A kind of coking method for improving the lump degree of tamping coke and tamping coke prepared by the method

A technology of tamping coke and fineness, which is applied in coke ovens, special forms of dry distillation, petroleum industry, etc. It can solve the problems of not being able to use tamping coke to reduce costs, coke pushing difficulties, production accidents, and coke production decline.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

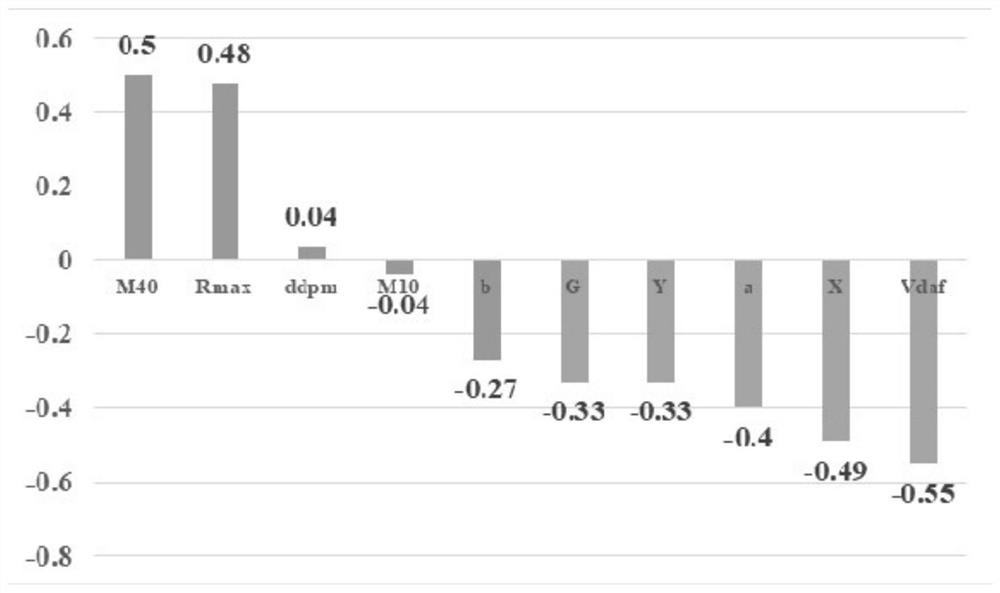

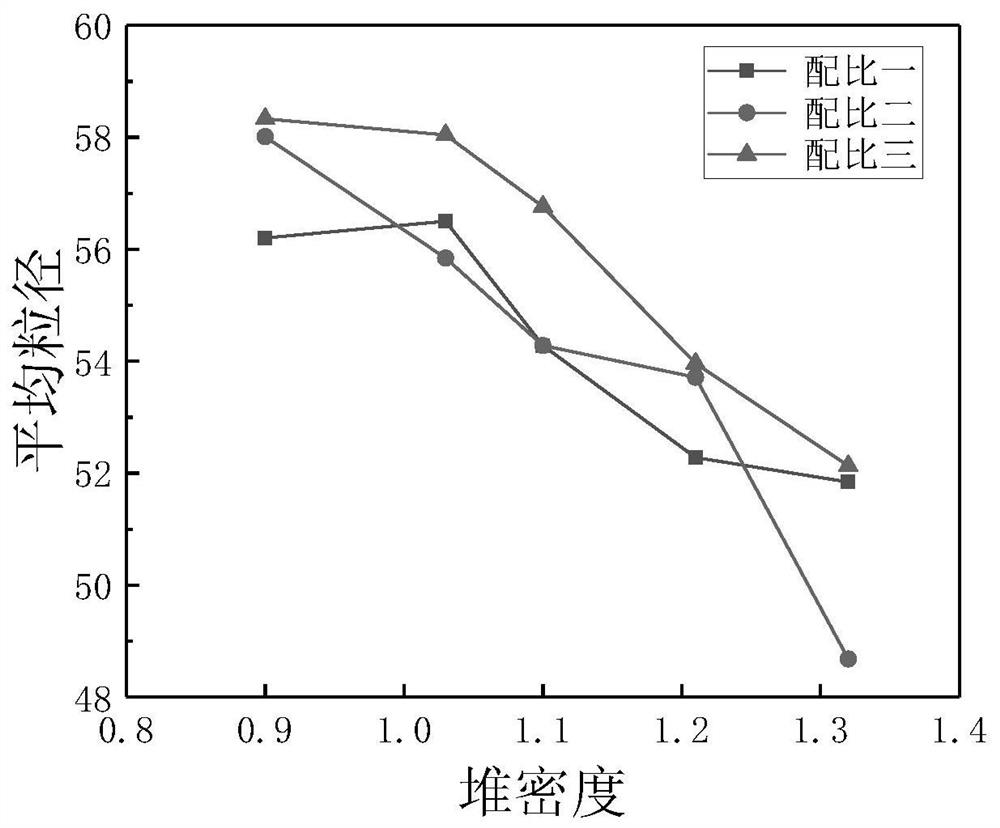

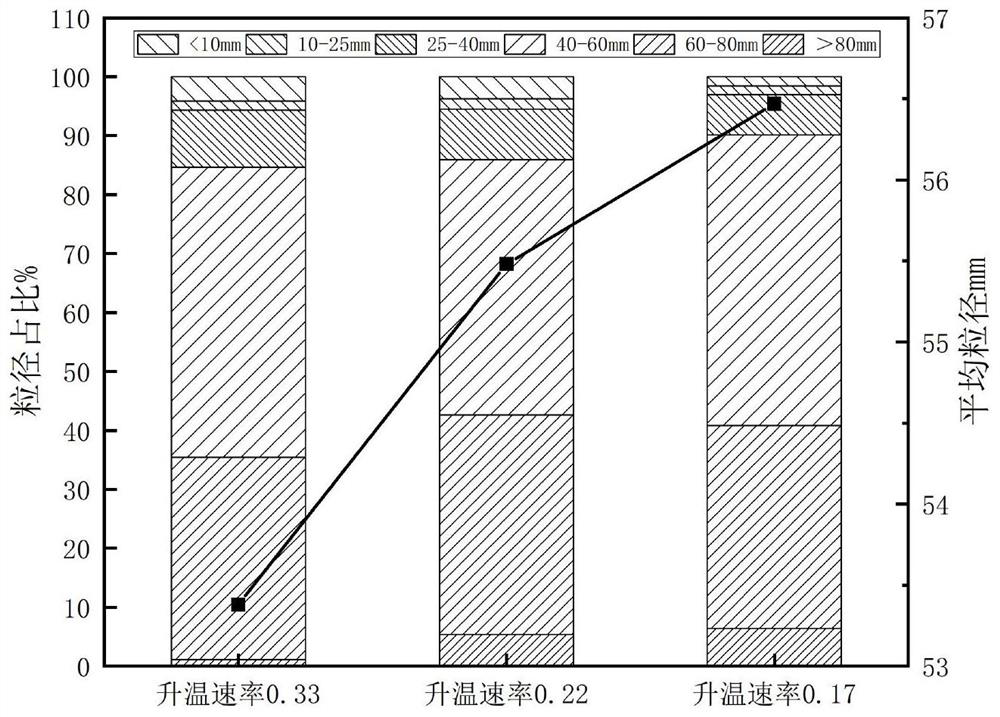

[0060] Embodiment 1: prepare coking blending coal according to conventional method as furnace coal (determining blending coal index is: Mt is 11.8%, V daf G is 29.3%, G is 68, Y is 12.5mm, X is 46mm; the crushing fineness (the proportion less than 3mm) is 89.2%, of which the proportion of 0.5-3mm accounts for 48%; the tamping bulk density is 1.02t / m 3 ; the coking time is 22.5 hours, the machine-measured standard temperature is 1330°C, and the coke side standard temperature is 1350°C), and the coking blend coal is pounded into a coal cake slightly smaller than the size of the carbonization chamber with a tamping machine in the coal box, and then The briquettes are stamped and coked in the carbonization chamber under the actual coking time, coking rate and actual heating standard temperature determined by the following method, and finally the coke is quenched by wet method.

[0061] In this embodiment, a 4.3-meter stamped coke oven is used: the width of the carbonization chambe...

Embodiment 2

[0074] Embodiment 2: Coal blending coking is carried out in the same procedure as in Embodiment 1, the difference is that a 5.5-meter tamping coke oven is used: the width of the carbonization chamber is 550 mm, the width of the briquette is 500 mm, and the blending coal index is: Mt is 11.3% , V daf G is 28.8%, G is 67, Y is 12.8mm, X is 43mm; the crushing fineness (the proportion less than 3mm) is 88.2%, of which the proportion of 0.5-3mm accounts for 46%; the tamping bulk density is 1.06t / m 3 ; The coking time is 25.5 hours, the standard temperature of the machine test is 1320°C, the standard temperature of the coke side is 1340°C, and the coke is quenched by dry method.

[0075] Based on the above blended coal indicators, the coking conditions are determined as follows:

[0076] (1) Determine the reasonable actual coking time T 实 :

[0077] According to the volatile content of coal into the furnace V daf 28.8% belong to 28.5% daf <30%, a value is 1 hour;

[0078] Accor...

Embodiment 3

[0088]Example 3: The same procedure as in Example 1 is used for coal blending and coking, except that a 6.25-meter tamping coke oven is used: the width of the carbonization chamber is 540 mm, the width of the briquette is 480 mm, and the index of blending coal is: Mt is 12.3% , V daf G is 27.5%, G is 70, Y is 13.0mm, X is 40mm; crushing fineness (ratio of less than 3mm) is 89.5%, of which 0.5-3mm accounts for 48%; tamping bulk density is 1.04t / m 3 ; The coking time is 25 hours, the standard temperature of the machine test is 1330°C, the standard temperature of the coke side is 1370°C, and the coke is quenched by dry method.

[0089] Based on the above blended coal indicators, the coking conditions are determined as follows:

[0090] (1) Determine the reasonable actual coking time T 实 :

[0091] According to the volatile content of coal into the furnace V daf 27.5% fall under 26% ≤ V daf ≤28.5%, a value is 0 hours;

[0092] According to the moisture Mt of coal entering th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com