Patents

Literature

61 results about "Mixed dust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Resource utilization method of blast furnace dust and coke furnace dust

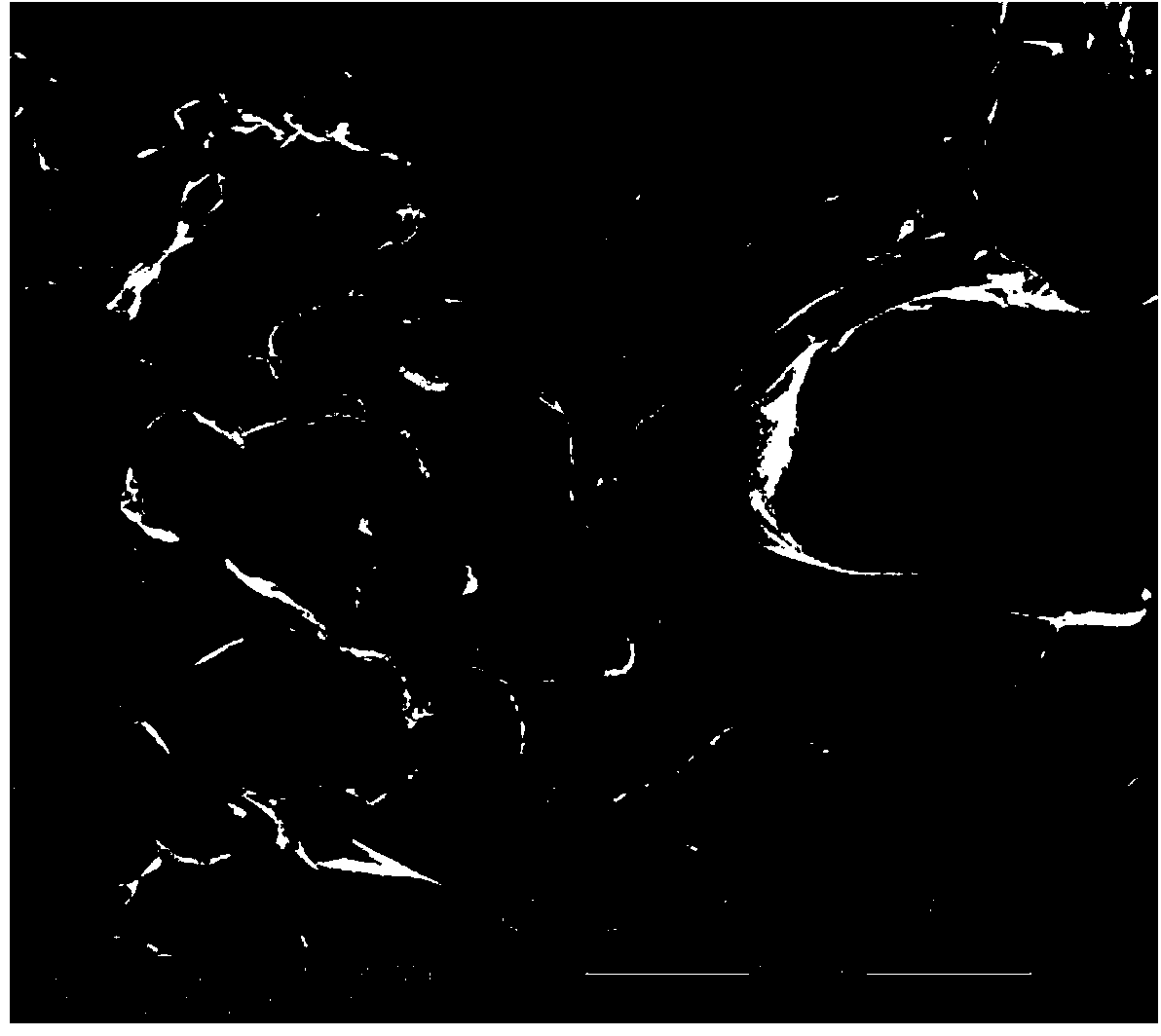

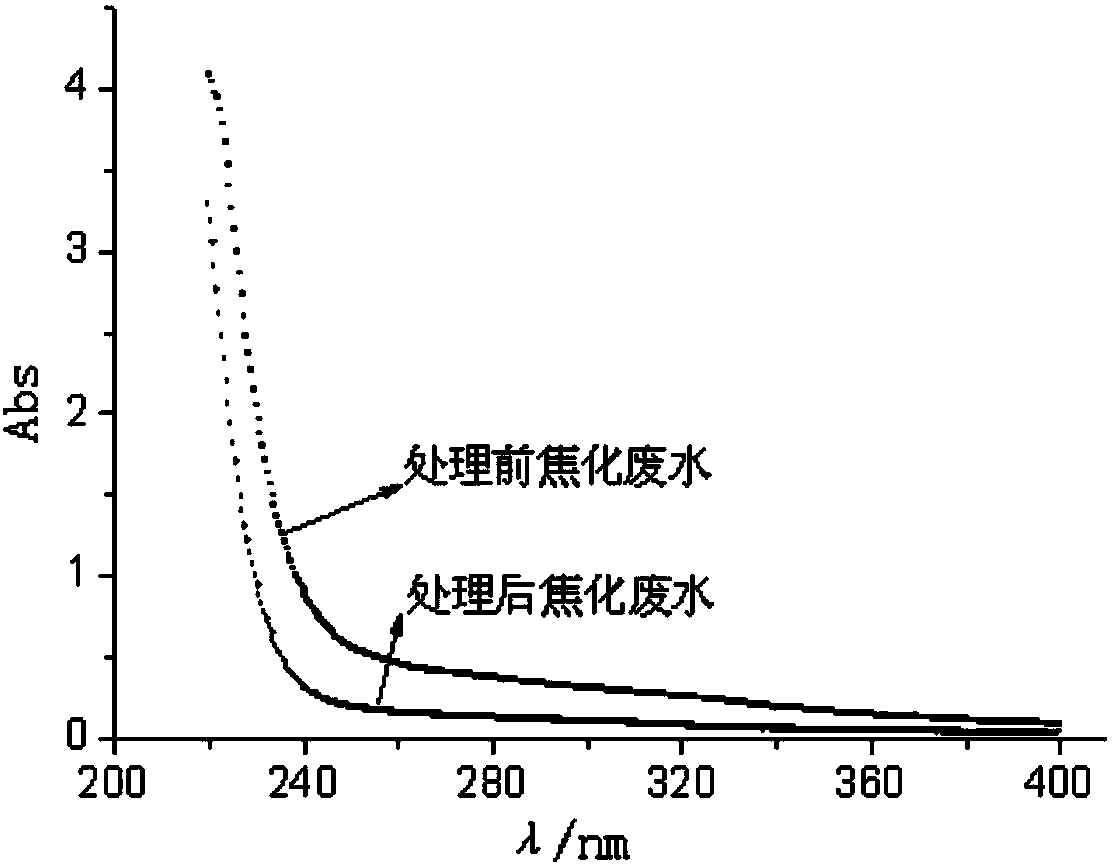

ActiveCN104310535ALoose structureLarge specific surface areaOther chemical processesTransportation and packagingResource utilizationCoke oven

The invention discloses a resource utilization method of blast furnace dust and coke furnace dust. The resource utilization method comprises the following steps: 1) sieving out the blast furnace dust and the coke furnace dust with the grain sizes of 150-400 meshes; 2) mixing the sieved blast furnace dust and the sieved coke furnace dust according to a mass ratio of (2-5): 1, adding bentonite and an ammonium salt solution, stirring uniformly, granulating to obtain granules with the grain sizes of 1.5- 5.0mm; 3) drying the granules, adding the granules into a muffle furnace, rising the temperature to be 400- 650 DEG C at a heating speed of 12-18 DEG C / min in an inert gas atmosphere, roasting for 1-2h, sintering to obtain mixed dust granules; 4) adding the mixed dust granules into coking biochemical effluent, adjusting the PH value to 3-5, uniformly stirring and mixing, sufficiently degrading organic substances in the coking biochemical effluent for deep treatment. By the resource utilization method, the problems of environment pollution and large floor area of the blast furnace dust and the coke furnace dust are solved, the deep treatment of the coking biochemical effluent is implemented and the treatment cost of the coking wastewater is reduced.

Owner:武汉武钢绿色城市技术发展有限公司

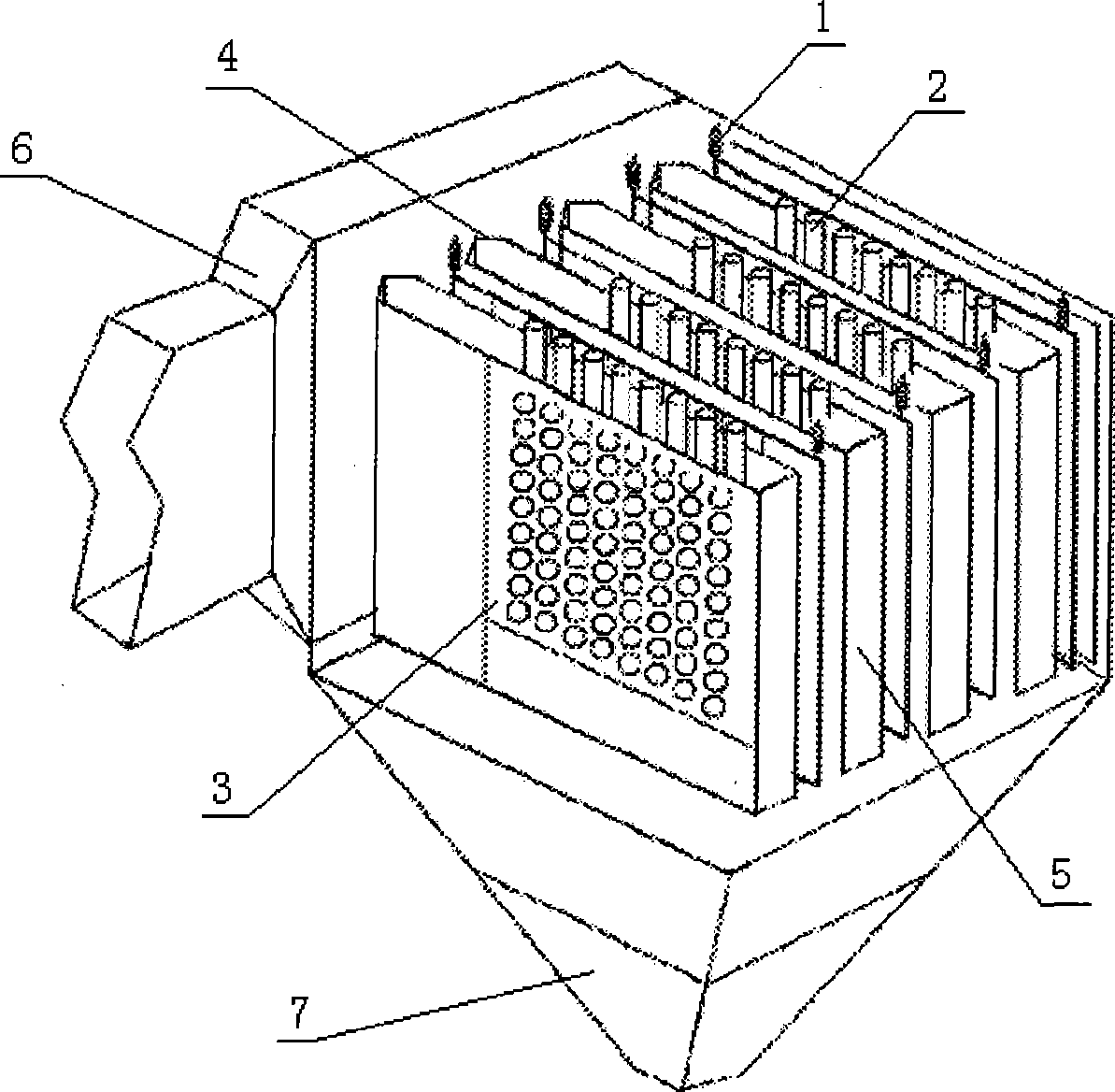

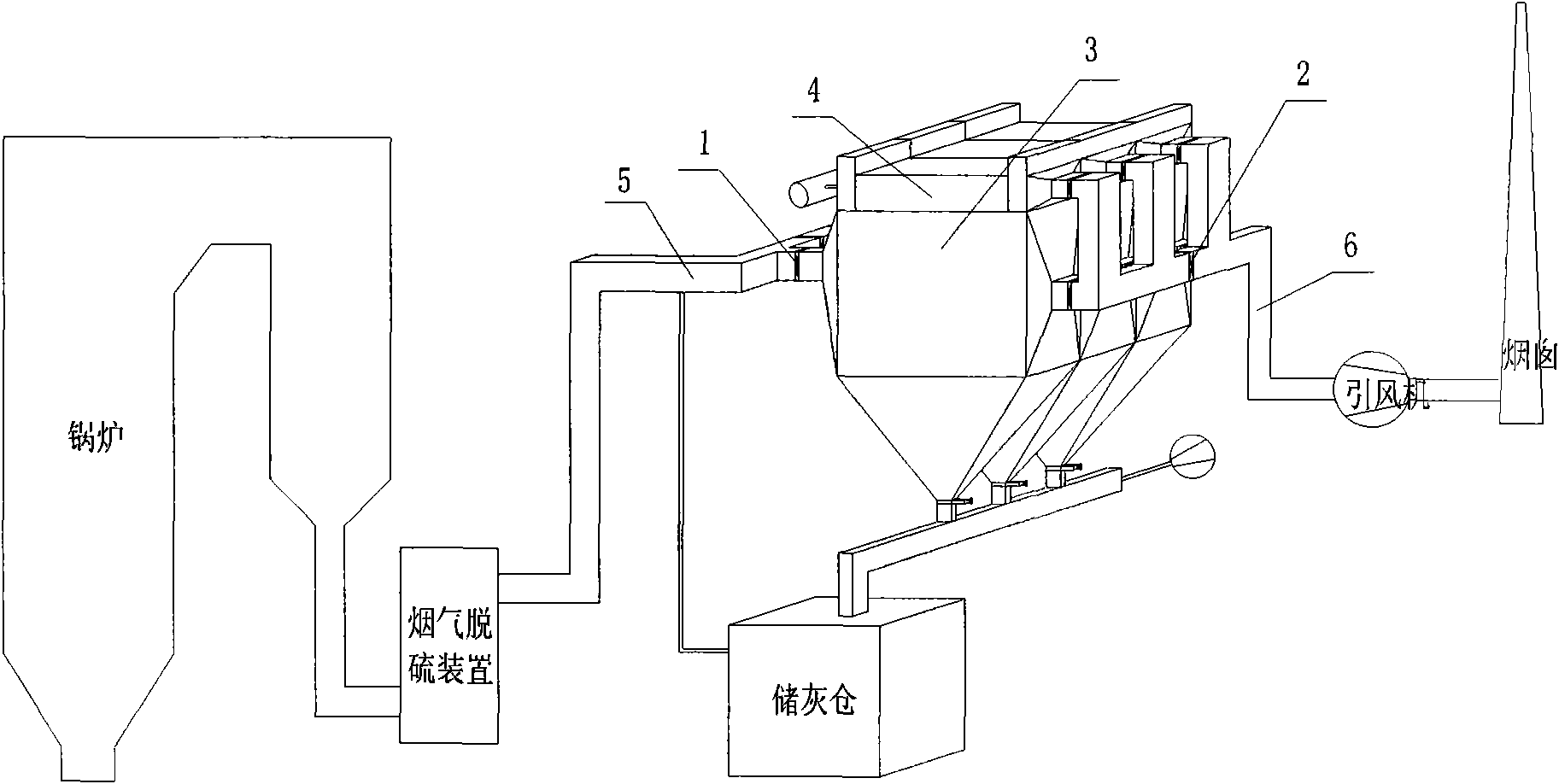

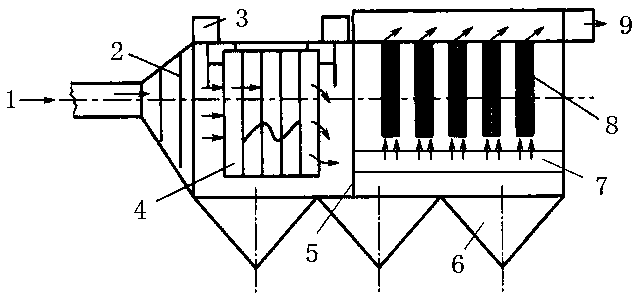

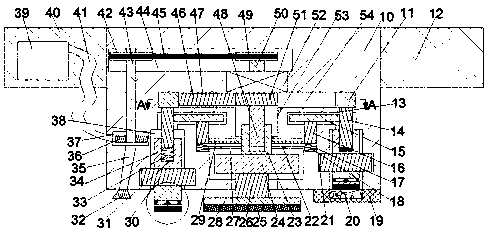

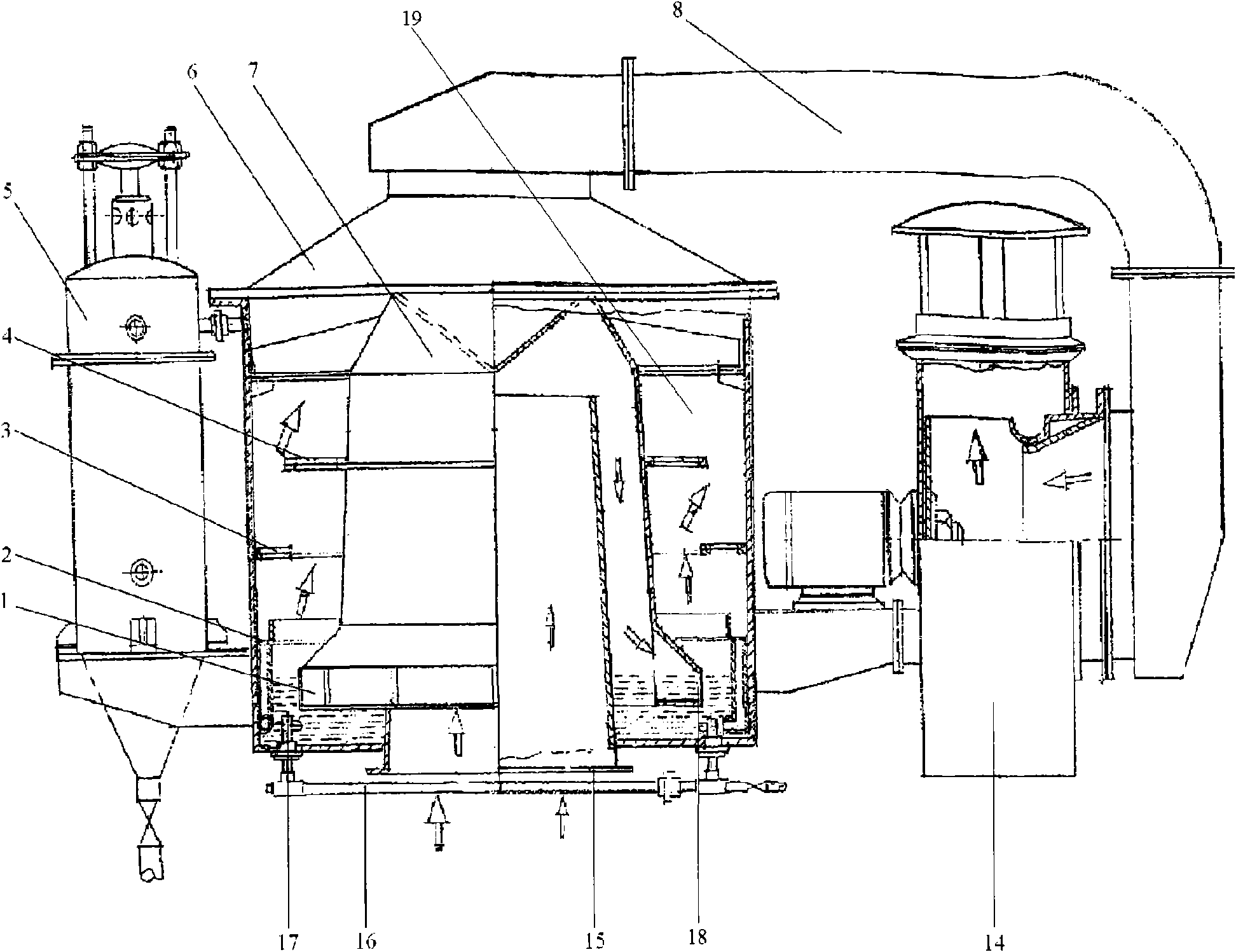

Electrostatic bag type mixed dust collector

ActiveCN101530709AImprove performanceExtended service lifeCombination devicesDispersed particle filtrationVena contracta diameterFiltration

The invention provides an electrostatic bag type mixed dust remover, which relates to the technical field of flue gas cleaning and dust removal. The electrostatic bag type mixed dust remover comprises a plurality of rows of discharge electrodes arranged at intervals along the direction of the gas flow at an inlet and a plurality of rows of filter bags. Two sides of each row of filter bags are provided with dust-collecting polar plates, and V-shaped deflectors and V-shaped sealing plates are arranged at the front and back ends of two adjacent dust-collecting polar plates respectively. The electrostatic bag type mixed dust remover has the structural characteristic that the dust-collecting polar plates consist of front dust-collecting polar plates positioned at a front section and connected with the deflectors, dust-collecting orifice plates positioned at a back section and connected with the upper parts of the front dust-collecting polar plates, and lower dust-collecting polar plate connected with the lower parts of the front dust-collecting polar plates. The dust-collecting orifice plates are uniformly distributed with a plurality of orifices, and the rows of filter bags are arranged at the back sections of the dust-collecting polar plates at the positions of the dust-collecting orifice plates. The invention adopts combined dust-collecting polar plates, reduces the ash filtration load of the filter bags, realizes a complete ash cleaning process, and improves the performance of a whole dust-removal system.

Owner:TONGFANG ENVIRONMENT

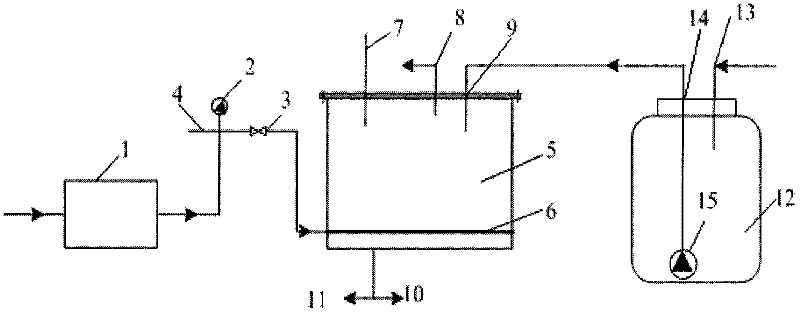

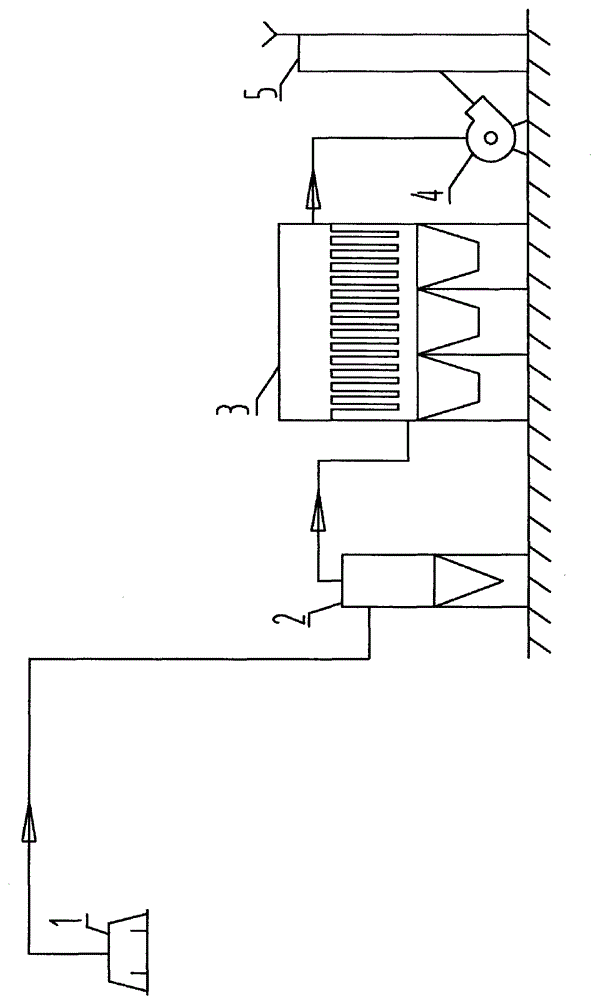

Mixed dust removal device for removing paint mist in spray paint waste gas

InactiveCN110064268AReduce processing costsEfficient removalCombination devicesGas treatmentMixed dustCyclonic spray scrubber

The invention discloses a mixed dust removal device for removing paint mist in spray paint waste gas. The mixed dust removal device comprises a Venturi tube dust remover, a cyclone dust remover, a bagfilter, a fan, a circulating water pump and a circulating water tank. One end of the Venturi tube dust remover is provided with a gas inlet for enabling spray paint waste gas to flow in, the other end of the Venturi tube dust remover is provided with a water-gas mixture outlet connected with a water-gas mixture inlet of the cyclone dust remover, a dust discharge outlet formed in the lower end ofthe cyclone dust remover is formed in the circulating water tank, an exhaust port at the upper end of the cyclone dust remover is connected with a gas inlet of the bag filter, a gas outlet of the bagfilter is connected with a gas inlet of the fan, gas can be exhausted from a gas outlet of the fan finally, a liquid inlet of the circulating water pump is communicated with the circulating water tank, and a liquid outlet of the circulating water pump is connected with a spraying liquid inlet of the Venturi tube dust remover. Paint mist and other dust particualte matter in spray paint can be effectively removed.

Owner:CHINA NAT ELECTRIC APP RES INST

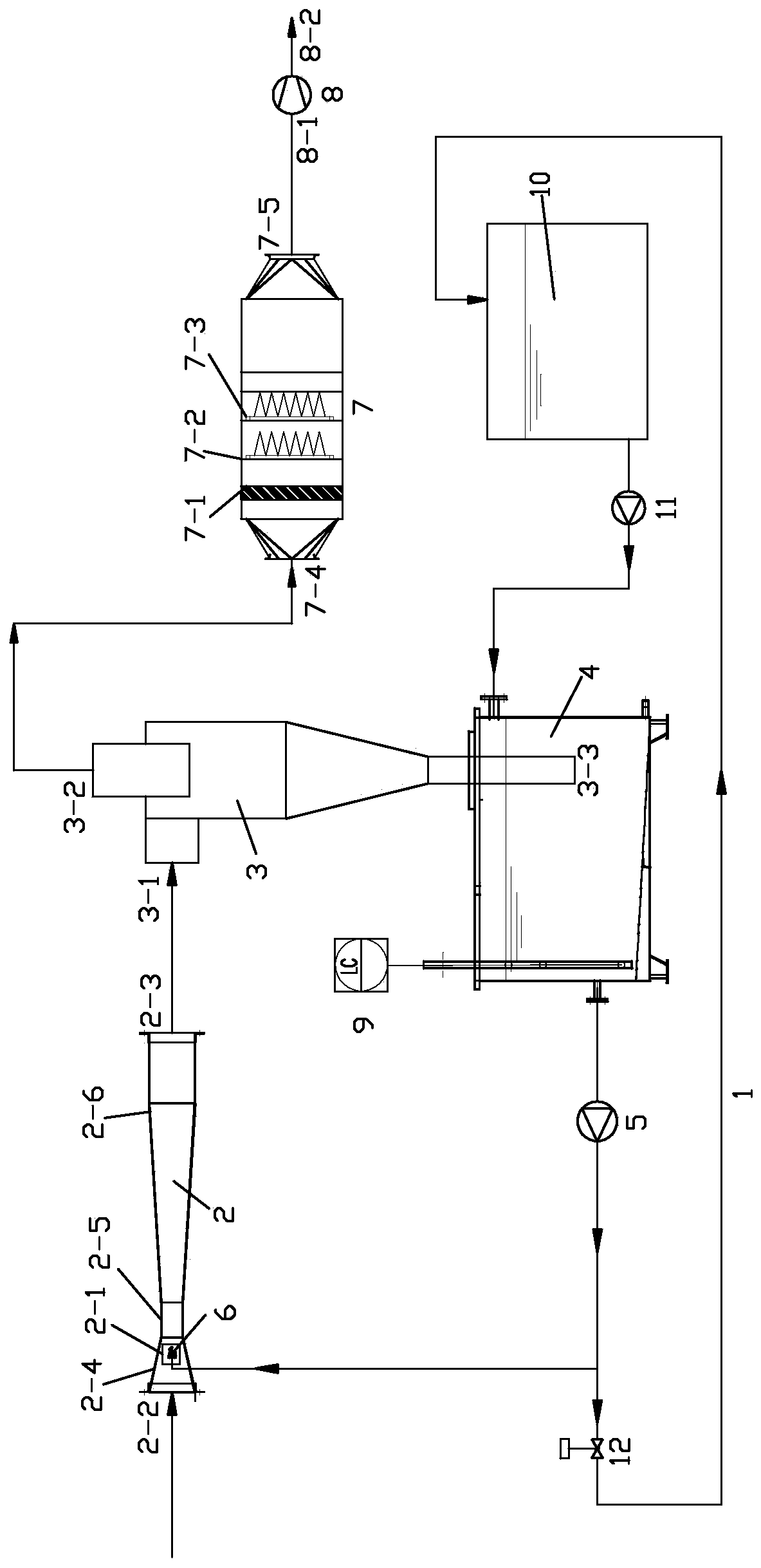

Method for treating sulfur slag

InactiveCN103194621AImprove direct yieldThe separation effect is thoroughPhotography auxillary processesProcess efficiency improvementTin dioxideElectrolysis

A method for treating sulfur slag comprises the following steps of: performing liquation treatment on sulfur slag containing 65-73% of tin and 6-15% of copper on the crude tin liquid in an iron pot in the range of 500-700 DEG C, thereby obtaining liquid crude tin and liquation slag containing 48-60% of tin and 8-23% of copper, recovering the liquid crude tin in the pot and completely oxidizing the liquation slag by industrial oxygen at a high temperature into mixed dust of copper oxide and tin dioxide, leaching the mixed dust for 2-3 hours under conditions of normal temperature and normal pressure, 70-120 g / L initial acid, and then filtering; reducing and smelting the filter residue to obtain crude tin, and concentrating, crystallizing and separating the filtrate to produce copper sulfate pentahydrate or performing electrolysis to produce electrolytic copper; and then returning the crystallization mother liquor or the liquid after electrolysis to the leaching process for liquid preparation. The method provided by the invention is capable of directly recovering most metal tin and realizing recovery of tin and copper in the sulfur slag without generating wastewater, waste gas and waste residues.

Owner:吴鋆

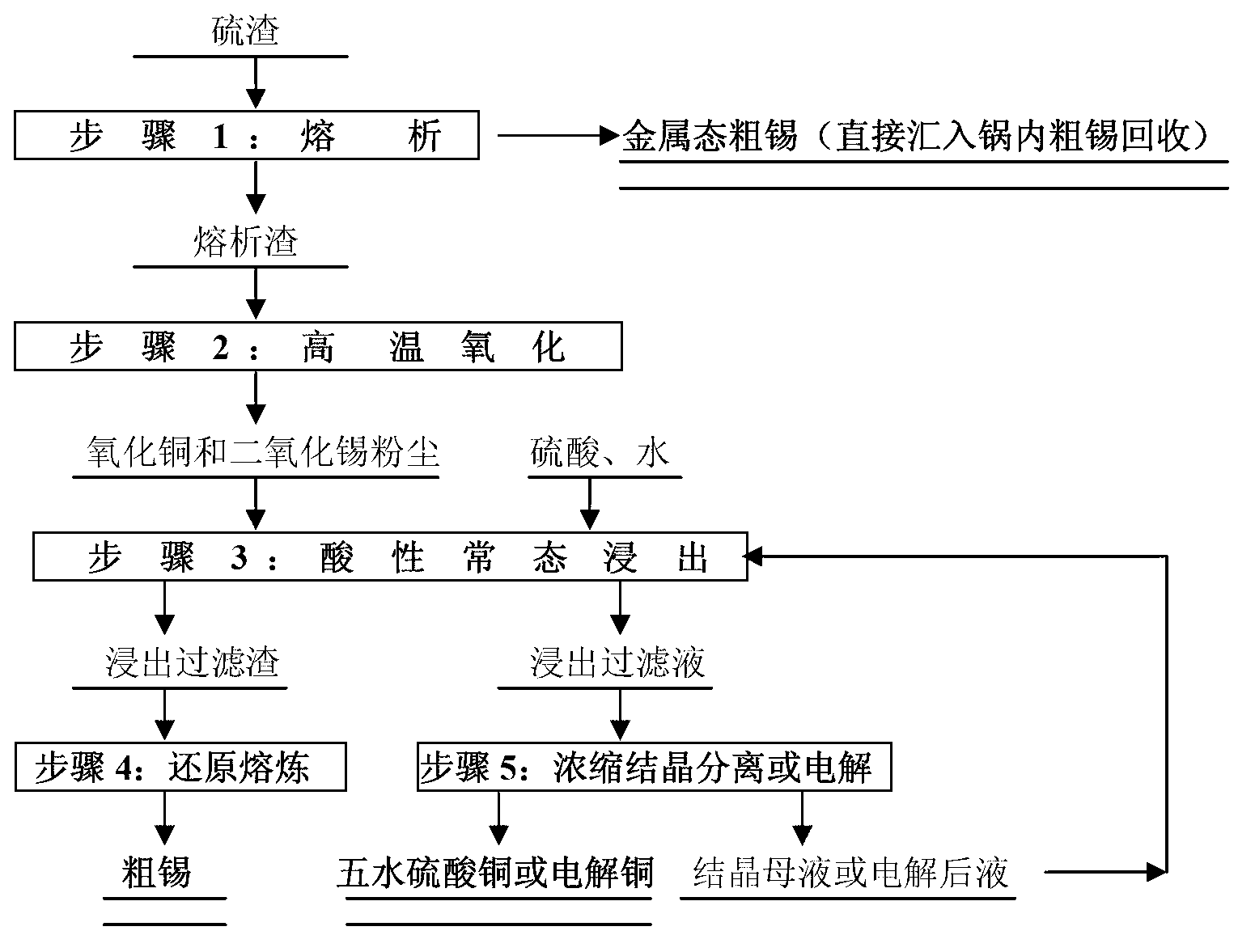

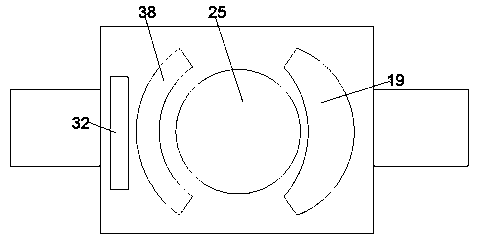

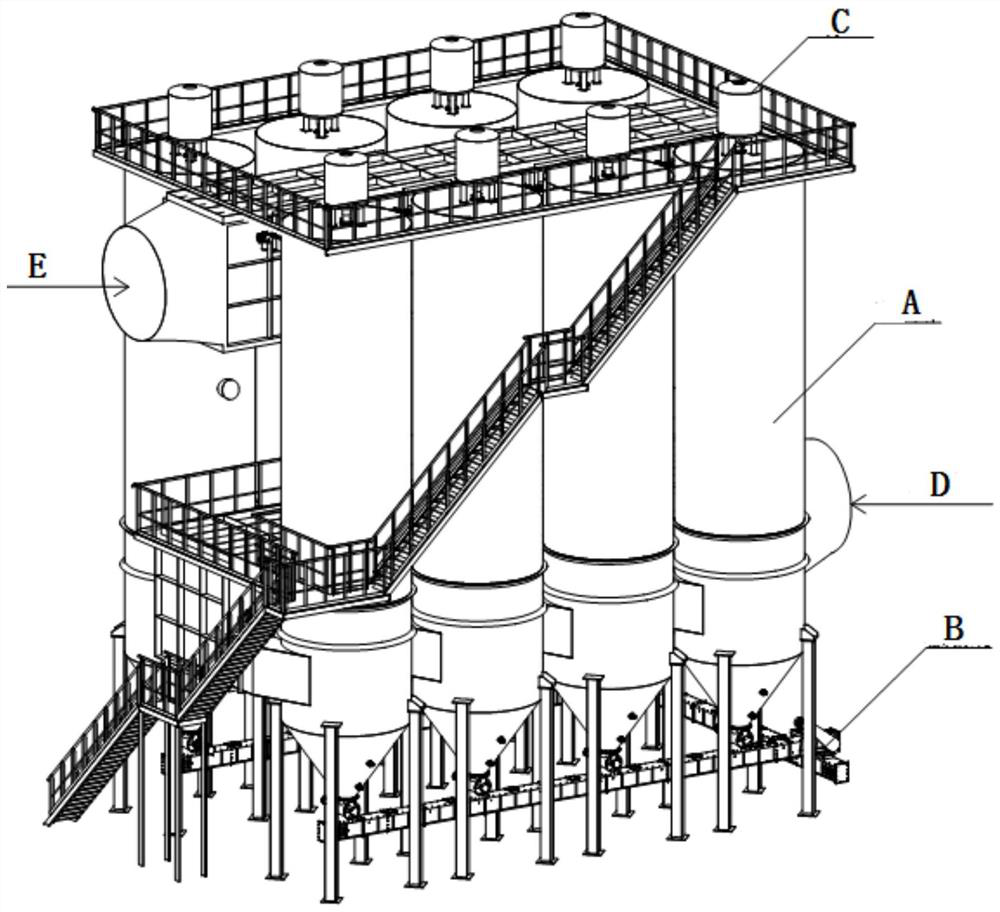

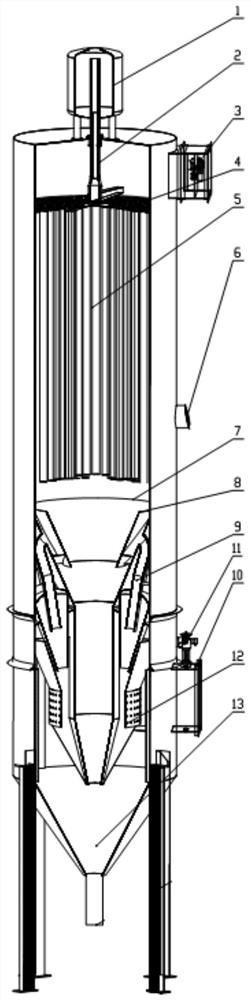

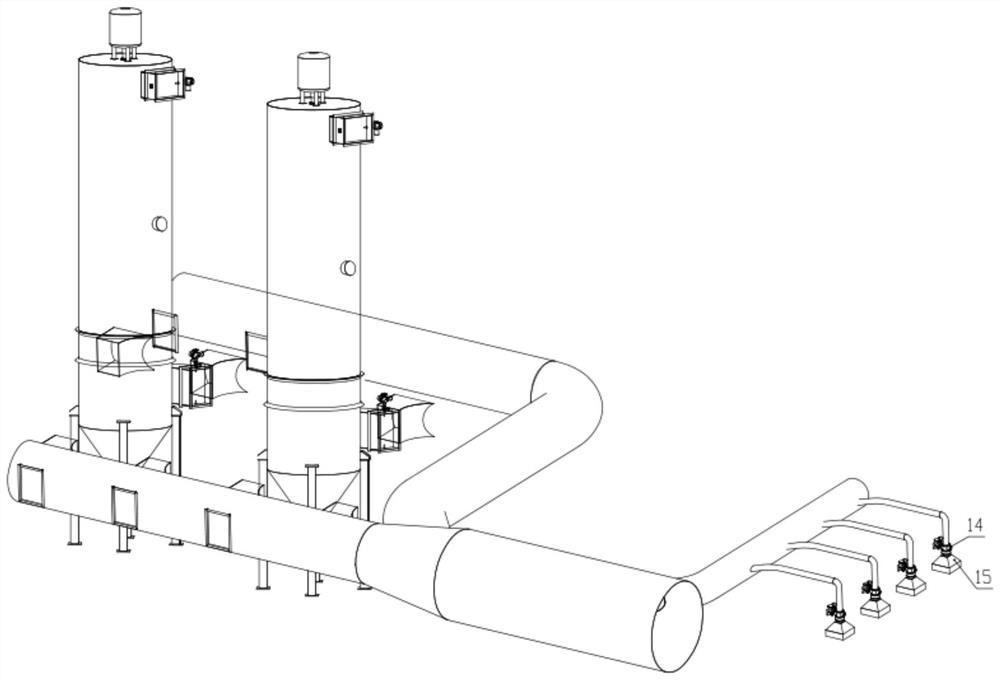

Static hop-pocket mixed dust removal device and control method thereof

ActiveCN101590351AAdjust the mode of operation in due courseAchieve economical operationCombination devicesFlue gasOperation mode

The invention provides a static hop-pocket mixed dust removal device and a control method thereof, belonging to the technical field of flue gas purification and dust removal. The device of the invention comprises a plurality of static hop-pocket mixed dust chambers and is structurally characterized in that the flue gas inlet of the static hop-pocket mixed dust chamber is connected with an inlet main flue by an outlet sub flue provided with a flue gas stop valve. The flue gas outlet of the static hop-pocket mixed dust chamber is connected with an outlet main flue by an outlet sub flue provided with the flue gas stop valve, and a flue gas purification chamber at the top part of the static hoop-pocket mixed dust chamber is connected with the outlet main flue by an upper outlet sub flue provided with the flue gas pipe valve. The inlet main flue and the outlet main flue are respectively provided with a flue gas interconnection valve on the main flues arranged between two adjacent front inlet sub flues and between two adjacent rear outlet sub flues. The invention can realize flexible conversion of multiple operation modes, and improves dust removal efficiency of the whole dust removal system.

Owner:TONGFANG ENVIRONMENT

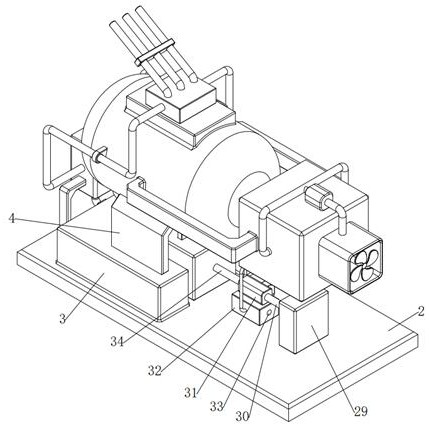

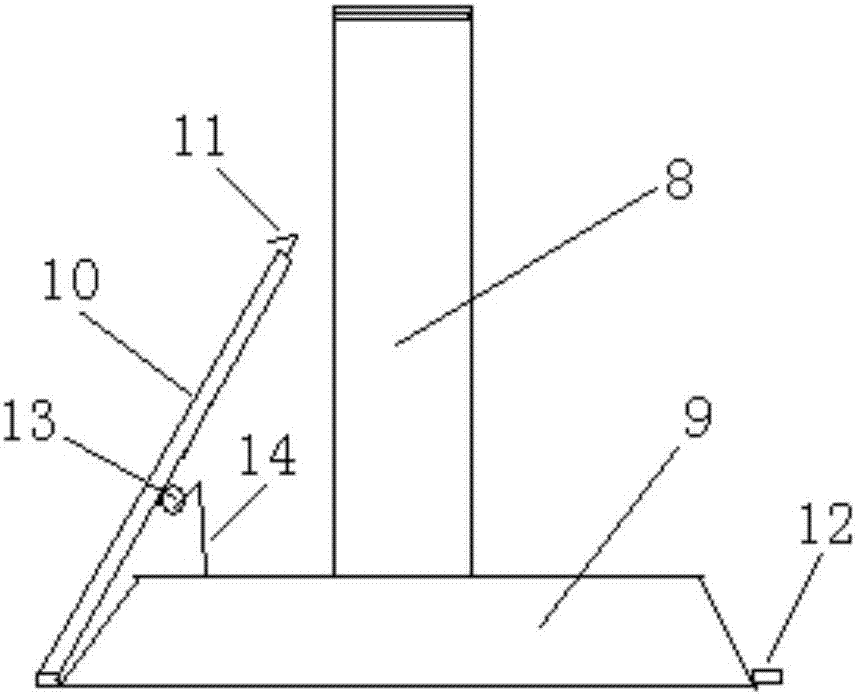

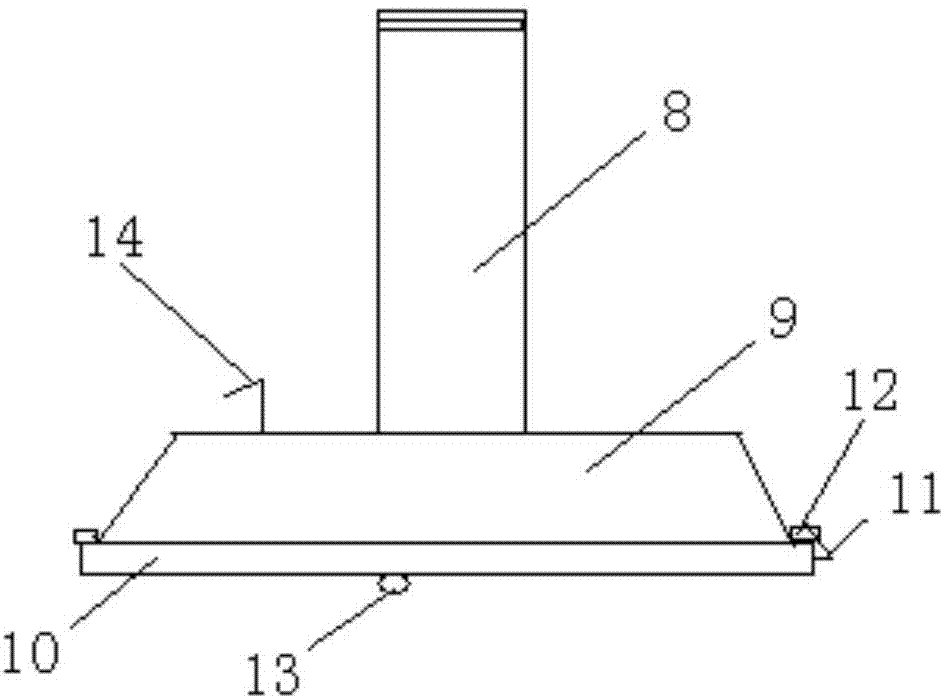

Constructional engineering dust falling device based on impact-jet airflow combination and use method thereof

InactiveCN114130533AAchieve adsorptionRealize multi-directional coolingLighting and heating apparatusElectrostatic separationWater storageJet flow

The invention discloses a building engineering dust falling device based on collision and jet airflow combination and a using method thereof. Comprising a main body supporting mechanism, a dual-action type magnetoelectric mixed dust adsorbing and filtering mechanism, a jet flow multi-direction type anti-static adhesion type high-temperature rapid cooling mechanism, a collision mixed type atomization dust falling type dusty air water mist cleaning mechanism and a collision friction type ion increasing type air purifying and conveying mechanism. The main body supporting mechanism comprises a bottom plate, a water storage tank body, a supporting plate, an adsorption tank body, a friction tank body and a fixing frame. The invention belongs to the technical field of constructional engineering equipment, and particularly relates to a constructional engineering dust falling device based on impact and jet airflow combination and a using method thereof. According to the building engineering dust falling device based on impact and jet airflow combination and the using method thereof, dust can be adsorbed and treated through the two-way effect, water can be fully utilized, and the dust falling process can be cooled in multiple directions.

Owner:江苏建信网络科技有限公司

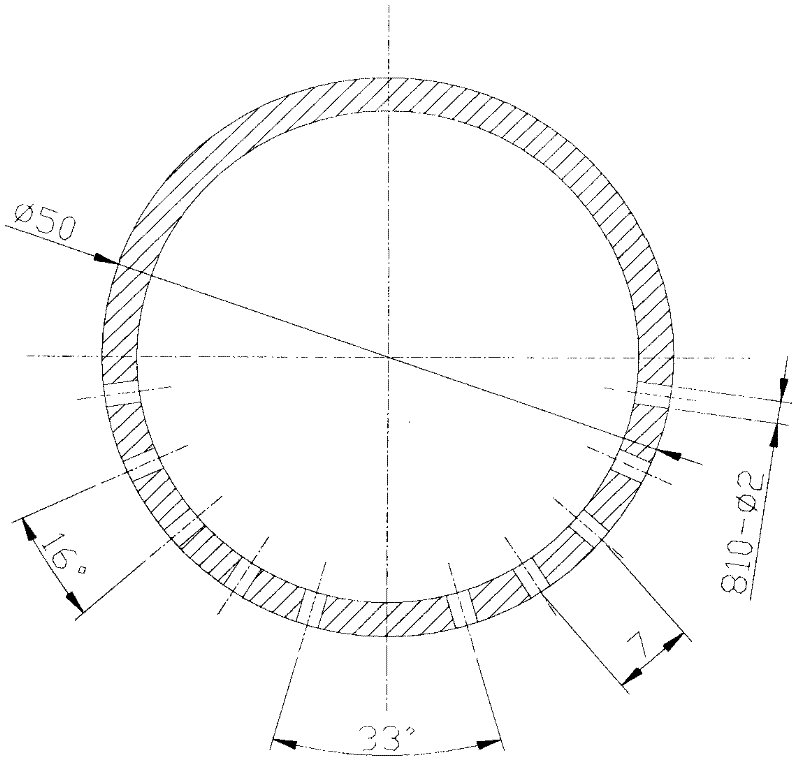

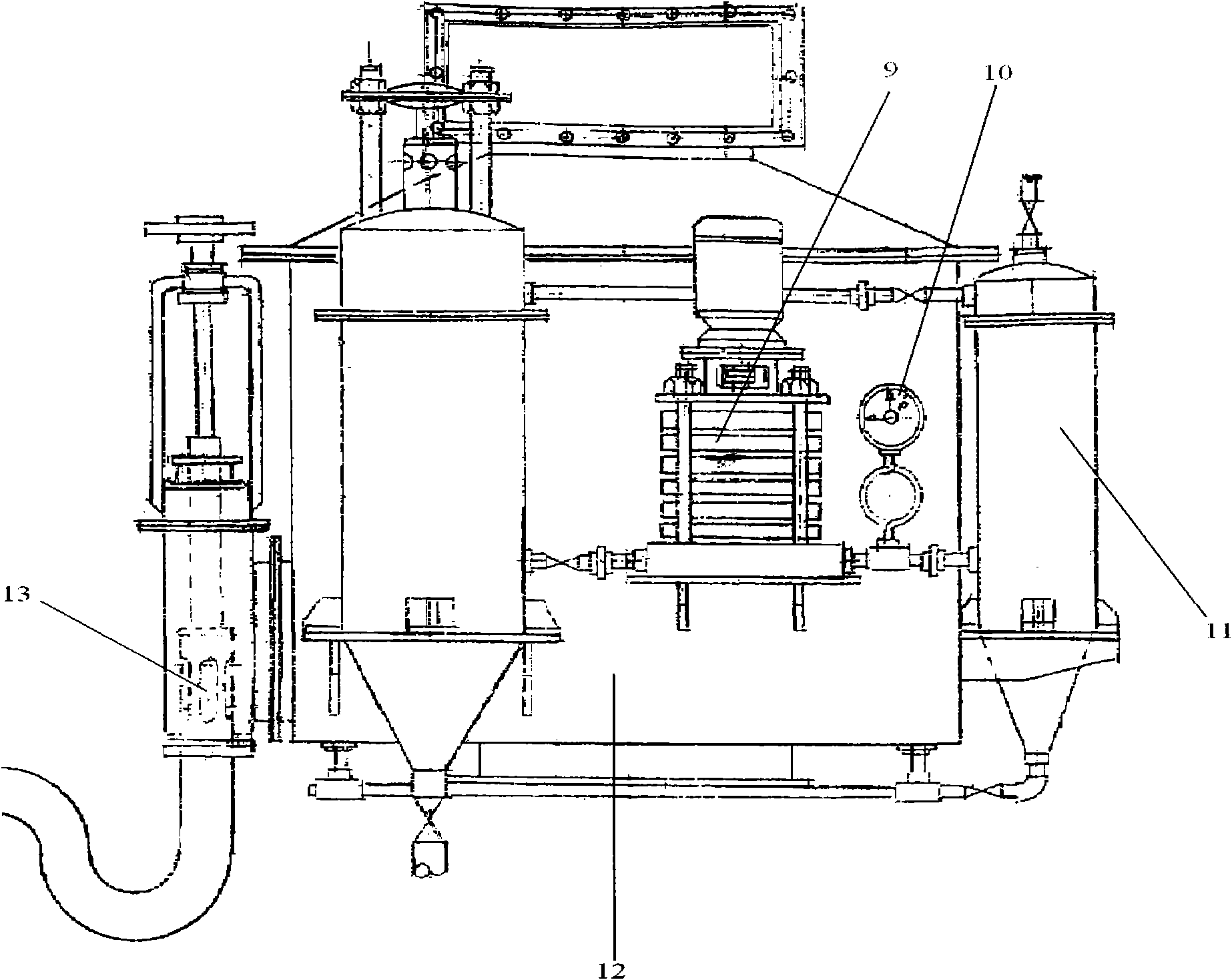

Titanium high temperature electrolytic furnace special-purpose tail gas processing system

InactiveCN102294170AEasy to operatePromote absorptionDispersed particle separationHydrogen fluorideTitanium

The invention relates to a titanium high temperature electrolytic furnace special-purpose tail gas processing system, wherein the tail gas contains a hydrogen fluoride gas and a few solid calcium fluoride dust or calcium fluoride and lithium fluoride mixed dust. The system provided by the invention comprises a deduster, a pneumatic tube, a tail gas control device, a tail gas processing device, a woven hose and a proportioning device, wherein the deduster is used to remove a few solid calcium fluoride dust or the calcium fluoride and lithium fluoride mixed dust contained in the tail gas; the pneumatic tube is used to convey the tail gas into the tail gas processing device; the tail gas control device is used to control the flow of the tail gas; the woven hose is used to convey an absorption liquid into the tail gas processing device; and the proportioning device is used to proportion the absorption liquid and pump the absorption liquid into the tail gas processing device through the woven hose.

Owner:宝纳资源控股(集团)有限公司

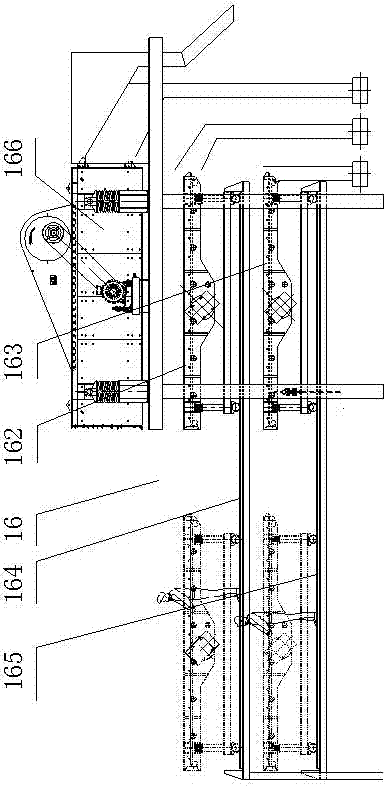

Linear vibrating screen underneath type dust removal system and method

ActiveCN104759403AAvoid confusionEnsure normal dischargeCombination devicesSievingMovable typeMixed dust

The invention relates to a linear vibrating screen underneath type dust removal system and a linear vibrating screen underneath type dust removal method. The linear vibrating screen underneath type dust removal system and the linear vibrating screen underneath type dust removal method not only an achieve dustless discharge during the sand screening process, but also can reduce electric energy used in a background technology by about 50%. The linear vibrating screen underneath type dust removal system comprises a fixed type linear vibrating screen, wherein one layer or multiple layers of movable type vibrating linear screens are arranged below the fixed type linear vibrating screen, a seal cover covers the periphery of a discharge hole of the fixed type linear vibrating screen and the multiple layers of the movable type vibrating linear screens, and a negative pressure dust suction port is located on the discharge hole of the fixed type linear vibrating screen, and communicated with the movable type vibrating linear screen on the upper layer of the multiple layers of the movable type vibrating linear screens through the seal cover. The linear vibrating screen underneath type dust removal system and the linear vibrating screen underneath type dust removal method have the advantages of 1) needing no wind to blow sand, being capable of completely sucking mixed dust screened out by the fixed type linear vibrating screen, preventing the dust and the sand from being mixed, and obtaining pure sand; 2) being low in energy consumption, and then saving energy due to the fact that sucked material of a cyclone dust collector is the dust low in weight; 3) guaranteeing that cleaning gas is discharged through an exhaust pipe of a pulse bag type dust collector.

Owner:ZHEJIANG SHUANGJIN MACHINERY HLDG

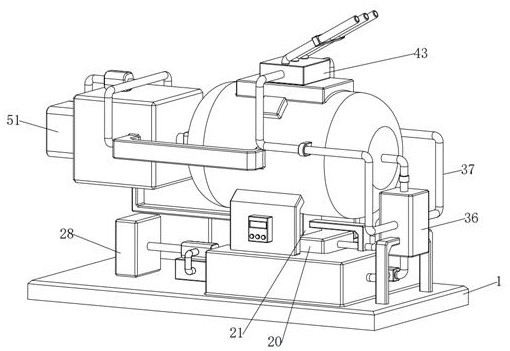

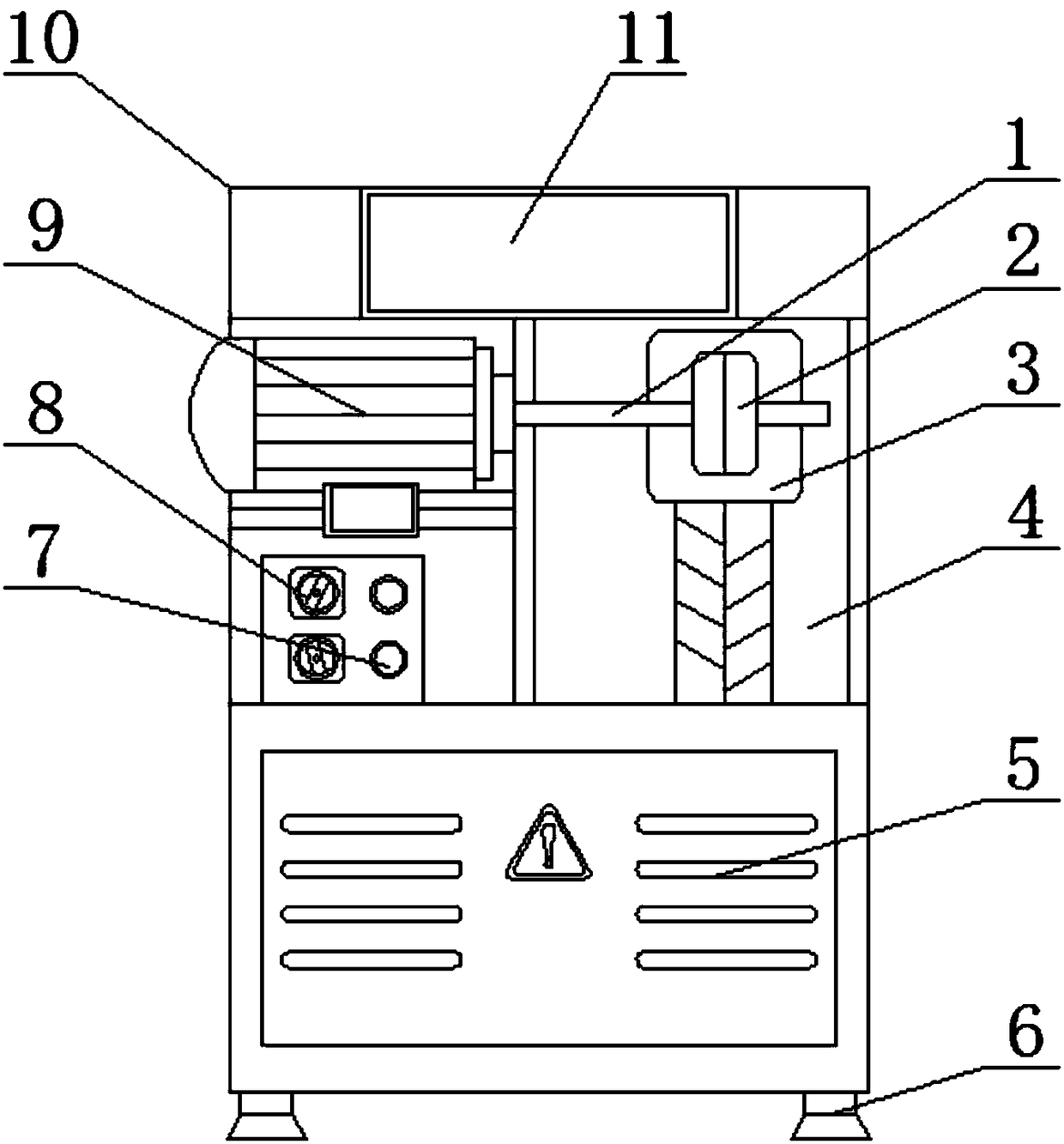

Dust-absorbing speed-regulating upper grinding machine

InactiveCN108113125AReduce economic investmentAvoid damageShoemaking devicesUsing liquid separation agentWater storageEngineering

The invention discloses a dust-absorbing speed-regulating upper grinding machine which comprises a grinding machine body, a rotating shaft, a water pipe, an induced draft fan and an atomizing nozzle.The top of the grinding machine is provided with a nameplate, and a motor is arranged below the left side of the nameplate. A speed control button is disposed below the motor, an indicator light is disposed below the right side of the speed control button, and the rotating shaft is mounted on the motor. A dust removal circulation system is disposed inside the original grinding machine, and the induced draft fan adsorbs dust generated by grinding into a dust removing tank, the atomizing nozzle liquefies the dust in the dust removing tank, the liquid mixed with the dust is transported to a watercirculating tank through a water pipe, and the dust is filtered through a filter screen and gathered in a dust separating area, and water is stored in a water storage area for recycling. At the sametime, the induced draft fan can eliminate dust odor, reduce the respiratory damage to an operator, reduce the outside dust residue, reduce the safety hazard in a production workshop, and reduce the additional economic investment on the dust treatment.

Owner:广西玉林市汉龙环保科技有限公司

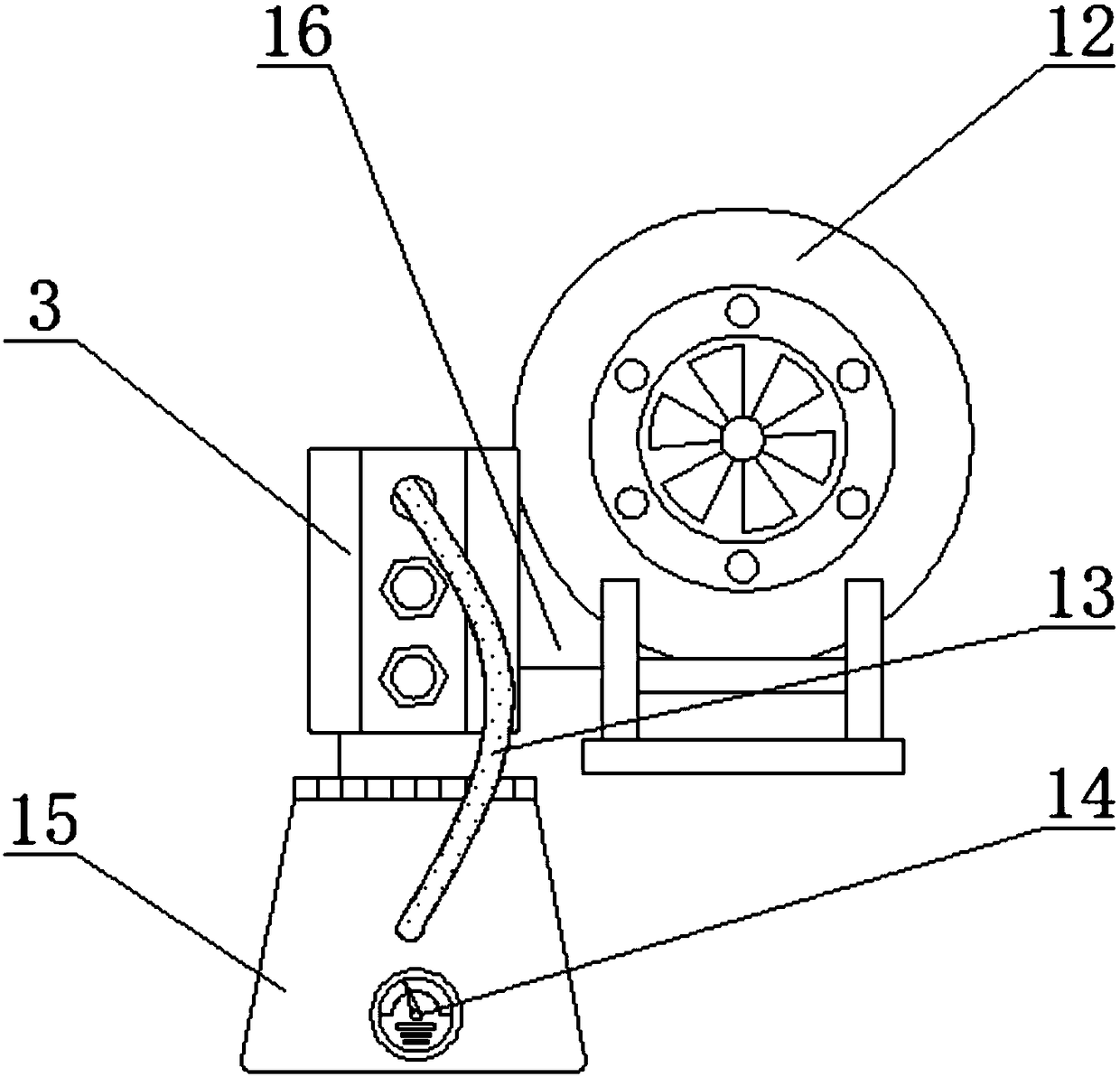

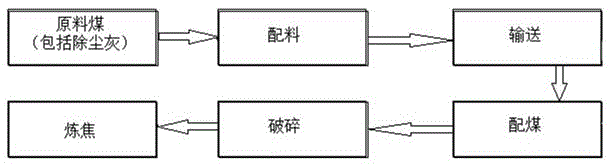

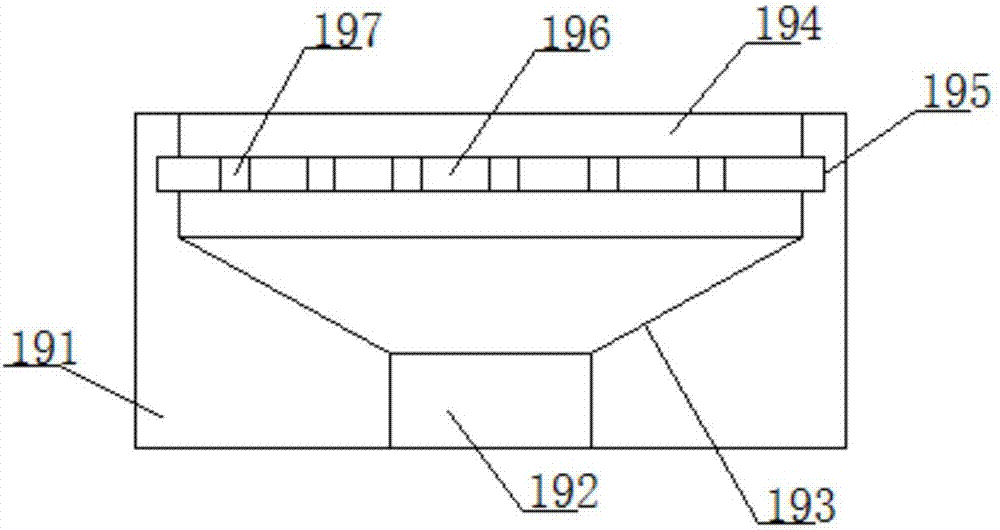

Mixed dust removal device

InactiveCN105363288AReduce tensionExtended service lifeDispersed particle filtrationElectrostatic separationElectricityEngineering

The invention discloses a mixed dust removal device comprising a dust removal chamber; the bottom of the dust removal chamber is provided with dust hoppers. The mixed dust removal device is characterized in that the dust removal chamber is divided into an electric dust removal chamber and a bag dust removal chamber by a segregation plate, one side of the electric dust removal chamber is provided with an airflow inlet, the electric dust removal chamber is internally provided with a polar plate, and the top of the electric dust removal chamber is provided with a power supply; and the bag dust removal chamber is internally provided with a plurality rows of filter bags, the top of the bag dust removal chamber is provided with an airflow outlet, the bottom of the bag dust removal chamber is horizontally provided with a guide pipe communicating with the electric dust removal chamber, and the guide pipe is provided with opening holes. With combination of working principles of an electric dust removal device and a bag dust removal device, the structures and positions of various components are reasonable arranged, and the dust removal efficiency and the dust removal effect are improved.

Owner:吕珩

Mixed dust collection system used in cutting process of circuit board substrate and using method thereof

PendingCN106944445ASimple structureEasy to useDirt cleaningMaintainance and safety accessoriesCollection systemEngineering

The invention discloses a mixed dust collection system used in the cutting process of a circuit board substrate and a using method thereof. The mixed dust collection system comprises an aluminum powder dust collector, a common powder dust collector, a first hose, a second hose, a dust collection chamber, dust collection pipes and dust collection covers. The dust collection chamber comprises a first dust collection channel and a second dust collection channel. The first dust collection channel is connected with the aluminum powder dust collector through the first hose. The second dust collection channel is connected with the common powder dust collector through the second hose. The first dust collection channel is provided with two or more first inserting openings, and the second dust collection channel is provided with two or more second inserting openings. Both the first inserting openings and the second inserting openings are circular holes with the same caliber, and the circular holes are all provided with internal threads. The number of the dust collection pipes and the number of the dust collection covers are both two or more. One end of each dust collection pipe is connected with the corresponding dust collection cover, and the other end of each dust collection pipe is provided with external threads matched with the first inserting openings and the second inserting openings. The mixed dust collection system is simple in structure, convenient to use and capable of saving labor. Dust collection equipment can be replaced simply and quickly, so that aluminum powder is separated from common powder, and cost is reduced.

Owner:南京市罗奇泰克电子有限公司

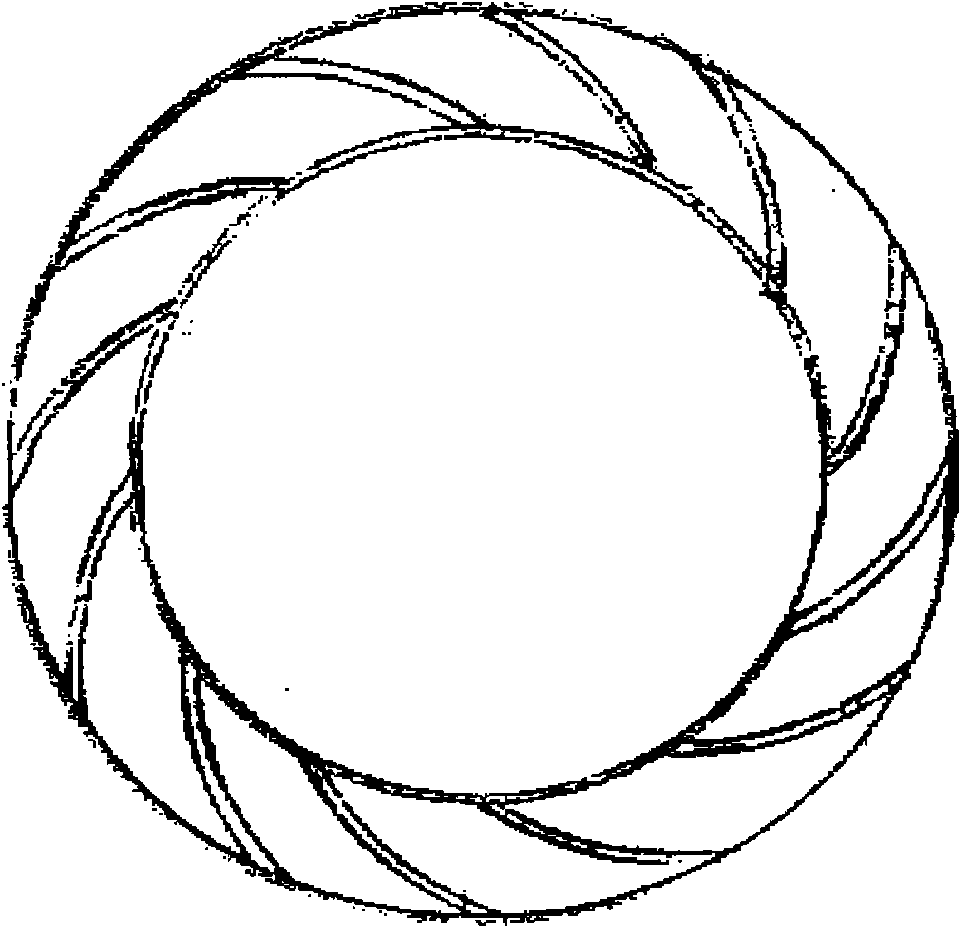

Integrated device for waxing and polishing surface of automobile

InactiveCN111558890AQuality improvementCar wax scratchesPolishing machinesVehicle servicing/repairingPolishingStructural engineering

The invention discloses an integrated device for waxing and polishing the surface of an automobile. The integrated device for waxing and polishing the surface of the automobile comprises a main body,wherein a waxing channel with a downward opening and in a circular ring shape is arranged in the main body, a waxing device is arranged in the waxing channel, the waxing device comprises sliding chutes symmetrically formed in the inner side end wall and the outer side end wall of the waxing channel, sliding blocks are arranged in the sliding chutes in a sliding manner, and movable blocks capable of sliding in the waxing channel are fixed to the upper sides of the sliding blocks. According to the integrated device for waxing and polishing the surface of the automobile, dust and other substanceswhich are attached to the surface of the automobile and are easy to remove can be sucked away, inclusion of dust is avoided during waxing, car paint is prevented from being scratched by mixed dust during subsequent polishing operation, subsequent polishing quality of the automobile is improved, waxing speed can be improved, and overall working efficiency is improved.

Owner:杭州味想汽车用品有限公司

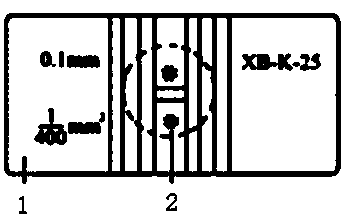

Determination method for dispersity of dust in air of working field

The invention relates to a determination method for the dispersity of dust in air of a working field. The determination method comprises the following steps: preparation of a dust suspension solution according to GBZ / T192.3-2007 and ocular lens micrometer calibration; preparation of a dust sample, namely inflating the uniformly-mixed dust suspension solution into a counting tank of a blood counting plate; standing and depositing dust grains at the bottom of the counting tank; dispersity determination, namely taking off an objective lens micrometer and putting the blood counting plate into which the dust sample is dropped on an objective table; finding out the dust grains by using a low-power lens; observing with magnifying power by a calibration ocular lens micrometer; selecting four corners of a large square cell at the center of the counting tank and five middle square cells at the center of the counting tank; sequentially determining the size of each dust grain by using the objective lens micrometer; measuring a long diameter when meeting a long diameter amount and measuring a short diameter when meeting a short diameter amount; and recording by groups and calculating the percentage. According to the determination method, a blood counting plate method is used for determining the dispersity of the dust so as to effectively avoid the error caused by human factors of smearing and measuring links in a previous method, and guarantee the accuracy of a determination result.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

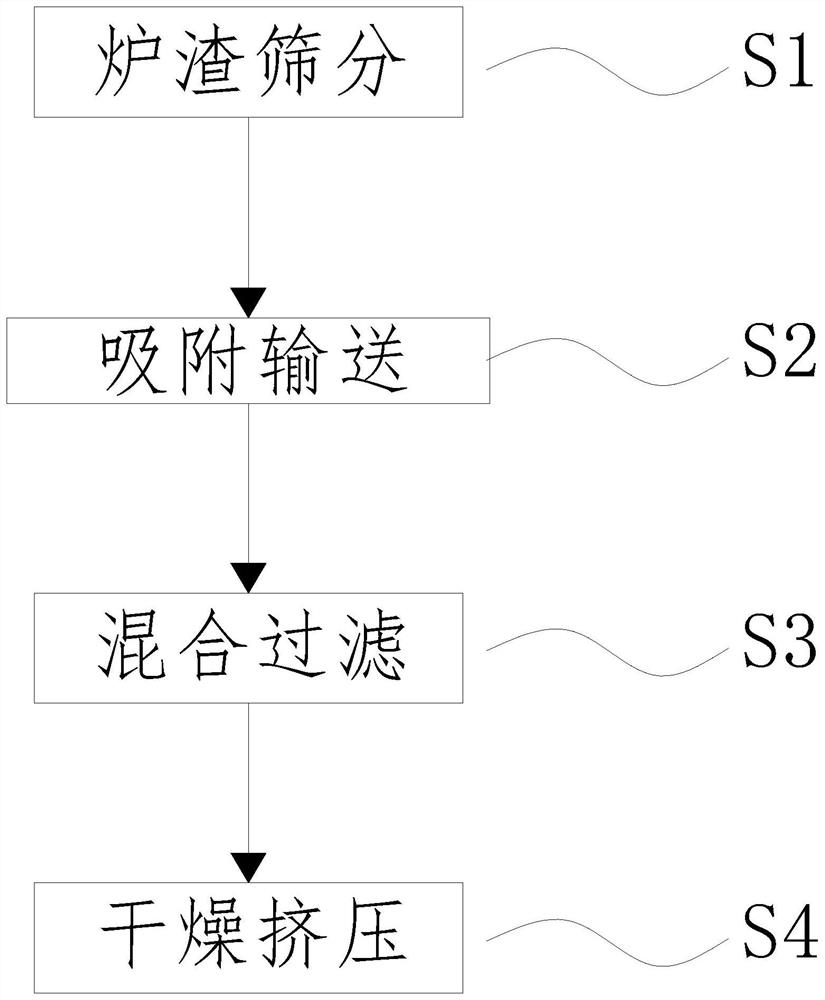

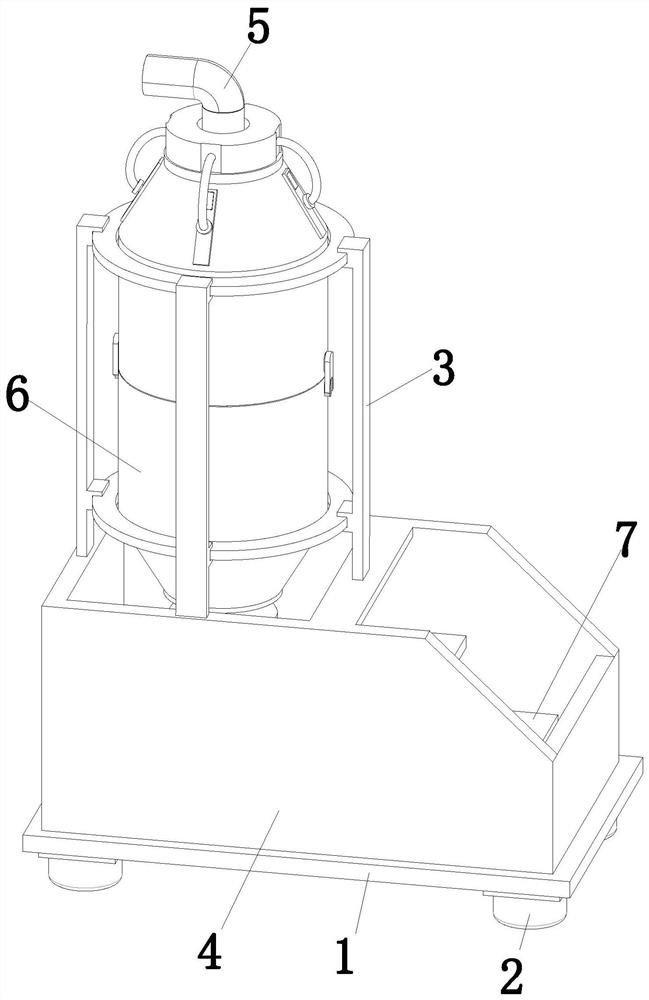

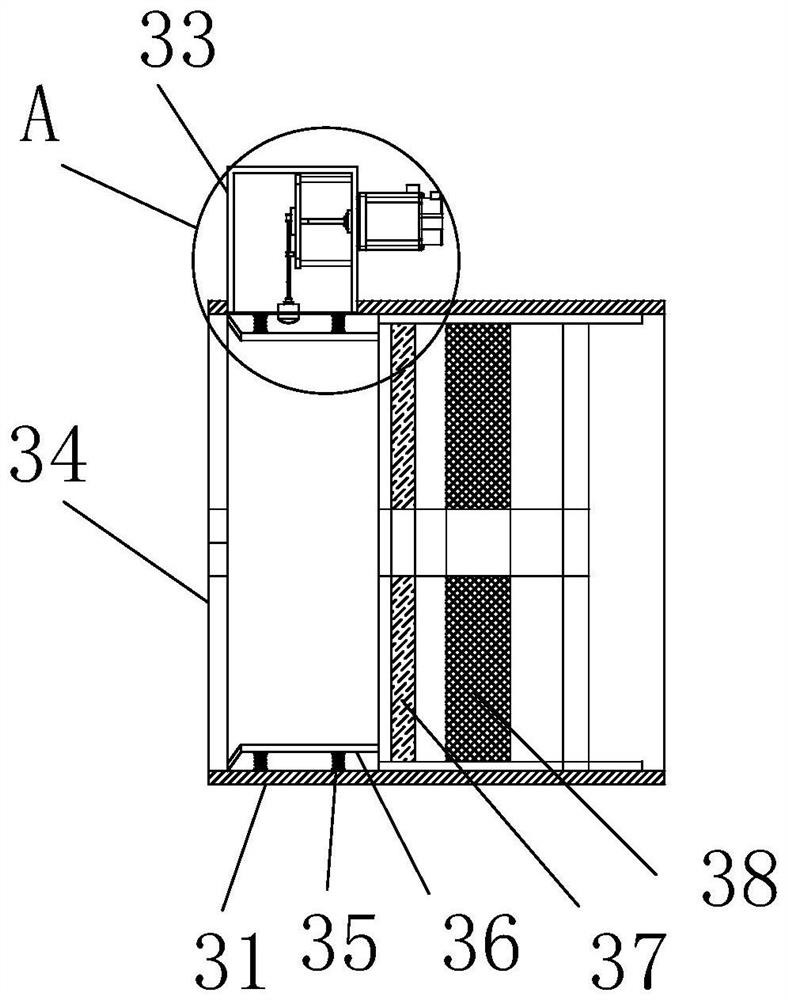

Industrial boiler slag solid waste comprehensive environment-friendly treatment method

InactiveCN113244721ARealize secondary recyclingQuick installationTransportation and packagingSolid waste disposalBoiler furnaceBoiler slag

The invention relates to an industrial boiler slag solid waste comprehensive environment-friendly treatment method, in particular to an industrial boiler slag solid waste comprehensive environment-friendly treatment device which comprises a mounting bottom plate, supporting legs, a supporting frame, a collecting box, a feeding port, a mixing mechanism and a stirring mechanism. The method can solve the problems that in the process of an industrial boiler slag solid waste comprehensive environment-friendly treatment method, the mixing proportion and the mixing degree of dust and water mist are difficult to control, mixed dust slurry is difficult to effectively scrape, mixed loose dust slurry is difficult to convey and guide, and the adhesion and accumulation phenomena of the dust slurry are generated, the mixed dust slurry is difficult to push and flatten in the circumferential direction, and the drying efficiency and the forming effect of the slurry dust are reduced.

Owner:苏哲

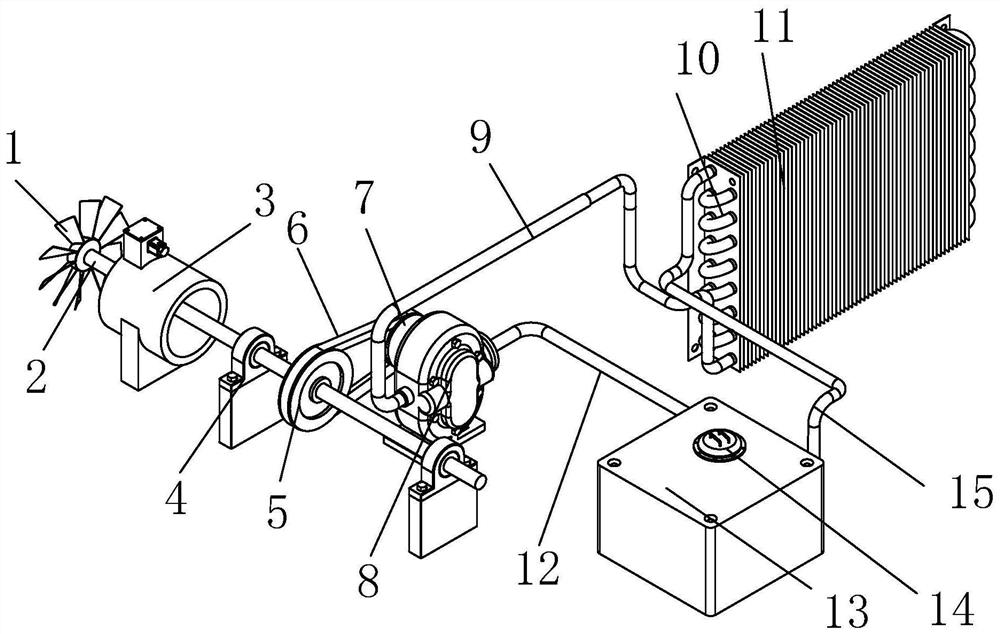

Utilization device of integral natural gas compressor energy-saving technique

InactiveCN111636939ADoes not affect rotationImplement filteringDispersed particle filtrationTransportation and packagingHEPAAir filter

The invention discloses a utilization device of an integral natural gas compressor energy-saving technique. The utilization device comprises a fan blade, a driving shaft, an efficient air filter, a shaft seat, a driving pulley, a synchronous belt, a driven pulley, a circulating pump, a drain pipe, a copper pipe, fins, a pumping pipe, a water tank, an injection port and an access pipe. According tothe utilization device, the efficient air filter is installed on the right end of the fan blade, the driving shaft passes through the efficient air filter, the rotation of the driving shaft cannot beinfluenced, and additionally, a primary filter screen and an efficient filter screen are installed in the efficient air filter, so that tail gas is filtered, and mixed dust can be blocked; a dust removal mechanism is installed on the left end of the inner top of the efficient air filter, a reciprocating driving mechanism is arranged in the dust removal mechanism, and the mechanism is controlled by an independent motor, so that an inner pipe is stricken in a reciprocating mode by a bottom impact block, dust attached to the inner wall of the inner pipe conveniently falls off, and the manual cleaning is facilitated.

Owner:林威臻

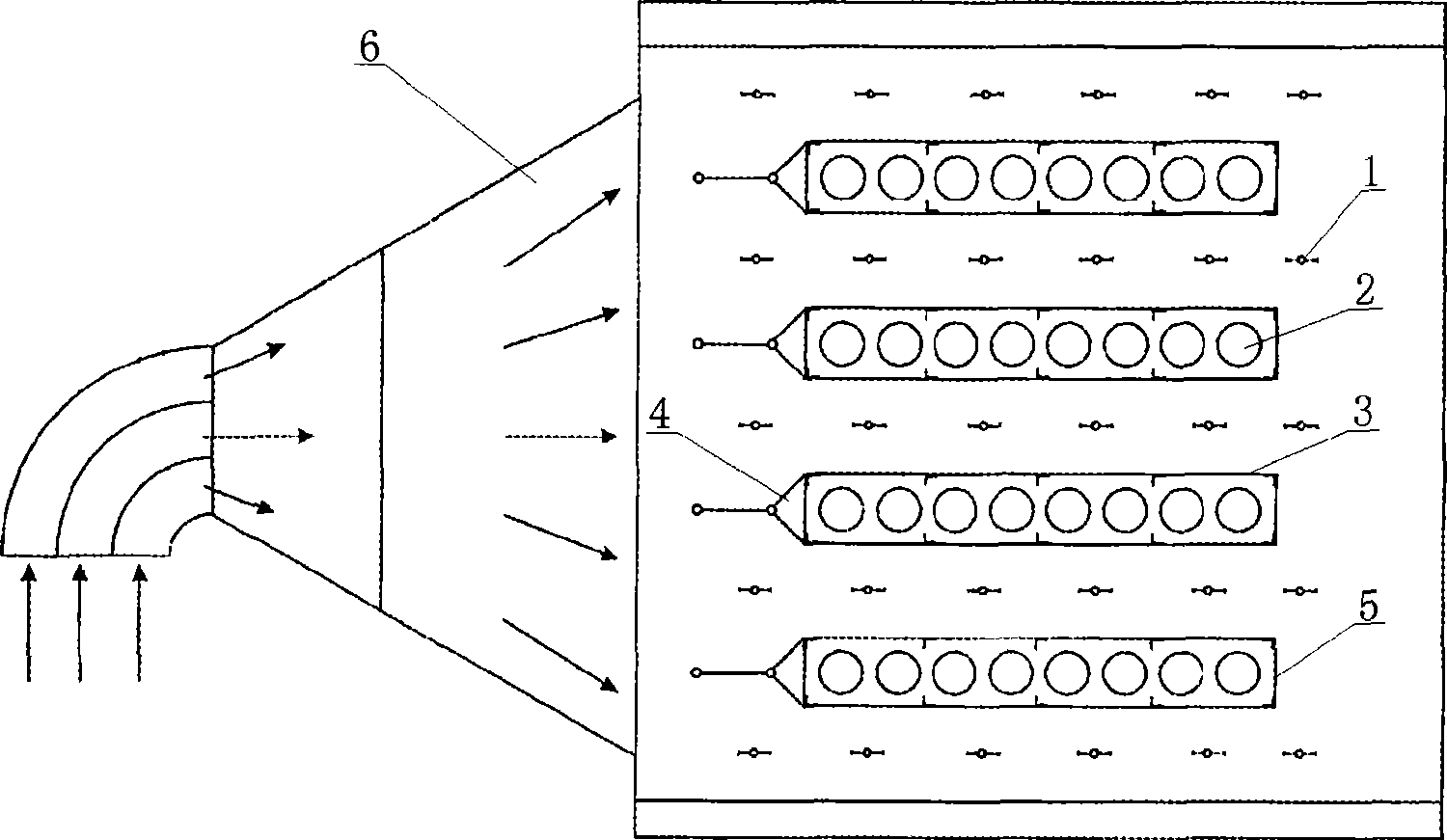

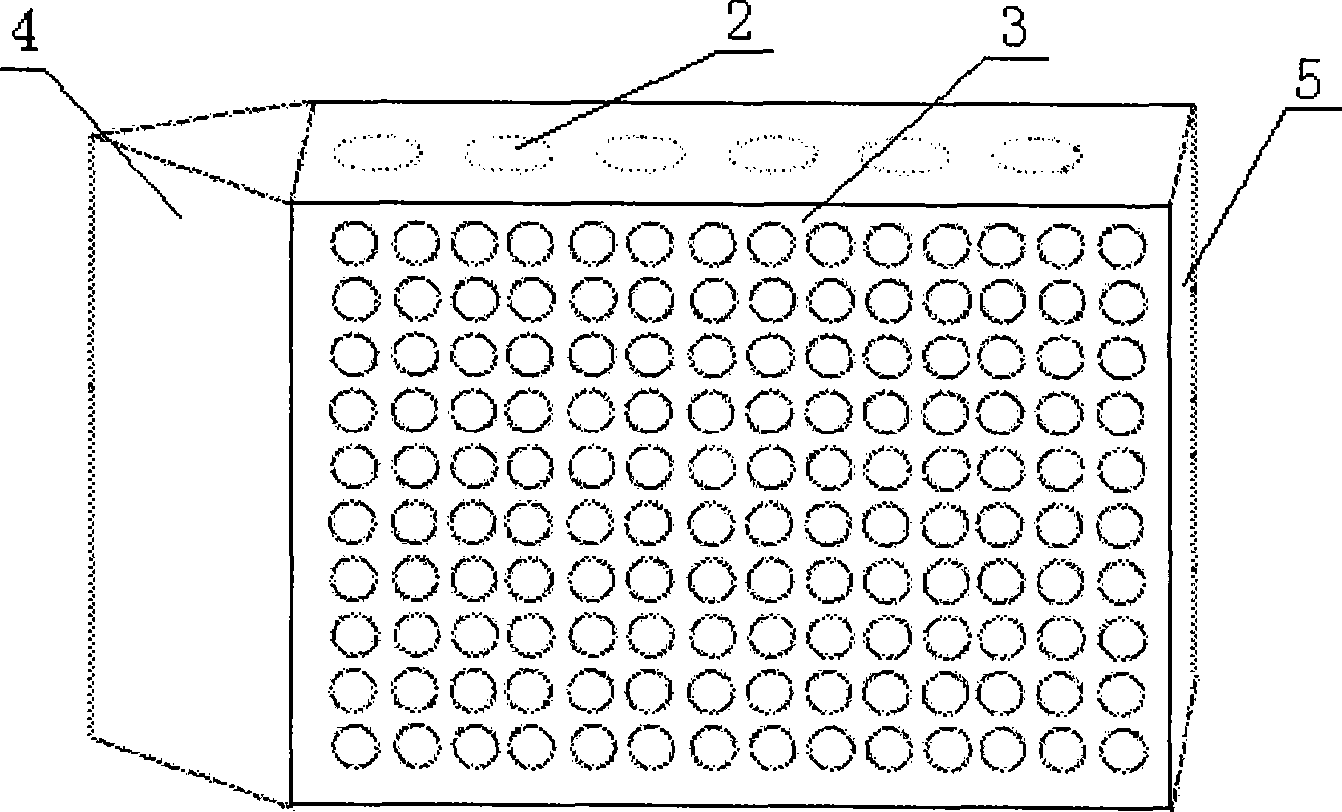

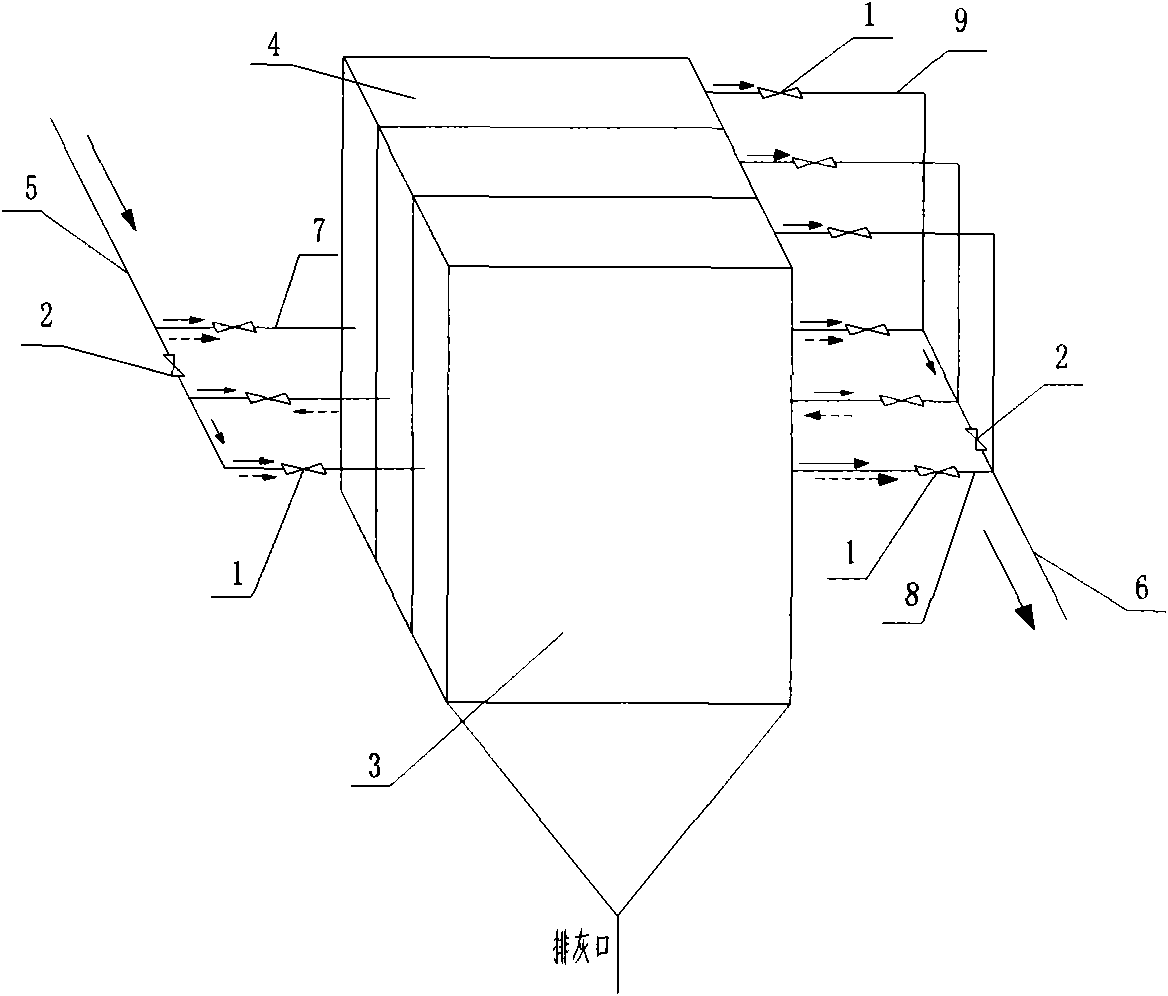

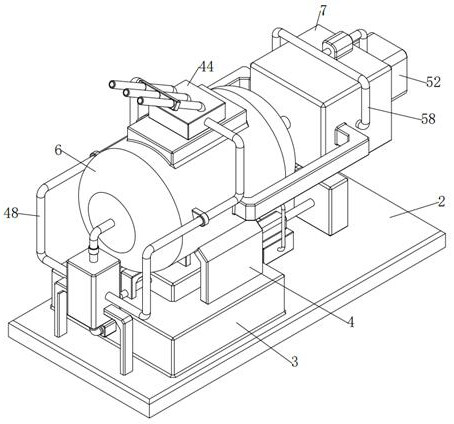

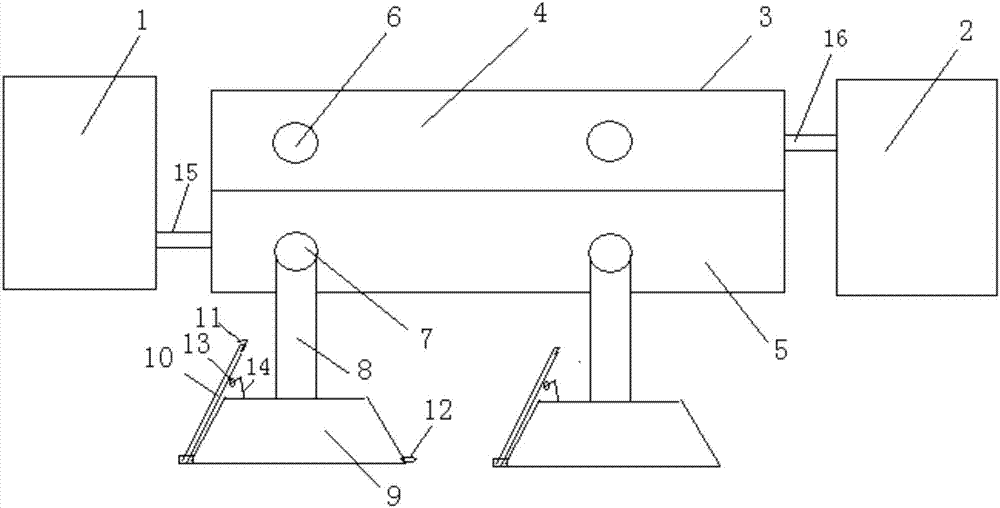

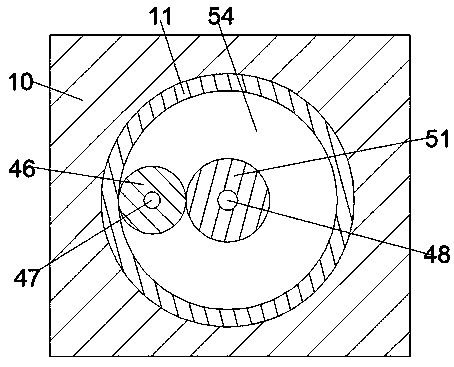

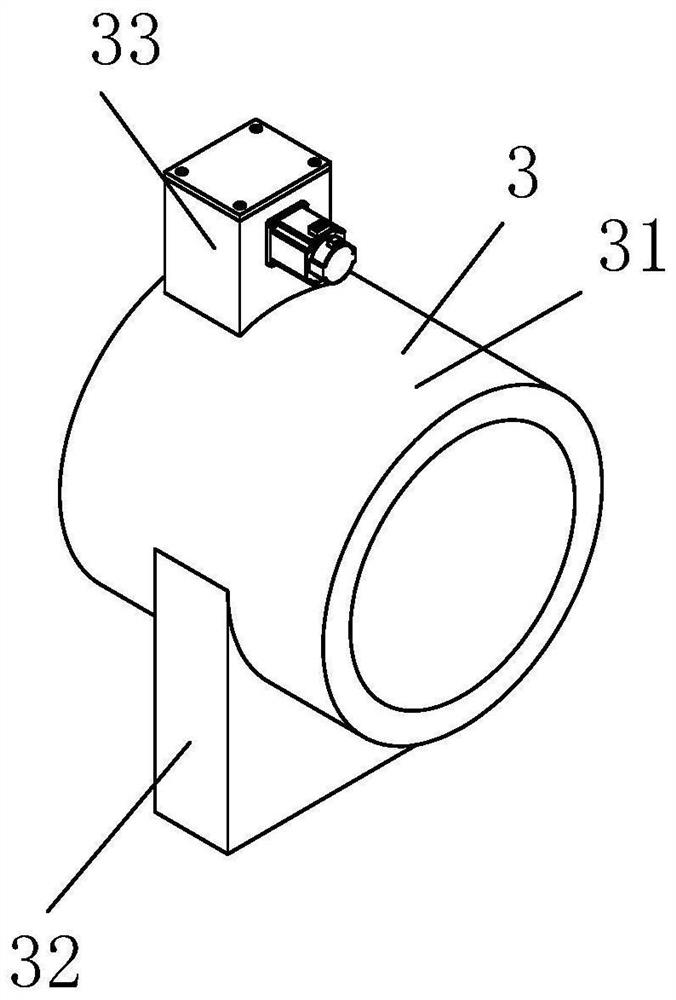

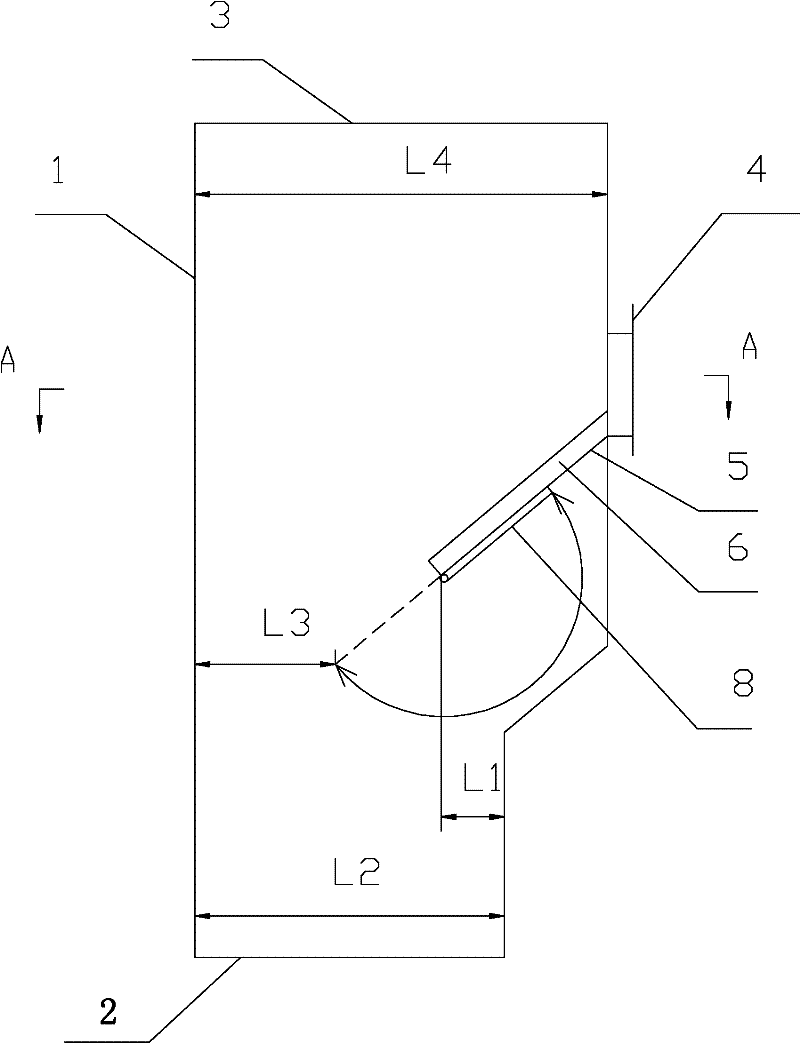

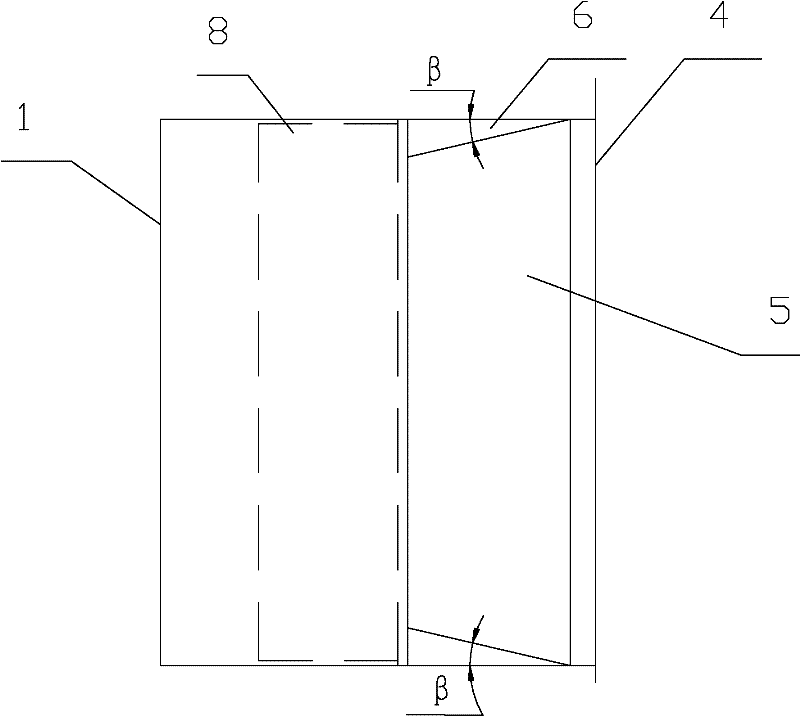

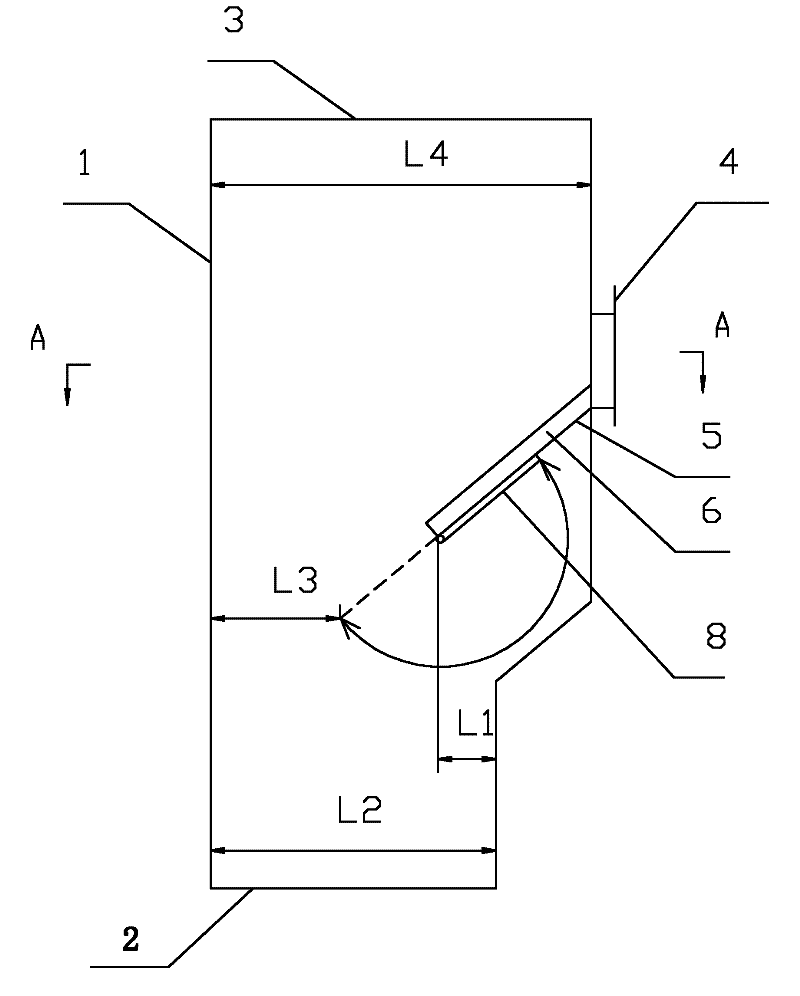

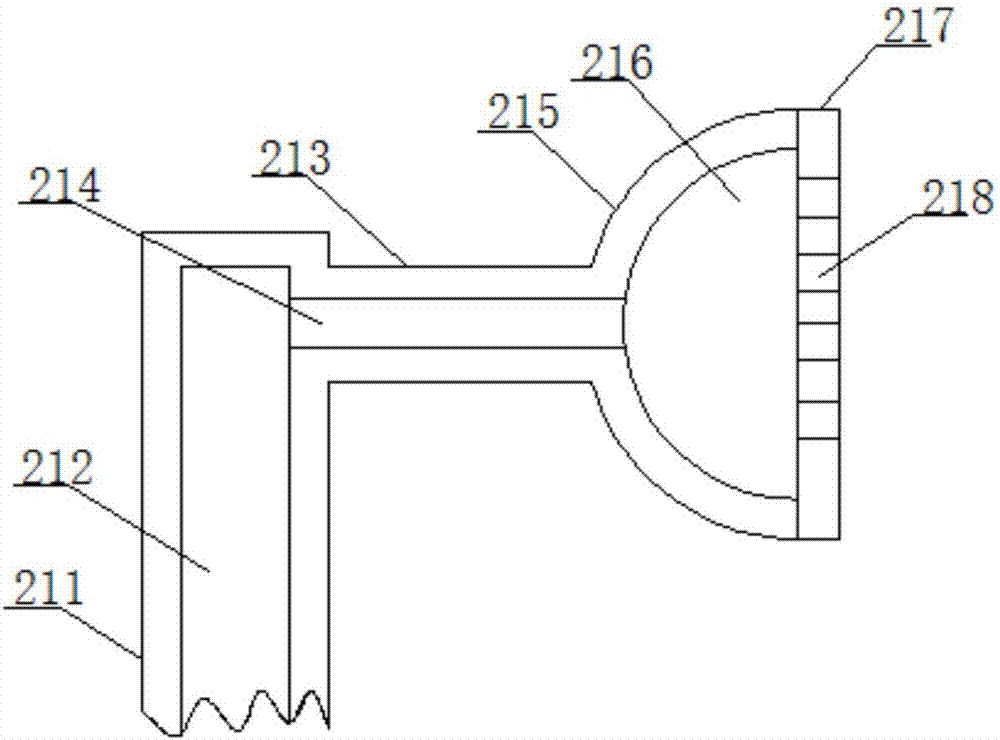

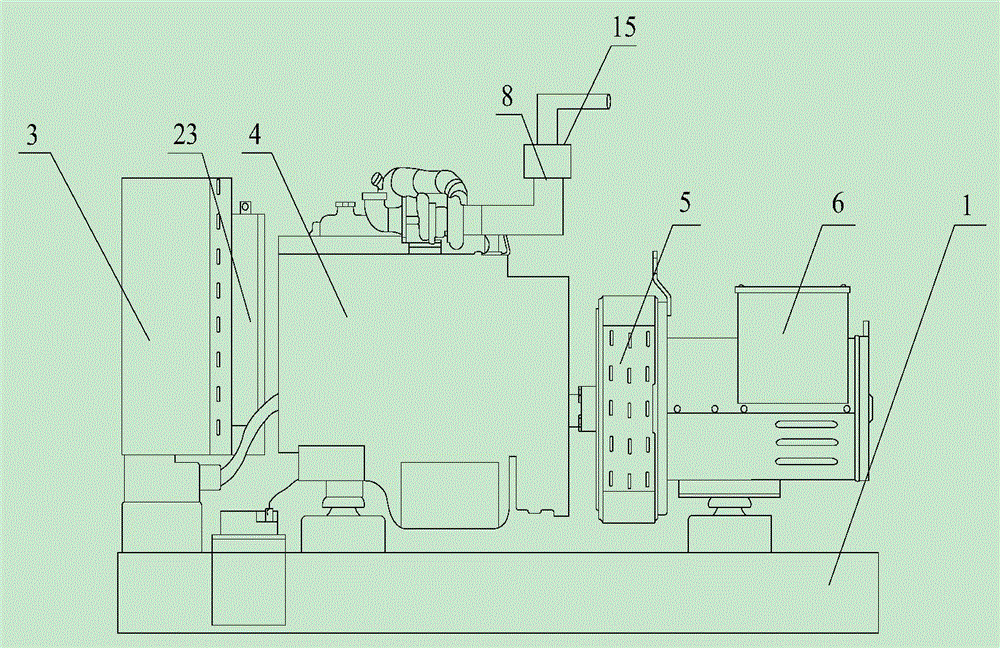

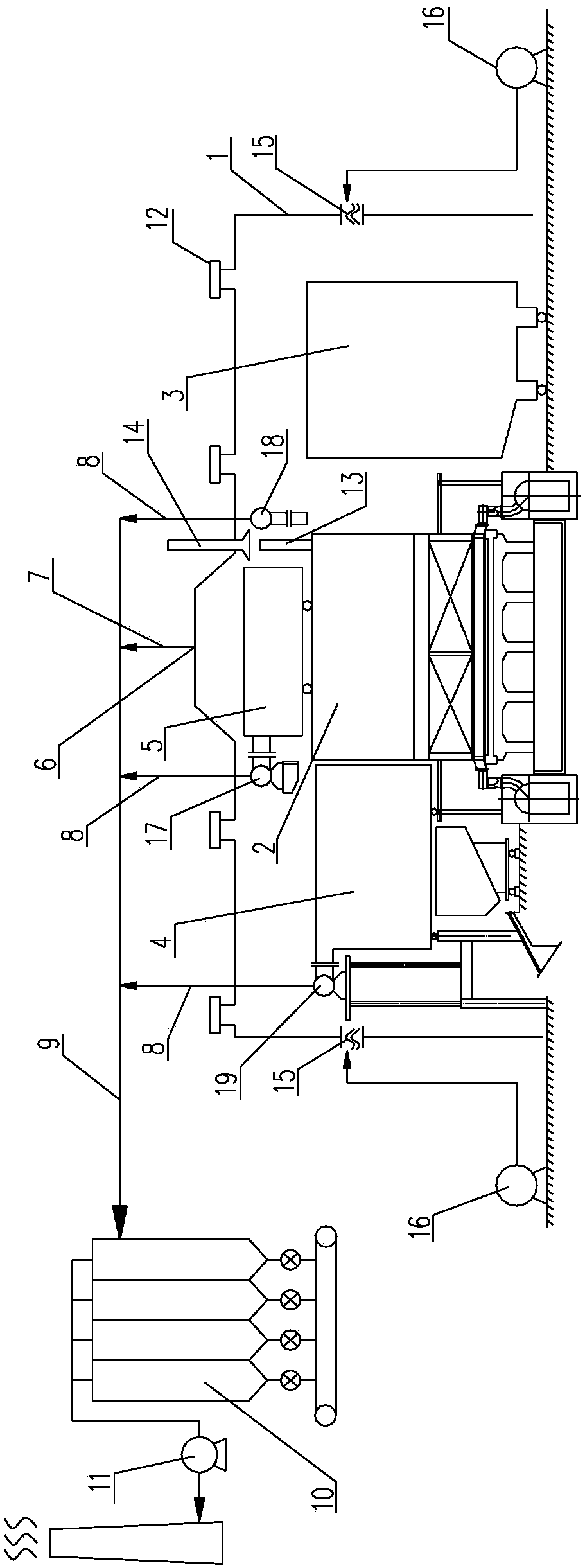

Dust-gas mixing device for semi-dry desulphurization reactors

InactiveCN102389706AGuaranteed uptimeEvenly distributedDispersed particle separationFlue gasEngineering

The invention discloses a dust-gas mixing device for semi-dry desulphurization reactors, which comprises a dust-gas mixing section, wherein the lower port of the dust-gas mixing section is a flue gas inlet, the upper port of the dust-gas mixing section is a flue gas outlet, and the cross-sectional area of the flue gas outlet is greater than that of the flue gas inlet; the right side face of the dust-gas mixing section is provided with a mixed dust inlet; and the inside of the dust-gas mixing section below the mixed dust inlet is provided with a declivitous distributing plate. The dust-gas mixing device disclosed by the invention has the advantages that flue gas is fed into the dust-gas mixing device from the flue gas inlet at the lower part of the dust-gas mixing section, and mixed dust is fed into the dust-gas mixing device from the mixed dust inlet; and under the action of the distributing plate, the mixed dust and the flue gas are excited and mixed and uniformly distributed in the whole cross section of the dust-gas mixing device, so that a flue gas purifying device keeps efficient operation.

Owner:浙江菲达脱硫工程有限公司 +1

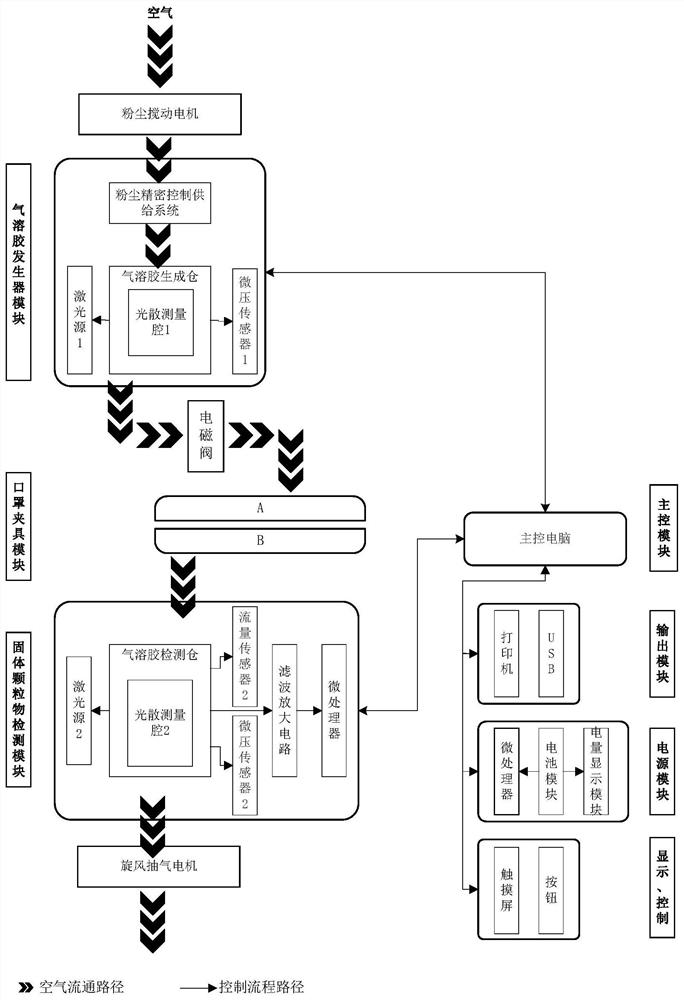

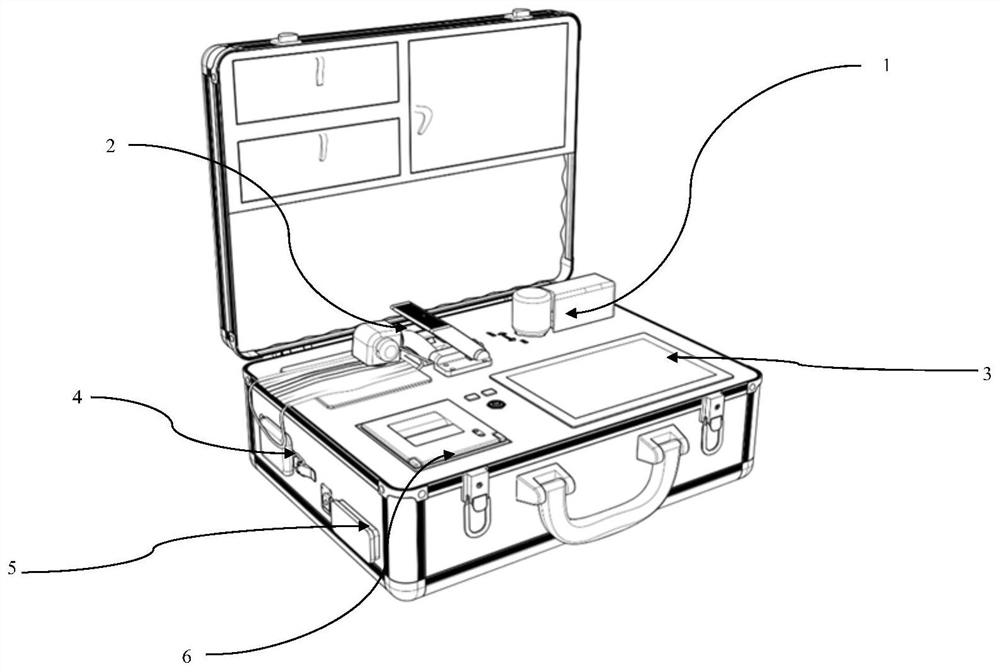

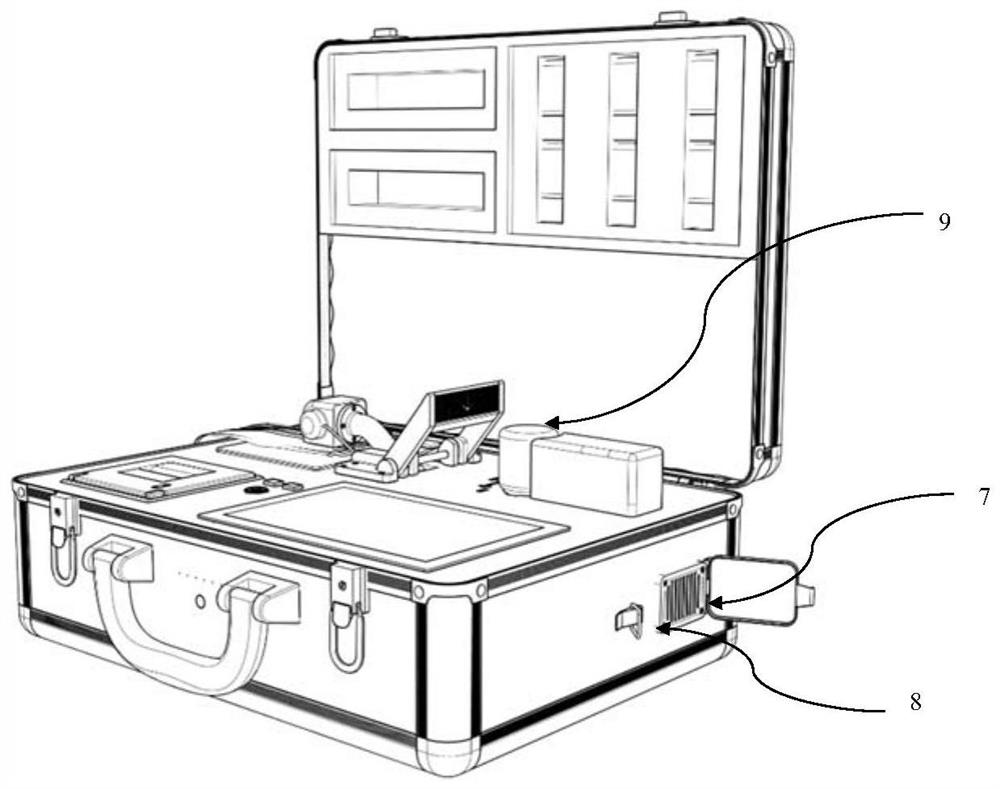

Portable mask rapid detection method and system

PendingCN112161906AIngenious structureReasonable designParticle suspension analysisPermeability/surface area analysisRespiratorSimulation

The invention provides a portable mask rapid detection method and system, and the method comprises an aerosol generation step of adding dust into an aerosol generation cabin, and uniformly mixing thedust; a simulation transmission step of enabling the mixed dust in the aerosol generation bin to enter an aerosol detection bin through a test mask; a detection step of respectively testing the air pressure and / or dust concentration in the aerosol generation bin and the aerosol detection bin separately by a test device, and recording the detection data; a repeating step of repeating the aerosol generation step, the detection step and the detection step for multiple times; and a control output step of using a main control module to receive the detection data and output a detection result according to the average value of the detection data of multiple times. The system is ingenious in structure, reasonable in design and is convenient to operate; according to the invention, the mask can be quickly tested, and the limitation of huge volume of the aerosol generating device is eliminated; according to the invention, a pressure clamping sealing mode is adopted to replace a traditional sealing mode of using sealing cement gum in a test, and the test steps are simplified.

Owner:海宁博瑞医疗科技有限公司

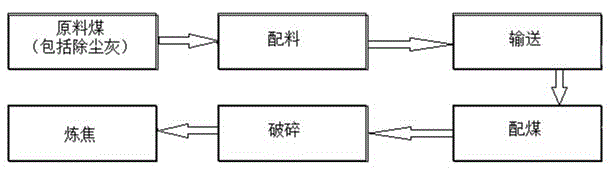

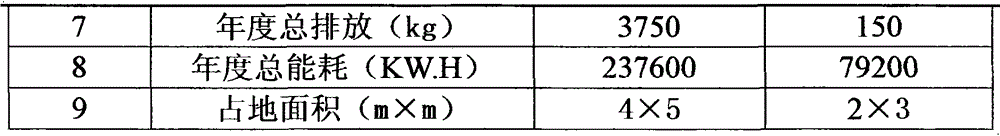

Blending method of dry coke quenching dust-removal ash in coal blending process

The invention discloses a blending method of dry coke quenching dust-removal ash in a coal blending process. The blending method comprises the following steps: transporting dust-removal ash generated by dry coke quenching every day to a coal storage yard through an ash discharge opening, arranging the dust-removal ash near low-sulfur coking coal of which the content of sulfur is less than 0.4% and low-ash meager lean coal of which the content of ash is less than 8.5% which can be blended for separately storing; according to the blending ratio required by the blending instruction of a forklift in a coal blending workshop, fully and uniformly blending the dry coke quenching dust-removal ash, low-sulfur coking coal and the low-ash meager lean coal at a weight ratio of 1:5:5 to form novel mixed dust-removal ash; conveying the mixed dust-removal ash to a coal blending bin, blending the mixed dust-removal ash and 1 / 3 coking coal, gas coal, coking coal and meager lean coal at a weight ratio of 7: 3 and rich coal to form into-the-furnace coal, crushing the into-the-furnace coal, adding water and conveying to the coal storage bin for coking coal production to replace partial meager lean coal for return blending and coking, wherein the mixed dust-removal ash, the 1 / 3 coking coal, the gas coal, the coking coal and meager lean coal at a weight ratio of 7:3 and the rich coal respectively account for 15%, 32%, 15%, 21% and 17% of the into-the-furnace coal in weight ratio. The process is convenient to operate and has the characteristic of high flexibility.

Owner:山东泰山焦化有限公司

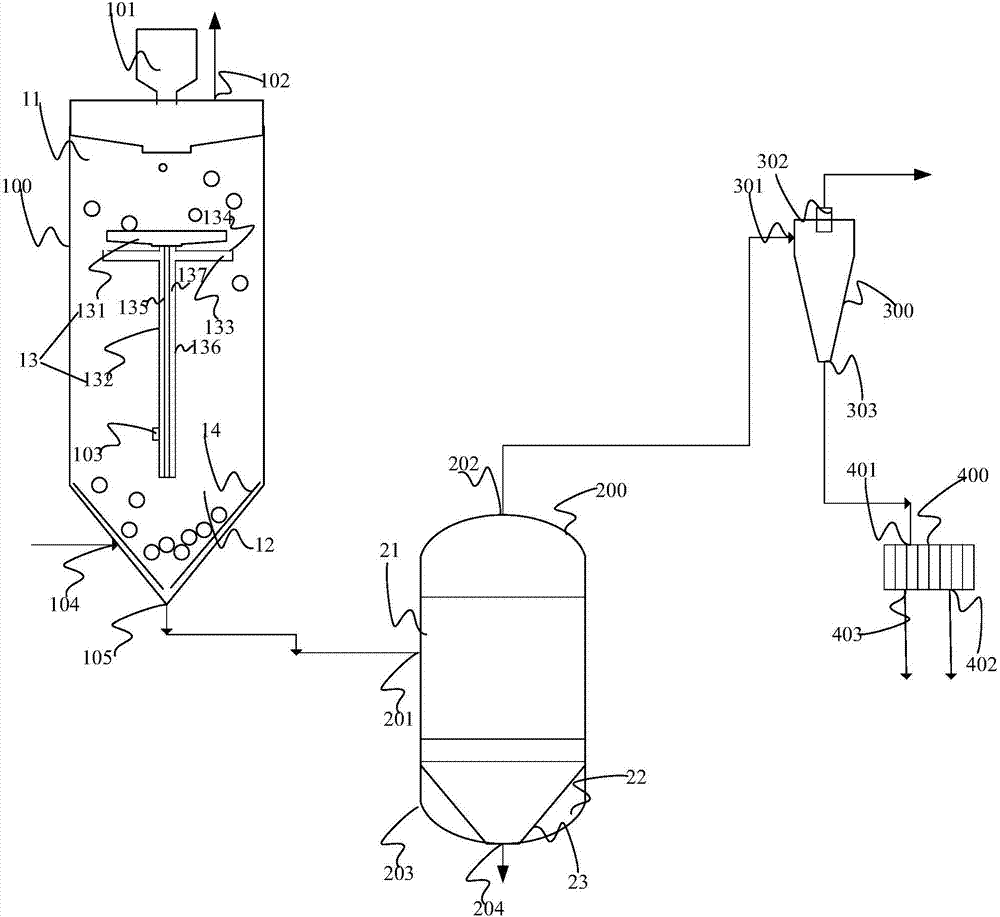

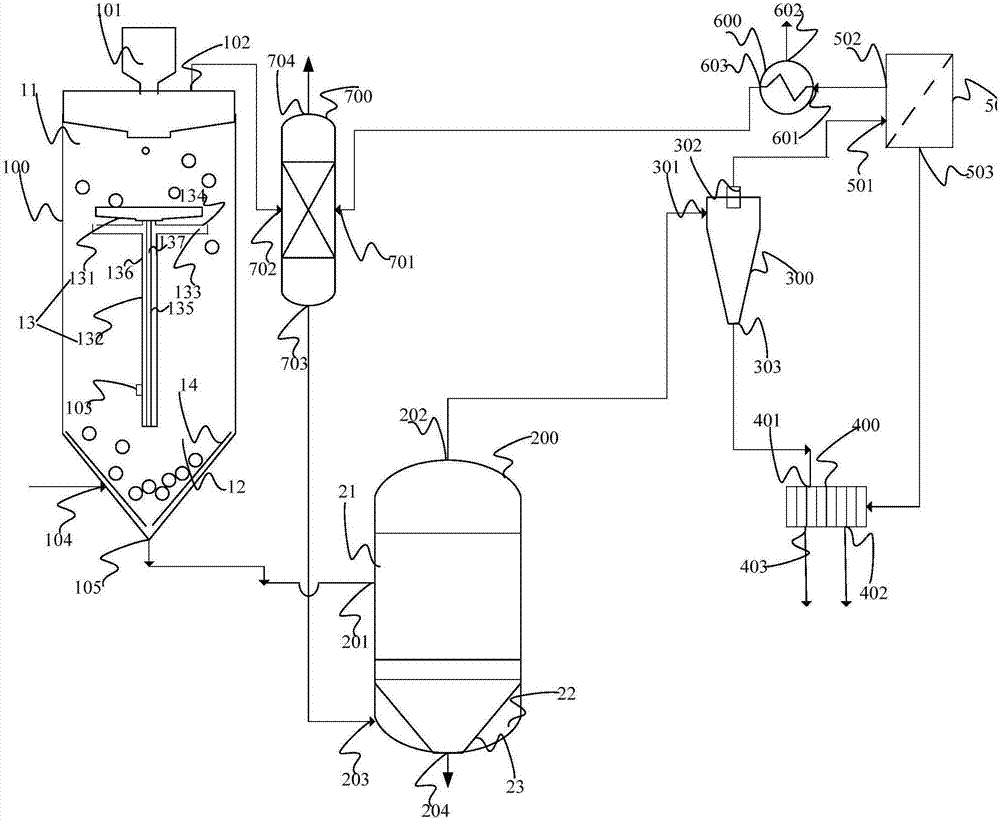

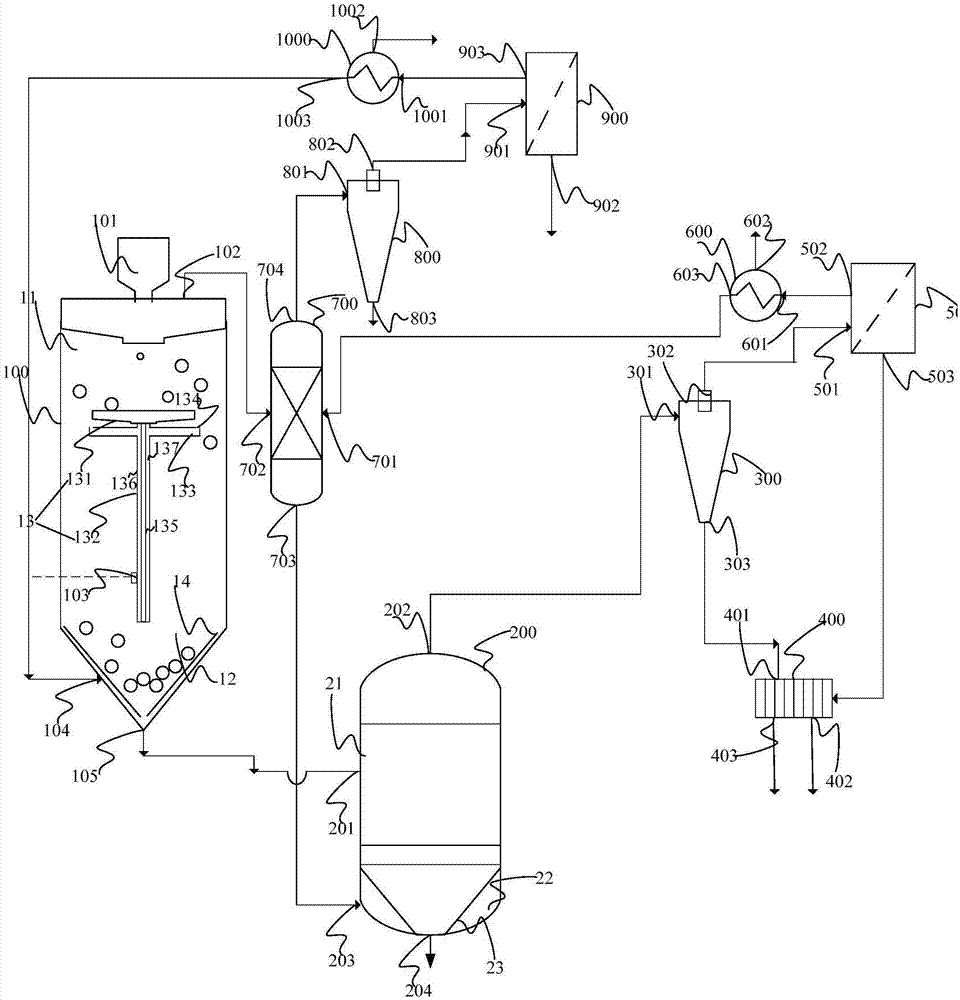

System for joint production of carbide, lime nitrogen and carbon black and method

The invention discloses a system and method for the joint production of calcium carbide, lime nitrogen and carbon black. The system includes: a calcium carbide granulation tower, in which a heat exchange area and a gas distribution area are defined from top to bottom. The granulator includes a rotating disk and a rotating shaft arranged at the lower end of the rotating disk. A carbon dioxide distribution disk is arranged below the rotating disk. An inlet of calcium carbide liquid and an outlet of carbon dioxide after heat exchange are arranged at the upper end of the heat exchange area. A second carbon dioxide is arranged in the gas distribution area. Inlet and outlet of calcium carbide particles; nitriding furnace, which defines the nitriding reaction space and gas distribution space from top to bottom. The nitriding reaction space has an inlet of calcium carbide particles and an outlet of gas after nitriding. Lime nitrogen outlet; first cyclone separator, with mixed gas inlet, first dedusted gas outlet and dust outlet containing lime nitrogen powder and carbon black; powder separation device, with mixed dust inlet, lime nitrogen powder outlet and carbon black Export.

Owner:SHENWU TECH GRP CO LTD

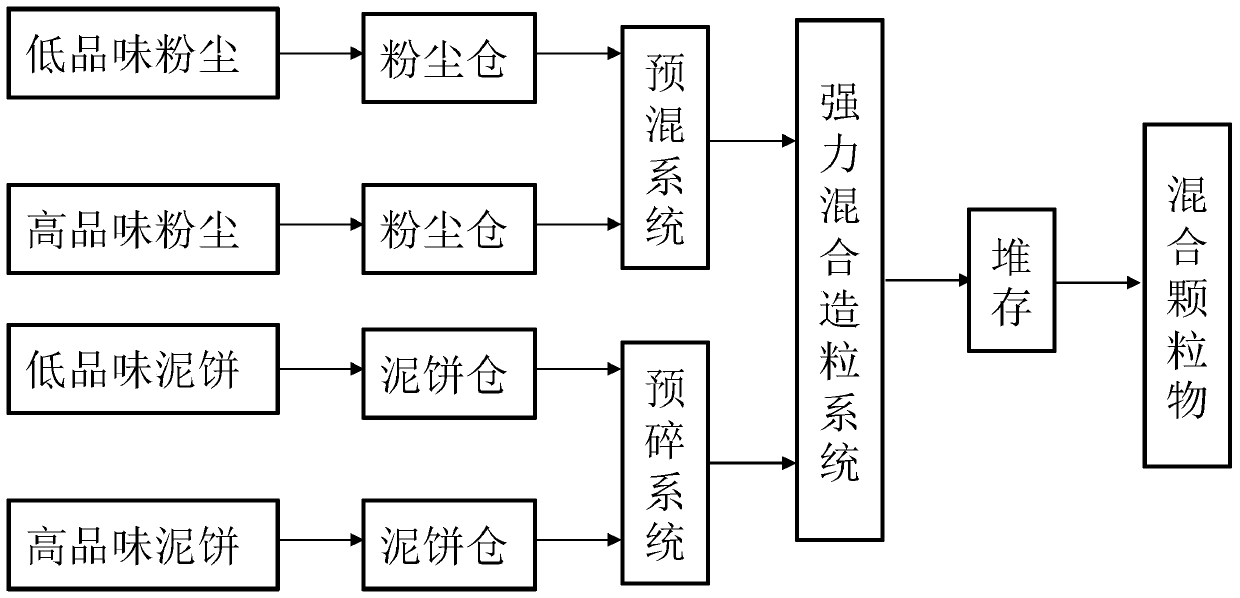

Treatment method of iron and steel smelting dust mud and iron correction material

InactiveCN111499231ASolve intractableRealize resource utilizationCement productionParticulatesThermodynamics

The invention discloses a treatment method of iron and steel smelting dust mud and an iron correction material. The treatment method of the iron and steel smelting dust mud comprises the following steps that S1, dust premixing is conducted, specifically, feeding low-grade dust and high-grade dust into a premixing system to be evenly mixed, and forming the mixed dust; S2, mud cake pre-crushing andmixing: feeding the low-grade mud cake and the high-grade mud cake into a pre-crushing system for crushing and mixing to obtain a mud cake mixture; s3, strong mixing granulation: sending the mixture of the mixed dust and the mud cake into a strong mixing granulation system, and fully mixing to prepare mixed particles; sending the mixed particles into a stockpiling area, and stockpiling for 1-3 days to form an iron correction material. According to the treatment method of the iron and steel smelting dust mud and the iron correction material, the problem that mud cakes generated by low-grade dust and sewage environment treatment are difficult to treat is solved, resource utilization of the iron and steel smelting dust mud is achieved, and good economic and environmental benefits are achieved.

Owner:宝武集团环境资源科技有限公司

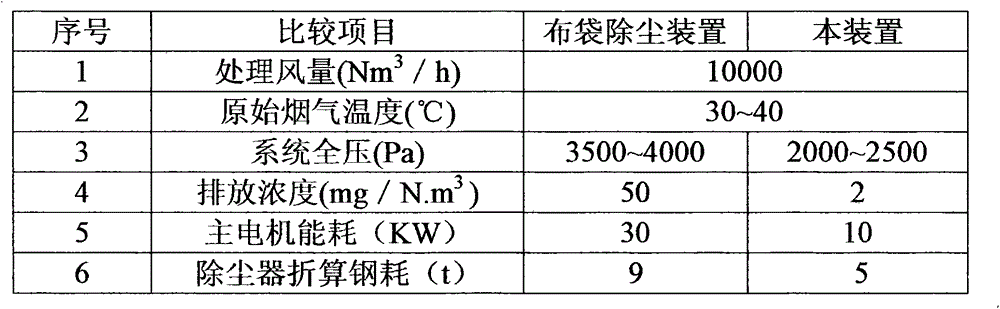

Micro-filtration method for treating PM2.5 (Particulate Matter 2.5) micro-dust formed by cleaning and polishing of casting

InactiveCN104097149AHigh precision of dust removalLarge filter areaCombination devicesGrinding/polishing safety devicesParticulatesOperating energy

The invention discloses a micro-filtration method for treating PM2.5 (Particulate Matter 2.5) micro-dust formed by cleaning and polishing of a casting. The method is characterized in that the casting of a valve is cleaned and polished to generate mixed dust of metal iron scraps, grinding wheel scraps and the like; the mixed dust enters a trapping cover and is conveyed to a cyclone dust collector through a pipeline; the cyclone dust collector filters large-particle dust, the dust collection efficiency is 95 percent, and the aim of dust pre-collection is achieved; after the dust is purified by a plastic sintering plate dust collector, the dust concentration is 2mg / Nm<3>, and the dust is pressed into a gas exhaust cylinder through a main fan and is exhausted into the atmosphere. According to the method, the large-particle dust is filtered by using the cyclone dust collector, so that the dust collection efficiency is high, and the aim of dust pre-collection is achieved; fine dust is collected by using the plastic sintering plate dust collector in the later stage, so that the dust collection efficiency is high, the smoke dust emission concentration is low, and a device is low in investment and low in operating energy consumption and has a good purification effect.

Owner:WUXI XIZHANG ENVIRONMENTAL PROTECTION EQUIP

Coke CDQ Dust Removal Ash Mixing Method in Coal Blending Process

Owner:山东泰山焦化有限公司

Liquid dust removal device with regional dust removal function

InactiveCN107970714AIncrease usageReduce wasteUsing liquid separation agentSeparation devicesWater sourceProduct gas

The invention discloses a liquid dust removal device with a regional dust removal function. The liquid dust removal device comprises a bottom liquid storage shell, wherein a bottom liquid storage space is formed in the bottom liquid storage shell; the center of the top end in the bottom liquid storage shell is provided with a main liquid inlet pipeline; and a liquid inlet is formed in the main liquid inlet pipeline. The liquid dust removal device provided by the invention can form mist-like water drops in a larger range, thereby adsorbing and dropping dust floating in surrounding air, and playing a role in dust falling; moreover, the device can reuse falling liquid, thereby improving the utilization rate of liquid and reducing the waste of water sources; in addition, the device has a solidseparation and liquid collection mechanism which can separate mixed dust and liquid and reuse liquid; and furthermore, the device is provided with a gas directional guide flow mechanism which can guide the surrounding air into mist-like liquid parts, thereby improving the dust falling quality and having strong practicability.

Owner:刘晓莉

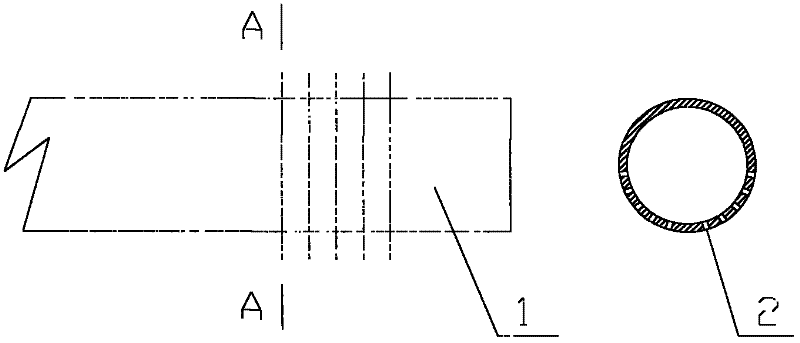

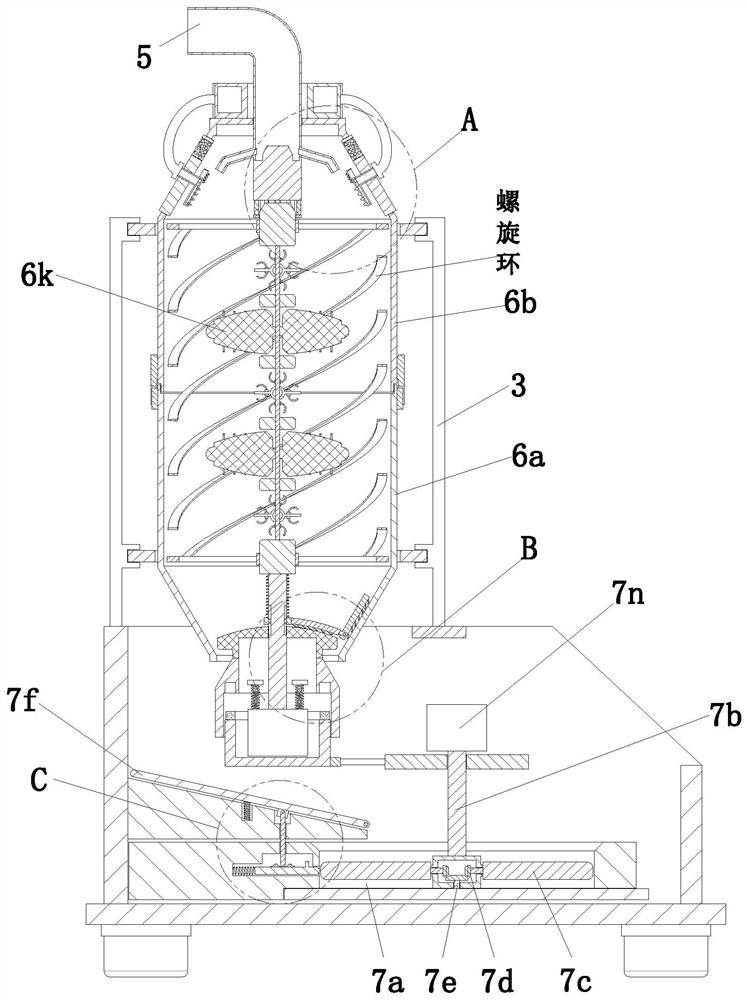

Dust removing device

InactiveCN101607160AReduce labor intensityReduce concentrationUsing liquid separation agentCycloneElectricity

The invention discloses a dust removing device comprising a mixed dust removing device, a fan and a water supply system, wherein the mixed dust removing device is connected with the fan by a duct pipeline, the mixed dust removing chamber is a hollow cylindrical structure, the lower end of the mixed dust removing chamber is provided with a turbo-cyclone splitting chamber, the upper end of the mixed dust removing chamber is contracted towards the middle slightly and sealed, the outer side of the mixed dust removing chamber is provided with a dust removing main barrel body, the lower end of the dust removing main barrel body is provided with an inner dust sucking duct pipe, the inner dust sucking duct pipe extends into the mixed dust removing chamber from the interior of the dust removing main barrel body, the upper end of the dust removing main barrel body is provided with an air collecting cover, and an opening is arranged at the middle of the air collecting cover and is connected with the duct pipeline to form a passage; the air collecting cover, the dust removing main barrel body, the inner dust sucking duct pipe and the mixed dust removing chamber are sequentially connected to form a cavity body, and water for removing dust is arranged in the cavity body. The dust removing efficiency of the dust removing device can reach 99.8 percent, the electricity consumption of the dust removing device is less than 1 / 3 of that of the common dust removing device, the energy conservation of the dust removing device reaches above 15 percent, and the water consumption of the dust removing device is 1 / 16 of that of the common dust removing device.

Owner:孙付江

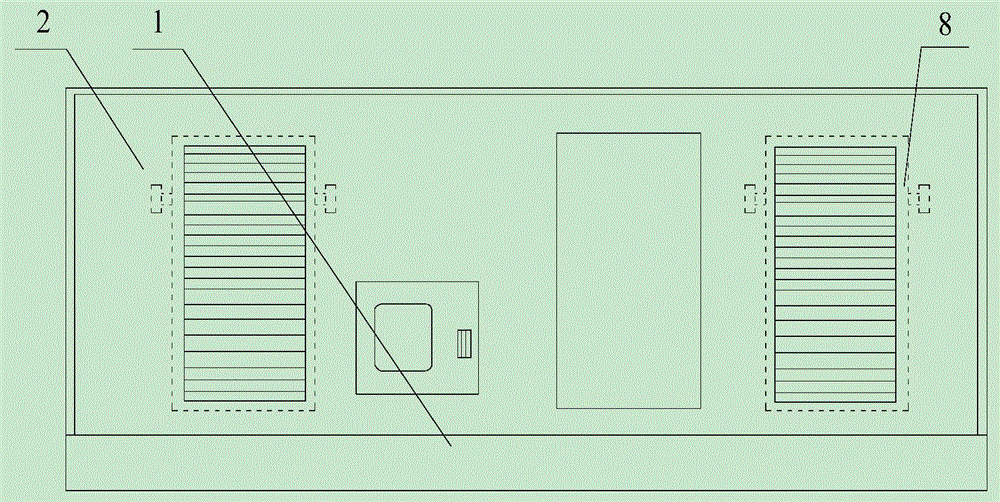

Energy-saving type diesel generator set

PendingCN107435586AAvoiding Wear Diesel Engine ProblemsHigh clarityMachines/enginesAir cleaners for fuelAir filtrationMolecular sieve

The invention discloses an energy-saving type diesel generator set, belongs to the technical field of power generating equipment, and solves the problems that a diesel generator set in the prior art is low in air clarity, poor in dust removing effect and poor in preheating effect are solved. The energy-saving type diesel generator group comprises a chassis, and a compartment is arranged above the chassis in a covering mode; a water tank, a diesel engine and a generator are sequentially arranged in the compartment, and an air filtering device is arranged on the diesel engine; the air filtering device comprises a drying dust-suction mechanism and a temperature pre-adjusting mechanism, the drying dust-suction mechanism comprises an air passage with a molecular sieve blocking opening, an electrostatic generating device and a dust accommodating chamber arranged at the bottom of the electrostatic generating device; and the temperature pre-adjusting mechanism is arranged on the other side of the drying dust-suction mechanism. According to the energy-saving type diesel generator set, air enters the diesel engine is purified by arranging the air filtering device, the air with particle dust is prevented from entering the diesel generators, an electrostatic producer is utilized to generate electrostatic, so that mixed dust and particles in the air are absorbed.

Owner:扬州沃尔特机械有限公司

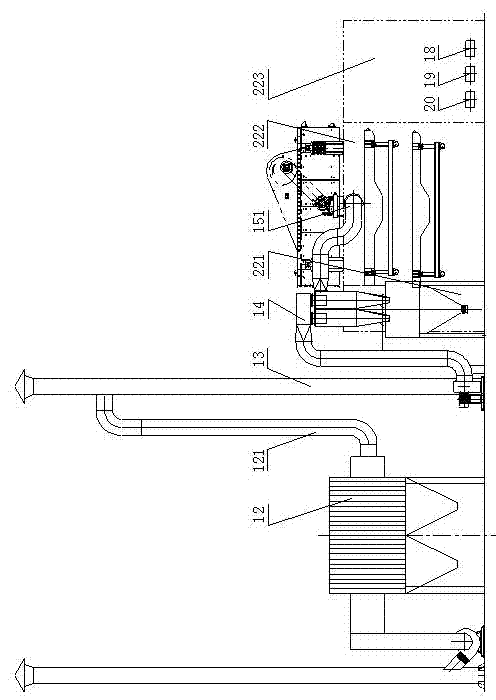

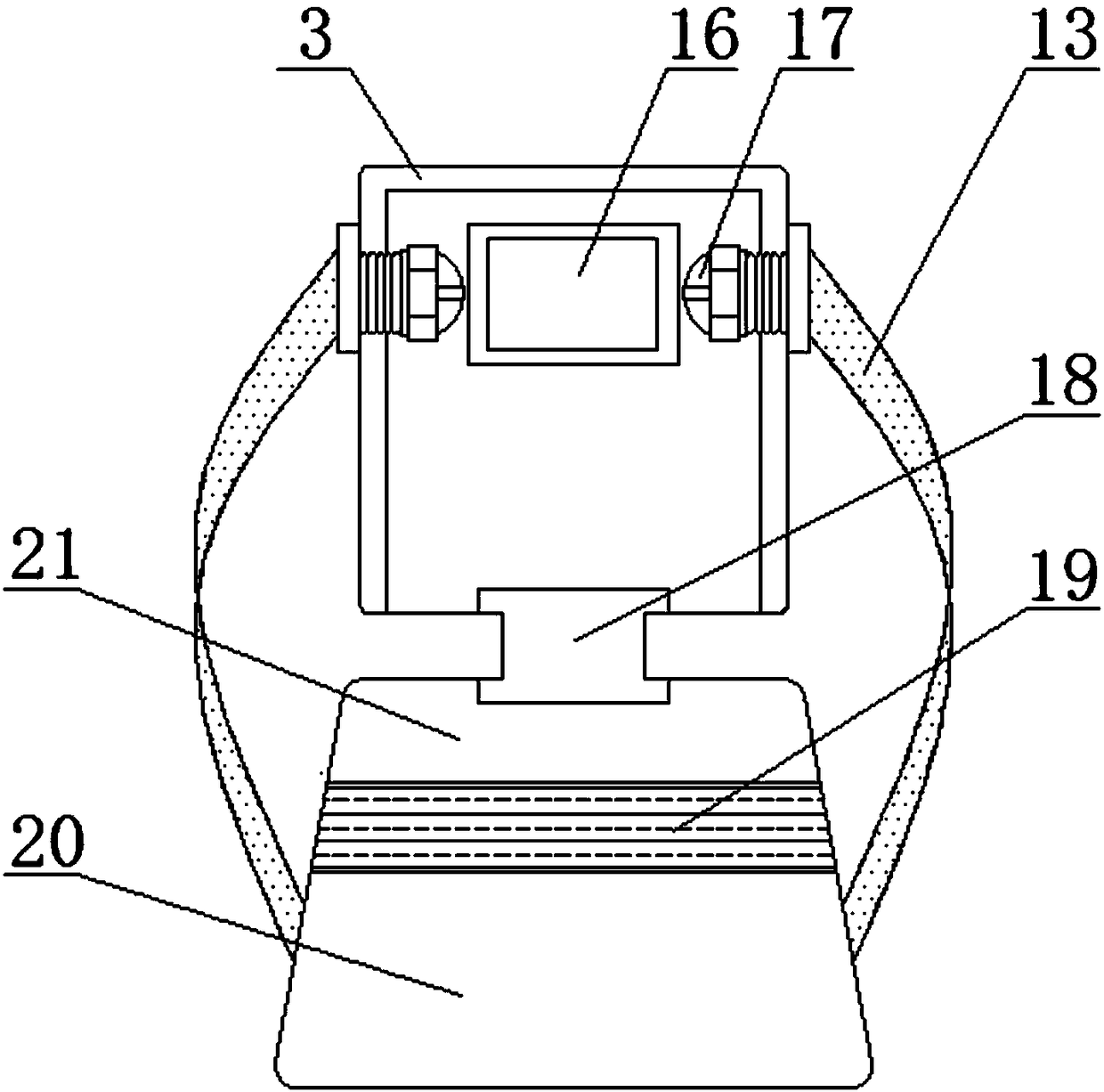

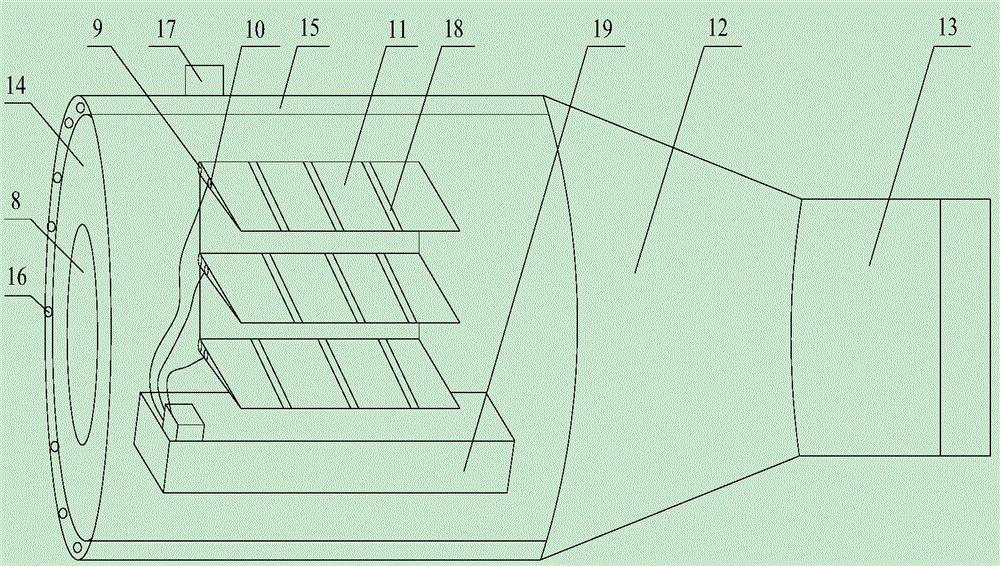

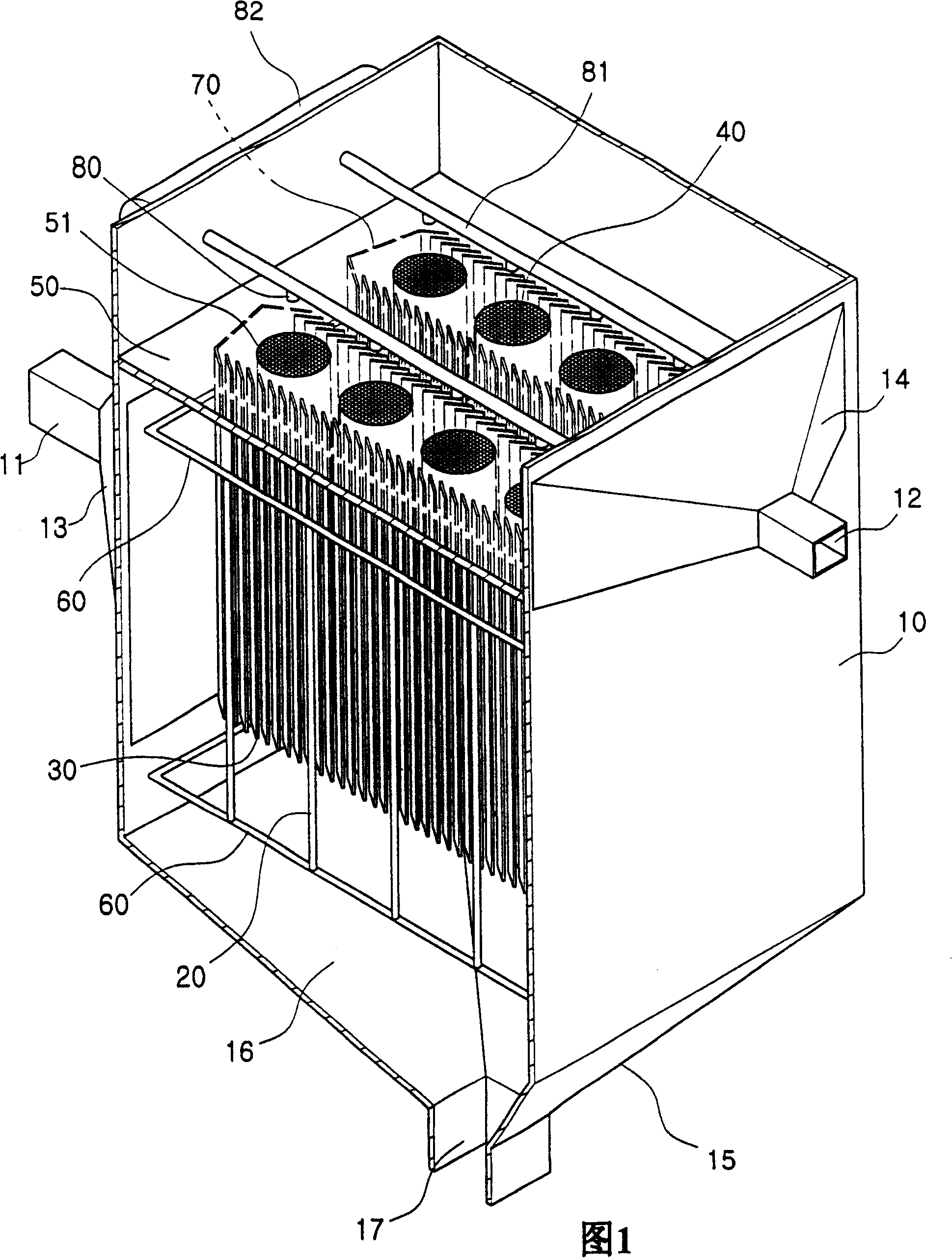

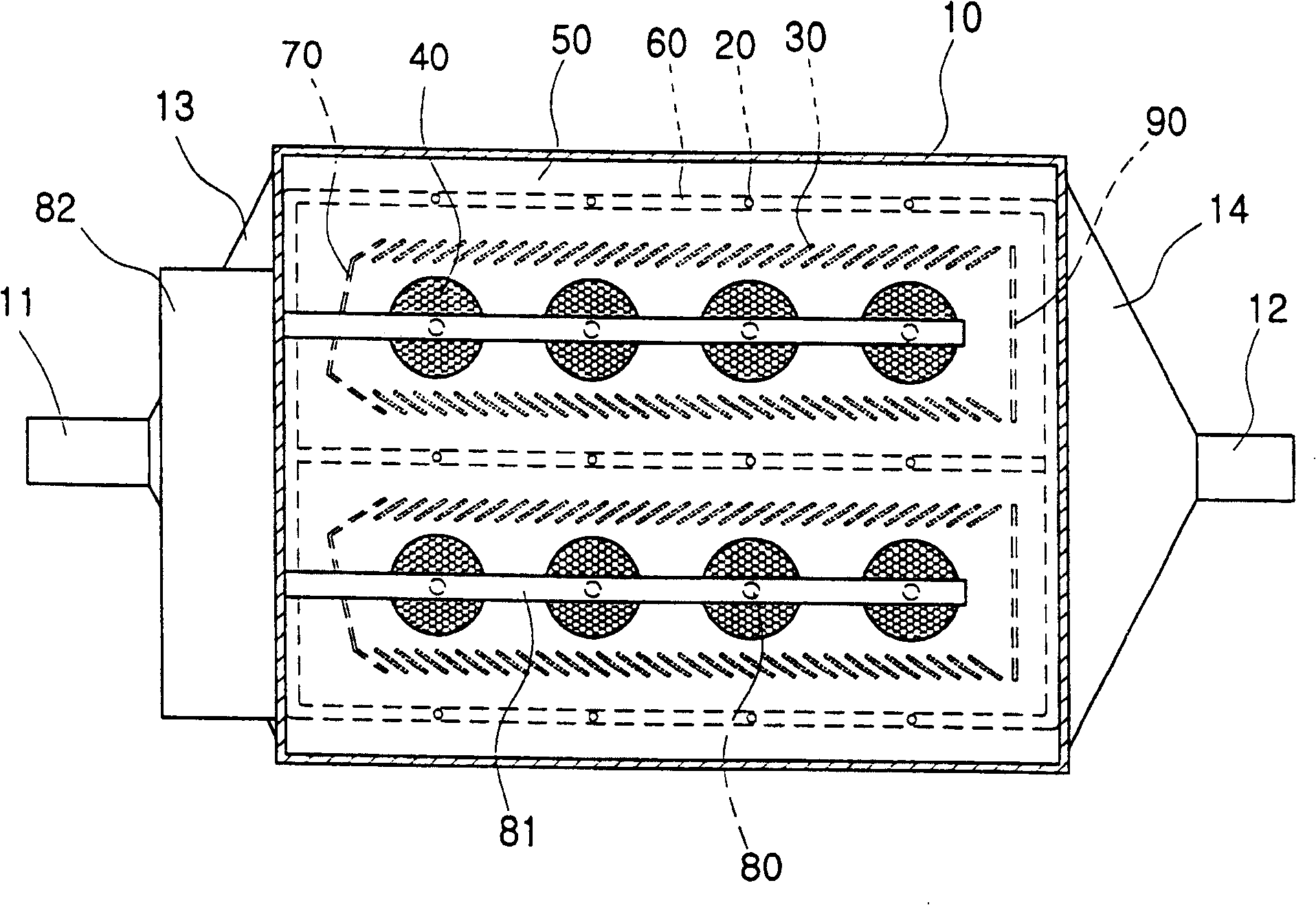

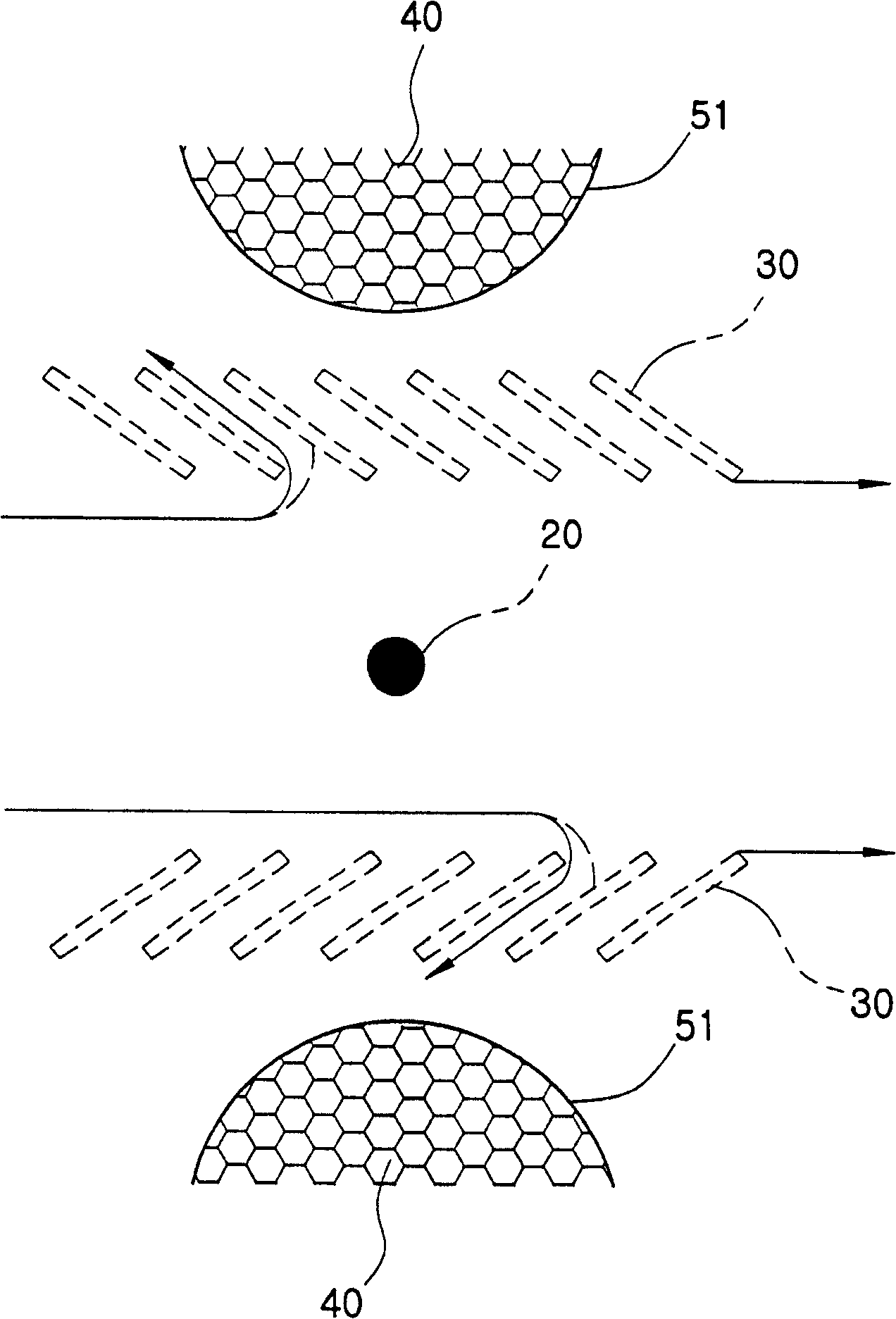

Mixed dust separating device

InactiveCN100444931CExtend working lifeImprove dust removal effectCombination devicesElectrostatic separation housingHybrid typeLife time

PURPOSE: A combination type dust collecting apparatus is provided which maintains high dust collecting performance of the dust collecting apparatus and substantially extends performance and life time of dust collecting filter at the same time. CONSTITUTION: In a combination type dust collecting apparatus in which discharge electrodes(20), collecting electrodes(30) and dust collecting filters(40) are installed inside a main body(10) having inlet(11) and outlet(12), the combination type dust collecting apparatus comprises a splitting plate(50) installed inside the main body between the inlet and outlet; a plurality of mounting holes(51) formed on the splitting plate with being spaced apart from each other in a certain distance; cylindrical dust collecting filters one end of which is insertingly adhered to the mounting holes in a lower part of the splitting plate, and which are horizontally installed in a plurality of rows; a plurality of collecting electrodes which are adhered to the lower surface of the splitting plate at both sides of the dust collecting filters with being spaced apart from each other, and which are arranged slantly and horizontally in a row; a plurality of discharge electrodes which are spaced apart from each other at an outer side of the collecting electrodes and adhered to a mounting ring(60) vertically installed inside the main body in a plurality of rows; guiding portions(70) installed at the lower surface of the splitting plate in front of the collecting electrodes and dust collecting filters corresponding to the inlet; and an outlet installed at one side of the main body in an upper part of the splitting plate.

Owner:KOREA INST OF ENERGY RES

Coke oven smoke dust fullytotally-closed scattered collection and centralized treatment method

ActiveCN109021992ARealize the collectionAchieve integrationOven incrustations prevention/removalEffective solutionCoke oven

The invention relates to a coke oven smoke dust fullytotally-closed scattered collection and centralized treatment method. A fullytotally-closed smoke dust collection cover is used for completely sealing a coke oven and accessory facilities thereof, after the coke oven escaped smoke dust collected on the top of the smoke dust collection cover is mixed with the smoke dust in a coal loading dust collection main pipe, a coke pushing dust collection main pipe and a coke discharging dust collection main pipe, the mixed dust is conveyed into a dust removal system to be centralized treated by virtueof a smoke dust conveying pipeline. By adopting the coke oven smoke dust fullytotally-closed scattered collection and centralized treatment method, the comprehensive collection of the coke oven escaped smoke dust and the integration of the coke oven dust collection system can be realized, and a complete safety facility is provided; and an actual effective solution is provided for solving the cokeoven smoke dust pollution problem which isperplexing to the enterprise.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Array type mixed dust removal device

The invention discloses an array type mixed dust removal device; a dust removal tank can utilize the array arrangement of a single split type dust removal tank, perform hierarchical filtration in thesingle tank body and perform graded dust removal on dusty gas, and finally treated smoke dust is merged into a chimney to be discharged to the atmosphere. Primary dust removal of the device comprisescyclone dust removal, gravity dust removal, inertia dust removal and electrostatic dust removal principles. First-layer treatment is carried out on dust with relatively large particle sizes; second-stage dust removal adopts the combination of second-stage cyclone and third-stage cyclone to carry out second-layer treatment on dust with smaller particle size, and third-stage dust removal adopts bagtype dust removal to carry out final centralized treatment on tiny dust. Grading and layering treatment is carried out according to the characteristics of particle size, dead weight, diffusion and thelike of dust, so that various dust removal principles achieve the optimal effect within the most applicable range.

Owner:吴钧 +3

A kind of medicine for treating rhinitis and its production process

ActiveCN104622924BGood treatment effectEasy to obtainRespiratory disorderPlant ingredientsPropolisTherapeutic effect

The invention discloses a medicine for treating rhinitis. The medicine consists of honeycombs and radix angelicae, wherein at least one traditional Chinese medicine can be added: flos magnolia, angelica sinensis, radix bupleuri, fried gardenia, radix scrophulariae, fritillaria and at least one of the following western medicines: cetirizine hydrochloride, promethazine hydrochloride and azelastine hydrochloride. The invention further discloses a production process of the medicine for treating rhinitis. The process comprises the following steps: (1) crushing raw materials; (2) adding other traditional Chinese medicines or / western medicines; and (3) preparing pills or capsules by mixed dust. The invention further discloses a production process of the medicine for treating rhinitis. The process comprises the following steps: (1) decocting the honeycombs and radix angelicae with water; (2) adding other traditional Chinese medicines or / western medicines; (3) filtering; and (4) adding propolis and beta-cyclodextrin to prepare a water decoction, an oral solution or an electuary. The medicine disclosed by the invention is good in curative effect, easily available in material, low in cost and high in utilization ratio of nutritional value.

Owner:李秀英

Mixed plastic treatment process and water treatment system

InactiveCN110154271AEasy to cleanEasy to classifySludge treatment by de-watering/drying/thickeningWater aerationWater treatment systemLitter

The invention relates to a mixed plastic treatment process. The mixed plastic treatment process comprises the following steps of primarily screening original garbage, and screening out mixed plastic garbage; conveying the mixed plastic to a crushing and dust removal system, and removing the mixed dust and soil particles in the mixed plastic; conveying the crushed plastic to a plastic winnowing system for sorting, conveying the high-quality plastic flowing out of a upper outlet of the plastic winnowing system to scrubbing equipment, conveying the scrubbed plastic to a washing tank for washing,and conveying a small amount of inferior plastic which is suspended in water and immersed into the water bottom to a centrifugal device to be dehydrated and dried by using a scraper; conveying the plastic floating on the water surface to a rinsing circulating tank, and rinsing the plastic; dewatering and drying the rinsed plastic to obtain the raw materials of the renewable plastics so as to complete the recovery treatment of the mixed plastics. On the whole, the mixed plastic treatment process and the water treatment system has the advantages of being reasonable in design, clear in classification, clean in cleaning, small in water consumption and free of pollution to the environment.

Owner:河南锦程过滤设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com