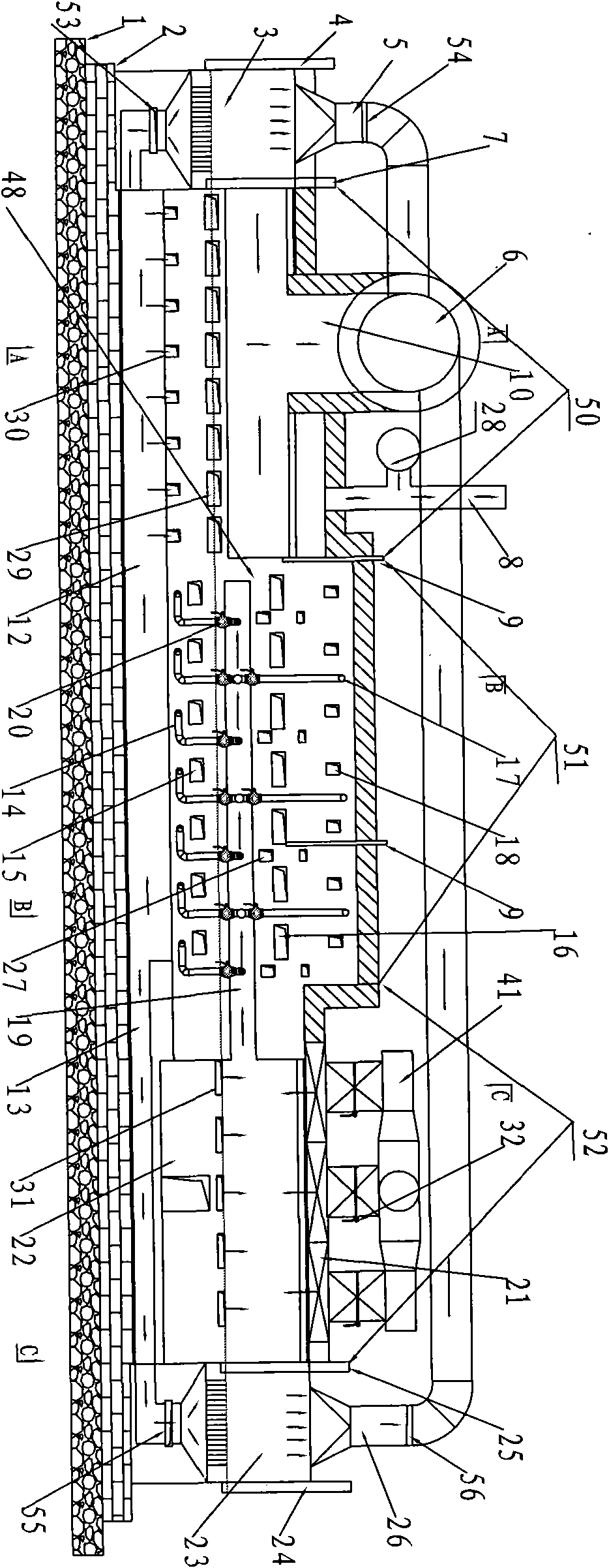

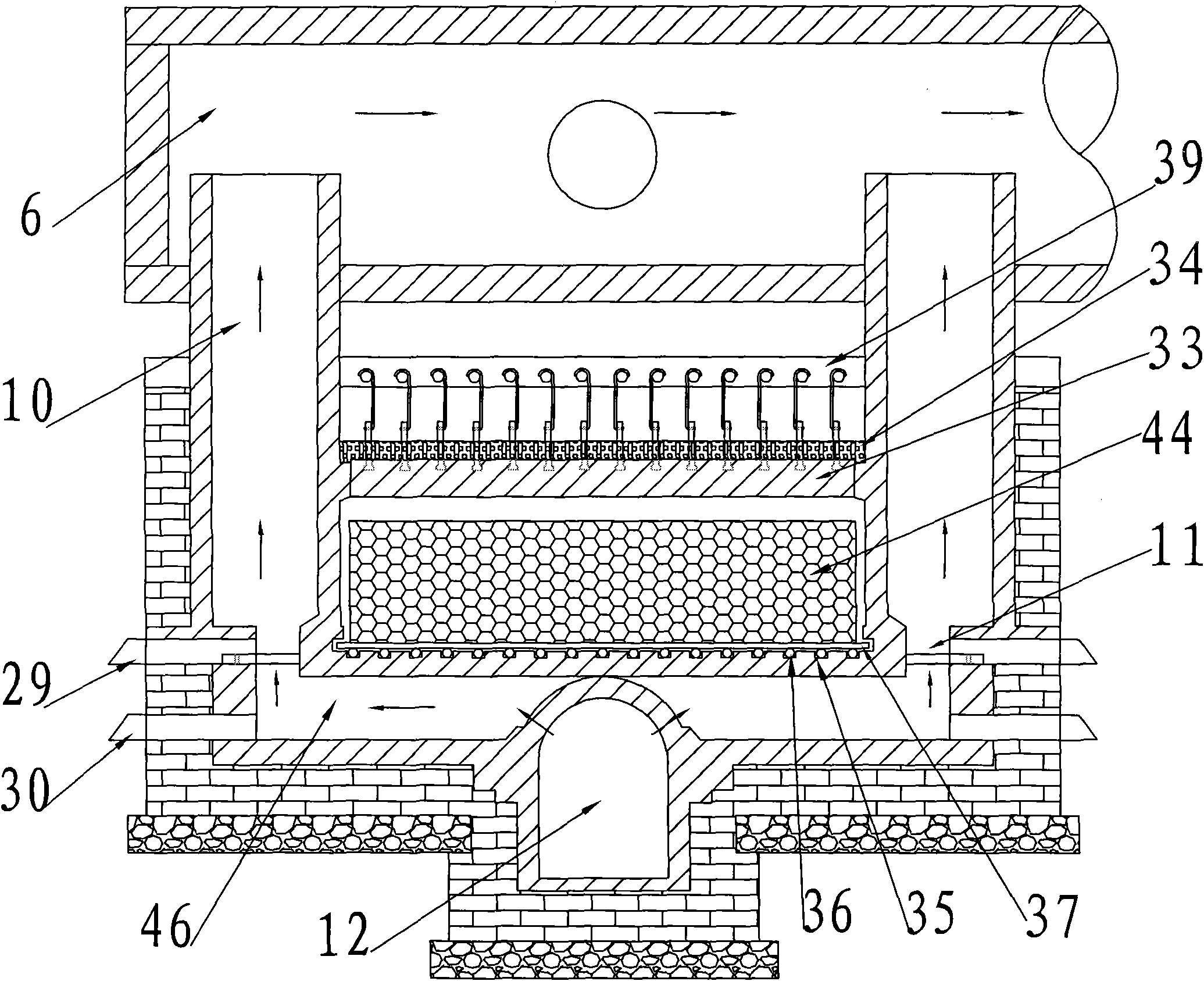

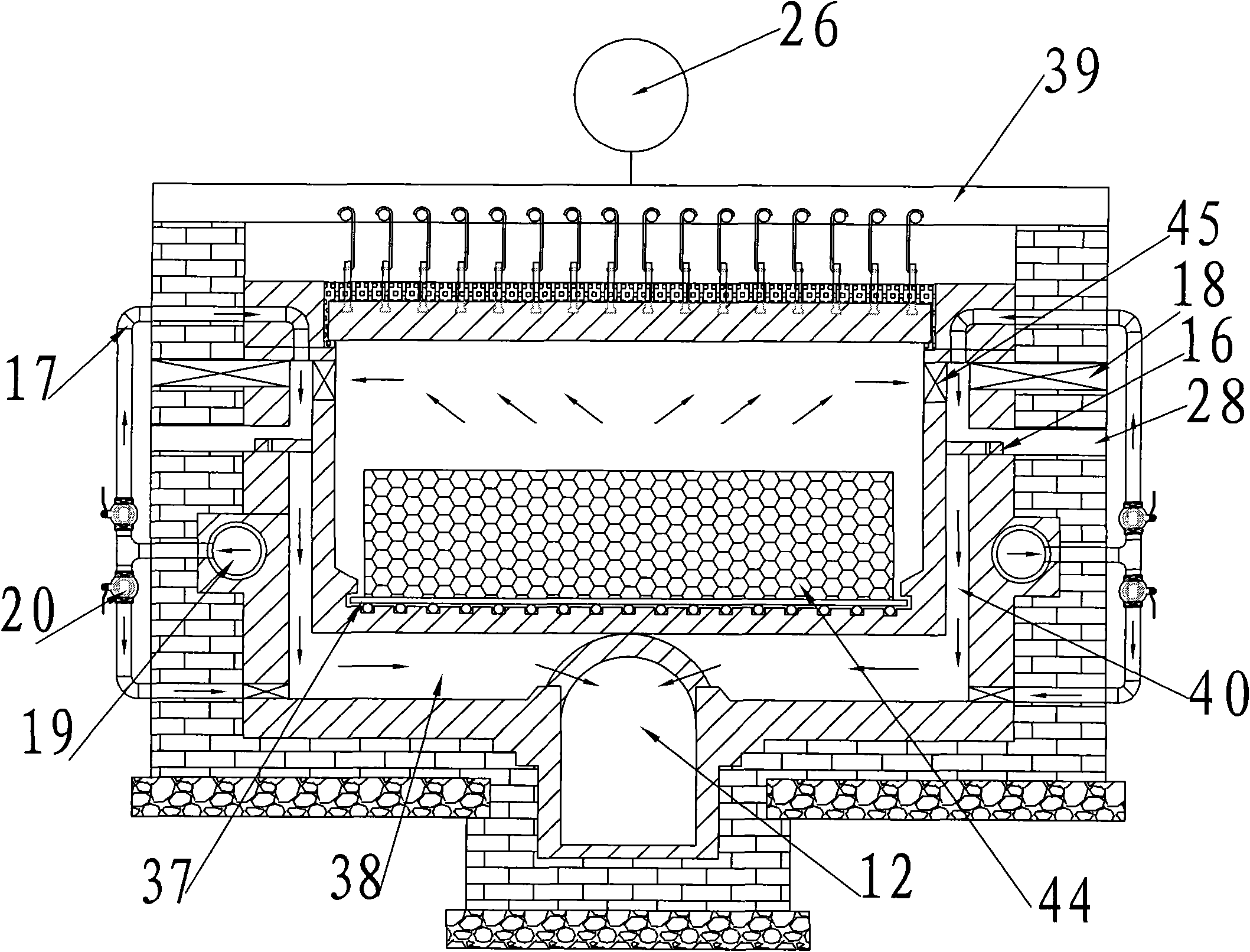

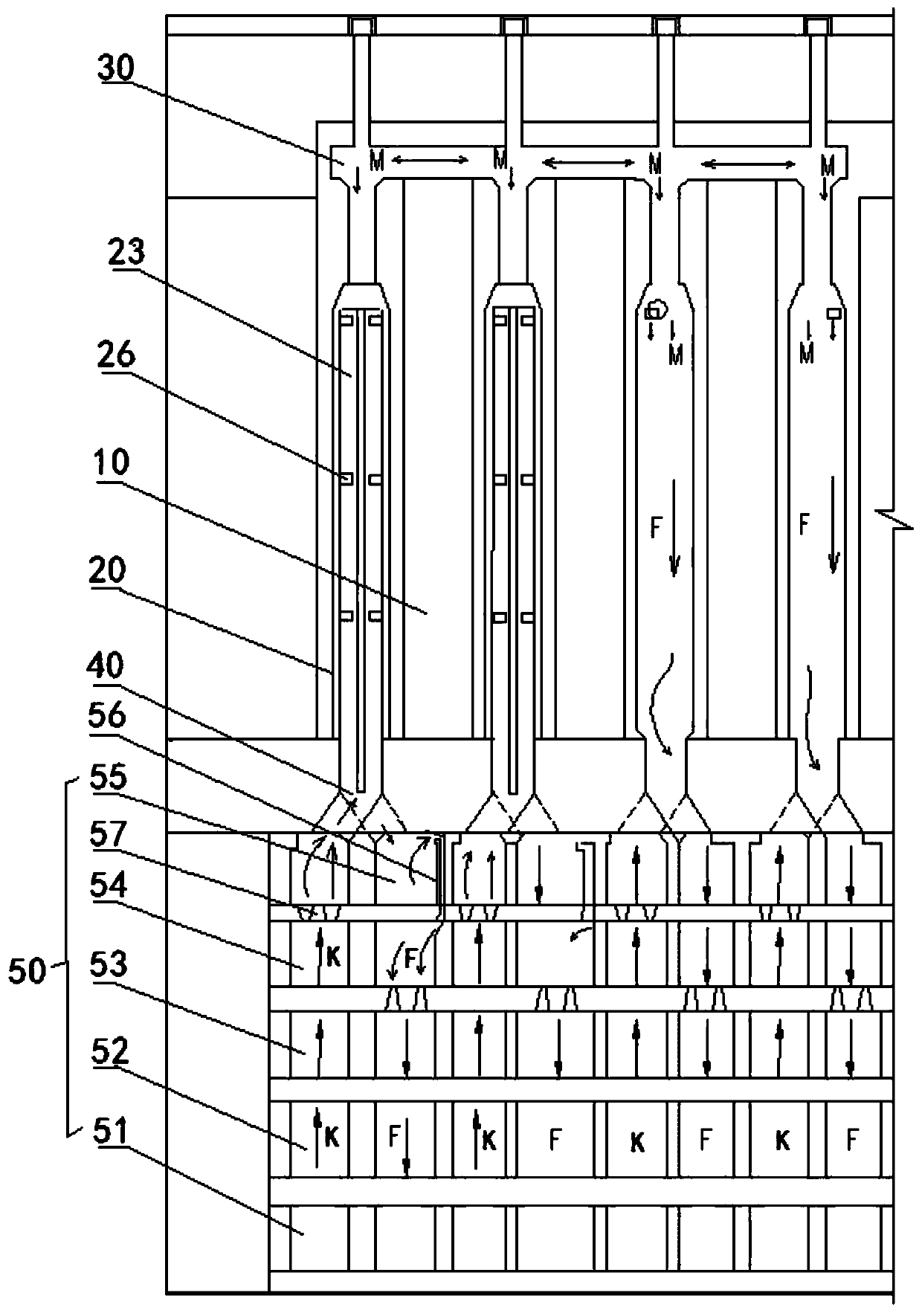

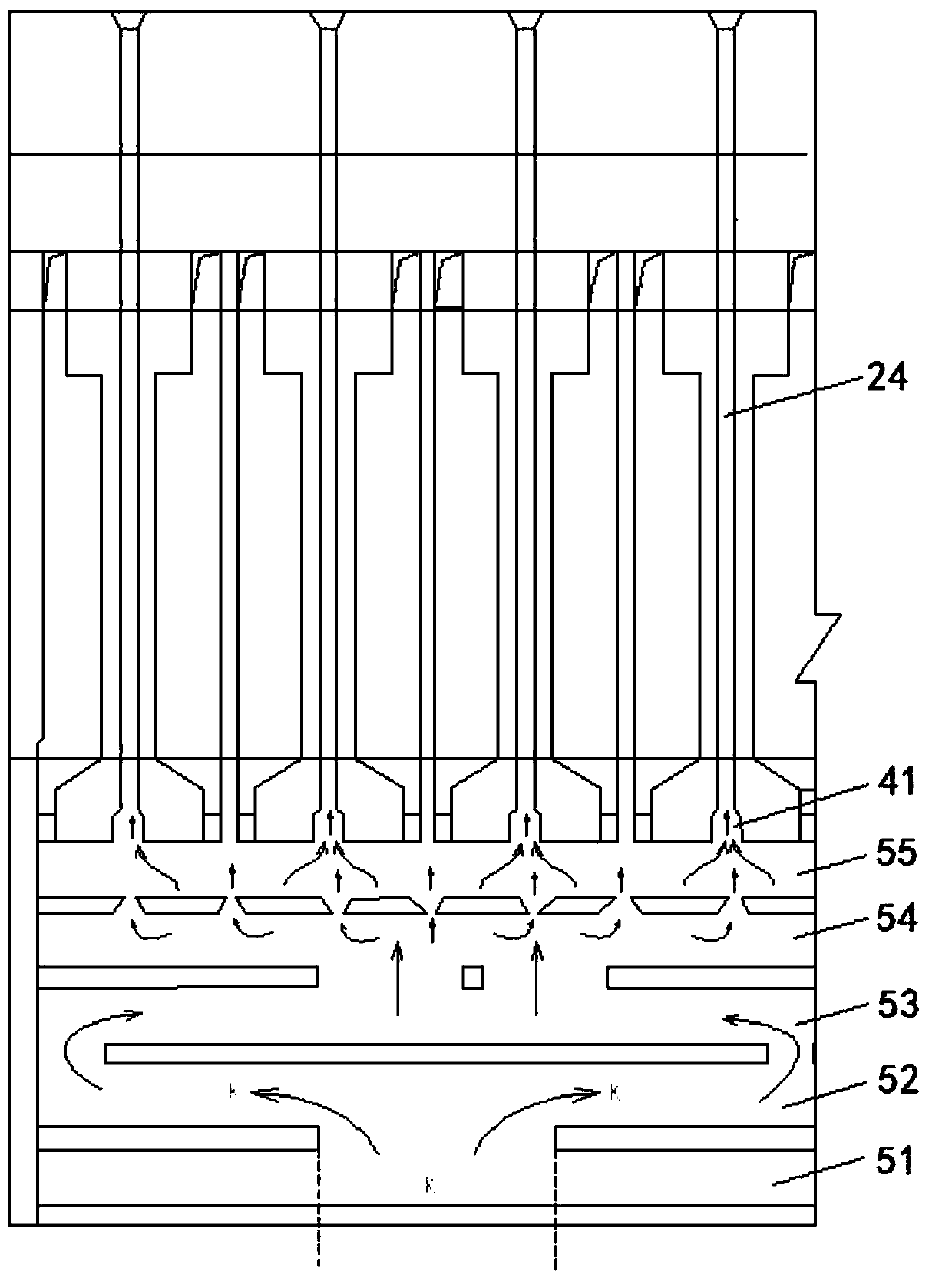

Movable slide bed tunnel type coke oven and use method thereof

InactiveCN101792676AReduce the amount of gasLow energy consumption for cokingMechanical conveying coke ovensHorizontal chamber coke ovensWater sourceFlue gas

The invention relates to a movable slide bed tunnel type coke oven and a use method thereof, and belongs to the field of coal processing and conversion and coking equipment. The coke oven comprises an oven body (48), a front sealing door (7) of the coke oven body, a back sealing door (25) of the coke oven body, a sub-flue (10), a bottom flue (12) and a main flue (6), and is characterized by comprising a coaling preparation chamber (3), a preheating section (50), a carbonization section (51), coke dry quenching section (52) and a coke outlet preparation chamber (23), each part has different structures, and the five parts are connected in series and communicated with each other; and a movable slide bed (37) of loading briquettes or tamping coal materials (44) sequentially pass through the five parts of the coke oven by intermittently moving on a slideway (35) of the slide bed, so that the coal materials are carbonized into coke. The produced coke has uniform specification, large lumpiness, good strength, high heat energy utilization rate, high degree of mechanization, and clean emission of flue gas, and the invention effectively protects atmosphere and water sources and realizes clean production.

Owner:GUIZHOU SUNNY CLEAN ENERGY TECH DEV

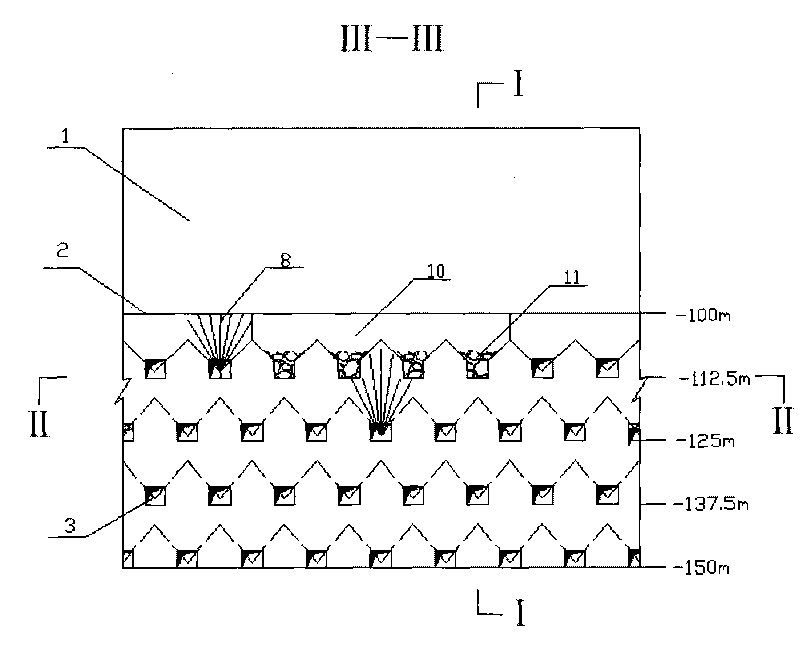

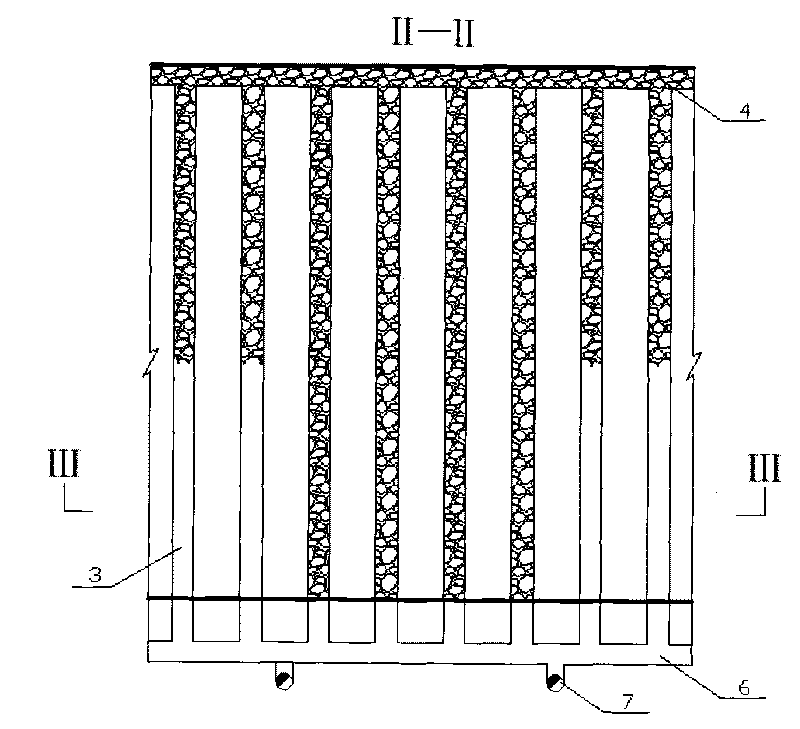

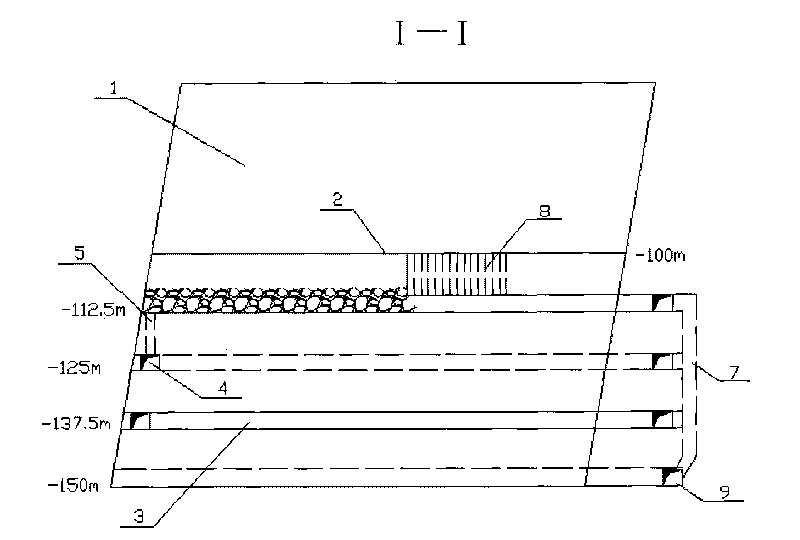

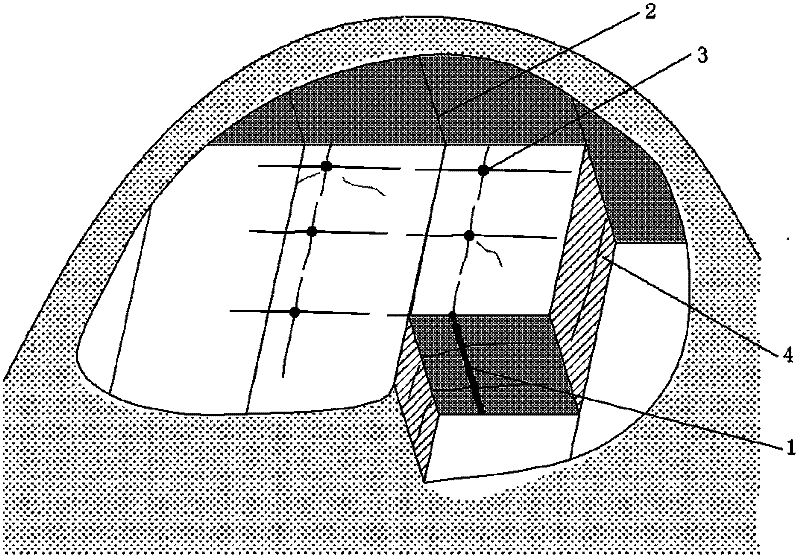

Covering layer forming method of blind ore bodies

The invention discloses a covering layer forming method of blind ore bodies with stable and massive roof surrounding rocks applying a bottom pillar-free subsection collapse method. The method can obviously reduce the work quantity of caving, has low caving cost and a little ore dilution, and improves the production efficiency and economic benefit of mines. The key points of the technical scheme are as follows: a first subsection mining tunnel is distributed in an ore body, and continuous gobs provided after the first subsection mining are used for inducing the roof rocks to collapse; and with the performing of the mining work, the areas of the gobs are expanded continuously, when the areas of the gobs reach the critical exposed area, the roof rocks at the gobs are unstable gradually and collapsed under the effects of stress and gravity so as to form a covering layer. When the first subsection mining tunnel distributes blast holes, the ore bodies among the access roads are required to be thoroughly collapse so as to cut off the support of the roof surrounding rocks completely and form continuous gobs with exposed area. The forming method is applicable to forming the covering layer of more stable and massive blind ore bodies of the roof surrounding rocks.

Owner:KUNMING UNIV OF SCI & TECH

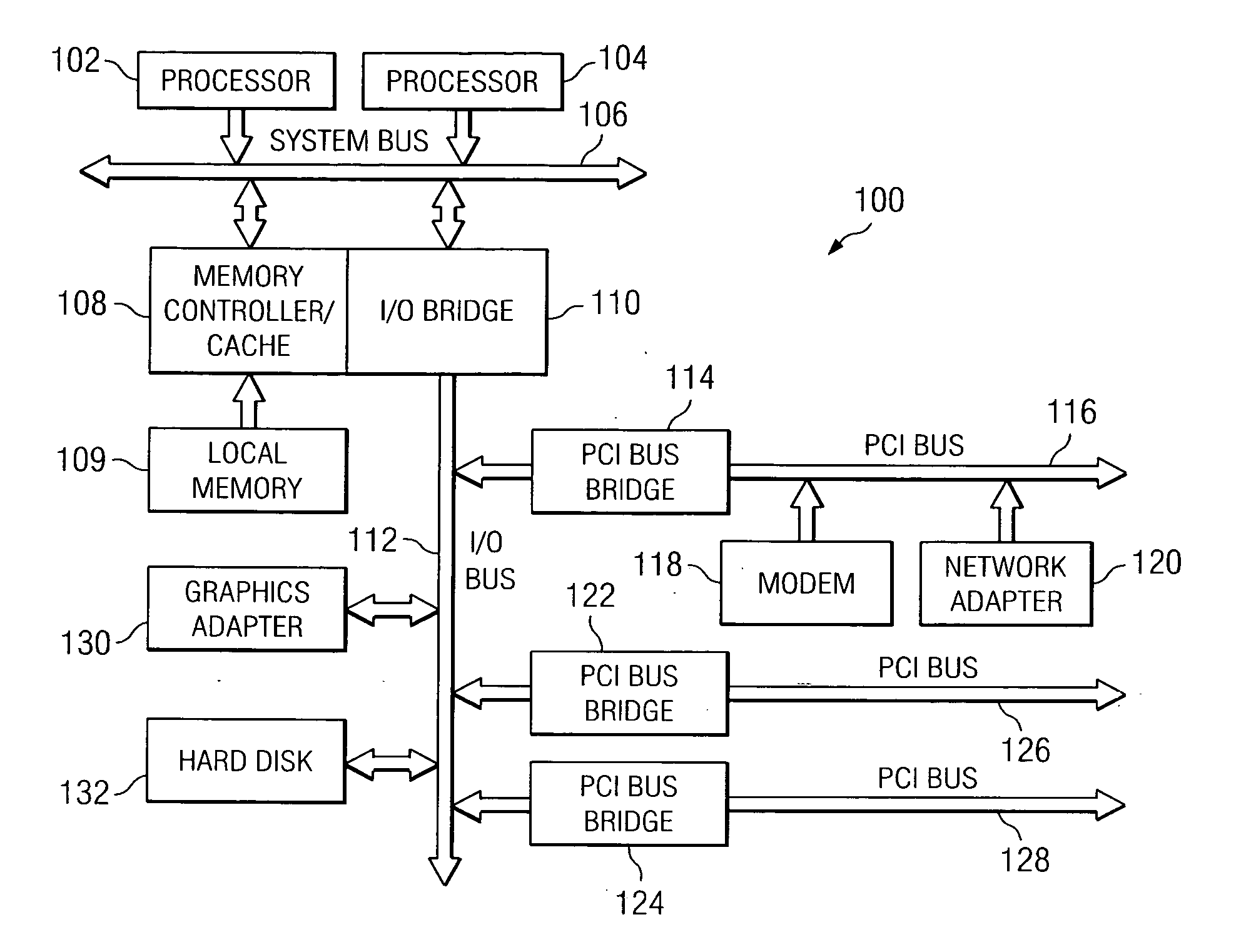

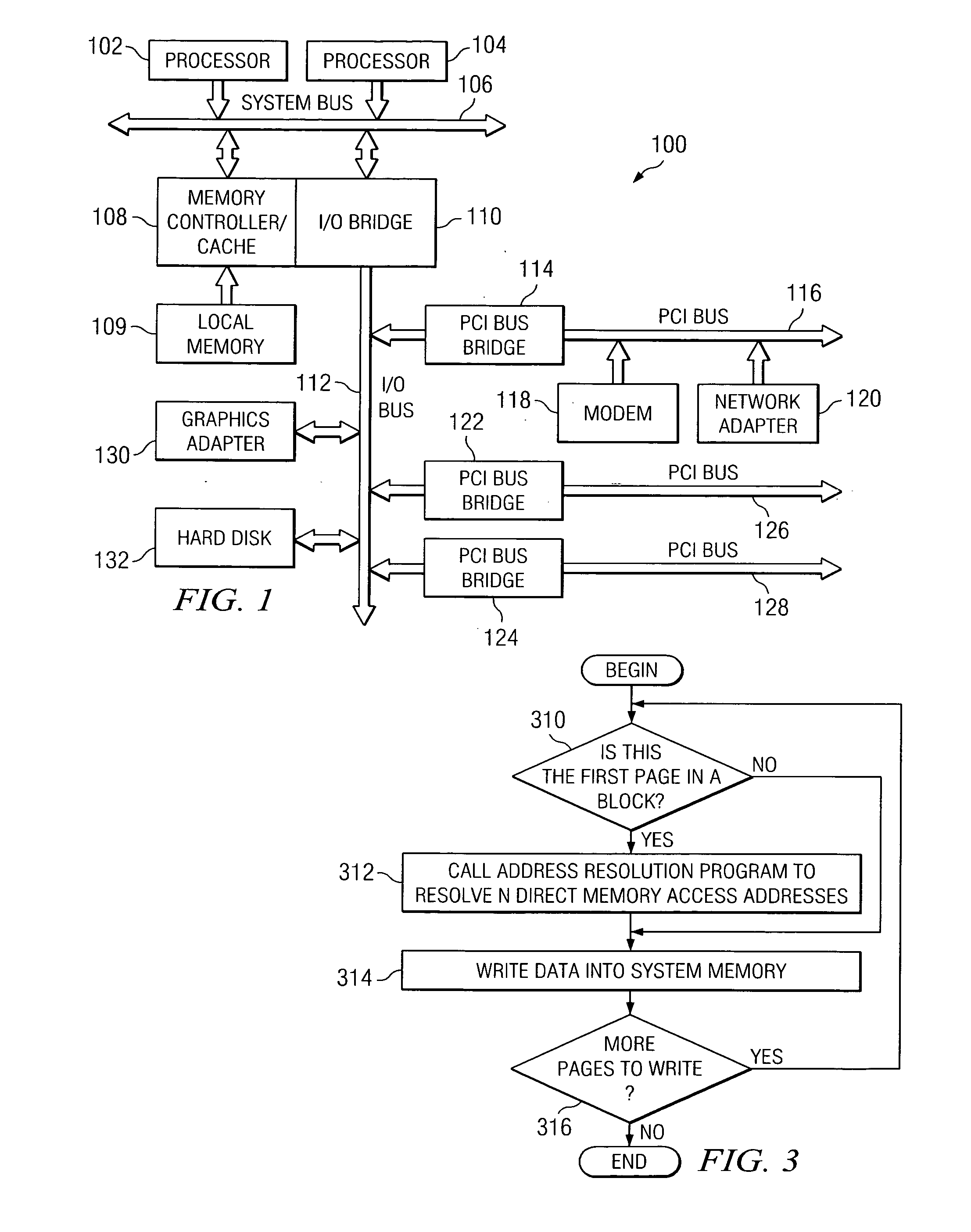

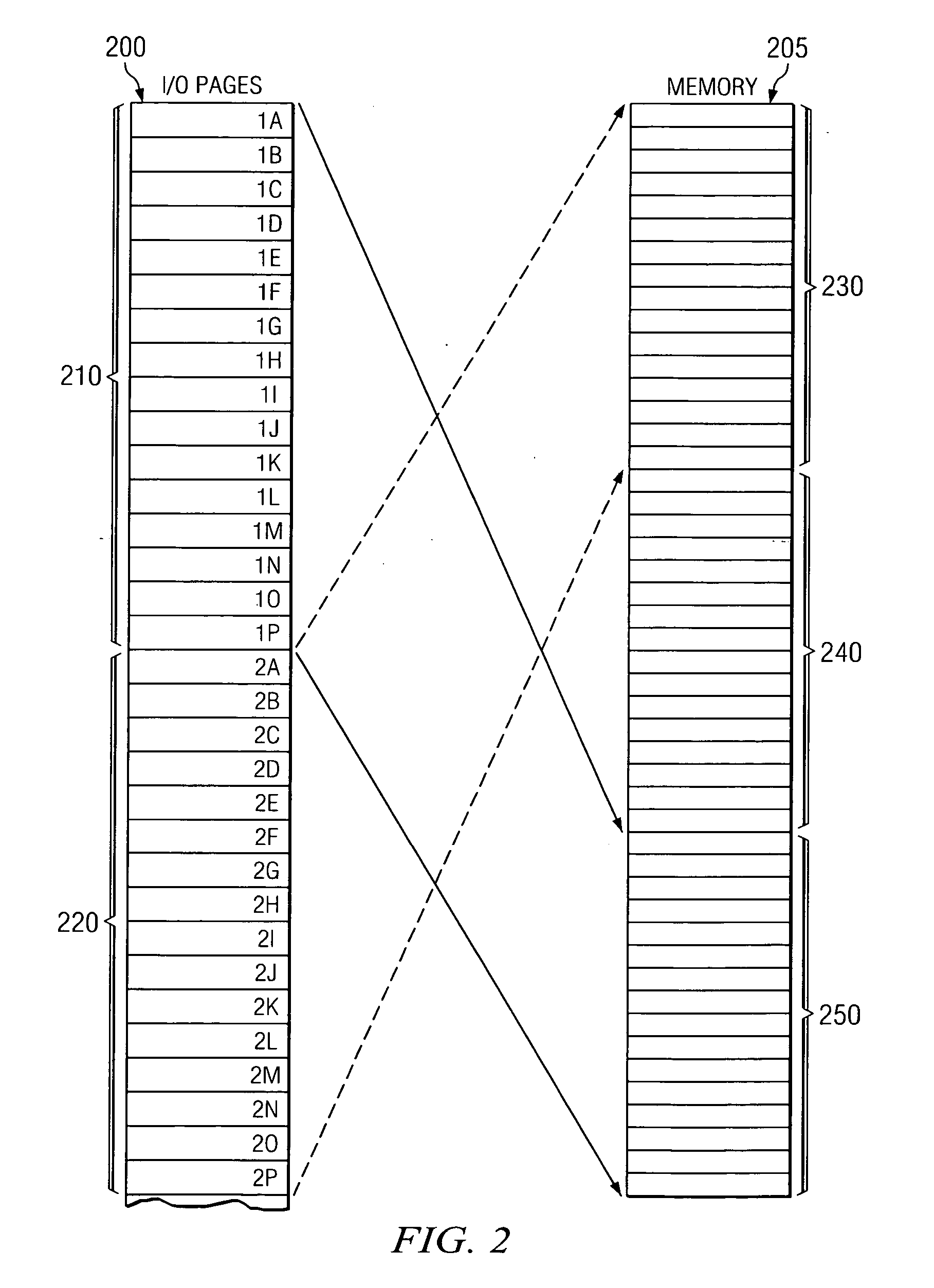

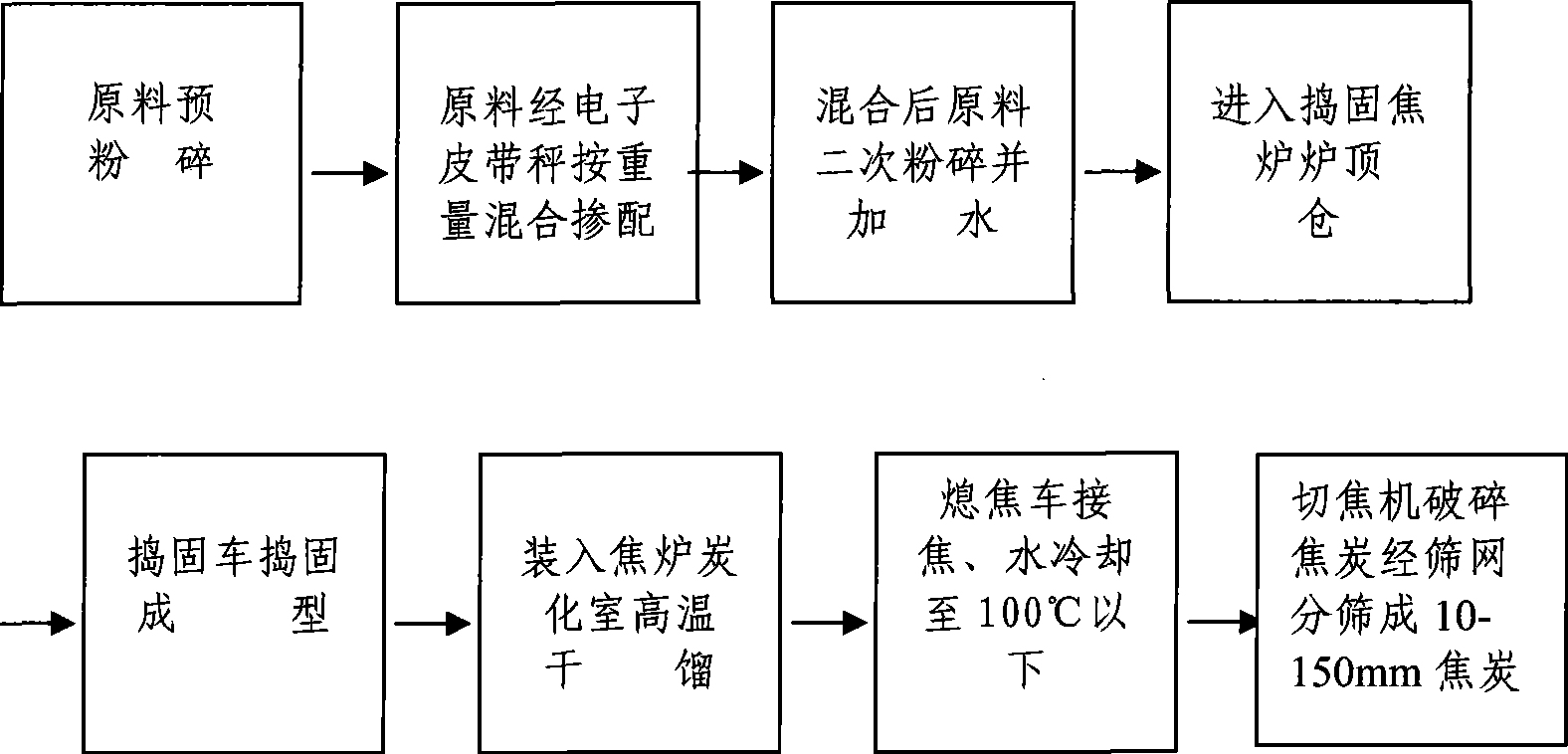

Method for minimizing the translation overhead for large I/O transfers

InactiveUS20060085569A1Minimal additional timeIncreasing I/O response timeMemory systemsMemory addressOperational system

A number of DMA addresses are resolved to system memory addresses at a time to decrease latency time. The number of addresses resolved at a time is preferably correlated to the number of DMA addresses that can be stored in a single cache line. Additionally, system memory is allocated in larger blocks that can store all of the information from the DMA addresses in a cache line. No change is required to the operating system, which can continue to operate on the page size it is set for. All changes are made in the hardware mapping programs and in the device driver software.

Owner:IBM CORP

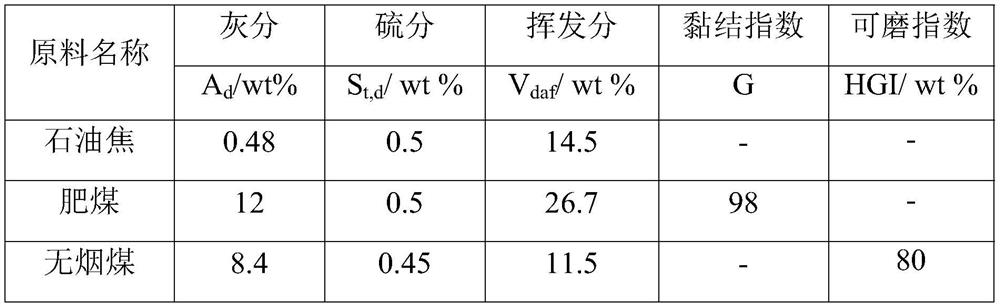

High-density calcined petroleum coke and preparation technology thereof

InactiveCN101362971AImprove adhesionIncreased crush strengthLiquid carbonaceous fuelsSpecial form destructive distillationPorosityPetroleum

The invention relates to a high-density calcined petroleum coke, the true specific gravity of the petroleum coke is 2.00 to 2.04 g / cm<3>, the apparent porosity is 32 to 36 percent and the particle size is 10 to 150mm; the sulfur content is 0.2 to 0.7 percent by weight, the ash content is 0.2 to 0.7 percent by weight, the content of volatile matters is 0.2 to 0.6 percent by weight, the water content is 0.4 to 3 percent by weight and the fixed carbon is 95 to 99.0 percent by weight. The production steps of a method for producing the high-density calcined petroleum coke are as follows: the water content of raw materials is controlled; the dry distillation is carried out on a stamp-charging coke oven; and the post-treatment of a product is carried out. The calcined petroleum coke which is produced by the coke oven can be randomly systematically adjusted according to the product quality of a user, thereby being capable of achieving the purposes of even quality, stability, reliability, high density and high strength.

Owner:SINOCHEM ZHENJIANG COKING

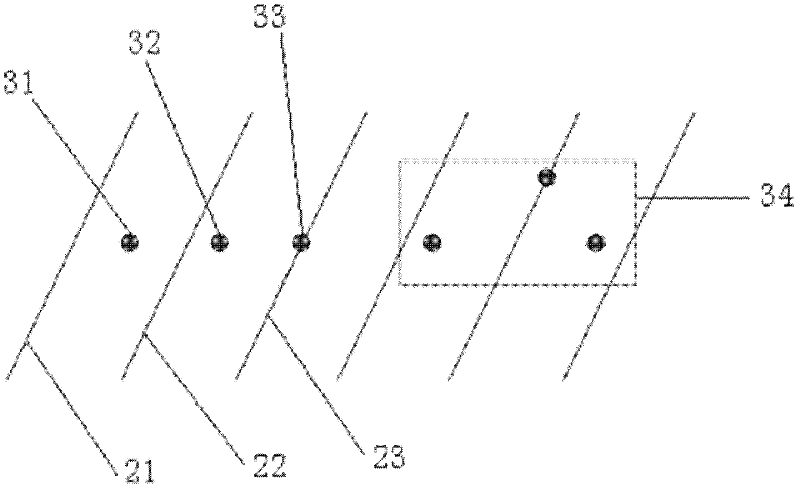

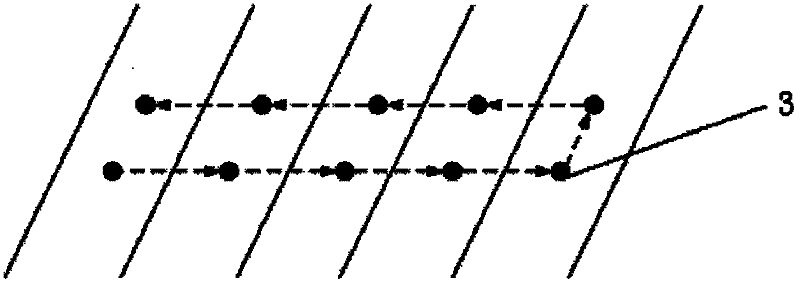

Explosion method of dimension stone production in joint development rock

The invention discloses an explosion method of dimension stone production in joint development rock, which comprises the following steps: determining the explosive loading direction, determining the explosive loading position, determining the hole net parameters, carrying out the explosion and the like. On one hand, the method disclosed by the invention controls the included angel between the propagation direction of explosion waves and the joint development surface by adjusting the axial angle between the working face and the blast hole to restrain the trend of the explosion crack; and on the other hand, the length of the explosion crack is adjusted by adjusting the opposite position of the explosive loading column and the joint development surface and combining or selecting the hole distribution mode of the blast hole in the middle of the joint development surface, in the position close to the joint development surface, at the position on the joint development surface and the like. The explosion method disclosed by the invention is specially used for exploding of the dimension stone production in the joint development rock, has the advantages of simple steps, strong operability and good explosion effects and can obtain a great quantity of dimension stone; and the dimension stone has the advantages of great dimension and uniform granularity and can meet the service requirements of various projects.

Owner:ENG COLLEGE OF ENG CORPS PLA UNIV OF SCI & TECH

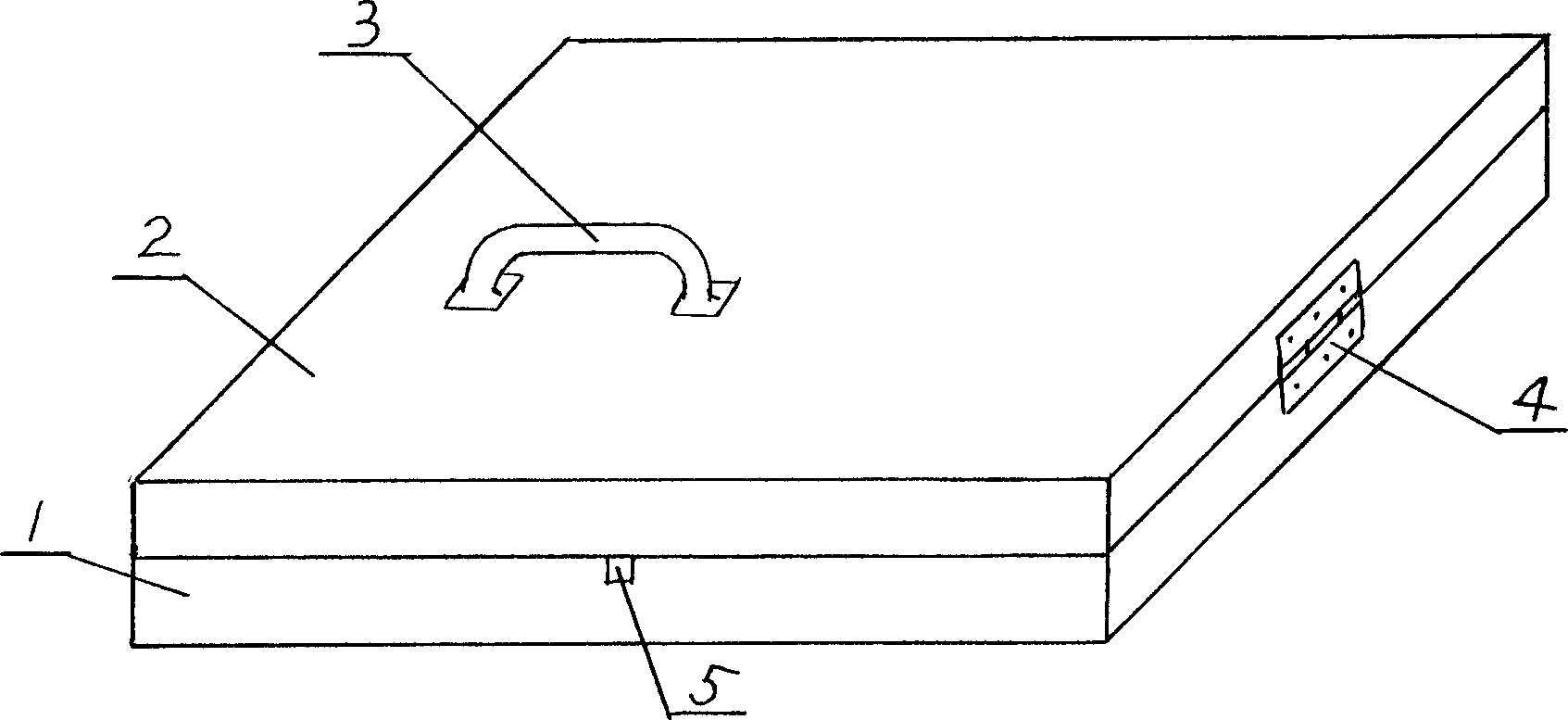

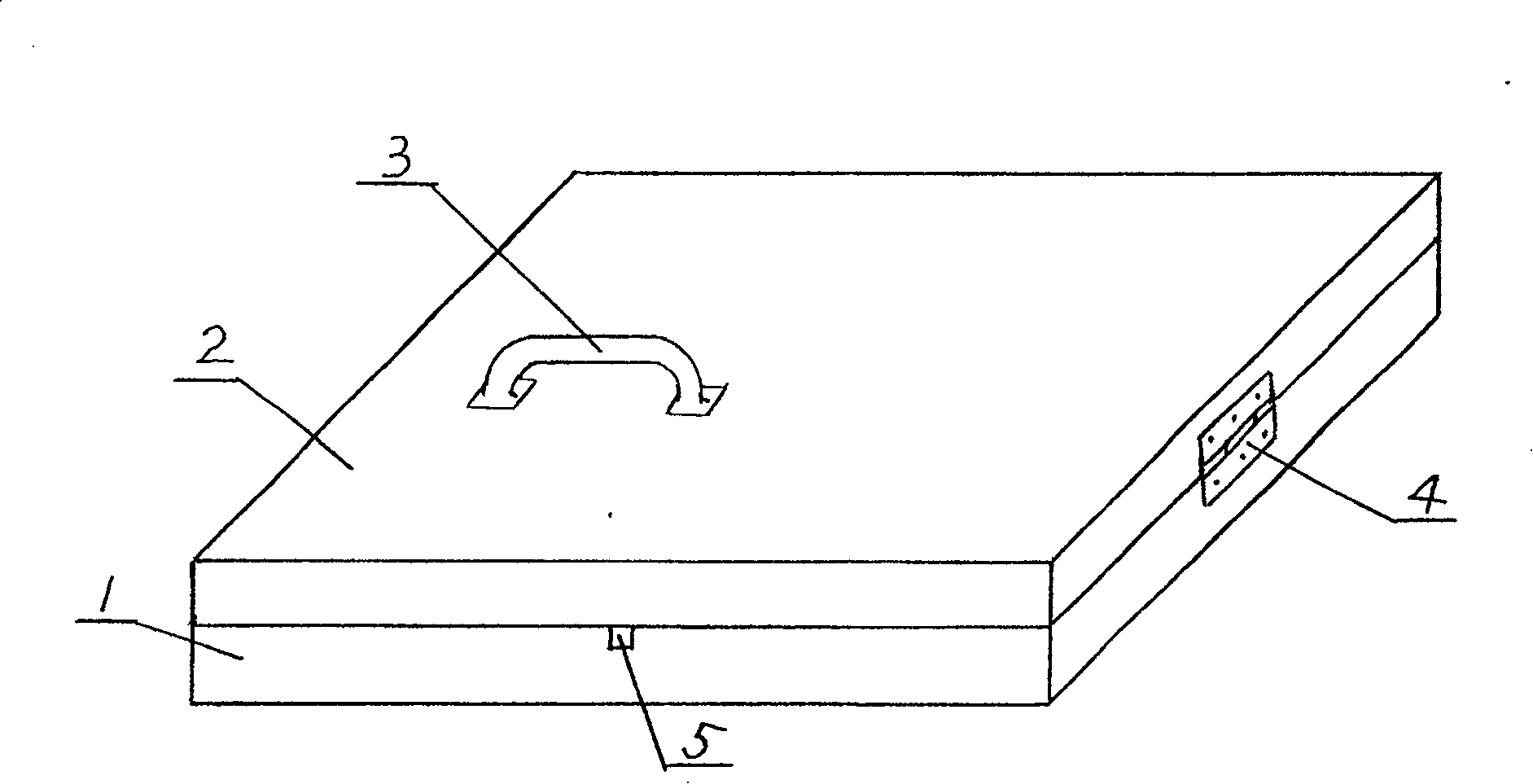

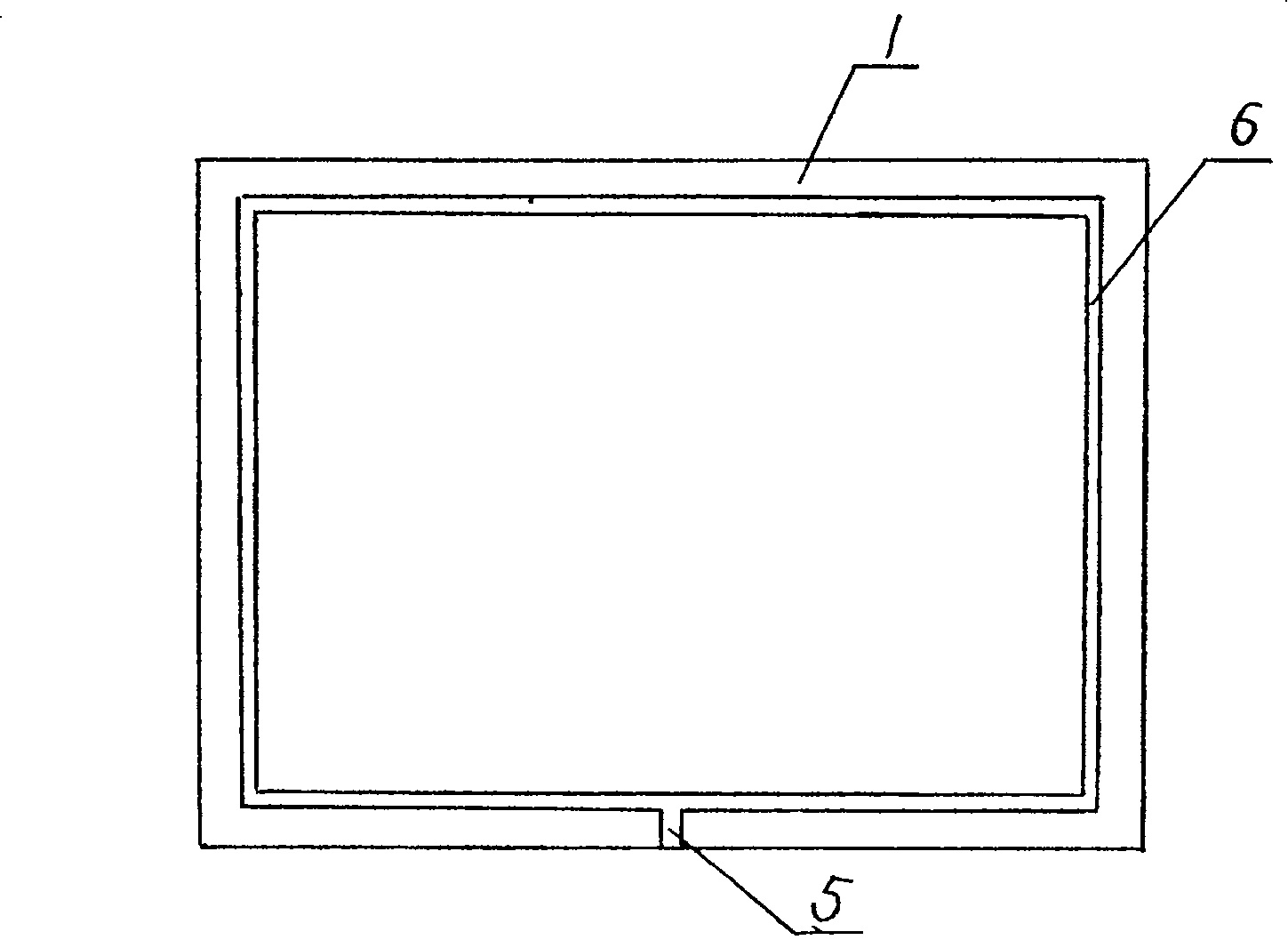

Method for producing stone plate roasted meat and its stone plate roasting meat device

InactiveCN1899089ALarge heat capacityEvenly heatedBaking vesselsFood preparationEdible oilEngineering

The present invention is method and device for making stone plate roasted meat. The device has two matched stone plate in the same size, including one upper cover plate and one lower roasting plate. The making process of stone plate roasted meat includes the following steps: heating the roasting plate inside some furnace to 200-300deg.c; smearing edible oil in the matched surface of the cover plate and spreading meat slices on the roasting plate and covering to stew for 2-5 min; turning the meat slices and covering to stew for 1-4 min; spreading salt on meat slices and covering to stew for 1-3 min, and turning the meat slices and covering to stew for 1-5 min; and spreading seasoning to both sides of meat slices and covering to stew for 0.5-2 min to make well roasted meat. The making process has no direct contact of meat to flame and homogeneous heating and is safe and sanitary, and the roasted meat is delicious.

Owner:叶尔江·买娜甫

Side loading coal method for mechanical coke oven

The method of side loading coal in mechanical coke oven includes pressing mixed coal into briquette, packing single briquette with inflammable matter, stacking in large packing box of inflammable matter, covering with heat insulating hood, eliminating the heat insulating hood after loading in the oven, and closing the oven door for coking. The present invention presses the mixed coal into briquette to raise the bulk density of coal in the oven, raises the strength of coke and makes it possible to increase the mixed weakly viscous coal to low cost and lower the ash, sulfur, phosphorus and other harmful components in coke. Packing the briquette can avoid the direct contact between the briquette and high temperature inside the oven to avoid raw gas, smoke and dust and to increase lump size of coke. The said coal loading method has less investment, high efficiency, high coke strength, and other advantages.

Owner:樊建忠

Coke with excellent thermal property and preparation method of coke

ActiveCN109097083AHigh strengthHigh degree of coalificationCoke quenchingMetallurgyUltimate tensile strength

The invention discloses coke with excellent thermal property and a preparation method. The coke with the excellent thermal property is formed by coking mixed coal, wherein the mixed coal is prepared from the following components in parts by weight: 45 to 55 parts of one-third coke, 10 to 20 parts of meager-lean coal, 15 to 25 parts of coking coal, 3 to 8 parts of blended coal and 10 to 15 parts offat coal. The coke with the excellent property, disclosed by the invention, has the beneficial effects of low reactivity and high strength after reaction.

Owner:沂州科技有限公司

Coke and preparation method thereof

The invention discloses coke and a preparation method thereof. The coke is made by coking of mixed coal; the mixed coal comprises, by weight, 65-75 parts of 1 / 3 coking coal, 5-10 parts of lean coal, 15-20 parts of coking coal, and 3-8 parts of meager lean coal. The coke and the preparation method thereof have the advantage that the coke has high crushing strength and wear resistance.

Owner:沂州科技有限公司

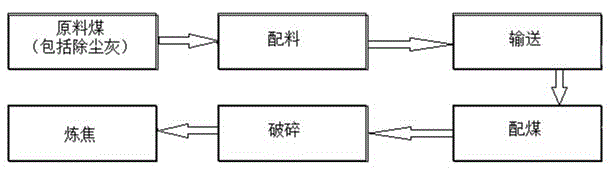

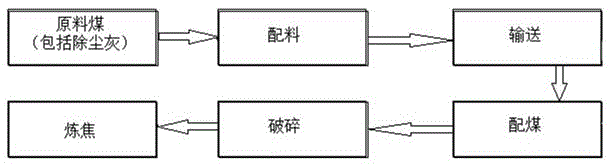

Blending method of dry coke quenching dust-removal ash in coal blending process

The invention discloses a blending method of dry coke quenching dust-removal ash in a coal blending process. The blending method comprises the following steps: transporting dust-removal ash generated by dry coke quenching every day to a coal storage yard through an ash discharge opening, arranging the dust-removal ash near low-sulfur coking coal of which the content of sulfur is less than 0.4% and low-ash meager lean coal of which the content of ash is less than 8.5% which can be blended for separately storing; according to the blending ratio required by the blending instruction of a forklift in a coal blending workshop, fully and uniformly blending the dry coke quenching dust-removal ash, low-sulfur coking coal and the low-ash meager lean coal at a weight ratio of 1:5:5 to form novel mixed dust-removal ash; conveying the mixed dust-removal ash to a coal blending bin, blending the mixed dust-removal ash and 1 / 3 coking coal, gas coal, coking coal and meager lean coal at a weight ratio of 7: 3 and rich coal to form into-the-furnace coal, crushing the into-the-furnace coal, adding water and conveying to the coal storage bin for coking coal production to replace partial meager lean coal for return blending and coking, wherein the mixed dust-removal ash, the 1 / 3 coking coal, the gas coal, the coking coal and meager lean coal at a weight ratio of 7:3 and the rich coal respectively account for 15%, 32%, 15%, 21% and 17% of the into-the-furnace coal in weight ratio. The process is convenient to operate and has the characteristic of high flexibility.

Owner:山东泰山焦化有限公司

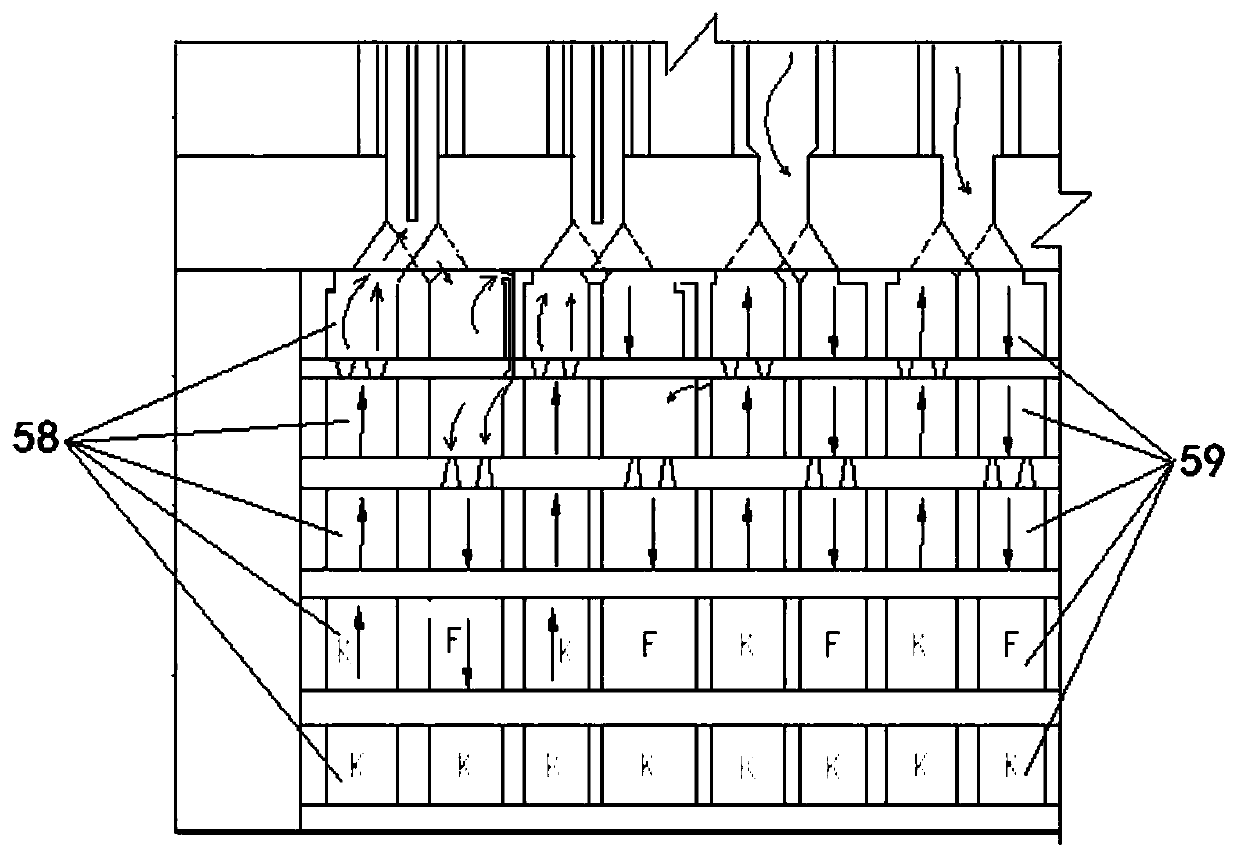

Heat exchange chamber of coke oven and coke oven

PendingCN110982538AImprove stabilityImprove reliabilityDirect heating destructive distillationIndirect and direct heating destructive distillationCombustion chamberFlue gas

The invention discloses a heat exchange chamber of a coke oven. The heat exchange chamber of the coke oven comprises a chamber body, the interior of the chamber body is of a multi-layer structure, anair channel and a flue gas channel are arranged in each layer of the multi-layer structure in a penetrating mode, the layers of the multi-layer structure are sequentially communicated, the air channelis used for being communicated with the external environment, and the flue gas channel is used for being communicated with the external environment. And the flue gas channel is used for communicatingwith a vertical flame path of a combustion chamber in the coke oven. The invention also provides the coke oven adopting the heat exchange chamber. The heat exchange chamber is simple in structure, and the heat exchange efficiency of the coke oven can be effectively improved.

Owner:HUATAI YONGCHUANG BEIJING TECH CO LTD

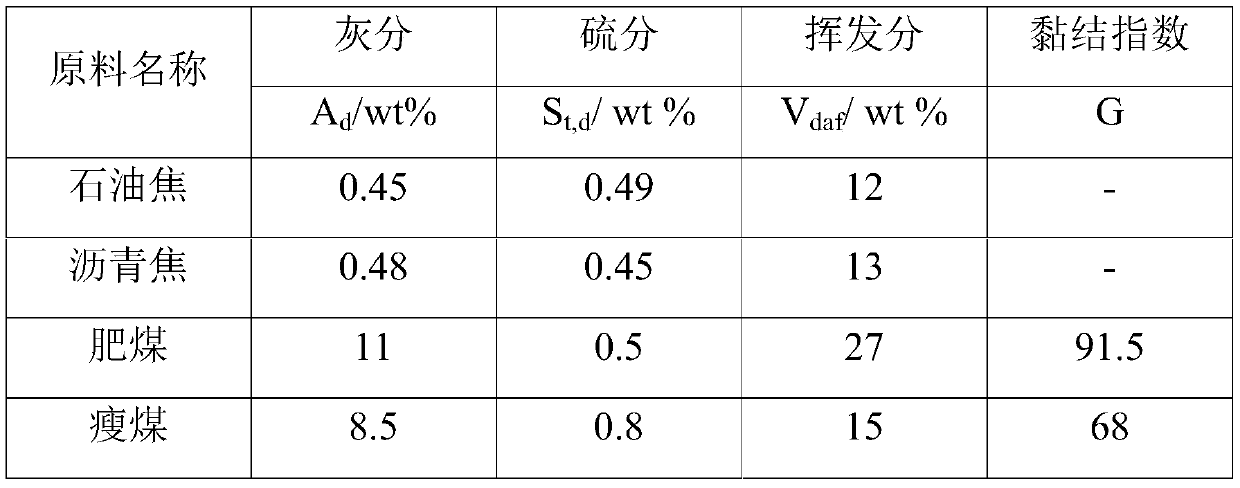

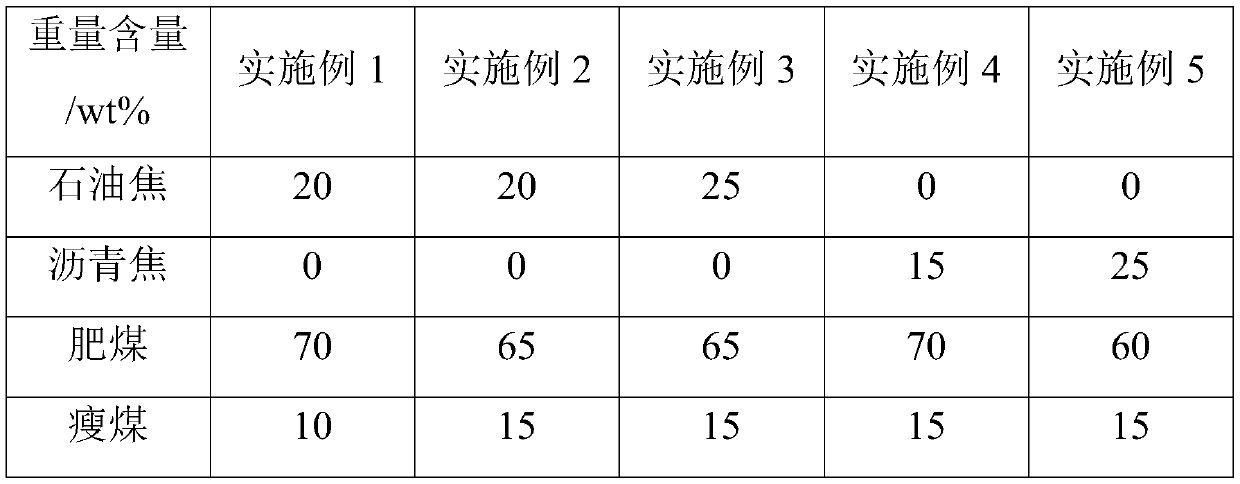

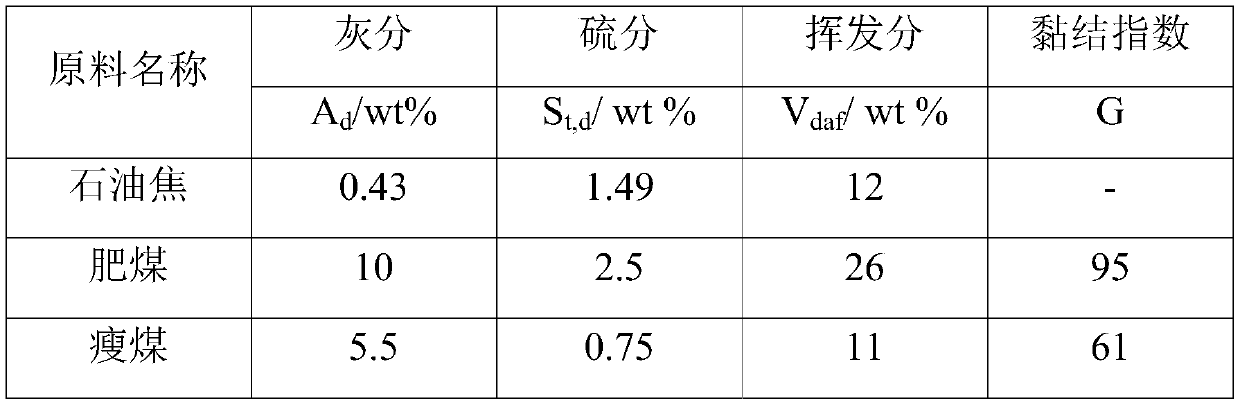

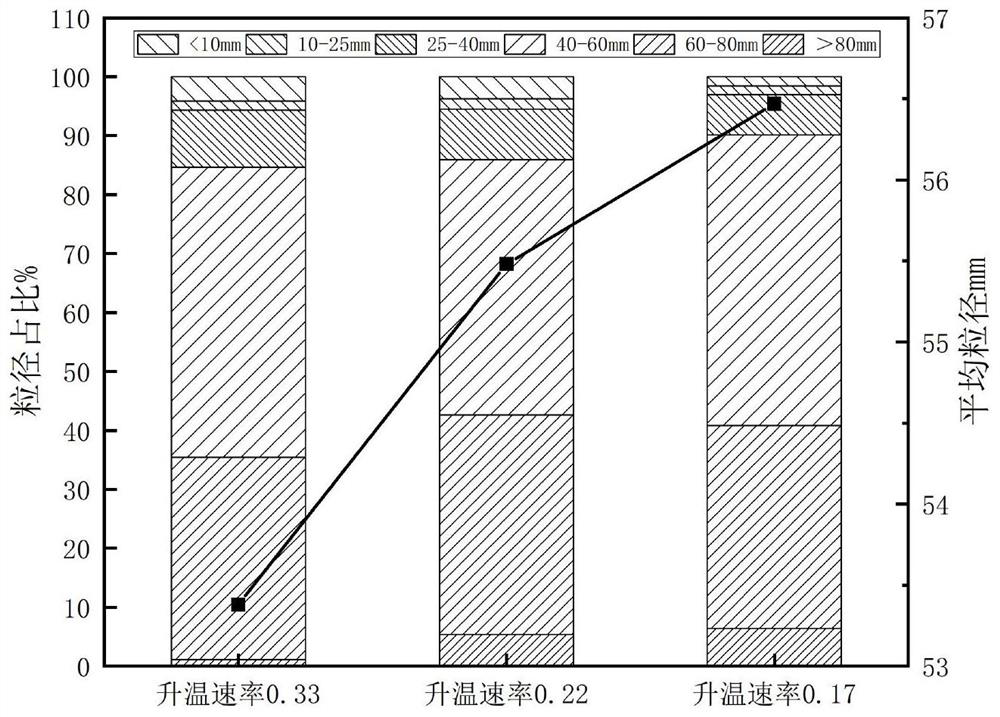

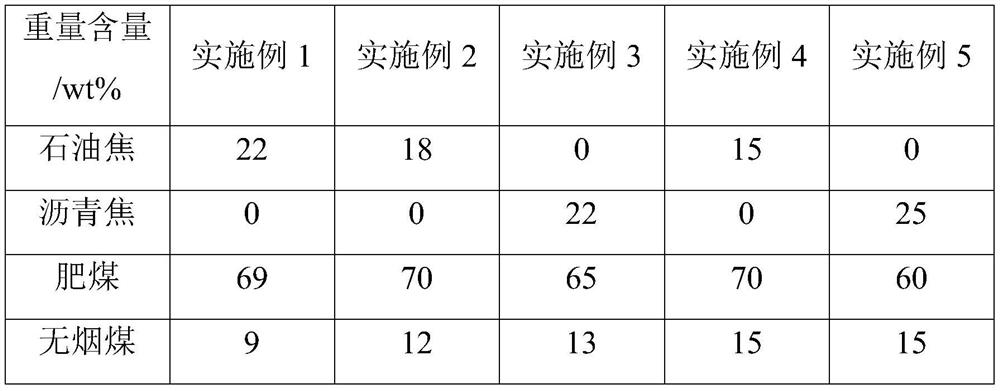

Formed coke and preparation method and application thereof

InactiveCN111575033AHigh lumpinessHigh hot and cold intensitySpecial form destructive distillationCoke ovenBriquette

The invention relates to the field of coal chemical industry, in particular to formed coke and a preparation method and application thereof. The preparation method of the formed coke comprises the following steps: (1) pressing mixed coal obtained by mixing raw materials to obtain formed coal; based on the total weight of the raw materials, the raw materials comprise 15-25 wt% of coke powder, 60-70wt% of fat coal and 5-15 wt% of lean coal; and (2) putting the formed coal into a coke oven at room temperature, heating the coke oven from room temperature to 1050-1200 DEG C at a rate of 6-10 DEG C / h, and carrying out destructive distillation at 1050-1200 DEG C for 350-400 hours to obtain the formed coke. The formed coke obtained in the invention has the advantages of few internal cracks, largelumpiness, high thermal strength and low ash content so that the formed coke has a wide application prospect.

Owner:山西沁新能源集团股份有限公司

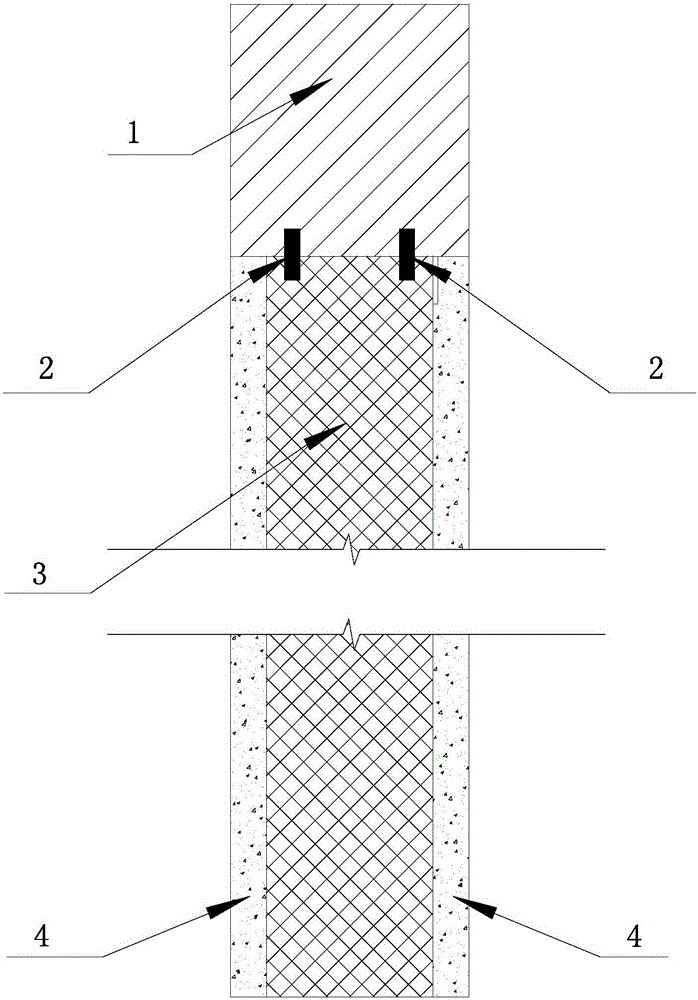

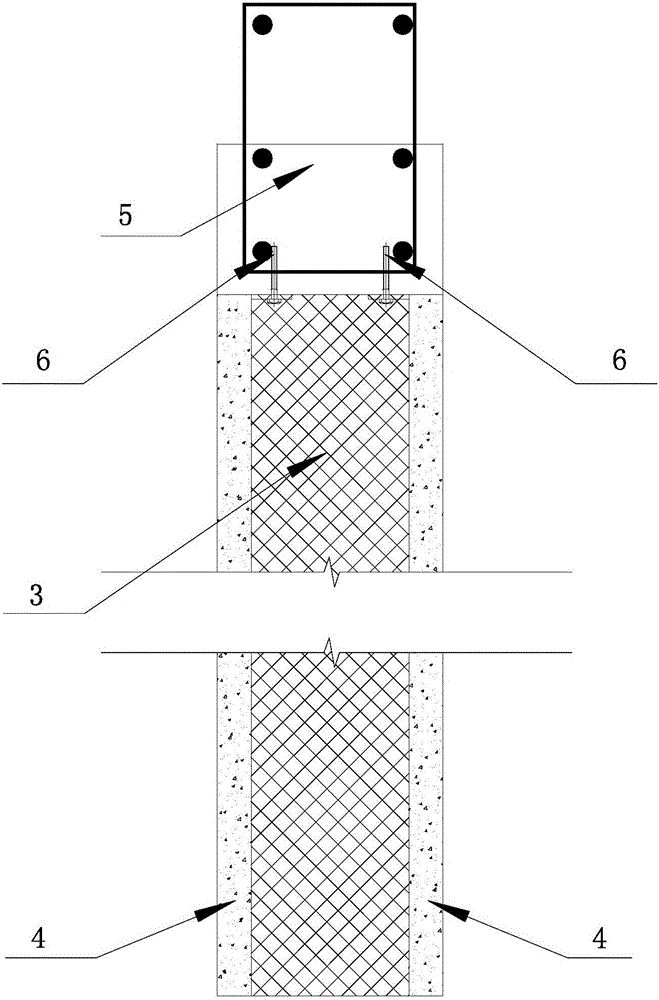

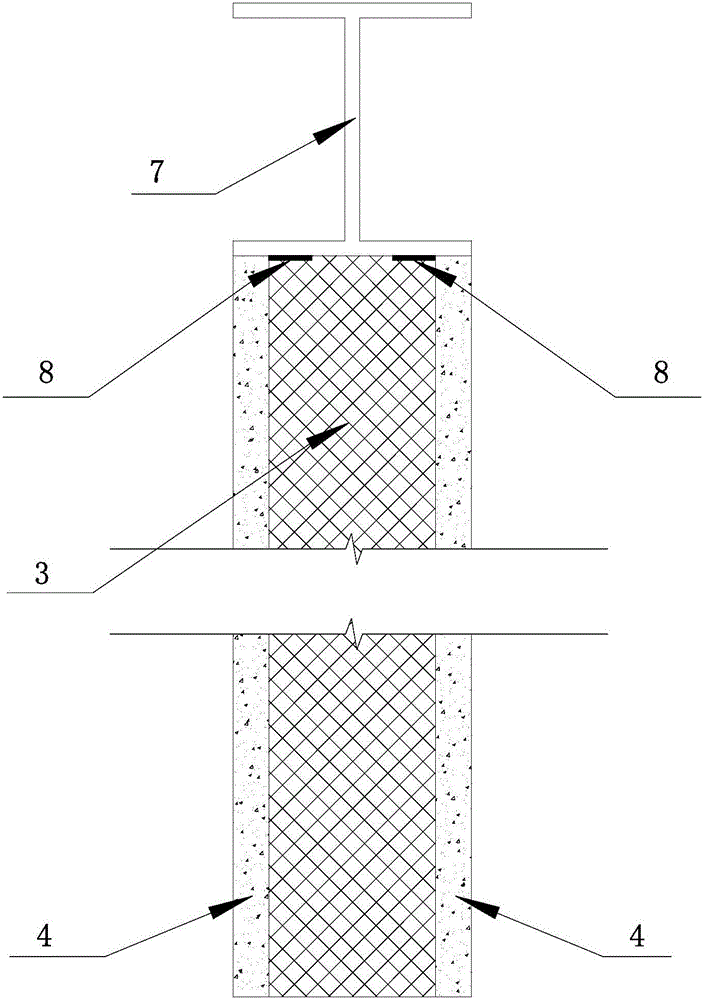

Precast fabricated type beam wall combination member

InactiveCN105908863AOvercome the disadvantage of too much splicingMeet the needs of construction industrializationWallsFilling materialsConcrete beams

The invention provides a precast fabricated type beam wall combination member, and relates to the technical field of a fabricated type beam wall combination member. The precast fabricated type beam wall combination member integrally consists of three parts of a precast fabricated type beam, a light-steel light-concrete wall body and connecting pieces between the precast fabricated type beam and the light-steel light-concrete wall body, wherein the precast fabricated type beam can be a precast fabricated type member in any other form, such as a precast fabricated type steel beam, a concrete superposed beam, or a concrete flat beam and the like; the light-steel light-concrete wall body is a light-steel light-concrete composite wall body which is integrally formed by light steel, light concrete and other components, wherein the light steel is used as a framework of the wall body; the light concrete is used as a filling material of the wall body; the connecting pieces between the precast fabricated type beam and the light-steel light-concrete wall body are connecting members between the precast fabricated type beam and the light-steel light-concrete wall body, and comprise a rear anchor fastener required by the connection between a light-steel framework and a precast fabricated type concrete beam, and a welding member between the light-steel light-concrete composite wall body and a precast steel beam. The precast fabricated type beam wall combination member disclosed by the invention is light in dead weight and low in rigidity, has favorable mechanical performance, and meets the requirements of buildings for filling wall bodies.

Owner:北京研创绿建科技有限公司

Coke CDQ Dust Removal Ash Mixing Method in Coal Blending Process

Owner:山东泰山焦化有限公司

Bulking brick

The invention provides an energy-saving and environment-friendly swelling brick, which relates to a material for building. In order to overcome the deficiency caused by common clay red bricks which consumes a great land resources and energy, and has serious pollution, small size but heavy deadweight, poor heat insulation performance, and increase of the total construction cost; the swelling brick of the invention takes argillo-arenaceous rock as main material, which enters a high temperature rotary furnace to charge oxygen and pressure for swelling after crushing and screening, then a secondary heating is performed after producing the swelling body, finally the shape is formed by mechanical squeezing. The swelling body after shaped by squeezing also can be mixed with the cement, the fly ash and the concrete additive. After mechanically agitating and watering, the swelling body is conveyed to a silo for squeezing to form the swelling brick which is characterized by light weight, rigid body, heat insulation, and fire resistance, nontoxic and being durable, thus being an ideal energy-saving building brick.

Owner:黑龙江省三江君合新材料科技开发有限公司

A kind of preparation method of coke

ActiveCN104194813BQuality improvementHigh strengthSpecial form destructive distillationPorosityCarbonization

A method for preparing coke. The invention provides a method for preparing molded coke in a vertical coke oven. The method of the invention includes dry distillation of main coking coal, anthracite, coke powder, pitch and petroleum coke as raw materials. In the invention, the blended coal is stirred at high temperature and high pressure according to a certain proportion, shaped, charged in a furnace, and carbonized to obtain molded coke. This formula effectively solves the impact of colloidal body changes during high temperature and rapid heating. The coke quality reaches the national standard first-level rate of more than 95%. It has uniform product specifications, large lumps, high strength, low porosity and reactivity, and ash content. The characteristics of low sulfur content.

Owner:SHANDONG JUMING ENERGY

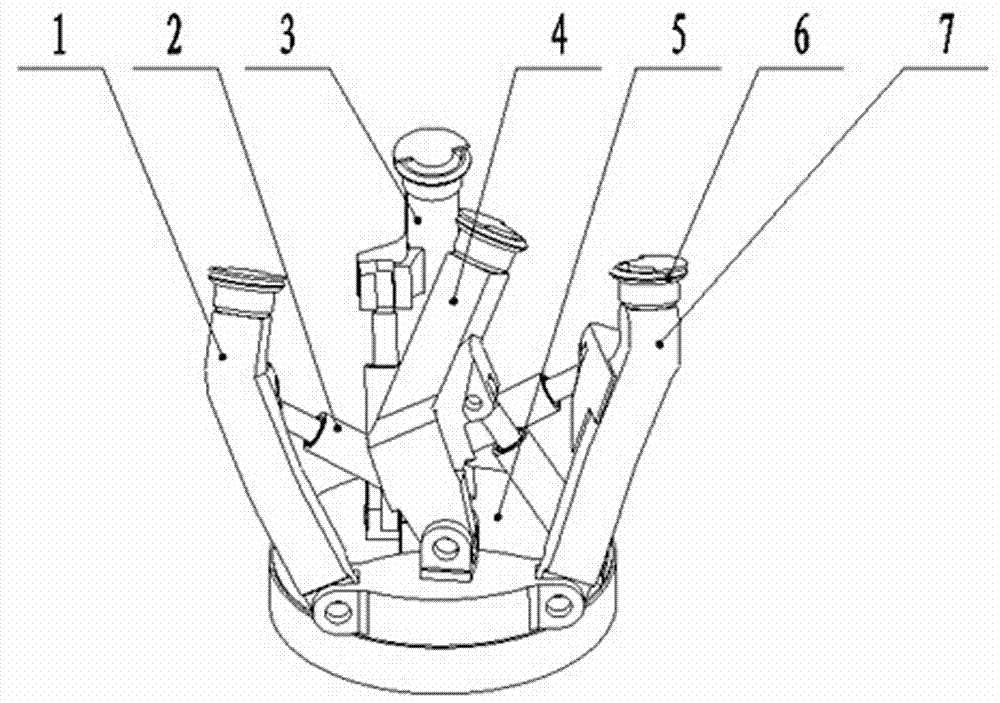

Cutting mechanism for multi-arm hob-type continuous tunneling machine

ActiveCN102953729BImprove rock breaking abilityImprove work efficiencyCutting machinesRock tunnelEngineering

The invention belongs to the technical field of cutting mechanism of tunneling machine, particularly provides a cutting mechanism for a multi-arm hob-type continuous tunneling machine, and solves the problems of an existing cutting mechanism of a continuous tunneling machine, such as unsuitability for hard rock tunnel and low rock breaking efficiency. The cutting mechanism comprises a slewing bearing, three outer rotation arms, an inner rotation arm, a disc hob and a swinging cylinder. The slewing bearing comprises an inner ring and an outer ring; the outer ring is fixed on a frame of the tunneling machine; the inner ring is connected to a motor output shaft of the tunneling machine; and outer rotation arms and the inner rotation arm are hinged to the inner ring through pins. The invention has beneficial effects of solving problems of weak rock breaking effect and low production efficiency of a longitudinal tunneling machine, reducing dust generation, improving cutting efficiency, and realizing forming of different section contours.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

A method for preparing bulk graphene airgel

The invention discloses a method for preparing block graphene aerogel. The method includes the specific steps that cheap small molecule epoxy propane serves as a cross-linking agent and is mixed with oxidized graphene or graphene dispersion liquid, a hydrothermal method is utilized to obtain graphene wet gel, drying is further conducted, and the graphene aerogel is obtained. The method is simple in operation step, good in repeatability, mild in reaction condition and suitable for industrialized production, the price of the cross-linking agent is low, and the finally obtained graphene aerogel is complete in block degree, low in density, good in elasticity and high in mechanical strength.

Owner:SOUTHEAST UNIV

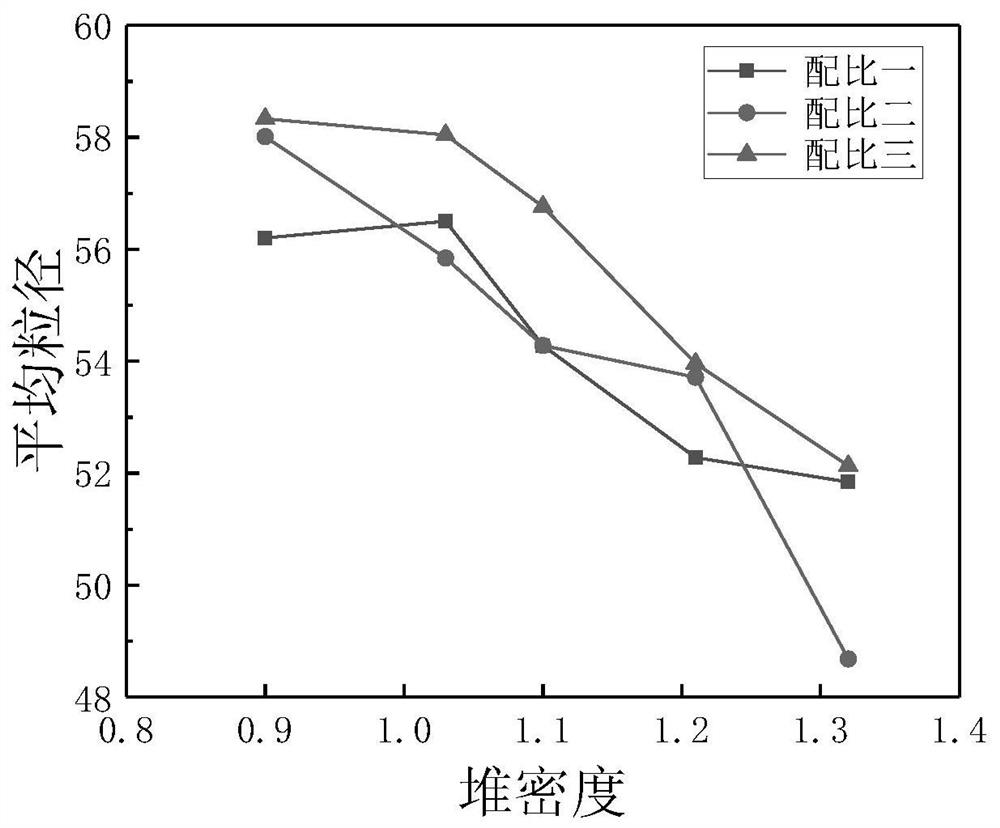

A kind of coking method for improving the lump degree of tamping coke and tamping coke prepared by the method

ActiveCN113604238BReduce outputHigh strengthSpecial form destructive distillationThermodynamicsCoke rate

The invention provides a coking method for increasing the degree of tamped coke lumps and tamped coke prepared by the method. In the method, the coking time, coking rate, and heating standard temperature during the tamping coking process are adjusted according to the actual index of the incoming coal relative to the benchmark index and the coke quenching method, so as to increase the lumpiness of the tamping coke. The method can not only improve the lumpiness of tamping coke, but also is suitable for coking production of any furnace type tamping coke oven, and there is no difficulty in pushing coke during coking production, and the coke oven wall will not be damaged.

Owner:河北中煤旭阳能源有限公司

A type of coke and its preparation method and application

ActiveCN111575034BLarge blockHigh heat intensitySpecial form destructive distillationCoke ovenAnthracite

The invention relates to the field of coal chemical industry, in particular to a molded coke and its preparation method and application. The preparation method of the molded coke includes: (1) pressing the mixed coal obtained by mixing raw materials to obtain molded coal; based on the total weight of the raw materials, the raw materials include: coke powder 15-25wt%, fat coal 60 ‑70wt%, anthracite 5‑15wt%; (2) put the briquettes into a coke oven at room temperature, raise the temperature of the coke oven from room temperature to 1000‑1200°C at a rate of 6‑10°C / h, and Dry distillation at ‑1200°C for 380‑480 hours to obtain molded coke. The molded coke obtained by the invention has very few internal cracks, large blockiness, high heat intensity and low ash content, so that it has broad application prospects.

Owner:山西沁新能源集团股份有限公司

Coke and its preparation method

The invention discloses coke and a preparation method thereof. The coke is made by coking of mixed coal; the mixed coal comprises, by weight, 65-75 parts of 1 / 3 coking coal, 5-10 parts of lean coal, 15-20 parts of coking coal, and 3-8 parts of meager lean coal. The coke and the preparation method thereof have the advantage that the coke has high crushing strength and wear resistance.

Owner:沂州科技有限公司

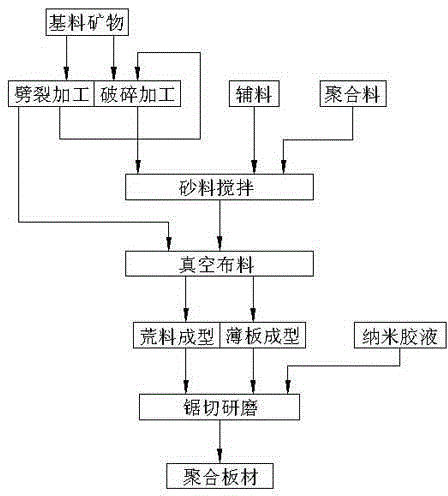

Preparation method of ecological synthetic stone

The invention belongs to the field of stone materials and artificial synthetic stones, particularly relates to a preparation method of ecological synthetic stone, and provides a preparation method of the ecological synthetic stone, which aims to improve the utilization value of the minerals such as ophiolite, tremolite, diopside, perlite and quartzite jade and aims to improve the environment purification performance of the synthetic stone at the same time. The preparation method is characterized in that the ecological synthetic stone is prepared from the following components in mass part: 70-90 parts of basic material, 7-25 parts of auxiliary material and 3-23 parts of polymerized material; a quarry stone or a thin sheet is prepared through the working procedures of splitting or breaking, sand agitation, vacuum material distribution, and quarry stone formation or thin sheet formation; a polymerized plate is prepared through the working procedures of saw cutting and grinding. With adoption of the product prepared through the method, an electromagnetic field and an anion release effect both beneficial to the human body can be produced, the appearance of the synthetic plate can be improved, the self cleaning and bacterium elimination effects can be achieved, and the synthetic product has better environment purification performance.

Owner:GUANGXI LISHENG STONE CO LTD

Method for producing stone plate roasted meat and its stone plate roasting meat device

InactiveCN100403924CNo pollution in the processEvenly heatedBaking vesselsFood preparationEngineeringHeating furnace

The present invention is method and device for making stone plate roasted meat. The device has two matched stone plate in the same size, including one upper cover plate and one lower roasting plate. The making process of stone plate roasted meat includes the following steps: heating the roasting plate inside some furnace to 200-300deg.c; smearing edible oil in the matched surface of the cover plate and spreading meat slices on the roasting plate and covering to stew for 2-5 min; turning the meat slices and covering to stew for 1-4 min; spreading salt on meat slices and covering to stew for 1-3 min, and turning the meat slices and covering to stew for 1-5 min; and spreading seasoning to both sides of meat slices and covering to stew for 0.5-2 min to make well roasted meat. The making process has no direct contact of meat to flame and homogeneous heating and is safe and sanitary, and the roasted meat is delicious.

Owner:叶尔江·买娜甫

Foam

Foam is prepared from 12-17 parts of ethyl acetate, 16-41 parts of magnesium stearate, 16-18 parts of vinyl trimethoxy silane, 12-21 parts of choline, 12-19 parts of polyoxyethylene sorbitol monolaurate, 2-12 parts of magnesium stearate, 23-31 parts of kaolin, 23-25 parts of aluminum oxide, 3-6 parts of pearl powder, 12-19 parts of glycerinum, 3-9 parts of ammonium heptamolybdate, 1-4 parts of lactic acid, 42-56 parts of inorganic gel and 12-18 parts of organic bentonite. The plastic foam is large in monomer particle size, not prone to breakage, easier to use, large in lumpiness and convenient to use.

Owner:齐红玉

Coke with excellent thermal properties and its preparation method

ActiveCN109097083BHigh strengthHigh degree of coalificationCoke quenchingUltimate tensile strengthCoal

The invention discloses coke with excellent thermal property and a preparation method. The coke with the excellent thermal property is formed by coking mixed coal, wherein the mixed coal is prepared from the following components in parts by weight: 45 to 55 parts of one-third coke, 10 to 20 parts of meager-lean coal, 15 to 25 parts of coking coal, 3 to 8 parts of blended coal and 10 to 15 parts offat coal. The coke with the excellent property, disclosed by the invention, has the beneficial effects of low reactivity and high strength after reaction.

Owner:沂州科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com