Preparation method of ecological synthetic stone

A preparation method and technology of synthetic stone, which is applied in the field of stone and artificial synthetic stone, can solve the problems of insufficient compactness, small amount of marble stones, poor appearance and other problems, and achieve the effect of strong purification of the environment and improvement of appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

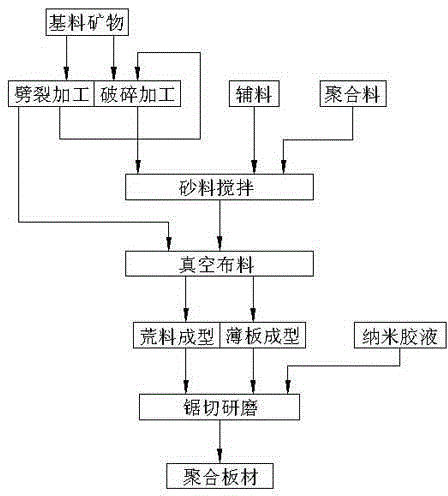

Image

Examples

Embodiment 1

[0047] A compounding method of ecological synthetic stone, base material, auxiliary material and polymer are formulated into blocks with a total weight of 6000-8500kg according to the mass ratio of 84:12:4. Among them, the base material is serpentine, serpentine jade, serpentine marble and rutile, the associated minerals of serpentine; the auxiliary material is aluminum hydroxide powder (200-1250 mesh); the polymer is unsaturated resin glue, made of Unsaturated resin, curing agent (methyl ethyl ketone peroxide), and accelerator (cobalt octanoate) are mixed in a mass ratio of 100:1.2:0.2.

[0048] The block molding process is adopted, and the specific steps are as follows:

[0049] 1) Splitting and crushing of the base material: Cut the minerals with a block size (particle size) greater than 40cm into an approximate square with a block size of 15-30cm with a JGZ-160 hydraulic stone splitter, and mix the rutile and snake The grain stone crushed stone is processed into sand grai...

Embodiment 2

[0055] A compounding method of ecological synthetic stone, base material, auxiliary material and aggregated material are prepared into blocks according to the mass ratio of 70:22:8. Among them, the base material is quartzite jade, tremolite, perlite and tourmaline; the auxiliary material is diatomite and aluminum hydroxide powder with a mass ratio of 200-1000 mesh and the mass ratio is 1:1; the polymer is unsaturated resin glue, It is prepared by unsaturated resin, curing agent (methyl ethyl ketone peroxide), and silane coupling agent in a mass ratio of 100:1.2:0.2.

[0056] The thin plate forming process is adopted, and the specific steps are as follows:

[0057] 1) Crushing and processing of the base material: crush the base material gravel into 4-80 mesh sand grains with a jaw crusher and a double-roller machine, and the sand grains of quartzite jade, tremolite, perlite, and black tourmaline are pressed 24:24:48:4 mass ratio selection;

[0058] 2) Agitation of sand materi...

Embodiment 3

[0063] A compounding method of ecological synthetic stone, base material, auxiliary material and aggregate material are prepared into block material according to the mass ratio of 70:7:23. Among them, diopside, obsidian (belonging to perlite series), skarn (night rose granite) and germanite mineral crushed stone are used as the base material; diatomite (stone) is processed into 10-200 mesh sand grains as Auxiliary material: water-based epoxy resin glue is mixed with white cement or white kaolin as aggregate material, and used for two base materials respectively.

[0064] The thin plate forming process is adopted, and the specific steps are as follows:

[0065] 1) Crushing and processing of base materials: crush four kinds of mineral crushed stones into sand grains, and the four kinds of mineral sand grains are prepared according to their mass ratio of 3:3:3:1;

[0066] 2) Agitation of sand materials: Divide two equal parts of base material sand into two vertical (double star)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com