Coke CDQ Dust Removal Ash Mixing Method in Coal Blending Process

A CDQ and coking coal technology, applied in coking ovens, petroleum industry, etc., can solve problems such as troublesome processing links, secondary pollution of the atmospheric environment, increased waste, etc., achieve a wide range of matching ratios, improve strength indicators, increase The effect of coke lumpiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

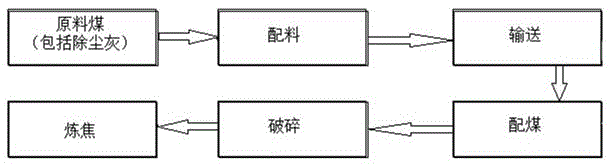

[0019] Such as figure 1 As shown, the method for using CDQ dedusting ash in the coal blending process includes the following process steps:

[0020] (1) The dedusting ash produced every day by CDQ is transported to the coal storage yard by car through the ash discharge port, and unloaded into low-sulfur coking coal with a sulfur content of <0.4% and low-ash lean coal with an ash content of <8.5%. Separate storage near the lean coal;

[0021] (2) Mix CDQ dedusting ash with low-sulfur coking coal with sulfur content <0.4% and low-ash lean coal with ash content <8.5% according to the weight ratio; Coke CDQ dedusting ash and low-ash coking coal and low-sulfur lean coal in a weight ratio of 1:5:5 are fully matched and evenly formed into a new mixed dedusting ash;

[0022] (3) Transport the uniformly mixed dust ash in step (2) to the coal blending bin, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com