Titanium high temperature electrolytic furnace special-purpose tail gas processing system

A technology of tail gas treatment and high-temperature electrolysis, which is applied to the separation of dispersed particles, chemical instruments and methods, and separation methods, can solve the problems of calcium fluoride dust polluting the environment and harming the human body, and achieve good absorption effects, environmental protection, and operation simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

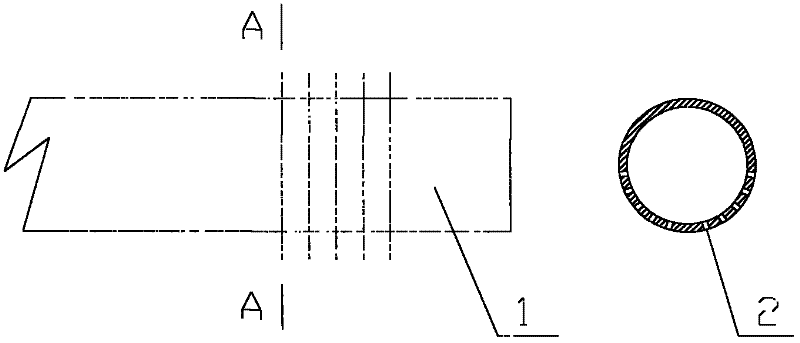

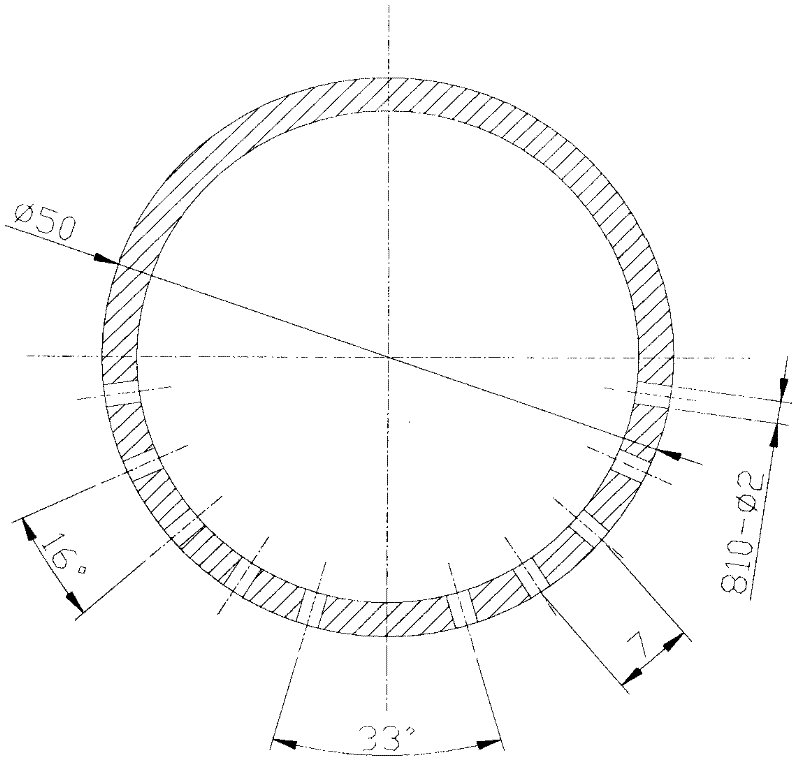

[0026] The present invention uses a wet purification method to remove soluble gas hydrogen fluoride, that is, a sodium carbonate solution with a content of 2%-10%, preferably 5%, is used to wash the tail gas. The principle is to make Na 2 CO 3 It reacts with HF in the exhaust gas to generate sodium bicarbonate and sodium fluoride. Because sodium fluoride is corrosive to glass, it is necessary to use plastic containers and pipelines to build an exhaust gas treatment system. Since the tail gas also contains a small amount of solid calcium fluoride or mixed dust of calcium fluoride and lithium fluoride, a dust collector is used to remove the solid dust in the tail gas before using the wet purification method, and the solid dust can be recycled after recycling. use. Of course, other solutions can also be used to scrub the tail gas, such as sodium hydroxide solution with a content of 2-6%.

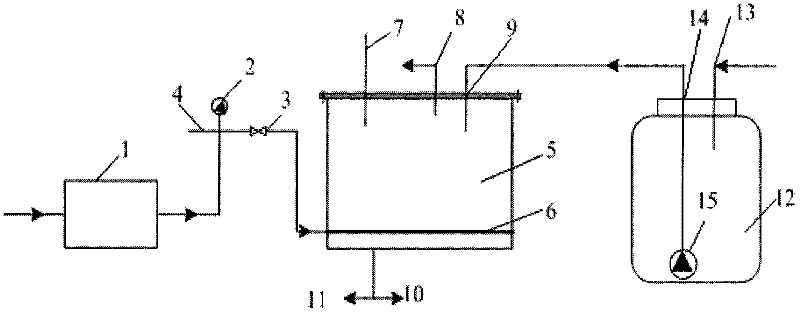

[0027] Such as figure 1 As shown, the tail gas treatment system of the present inventio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Cross-sectional area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com